Professional Documents

Culture Documents

DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)

Uploaded by

Johann ZabaletaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)

Uploaded by

Johann ZabaletaCopyright:

Available Formats

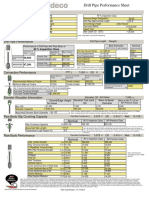

Drill Pipe Performance Sheet

www.NOV.com/GrantPrideco

Phone: +1 (281) 878-8000

Drill Pipe Configuration

Pipe Body OD

Pipe Body Wall Thickness

Pipe Body Grade

Drill Pipe Length

Connection

Tool Joint OD

Tool Joint ID

Pin Tong

Box Tong

(in)

(in)

(in)

(in)

(in)

(in)

80 % Inspection Class

Nominal Weight Designation

24.70

(ft) 31.8

Drill Pipe Approximate Length

(in) 3/32 Raised

SmoothEdge Height

(psi) 120,000

Tool Joint SMYS

Upset Type

IEU

(in) 5.688

Max Upset OD (DTE)

Friction Factor

1.0

5.500

0.415

G-105

Range2

XT57

7.000

4.000

10

15

Note: Tong space may include hardfacing.

Drill-Pipe Length

Drill Pipe Performance

Best Estimates

Performance of Drill Pipe with Pipe Body at

(without Coating)

80 % Inspection Class

Applied Make-up

Torque

Max Tension

Operational

Torque (ft-lbs)

(lbs)

(ft-lbs)

Maximum MUT

63,700

Minimum MUT

53,100

Tension Only

Combined Loading

Tension Only

Combined Loading

0

47,500

547,800

352,500

0

48,300

547,800

343,400

Drill Pipe Adjusted Weight

Fluid Displacement

Fluid Displacement

Fluid Capacity

Fluid Capacity

Drift Size

29.01

0.44

(Bbls/ft) 0.0106

(gal/ft) 0.85

(Bbls/ft) 0.0203

(in) 3.875

XT57

7.000

Applied Make-up

Tension at Shoulder

Torque

Separation

(ft-lbs)

63,700

53,100

(ft-lbs)

(lbs)

(lbs)

Tensile Limited

1,355,500

SmoothEdge Height

(in)

(lbs)

3/32 Raised

7.188

1,545,600

Assumed Elevator Bore Diameter

27.99

0.43

0.0102

0.87

0.0207

(lbs/ft)

0.85

0.0202

OD X

(in)

4.000

Tension at Connection

Yield

(lbs)

1,170,700

1,394,900

ID

(in)

120,000

(psi)

Tool Joint Dimensions

Balanced OD

(in)

Minimum Tool Joint OD for API

(in)

Premium Class

Minimum Tool Joint OD for

Counterbore

(in)

7.077

6.566

6.566

106,200

1,394,900

Elevator Shoulder Information

Box OD

Elevator Capacity

(least accurate)

(gal/ft)

Note: The maximum make-up torque should be applied when possible.

Note: To maximize connection operational tensile, a MUT (T4) = 54,600 (ft-lbs) should be applied.

Tool Joint Torsional Strength

Tool Joint Tensile Strength

Nominal

(with Coating)

Note: Oil field barrel equals 42 US gallons.

Note: Drill pipe assembly values are best estimates and may vary due to pipe body mill tolerance, internal plastic coating, and other factors.

Connection Performance

Maximum Make-up Torque

Minimum Make-up Torque

Range2

(in)

Elevator OD 3/32 Raised

Nominal Tool Joint

Worn to Bevel

OD

Diameter

Worn to Min TJ OD for

API Premium Class

7.000

1,315,600

6.566

806,500

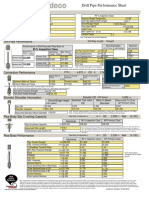

Pipe Body Slip Crushing Capacity

Pipe Body Configuration

Nominal

Assumed Slip Length

Transverse Load Factor (K)

(lbs)

(in)

Pipe Body Performance

470,300

(ft-lbs)

(ft-lbs)

(psi)

(psi)

(in)

(in)

(in)

(in^2)

(in^2)

(in^2)

(in^3)

(in^3)

5.5 (in) OD

80 % Inspection Class

374,400

Pipe Body Configuration

(lbs)

0.415 (in) Wall

G-105 )

API Premium Class

374,400

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe

Fail in the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference

only. Slip crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in

slips, drill pipe OD and wall variation, and other factors. Consult with the slip manufacturer for additional

information.

16.5

4.2

Nominal

Pipe Tensile Strength

Pipe Torsional Strength

TJ/PipeBody Torsional Ratio

80% Pipe Torsional Strength

Burst

Collapse

Pipe OD

Wall Thickness

Nominal Pipe ID

Cross Sectional Area of Pipe Body

Cross Sectional Area of OD

Cross Sectional Area of ID

Section Modulus

Polar Section Modulus

(in)

Note: Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100psi.

Note: A raised elevator OD increases elevator capacity without affecting make-up torque.

5.812

Slip Crushing Capacity

6.721

984,600

7.188

696,100

79,200

1.34

63,400

13,865

14,013

5.500

0.415

4.670

6.630

23.758

17.129

7.844

15.688

5.5 (in) OD

80 % Inspection Class

547,800

62,000

1.71

49,600

12,676

9,626

5.334

0.332

4.670

5.217

22.346

17.129

6.145

12.290

0.415 (in) Wall

G-105 )

API Premium Class

547,800

62,000

1.71

49,600

12,676

9,626

5.334

0.332

4.670

5.217

22.346

17.129

6.145

12.290

Note: Nominal Burst

calculated at 87.5% RBW

per API.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear

conditions (remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance

ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to

the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback

Customer Created 02-03-2014

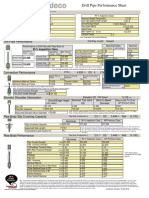

Operational Limits of Drill Pipe

Connection

Pipe Body

XT57

80 % Inspection Class

Tool Joint OD

(in)

7.000

Tool Joint ID

Pipe Body OD

(in)

5.5

Wall Thickness (in) 0.415

(in)

Combined Loading for Drill Pipe at

(ft-lbs)

0

2,500

5,000

7,500

10,000

12,500

15,000

17,500

20,000

22,500

25,000

27,500

30,000

32,500

35,000

37,500

40,000

42,500

45,000

47,500

(lbs)

547,800

547,400

546,000

543,800

540,600

536,600

531,600

525,600

518,600

510,500

501,400

491,100

479,500

466,600

452,300

436,400

418,800

399,100

377,200

352,500

G-105

Minimum Make-up Torque = 53,100

(ft-lbs)

Connection Max

Pipe Body

Max Tension Tension

(lbs)

Pipe Body Grade

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 63,700

Operational Assembly

Torque

Max Tension

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

4.000

Operationa Assembly

l Torque

Max Tension

(ft-lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(lbs)

(ft-lbs)

Connection

Max Tension

(lbs)

547,800

547,800

1,355,500

547,800

1,170,700

547,400

1,170,700

2,500

547,400

547,400

1,355,500

1,170,700

5,100

545,900

545,900

1,355,500

1,355,500

546,000

543,800

1,170,700

7,600

543,700

543,700

540,600

1,170,700

10,200

540,300

540,300

1,355,500

536,600

1,170,700

12,700

536,200

536,200

1,355,500

531,600

1,170,700

15,300

530,900

530,900

1,355,500

1,170,700

17,800

524,800

524,800

1,355,500

1,170,700

20,400

517,300

517,300

1,355,500

1,170,700

22,900

509,100

509,100

1,355,500

1,355,500

525,600

518,600

510,500

501,400

1,170,700

25,400

499,800

499,800

491,100

1,170,700

28,000

488,900

488,900

1,355,500

479,500

1,170,700

30,500

477,000

477,000

1,355,500

466,600

1,170,700

33,100

463,300

463,300

1,355,500

1,170,700

35,600

448,700

448,700

1,355,500

1,170,700

38,200

431,700

431,700

1,355,500

413,500

413,500

1,355,500

1,355,500

452,300

436,400

418,800

40,700

1,170,700

399,100

1,170,700

43,300

392,400

392,400

377,200

1,170,700

45,800

369,600

369,600

1,355,500

352,500

1,170,700

48,300

343,400

343,400

1,355,500

Operational drilling torque is limited by the torsional strength of the pipe

body.

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

53,100

54,300

55,500

56,600

57,800

59,000

60,200

61,300

62,500

63,700

Connection Max

Tension

(lbs)

1,355,500

1,386,200

1,373,600

1,346,400

1,316,700

1,287,000

1,257,300

1,230,100

1,200,400

1,170,700

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

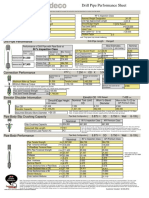

Connection Wear Table

Connection

XT57

Tool Joint OD

Connection

Wear

Tool

Joint OD

New OD

(in)

7

6.961

6.921

6.882

6.842

6.803

6.763

6.724

6.684

6.645

6.605

6.566

Worn OD

(in)

7.000

Tool Joint ID

(in)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

4.000

Connection Max

Tension

Connection

Torsional

Strength (ft-lbs)

Max

MUT

106,200

103,700

101,200

98,700

96,300

93,900

91,400

89,000

86,600

84,300

81,900

79,700

63,700

62,200

60,700

59,200

57,800

56,300

54,800

53,400

52,000

50,600

49,200

47,800

(ft-lbs)

Connection Max

Tension

Min MUT

(lbs)

(lbs)

(ft-lbs)

1,170,700

1,201,900

1,232,600

1,263,200

1,290,800

1,297,000

1,276,300

1,252,600

1,210,900

1,137,900

1,066,000

997,500

53,100

1,355,500

51,900

1,331,300

50,600

1,304,500

49,400

1,280,100

48,100

1,253,100

46,900

1,206,400

45,700

1,138,100

44,500

1,072,700

43,300

1,008,300

42,200

949,000

41,000

888,400

39,800

830,500

Pipe Body

Combined Loading Table (Torque-Tension)

Pipe Body

Pipe Body OD

80 % Inspection Class

Pipe Body Torque

(in)

5.5

Wall Thickness (in) 0.415

Pipe Body Grade

G-105

5,600

11,300

16,900

22,600

28,200

33,800

39,500

45,100

50,800

56,400

62,000

545,600

538,600

527,100

510,200

488,000

459,400

422,500

376,200

314,500

228,400

21,600

(ft-lbs)

Pipe Body Max

547,800

Tension

(lbs)

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

You might also like

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Drill Pipe Performance and SpecificationsDocument3 pagesDrill Pipe Performance and SpecificationsИнженер Луис А. ГарсиаNo ratings yet

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Drill Pipe Performance Data SheetDocument3 pagesDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- Drill pipe performance and operational limitsDocument3 pagesDrill pipe performance and operational limitsGarcia C L AlbertoNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetSaurav SenguptaNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- HeavyWeight 3.5 25.58lbs NC-38Document3 pagesHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNo ratings yet

- Trispiral XT39Document1 pageTrispiral XT39Cerón Niño SantiagoNo ratings yet

- 2.500 X 1.375 DC With MW20 SlickDocument1 page2.500 X 1.375 DC With MW20 SlickHadi Bapir SlemanNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular Assemblymsm.ele2009No ratings yet

- Drill CollarDocument1 pageDrill CollarGuillermo Rangel AvalosNo ratings yet

- 4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BDocument3 pages4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BjohangomezruizNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaNo ratings yet

- Xt39 Spec SheetDocument3 pagesXt39 Spec SheetjdcomptonNo ratings yet

- 5 7/8" VM-165 R2 Pipe SpecsDocument2 pages5 7/8" VM-165 R2 Pipe SpecsTiffany DacinoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- 5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BDocument3 pages5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BJeaneth HerreraNo ratings yet

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pages5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Landing String 6.625 .938 v150 FH Slip Proof 95rbw PDFDocument4 pagesLanding String 6.625 .938 v150 FH Slip Proof 95rbw PDFMarcelo VeronezNo ratings yet

- Wedge Thread Tool Joints Applications and EconomicsDocument9 pagesWedge Thread Tool Joints Applications and EconomicsalexintelNo ratings yet

- 6-15-0003 Rev 4Document9 pages6-15-0003 Rev 4cynideNo ratings yet

- Welded Tube Joint SpecDocument8 pagesWelded Tube Joint SpecAvinash ShuklaNo ratings yet

- Section 19 - Appendix C - FormsDocument52 pagesSection 19 - Appendix C - Formsfivehours5No ratings yet

- API 5B Updates (16th Edition)Document9 pagesAPI 5B Updates (16th Edition)Albert Tu100% (1)

- ITEM 564.00010001 - Bridge Hanger Fabrication and InstallationDocument14 pagesITEM 564.00010001 - Bridge Hanger Fabrication and InstallationKY PengNo ratings yet

- 2.875 N80 6.51ppf EUEDocument1 page2.875 N80 6.51ppf EUEANSARAKUNo ratings yet

- Welding Inspection Ass 1Document7 pagesWelding Inspection Ass 1mohd as shahiddin jafriNo ratings yet

- 10080-1-SS-PP-007Document44 pages10080-1-SS-PP-007SURAJ PRSADNo ratings yet

- Federal Brake Lining Specifications - CID a-A-52522BDocument6 pagesFederal Brake Lining Specifications - CID a-A-52522BBrian RenekerNo ratings yet

- Beam End Connection ReportDocument6 pagesBeam End Connection ReportHibri HalimNo ratings yet

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDocument14 pagesAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89No ratings yet

- Oil Sands Fact SheetDocument47 pagesOil Sands Fact SheetAnonymous B7pghhNo ratings yet

- 44AC9100-000-V.02-0106-A4 - Rev B - GENERAL SPECIFICATION FOR EXPANDED TUBE TO TUBE SHEET JOINTDocument6 pages44AC9100-000-V.02-0106-A4 - Rev B - GENERAL SPECIFICATION FOR EXPANDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNo ratings yet

- Saudi Aramco DTI Bolt Test ProcedureDocument4 pagesSaudi Aramco DTI Bolt Test ProcedureJoel AlcantaraNo ratings yet

- Packer Shoes Casing Manual Section 7Document22 pagesPacker Shoes Casing Manual Section 7Tong Chaipanyakul100% (1)

- Type 501 453 UniversalDocument1 pageType 501 453 Universalrambala123No ratings yet

- Steel Kract Cid-28t-C (Pe) - 1 (SMJ 8224) K60101cid-Page 1-130Document130 pagesSteel Kract Cid-28t-C (Pe) - 1 (SMJ 8224) K60101cid-Page 1-130Giovanny100% (1)

- Welding Procedure SpecificationDocument30 pagesWelding Procedure Specificationrahman196011100% (1)

- Flang ManegmentDocument12 pagesFlang ManegmentYasser Abd El Fattah100% (1)

- Diameter TubeDocument8 pagesDiameter TubeEnd LabNo ratings yet

- 5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Document3 pages5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Johann ZabaletaNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaNo ratings yet

- Blanking Chart XT - XT-M Pin 1d68Document2 pagesBlanking Chart XT - XT-M Pin 1d68Johann ZabaletaNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- 5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Document3 pages5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Johann ZabaletaNo ratings yet

- 5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Document3 pages5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Johann ZabaletaNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- 5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Document3 pages5-7 - 8-In .750-In Wall S-135 XT57 (7-1 - 4 X 3-1 - 2) 10p 15b R2Johann ZabaletaNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- For Reference Only: Drill Pipe Performance Characteristics ©Document3 pagesFor Reference Only: Drill Pipe Performance Characteristics ©doploveNo ratings yet

- LDW LogDocument9 pagesLDW LogJohann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- Grant Prideco Rotary Shoulder HandbookDocument112 pagesGrant Prideco Rotary Shoulder Handbookrlk2806No ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- MusicDocument1 pageMusicJohann ZabaletaNo ratings yet

- EnglishDocument1 pageEnglishJohann ZabaletaNo ratings yet

- MatrixDocument1 pageMatrixJohann ZabaletaNo ratings yet

- Estilo IndirectoDocument2 pagesEstilo IndirectoLelyLealGonzalezNo ratings yet

- 6 Chemical FloodingDocument73 pages6 Chemical FloodingJohann ZabaletaNo ratings yet

- Tool and Curve Mnemonics for Reeves TechnologiesDocument47 pagesTool and Curve Mnemonics for Reeves TechnologiesJohann ZabaletaNo ratings yet

- Casing Repair-15062015080103Document16 pagesCasing Repair-15062015080103Johann ZabaletaNo ratings yet

- Hydrostatic Pressure CalculationDocument2 pagesHydrostatic Pressure CalculationJohann ZabaletaNo ratings yet

- ChE212 Implicit Eqn Soln and OptimizationDocument3 pagesChE212 Implicit Eqn Soln and OptimizationJohann ZabaletaNo ratings yet

- List of Comparative and Superlative AdjectivesDocument3 pagesList of Comparative and Superlative AdjectivesJohann ZabaletaNo ratings yet

- Lista de Verbos Regulares e Irregulares en InglesDocument33 pagesLista de Verbos Regulares e Irregulares en InglesAdmirador Bueno67% (21)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensFrom EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNo ratings yet

- Arizona, Utah & New Mexico: A Guide to the State & National ParksFrom EverandArizona, Utah & New Mexico: A Guide to the State & National ParksRating: 4 out of 5 stars4/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptFrom EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptRating: 5 out of 5 stars5/5 (1)

- The Bahamas a Taste of the Islands ExcerptFrom EverandThe Bahamas a Taste of the Islands ExcerptRating: 4 out of 5 stars4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksFrom EverandNew York & New Jersey: A Guide to the State & National ParksNo ratings yet

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoFrom EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoRating: 5 out of 5 stars5/5 (1)