Professional Documents

Culture Documents

Drill Pipe Performance Data Sheet

Uploaded by

Garcia C L AlbertoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drill Pipe Performance Data Sheet

Uploaded by

Garcia C L AlbertoCopyright:

Available Formats

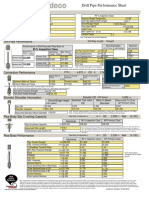

Drill Pipe Performance Sheet

www.NOV.com/GrantPrideco

Phone: +1 (281) 878-8000

Warning: Connection ID is too large.

Drill Pipe Configuration

Pipe Body OD

Pipe Body Wall Thickness

Pipe Body Grade

Drill Pipe Length

Connection

Tool Joint OD

Tool Joint ID

Pin Tong

Box Tong

(in)

(in)

(in)

(in)

(in)

(in)

80 % Inspection Class

Nominal Weight Designation

15.50

(ft) 31.8

Drill Pipe Approximate Length

(in) 3/32 Raised

SmoothEdge Height

(psi) 120,000

Tool Joint SMYS

Upset Type

EU

(in) 3.875

Max Upset OD (DTE)

Friction Factor

1.0

3.500

0.449

G-105

Range2

XT39

4.938

2.563

10

15

Note: Tong space may include hardfacing.

Drill-Pipe Length

Drill Pipe Performance

Best Estimates

Performance of Drill Pipe with Pipe Body at

(without Coating)

80 % Inspection Class

Applied Make-up

Torque

Max Tension

Operational

Torque (ft-lbs)

(lbs)

(ft-lbs)

Maximum MUT

23,400

Minimum MUT

19,500

Tension Only

Combined Loading

Tension Only

Combined Loading

0

17,900

350,900

214,100

0

17,500

350,900

222,400

Drill Pipe Adjusted Weight

Fluid Displacement

Fluid Displacement

Fluid Capacity

Fluid Capacity

Drift Size

17.80

0.27

(Bbls/ft) 0.0065

(gal/ft) 0.27

(Bbls/ft) 0.0063

(in) 2.438

XT39

4.938

Applied Make-up

Tension at Shoulder

Torque

Separation

(ft-lbs)

23,400

19,500

(ft-lbs)

(lbs)

Tensile Limited

705,500

SmoothEdge Height

(in)

(lbs)

3/32 Raised

5.125

909,200

Assumed Elevator Bore Diameter

17.19

0.26

0.0063

0.28

0.0066

(lbs/ft)

0.26

0.0062

(lbs)

OD X

(in)

2.563

Tension at Connection

Yield

(lbs)

605,600

724,100

ID

(in)

120,000

(psi)

Tool Joint Dimensions

Balanced OD

(in)

Minimum Tool Joint OD for API

(in)

Premium Class

Minimum Tool Joint OD for

Counterbore

(in)

4.992

4.653

4.653

39,000

724,100

Elevator Shoulder Information

Box OD

Elevator Capacity

(least accurate)

(gal/ft)

Note: The maximum make-up torque should be applied when possible.

Note: To maximize connection operational tensile, a MUT (T4) = 20,000 (ft-lbs) should be applied.

Tool Joint Torsional Strength

Tool Joint Tensile Strength

Nominal

(with Coating)

Note: Oil field barrel equals 42 US gallons.

Note: Drill pipe assembly values are best estimates and may vary due to pipe body mill tolerance, internal plastic coating, and other factors.

Connection Performance

Maximum Make-up Torque

Minimum Make-up Torque

Range2

(in)

Elevator OD 3/32 Raised

Nominal Tool Joint

Worn to Bevel

OD

Diameter

Worn to Min TJ OD for

API Premium Class

4.938

746,000

4.653

510,100

Pipe Body Slip Crushing Capacity

Pipe Body Configuration

Nominal

Assumed Slip Length

Transverse Load Factor (K)

(lbs)

(in)

Pipe Body Performance

352,400

(ft-lbs)

(ft-lbs)

(psi)

(psi)

(in)

(in)

(in)

(in^2)

(in^2)

(in^2)

(in^3)

(in^3)

3.5 (in) OD

80 % Inspection Class

277,200

Pipe Body Configuration

(lbs)

0.449 (in) Wall

G-105 )

API Premium Class

277,200

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe

Fail in the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference

only. Slip crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in

slips, drill pipe OD and wall variation, and other factors. Consult with the slip manufacturer for additional

information.

16.5

4.2

Nominal

Pipe Tensile Strength

Pipe Torsional Strength

TJ/PipeBody Torsional Ratio

80% Pipe Torsional Strength

Burst

Collapse

Pipe OD

Wall Thickness

Nominal Pipe ID

Cross Sectional Area of Pipe Body

Cross Sectional Area of OD

Cross Sectional Area of ID

Section Modulus

Polar Section Modulus

(in)

Note: Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100psi.

Note: A raised elevator OD increases elevator capacity without affecting make-up torque.

3.969

Slip Crushing Capacity

4.786

618,600

5.125

451,900

29,500

1.32

23,600

23,573

23,484

3.500

0.449

2.602

4.304

9.621

5.317

2.923

5.847

3.5 (in) OD

80 % Inspection Class

350,900

22,600

1.73

18,100

21,552

20,260

3.320

0.359

2.602

3.342

8.659

5.317

2.239

4.477

0.449 (in) Wall

G-105 )

API Premium Class

350,900

22,600

1.73

18,100

21,552

20,260

3.320

0.359

2.602

3.342

8.659

5.317

2.239

4.477

Note: Nominal Burst

calculated at 87.5% RBW

per API.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear

conditions (remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance

ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to

the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback

Customer Created 02-03-2014

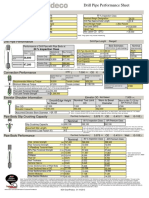

Operational Limits of Drill Pipe

Connection

Pipe Body

XT39

80 % Inspection Class

Tool Joint OD

(in)

4.938

Tool Joint ID

Pipe Body OD

(in)

3.5

Wall Thickness (in) 0.449

(in)

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 23,400

Operational Assembly

Torque

Max Tension

(ft-lbs)

0

900

1,900

2,800

3,800

4,700

5,700

6,600

7,500

8,500

9,400

10,400

11,300

12,300

13,200

14,100

15,100

16,000

17,000

17,900

(lbs)

350,900

350,600

349,600

348,200

345,900

343,200

339,500

335,600

331,000

325,100

319,100

311,500

303,900

294,400

284,800

274,200

261,100

247,900

231,300

214,100

Pipe Body Grade

Minimum Make-up Torque = 19,500

(ft-lbs)

Operationa Assembly

l Torque

Max Tension

(ft-lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(lbs)

(lbs)

350,900

350,900

705,500

350,900

605,600

350,600

605,600

900

350,600

350,600

705,500

605,600

1,800

349,800

349,800

705,500

705,500

348,200

605,600

2,800

348,200

348,200

345,900

605,600

3,700

346,100

346,100

705,500

343,200

605,600

4,600

343,500

343,500

705,500

339,500

605,600

5,500

340,300

340,300

705,500

605,600

6,400

336,500

336,500

705,500

605,600

7,400

331,500

331,500

705,500

605,600

8,300

326,400

326,400

705,500

705,500

335,600

331,000

325,100

319,100

605,600

9,200

320,500

320,500

311,500

605,600

10,100

313,900

313,900

705,500

303,900

605,600

11,000

306,500

306,500

705,500

294,400

605,600

12,000

297,300

297,300

705,500

605,600

12,900

288,100

288,100

705,500

605,600

13,800

277,900

277,900

705,500

266,500

266,500

705,500

705,500

284,800

274,200

261,100

14,700

605,600

247,900

605,600

15,600

253,900

253,900

231,300

605,600

16,600

238,200

238,200

705,500

214,100

605,600

17,500

222,400

222,400

705,500

Operational drilling torque is limited by the torsional strength of the pipe

body.

(ft-lbs)

Connection

Max Tension

349,600

G-105

Combined Loading for Drill Pipe at

Connection Max

Pipe Body

Max Tension Tension

(lbs)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

2.563

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

19,500

19,900

20,400

20,800

21,200

21,700

22,100

22,500

23,000

23,400

Connection Max

Tension

(lbs)

705,500

720,000

710,500

696,500

682,600

665,100

651,100

637,100

619,600

605,600

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

Connection Wear Table

Connection

XT39

Tool Joint OD

Connection

Wear

Tool

Joint OD

New OD

(in)

4.938

4.912

4.886

4.86

4.834

4.808

4.782

4.756

4.731

4.705

4.679

4.653

Worn OD

(in)

4.938

Tool Joint ID

(in)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

2.563

Connection Max

Tension

Connection

Torsional

Strength (ft-lbs)

Max

MUT

39,000

38,200

37,300

36,500

35,700

34,900

34,100

33,300

32,500

31,700

30,900

30,100

23,400

22,900

22,400

21,900

21,400

20,900

20,400

20,000

19,500

19,000

18,500

18,100

(ft-lbs)

Connection Max

Tension

Min MUT

(lbs)

(lbs)

(ft-lbs)

605,600

620,100

634,500

648,600

662,600

676,400

687,500

675,000

665,900

649,900

614,200

582,800

19,500

705,500

19,100

694,300

18,700

683,100

18,300

671,900

17,800

656,900

17,400

645,600

17,000

631,800

16,600

600,400

16,200

570,300

15,800

540,400

15,500

514,600

15,100

486,200

Pipe Body

Combined Loading Table (Torque-Tension)

Pipe Body

Pipe Body OD

80 % Inspection Class

Pipe Body Torque

(in)

3.5

Wall Thickness (in) 0.449

Pipe Body Grade

G-105

2,100

4,100

6,200

8,200

10,300

12,300

14,400

16,400

18,500

20,500

22,600

349,400

345,000

337,400

327,000

312,300

294,400

270,500

241,500

201,600

147,800

7,100

(ft-lbs)

Pipe Body Max

350,900

Tension

(lbs)

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

You might also like

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsRating: 4 out of 5 stars4/5 (9)

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbFrom EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- 11 5000 Hydril GK Screwed Annular Bop Spec SheetDocument1 page11 5000 Hydril GK Screwed Annular Bop Spec SheetJoel SNo ratings yet

- Rutong DH 吊环使用说明书(ZY)2013 links - 1Document3 pagesRutong DH 吊环使用说明书(ZY)2013 links - 1QAMAR ALI KHANNo ratings yet

- Min - TJL API RP 7G-2 - For MSDocument1 pageMin - TJL API RP 7G-2 - For MSQuality controllerNo ratings yet

- Varco (Manual) - Weldless, Toolpusher, Perfections Links - OptDocument2 pagesVarco (Manual) - Weldless, Toolpusher, Perfections Links - Optrenjith rsNo ratings yet

- Parveen Well Head PDFDocument25 pagesParveen Well Head PDFRatnakar PatilNo ratings yet

- 13.625 10K Double Cameron U BOP PDFDocument2 pages13.625 10K Double Cameron U BOP PDFAndung Suwarto100% (1)

- Demco Gate ValvesDocument52 pagesDemco Gate ValvesJuan Lorenzo100% (1)

- BVM Catelogue New-2016 PDFDocument116 pagesBVM Catelogue New-2016 PDFOperation100% (1)

- Varco BushingsDocument1 pageVarco BushingsVision100% (1)

- Hydril GK Annular DataDocument2 pagesHydril GK Annular DataAndrés Ramírez100% (3)

- Cameron Ram Selection ChartDocument1 pageCameron Ram Selection ChartGlen AshwellNo ratings yet

- Westrom Cameron PartsDocument22 pagesWestrom Cameron PartsEd CalheNo ratings yet

- WECO Hammer Union AlertDocument22 pagesWECO Hammer Union AlertiljicsNo ratings yet

- DL Annular Blowout Preventer 21-1/4" 3000 Psi WPDocument27 pagesDL Annular Blowout Preventer 21-1/4" 3000 Psi WPJeneesh Shanmughan100% (1)

- Bop Test Info PDFDocument18 pagesBop Test Info PDFjairaso2950No ratings yet

- 5-0001 Wire Line Guide BJDocument1 page5-0001 Wire Line Guide BJJacekNo ratings yet

- Api 7K & ASTME 165E/E709Document1 pageApi 7K & ASTME 165E/E709engmuhmudNo ratings yet

- Instructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Document7 pagesInstructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Heri VillaNo ratings yet

- BOP 2006 E-CatalogDocument32 pagesBOP 2006 E-Catalogwoodiehed903950% (2)

- Manual Manual Power TongDocument13 pagesManual Manual Power TongJAVIER EDUARDO MANTILLA BUITRAGONo ratings yet

- Handling ToolsDocument33 pagesHandling ToolsDaladier LozanoNo ratings yet

- English CatalogDocument10 pagesEnglish Catalogcorsini999No ratings yet

- KellyguardDSV (6845C)Document22 pagesKellyguardDSV (6845C)David0% (1)

- T3 Bop 6012Document6 pagesT3 Bop 6012TitanBOP60% (5)

- Operations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0Document18 pagesOperations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0dowel hernandezNo ratings yet

- HRSB 13 5.8 - 10M PDFDocument33 pagesHRSB 13 5.8 - 10M PDFJuan Felipe Garza GNo ratings yet

- 21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Document28 pages21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Mehdi SoltaniNo ratings yet

- Circulating SwagesDocument1 pageCirculating Swageskaveh-bahiraeeNo ratings yet

- Shaffer NOV Type 72 ShearsDocument2 pagesShaffer NOV Type 72 ShearsTitanBOP100% (1)

- Spider Elevator 500tonDocument8 pagesSpider Elevator 500tonrageshmv0% (1)

- Annular Bop Packing Elements: Otu Se (Axs)Document2 pagesAnnular Bop Packing Elements: Otu Se (Axs)JoseManuelDominguezHuertaNo ratings yet

- Bop RepairDocument13 pagesBop Repairnjava1978100% (1)

- Ram BOP Manual PDFDocument68 pagesRam BOP Manual PDFhendriahmadi0410No ratings yet

- Master and Casing Bushing - ACEWELDocument8 pagesMaster and Casing Bushing - ACEWELcristinelb100% (1)

- RP Insp Rep 01Document8 pagesRP Insp Rep 01advantage025No ratings yet

- Catalog PDFDocument222 pagesCatalog PDFLeandro100% (1)

- Understanding Special Drift CasingDocument2 pagesUnderstanding Special Drift CasingLuis David Concha CastilloNo ratings yet

- Cat III Inspection Mud 2021Document56 pagesCat III Inspection Mud 2021Fāōū ZīNo ratings yet

- LXT Shaffer 13 5-8 5M Spare PArtsDocument6 pagesLXT Shaffer 13 5-8 5M Spare PArtscorsini999100% (1)

- Manual: CDQ (S) Sucker Rod ElevatorsDocument5 pagesManual: CDQ (S) Sucker Rod ElevatorsDarshan MakwanaNo ratings yet

- Master Bushing-Bowls - DENCON ToolDocument5 pagesMaster Bushing-Bowls - DENCON ToolcristinelbNo ratings yet

- RTTS Packer: Technical Data SheetDocument5 pagesRTTS Packer: Technical Data SheetHamid Reza Babaei100% (1)

- Weco PDFDocument18 pagesWeco PDFyveslio100% (1)

- TC104 00天车图册-EDocument16 pagesTC104 00天车图册-EKaleem UllahNo ratings yet

- Side Entry Subs (Welded) - Oil Rig Drill String Accessories - Downhole Oil Tools, IncDocument2 pagesSide Entry Subs (Welded) - Oil Rig Drill String Accessories - Downhole Oil Tools, Inccaballero_tigreNo ratings yet

- Wellhead Equipment CatalogDocument29 pagesWellhead Equipment CatalogDewy PambayunNo ratings yet

- Cameron EB 538 D Rev D2 - Shear Rams - Op & MaintDocument7 pagesCameron EB 538 D Rev D2 - Shear Rams - Op & MaintCanrig RamdeNo ratings yet

- Hydraulic Liner Hanger 4.5 InchDocument1 pageHydraulic Liner Hanger 4.5 InchriobmNo ratings yet

- Cameron Bop PartsDocument62 pagesCameron Bop PartsSurya Prakash DubeyNo ratings yet

- Tiw Valves BrochureDocument4 pagesTiw Valves BrochureBahman MatouriNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- Drill Pipe Performance and SpecificationsDocument3 pagesDrill Pipe Performance and SpecificationsИнженер Луис А. ГарсиаNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- DPPSDocument2 pagesDPPSGarcia C L AlbertoNo ratings yet

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pages5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoNo ratings yet

- DPPS PDFDocument2 pagesDPPS PDFStowartNo ratings yet

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pages5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- WS36-01 DPPSDocument2 pagesWS36-01 DPPSGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Drill Pipe Performance Data SheetDocument3 pagesDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDocument3 pages3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- Drill Pipe Performance Data SheetDocument3 pagesDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- Zeroth Law and Introductory ConceptsDocument13 pagesZeroth Law and Introductory ConceptsMohd Danial Muhd AliNo ratings yet

- CalorDocument14 pagesCaloreka123No ratings yet

- Nasa Rotor67Document12 pagesNasa Rotor67prakulmittal2No ratings yet

- Earth Pressure Distribution On A Rigid Box Convered With U-Shaped Geofoam WrapDocument14 pagesEarth Pressure Distribution On A Rigid Box Convered With U-Shaped Geofoam Wraple phuongNo ratings yet

- JEE Main 2021 - July 27th - Afternoon SessionDocument21 pagesJEE Main 2021 - July 27th - Afternoon SessionJaynandan KushwahaNo ratings yet

- Aer320 Outline f11 FVDocument3 pagesAer320 Outline f11 FVbatmanbittuNo ratings yet

- GUIDE TO WAVE PROPERTIES TABLES C-1 AND C-2Document27 pagesGUIDE TO WAVE PROPERTIES TABLES C-1 AND C-2Iqbal Jatmiko Putra50% (2)

- The Law of Conservation of MomentumDocument6 pagesThe Law of Conservation of Momentumbakhtawar soniaNo ratings yet

- Propeller Blade Shape Optimization For Efficiency ImprovementDocument13 pagesPropeller Blade Shape Optimization For Efficiency ImprovementNurhayyan Halim RosidNo ratings yet

- RC 3Document4 pagesRC 3Mayya BonaNo ratings yet

- G16 - A21 - DAA 2723 WBPDocument16 pagesG16 - A21 - DAA 2723 WBPanazraf 23MzNo ratings yet

- Handbook - ABB Flowmeters (9!9!05)Document82 pagesHandbook - ABB Flowmeters (9!9!05)Rubén Jimenez CastroNo ratings yet

- DOD STD 1399 301 Ship MotionsDocument24 pagesDOD STD 1399 301 Ship Motionsdnvrus100% (1)

- Bernoulli's Theorem ExperimentDocument17 pagesBernoulli's Theorem ExperimentMimi Hashim95% (19)

- 1 Magnetic CircuitsDocument36 pages1 Magnetic Circuitssai dharmaNo ratings yet

- Numerical Simulation of Turbulent Flow Over Aircraft FuselageDocument13 pagesNumerical Simulation of Turbulent Flow Over Aircraft FuselageAditya R BharadwajNo ratings yet

- SEAMANSHIP MIDTERM ASSESSMENTDocument3 pagesSEAMANSHIP MIDTERM ASSESSMENTLabLab ChattoNo ratings yet

- ETABS Concrete Frame Design: IS 456:2000 Column Section DesignDocument2 pagesETABS Concrete Frame Design: IS 456:2000 Column Section DesigniftikharmullaNo ratings yet

- 2021 - Rivision Unit 2 Part 4Document30 pages2021 - Rivision Unit 2 Part 4Sanvidu RathnayakeNo ratings yet

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoDocument2 pagesAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987No ratings yet

- Q E R RDocument3 pagesQ E R Rsadam gebiNo ratings yet

- Forces and FieldsDocument12 pagesForces and Fieldslyka deguzmanNo ratings yet

- Attachment 07.1 - ARGAL - Vertical PumpsDocument28 pagesAttachment 07.1 - ARGAL - Vertical PumpsJefferson GilNo ratings yet

- Magnetic Fields and Circuits ReviewDocument6 pagesMagnetic Fields and Circuits ReviewJoseph SebastianNo ratings yet

- Bell, K. J.Document6 pagesBell, K. J.Biju KuzhiveliNo ratings yet

- Magnetic Fields AS Unit 4: Drawing Field DiagramsDocument6 pagesMagnetic Fields AS Unit 4: Drawing Field DiagramsL5YARBNo ratings yet

- 07a70102 Finite Element Methods in Civil EngineeringDocument10 pages07a70102 Finite Element Methods in Civil EngineeringSamiullah MohammedNo ratings yet

- Course Guide - General Physics 1 SY 2020-2021Document7 pagesCourse Guide - General Physics 1 SY 2020-2021Naega HoshNo ratings yet

- Osborne Reynolds Experiment Visualizes Laminar, Turbulent FlowDocument1 pageOsborne Reynolds Experiment Visualizes Laminar, Turbulent FlowDennis Angelo PablicoNo ratings yet

- Convective Heat Transfer Coefficients Table ChartDocument4 pagesConvective Heat Transfer Coefficients Table Chartmiguel_vera6592No ratings yet