Professional Documents

Culture Documents

Saudi Aramco DTI Bolt Test Procedure

Uploaded by

Joel AlcantaraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco DTI Bolt Test Procedure

Uploaded by

Joel AlcantaraCopyright:

Available Formats

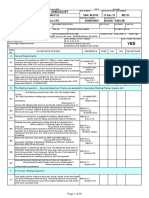

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

REV 3

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

Pre-Installation Procedure Verification Testing of Direct

Tensioning Indicator (ASTM A325 or ASTM A490 Bolts)

PROJECT TITLE

SATR-M-2003

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED TEST DATE & TIME

ACTUAL TEST DATE & TIME

30-Jun-08

DATE APPROVED

QR NUMBER

15-Dec-09

MECH-

CONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

TEST PROCEDURE ACCEPTANCE CRITERIA

REFERENCE

PRETENSIONING PROCEDURE VERIFICATION TESTING for Direct Tension Indicators:

A1

Direct tension indicators have been inspected and verified to meet the

material requirements of ASTM F959 through checklist, SAIC-M-2021.

{PIP STS05130, Para. 6.5.2}

12-SAMSS-008,

Sec. I

A2

A calibrated tension calibrator shall be onsite when tightening is to be

performed on pretensioned joints and slip-critical joints.

(PIP STS05130, Para. 6.5.2 & AISC Specification for Structural Joints

Using ASTM A325 or A490 Bolts, Para. 8.2.4 )

12-SAMSS-008,

Sec. I

A3

A representative sample of three complete fastener assemblies of each

combination of diameter, length, grade and lot to be used in the work

shall be checked at the site of installation in a tension calibrator. (PIP

STS05130, Para. 6.5.2 & AISC Specification for Structural Joints Using

ASTM A325 or A490 Bolts, Para. 8.2.4)

12-SAMSS-008,

Sec. I

A4

Washers are used in the pre-installation verification assemblies as

required in the work. (PIP STS05130, Para. 6.5.2 & AISC Specification

for Structural Joints Using ASTM A325 or A490 Bolts, Para. 8.2.4)

12-SAMSS-008,

Sec. I

A5

The direct-tension indicator arches are oriented to bear against the

hardened bearing surface of the bolt head or nut or against a hardened

flat washer if used under turned element whether that turned element is

the nut or the bolt. Proper use and orientation is

illustrated in Figure C-8.1, Attachment 2. (PIP STS05130, Para. 6.5.2 &

AISC Specification for Structural Joints Using ASTM A325 or A490 Bolts,

Para. 8.2.4)

12-SAMSS-008,

Sec. I

A6

Prior to pretensioning, the appropriate feeler gage is accepted in at least

half of the spaces between the protrusions of the

12-SAMSS-008,

direct tension indicator. (PIP STS05130, Para. 6.5.2 & AISC Specification

Sec. I

for Structural Joints Using ASTM A325 or A490 Bolts, Para. 9.2.4)

A7

The bolt assembly was tightened with the direct tension indicator until a

pretension of 1.05 times that specified for installation and inspection in

Table 8.1 in Attachment 1 of this checklist was reached. (PIP STS05130,

Para. 6.5.2 & AISC Specification for Structural Joints Using ASTM A325

or A490 Bolts, Para. 8.2.4)

12-SAMSS-008,

Sec. I

A8

After pretensioning, the appropriate feeler gage is refused

entry into at least half of the spaces between the protrusions.

(PIP STS05130, Para. 6.5.2 & AISC Specification for Structural Joints

Using ASTM A325 or A490 Bolts, Para. 9.2.4)

12-SAMSS-008,

Sec. I

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-TEST DATE

Caution: From past experience, the small arch-like protrusions on the direct tension indicator washers (DTI) did not deform when the bolts

NOTE: are tightened, instead, the protrusions gouged itself into the bearing surface of the hardened washer or on to the underside of the bolt head or

nut, wherever the DTI was positioned. It is recommended to perform item A9 below.

Page 1 of 4

A9

After passing the feeler gage test, lossen the bolted assembly and

examine the DTI and the bearing surface for the following acceptable

conditions:

a. The protrusions on the DTI were deformed.

b. The bearing surface has no significant depth of indentation

or gouge.

(PIP STS05130, Para. 6.5.2 & AISC Specification for Structural Joints

Using ASTM A325 or A490 Bolts, Para. 9.2.5)

Page 2 of 4

12-SAMSS-008,

Sec. I

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

REV 3

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

Pre-Installation Procedure Verification Testing of Direct

Tensioning Indicator (ASTM A325 or ASTM A490 Bolts)

PROJECT TITLE

SATR-M-2003

WBS / BI / JO NUMBER

ITEM

No.

TEST RESULTS ACCEPTANCE CRITERIA

30-Jun-08

DATE APPROVED

QR NUMBER

15-Dec-09

MECH-

CONTRACTOR / SUBCONTRACTOR

REFERENCE

PASS

FAIL

N/A

RE-TEST DATE

TEST DETAILS & RESULT (Direct Tensioning Indicator-DTI)

Tension Calibrator: Model/Type___________________________

Date Calibrated: _______________________

Grade & Heat/Lot No._________________

Diameter:__________/ Length: __________

Bolt Material

Grade & Heat/Lot No._____________

Diameter:_______/ Length: __________

Bolt # 1

Bolt # 2

Bolt # 3

Bolt # 1

Bolt # 2

Bolt # 3

YES / NO

YES / NO

YES / NO

YES / NO

YES / NO

YES / NO

DTI Type and Heat/Lot Number

Actual Tension obtained at Required Nut

Rotation ( 1.05x Value in Table 8.1, Att. 1)

Feeler Gauge is refused entry into at least half of

the spaces between the protrusions.

RESULTS:

A) Suitability of the complete

fastener assembly, incl.

Lubrication for installation.

Satisfactory

Not satisfactory

Satisfactory

Not satisfactory

B) Application procedure and

Proper use by the bolting Crew

Satisfactory

Not satisfactory

Satisfactory

Not satisfactory

Bolting Crew: ___________________________________________________________________________________

REMARKS:

REFERENCE DOCUMENTS:

1- 12-SAMSS-007 -- Fabrication of Structural and Miscellaneous Steel, 03 September 2006

2- 12-SAMSS-008 -- Erection of Structural and Miscellaneous Steel, 28 January 2004

3- PIP STS05130 -- Erection of Structural and Miscellaneous Steel Specification, February 2002

4. AISC 348, Specification for Structural Joints Using ASTM A325 or A490 Bolts, (23 June, 2000)

Contractor / Third-Party

Technician Performing Test*

Name, Title, Department,

Company, Initials and Date:

Saudi Aramco

m

Test Performed Successfully and Results are Acceptable:

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

QC Inspector

PID Representative

Witnessed Test

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results

Y = YES

Page 3 of 4

N = NO F = FAILED

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

REV 3

SAUDI ARAMCO TEST REPORT

SATR NUMBER

Pre-Installation Procedure Verification Testing of Direct

Tensioning Indicator (ASTM A325 or ASTM A490 Bolts)

SATR-M-2003

Attachment 1 --

Page 4 of 4

30-Jun-08

DATE APPROVED

15-Dec-09

QR NUMBER

MECH-

You might also like

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistjunaidNo ratings yet

- Saic M 1065Document2 pagesSaic M 1065Hussain Nasser Al- NowiesserNo ratings yet

- Flang ManegmentDocument12 pagesFlang ManegmentYasser Abd El Fattah100% (1)

- Saic M 1072Document5 pagesSaic M 1072Hussain Nasser Al- Nowiesser100% (2)

- Saudi Aramco Inspection ChecklistDocument22 pagesSaudi Aramco Inspection ChecklistAhdal NoushadNo ratings yet

- King Abdulaziz International Airport Development Project: Bolt Tigting Check List (BTC)Document1 pageKing Abdulaziz International Airport Development Project: Bolt Tigting Check List (BTC)amrNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Document19 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefNo ratings yet

- Saudi Aramco Piping ChecklistDocument3 pagesSaudi Aramco Piping ChecklistphilipyapNo ratings yet

- Saudi Aramco Inspection ChecklistDocument14 pagesSaudi Aramco Inspection Checklistpookkoya thangalNo ratings yet

- SAIC-M-2012 Rev 7supportsDocument33 pagesSAIC-M-2012 Rev 7supportsvijayachiduNo ratings yet

- SAIC-W-2015 Rev 7 (NDE Selection)Document17 pagesSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduNo ratings yet

- SAIC-D-2022 Rev 2Document5 pagesSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saic A 2011Document5 pagesSaic A 2011Anonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Structural Re-Instatement Punchlisting SAIC-M-1074 18-May-05 CivilDocument5 pagesSaudi Aramco Inspection Checklist: Structural Re-Instatement Punchlisting SAIC-M-1074 18-May-05 Civil(*KaT*)No ratings yet

- SAIC-D-2009 Rev 2Document6 pagesSAIC-D-2009 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Inspection of Support Foundation Prior To Structural or Equipment Installation SAIC-M-2006 03-Apr-22 MechDocument2 pagesInspection of Support Foundation Prior To Structural or Equipment Installation SAIC-M-2006 03-Apr-22 MechsankuNo ratings yet

- Bolt Torque and Tap Check: Understanding ASTM A325, A490 Bolts and Derrick ConstructionDocument20 pagesBolt Torque and Tap Check: Understanding ASTM A325, A490 Bolts and Derrick Constructionbudymood100% (3)

- Tighting torque methodDocument6 pagesTighting torque methodibrahim hegazyNo ratings yet

- SAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSDocument2 pagesSAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSkarthi51289No ratings yet

- Turn-Of-Nut Bolting MethodDocument12 pagesTurn-Of-Nut Bolting MethodbNo ratings yet

- Saic N 2036Document6 pagesSaic N 2036aamirapiNo ratings yet

- Es 9-54 Fastener Installation and Torque ValuesDocument33 pagesEs 9-54 Fastener Installation and Torque ValuesCarlosFernandoMondragonDominguezNo ratings yet

- Assembly and Tensioning of High Strength Bolts andDocument14 pagesAssembly and Tensioning of High Strength Bolts andKirtichandraKomarrajuNo ratings yet

- Pre Installation VerificationDocument8 pagesPre Installation VerificationEngr Ahmed FadulNo ratings yet

- Chicksan Inspection ProcedureDocument9 pagesChicksan Inspection ProcedureBanu Stefan Adrian100% (7)

- ISO 9001 Certified QAP Guidelines for 140T Crane UndercarriageDocument44 pagesISO 9001 Certified QAP Guidelines for 140T Crane Undercarriagehardeep SinghNo ratings yet

- SAIC-A-2025 Rev 6 Pre Test Pressure VesselDocument4 pagesSAIC-A-2025 Rev 6 Pre Test Pressure Vesselpookkoya thangal100% (1)

- SAIC M 2012 (Structural Welding)Document30 pagesSAIC M 2012 (Structural Welding)rubda11100% (1)

- SATR-J-6602 Rev 0 PDFDocument9 pagesSATR-J-6602 Rev 0 PDFAdel KlkNo ratings yet

- Til 1214-3R3Document7 pagesTil 1214-3R3Hernan Giraut100% (2)

- Bearing Clearance CheckDocument3 pagesBearing Clearance ChecksxturboNo ratings yet

- Saic M 1069Document2 pagesSaic M 1069Hussain Nasser Al- NowiesserNo ratings yet

- SAIC-A-2016 Rev 0Document2 pagesSAIC-A-2016 Rev 0philipyapNo ratings yet

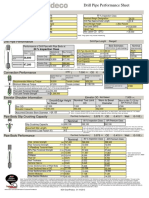

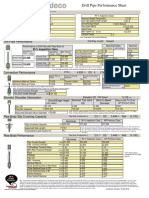

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNo ratings yet

- Saudi Aramco Inspection Checklist: Fireproofing Concrete Application Inspection SAIC-B-1002 1-Nov-09 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fireproofing Concrete Application Inspection SAIC-B-1002 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistaamirapi100% (2)

- GPT Installation Instructions - LoresDocument7 pagesGPT Installation Instructions - LoresEWheelerFKNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Procedures For Rotational Capacity Testing of Galvanized ASTM A325 ..Document14 pagesProcedures For Rotational Capacity Testing of Galvanized ASTM A325 ..Sayed Diab AlsayedNo ratings yet

- Saudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 Weldhamidjoyia100% (1)

- Piping and Ducting SupportDocument7 pagesPiping and Ducting SupportphilipyapNo ratings yet

- Drill Pipe Performance and SpecificationsDocument3 pagesDrill Pipe Performance and SpecificationsИнженер Луис А. ГарсиаNo ratings yet

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDocument14 pagesAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89No ratings yet

- SAIC-B-2001 Revw Proprietary Fireproofing MaterialsDocument2 pagesSAIC-B-2001 Revw Proprietary Fireproofing MaterialsAnonymous S9qBDVkyNo ratings yet

- Drill pipe performance and operational limitsDocument3 pagesDrill pipe performance and operational limitsGarcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- Drill Pipe Performance Data SheetDocument3 pagesDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- ISA Instrumentation Codes in Process Control SystemsDocument2 pagesISA Instrumentation Codes in Process Control SystemsJoel AlcantaraNo ratings yet

- To Oversee and Coordinate The PlanningDocument1 pageTo Oversee and Coordinate The PlanningJoel AlcantaraNo ratings yet

- App.4 Rev.2 Org - Structure 10-Jun-09Document1 pageApp.4 Rev.2 Org - Structure 10-Jun-09Joel AlcantaraNo ratings yet

- Responsibilities of key personnel on construction projectsDocument5 pagesResponsibilities of key personnel on construction projectsJoel AlcantaraNo ratings yet

- Erico Cadweld Plus Installation Guide - E297lt17wwen - LRDocument56 pagesErico Cadweld Plus Installation Guide - E297lt17wwen - LRJoel AlcantaraNo ratings yet

- Article 680-Swimming Pools, Spas, Hot Tubs, Fountains, and Similar InstallationsDocument30 pagesArticle 680-Swimming Pools, Spas, Hot Tubs, Fountains, and Similar InstallationsExperto 1100% (1)

- ISA Codes For Process InstrumentationDocument5 pagesISA Codes For Process InstrumentationJoel AlcantaraNo ratings yet

- IP-Ingress Protection RatingsDocument2 pagesIP-Ingress Protection RatingsJoel AlcantaraNo ratings yet

- App.1 Rev.2 - Dist. Matrix - 10-Jun-09Document4 pagesApp.1 Rev.2 - Dist. Matrix - 10-Jun-09Joel AlcantaraNo ratings yet

- Sizing Conductors and Selecting Protection Devices: Power Guide 2009 / Book 04Document71 pagesSizing Conductors and Selecting Protection Devices: Power Guide 2009 / Book 04zbyszko201234No ratings yet

- Electrical ITPDocument26 pagesElectrical ITPNorman Morales100% (2)

- Why Is ISO So ImportantDocument1 pageWhy Is ISO So ImportantAnkit ChawlaNo ratings yet

- App.3 Rev.2 - List of TWI - 10-Jun-09Document2 pagesApp.3 Rev.2 - List of TWI - 10-Jun-09Joel AlcantaraNo ratings yet

- Quality Control QuestionerDocument31 pagesQuality Control QuestionerKaukab Imam88% (42)

- Sabp A 012Document92 pagesSabp A 012Joel AlcantaraNo ratings yet

- Ge VFD MotorsDocument33 pagesGe VFD Motorssanjay.gawadeNo ratings yet

- Commissioning and Testing Complex Busbar Protection Schemes at PG&EDocument18 pagesCommissioning and Testing Complex Busbar Protection Schemes at PG&EJoel AlcantaraNo ratings yet

- Maintenance Program For EquipmentsDocument793 pagesMaintenance Program For EquipmentsJoel AlcantaraNo ratings yet

- Managing OH&S RisksDocument8 pagesManaging OH&S RisksJoel AlcantaraNo ratings yet

- Quality Records Examples ListDocument6 pagesQuality Records Examples ListJoel AlcantaraNo ratings yet

- Sabp A 001Document20 pagesSabp A 001Shahid Basha Syed100% (2)

- Power Supply For The Drop Arm BarrierDocument1 pagePower Supply For The Drop Arm BarrierJoel AlcantaraNo ratings yet

- Guide To Low Voltage Busbar Trunking Systems PDFDocument22 pagesGuide To Low Voltage Busbar Trunking Systems PDFJoel AlcantaraNo ratings yet

- MK Commando Range Industrial SocketDocument16 pagesMK Commando Range Industrial SocketJoel AlcantaraNo ratings yet

- 1.0 MS Casting Concrete For Box Culvert 20feb2016Document7 pages1.0 MS Casting Concrete For Box Culvert 20feb2016Joel AlcantaraNo ratings yet

- Method Statement For Cutting of Shoring Piles Rev 2Document3 pagesMethod Statement For Cutting of Shoring Piles Rev 2Joel Alcantara100% (1)

- Maintenance Program For Pressure GaugesDocument2 pagesMaintenance Program For Pressure GaugesJoel AlcantaraNo ratings yet

- The Top Quality QuestionsDocument22 pagesThe Top Quality QuestionsJoel AlcantaraNo ratings yet

- 7.0 MS - Sub-Base and Base Course Preparation RA-239 17 Mar 2016Document8 pages7.0 MS - Sub-Base and Base Course Preparation RA-239 17 Mar 2016Joel AlcantaraNo ratings yet

- Method of Cutting PilesDocument1 pageMethod of Cutting PilesJoel AlcantaraNo ratings yet