Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist

Uploaded by

Abdul HannanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Uploaded by

Abdul HannanCopyright:

Available Formats

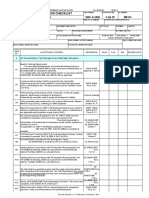

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.

00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Pre-Test Inspection of Pressure Vessels (All Applications,

SAIC-A-2025 15-Nov-17 MECH-

Including In-situ Testing of New Fin Fan Coolers)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Test Package Verification:

Test Diagram is submitted showing the following:

A) Limits of equipment to be tested incl. test manifold & equipment

included in the test.

A1 GI 2.102 Para

B) Test pressure of the system

5.1.2

C) Relief valve setting

D) Safety Instruction Sheet

• Hydrostatic testing for new vessels (field fabricated) shall be conducted

as per 32-SAMSS-004 and the original construction code.

Pneumatic test, when approved (refer to paragraph 5.4), shall be

conducted per UG-100 of ASME SEC VIII D1, or T-4 of ASME SEC VIII SAES-A-004,

A2 D2, whichever is applicable. Appendix F Item 3

• Pressure testing of small vessels shall be per the appropriate standard

as specified in 32-SAMSS-036.

• Hydrostatic testing for existing vessels shall be conducted per SAES-D-

008, Section 14.

A3 Procedure has been approved & meets the detailed requirements of GI 2.102 Para

SAIC-A-2001 (Review Procedure - Pressure Testing) 5.1.2

Verify drawing conformance of pressure vessel construction. Check all

32-SAMSS-004

nozzles, supports, attachments (orientation & dimension)

A4 Section 20

Systematically complete, verify & accept all drawings incl. details in

accordance with NMR-7919-1

Verify complete code construction incl. support attachments. Repairs 32-SAMSS-004,

A5

& Pick-up (ID/OD) are accepted. ASME VIII, UG-99 (a) Section 16.1.1

If block valves are used for blocking or isolating hydro test sections, the

differential pressure across the valve seat shall not exceed the seat test SAES-L-150 Para

A6

pressure during the strength test and shall not exceed the rated seat 5.10

pressure during the tightness test.

The hydrotest pressure of all internally coated vessels, tanks or piping SAES-A-004,

shall be reviewed against the coating limitations as per SAES-H-001. On Appendix F Item

A7

completing the hydrostatic test, the pressure should be reduced gradually 17

to prevent decompression failure of the internal coating.

Weld Summary Record (SAEP-1160 Welding Database) was verified to

SAEP-1160 Para

indicate completion/acceptance of all weld joints, repairs, modifications &

A8 5.1 & SAES-W-

any applicable weld inspection reqmts (visual, NDE).

010, Section 16

Verify SAIC-W-2008 & SATR-W-2008 details as applicable

All required inspection & testing (RT, MT, PT, PWHT, PMI) has been

completed & inspection control sheet has been signed by SA. (ASME 32-SAMSS-004,

A9

VIII, UG-99, Para. A-2) Para 14.1.3

As applicable, an SAEP-1160 Welding Database is reviewed

Saudi Aramco: Company General Use

Safety Instruction Sheet (SIS) for vessels/equipment is complete & SAES-A-005,

A10

approved. Verify correct test pressure for system/equipment. Para. 4.2

Test Pressure at top of vessel is verified against the SIS and conforms

to the following ASME Section VIII code, as applicable:

Test pressure measured at the top of the vessel shall be:

16.3.11.1(a) For Division 1 vessels per UG-99(b):

PT=1.3 MAWP (S/ST)

16.3.11.1(b) For Division 2 vessels per 8.2.1:

SAES-A-004,

Greater of:

Appendix F &

i) PT = 1.43 MAWP

A11 32-

ii) PT = 1.25 MAWP (ST/ S)

SAMSS-004,

Where,

Section 16.3.11

PT is the minimum test pressure

S is the allowable stress at design temperature

ST is the allowable stress at test temperature

ST/S is the lowest ratio for the pressure boundary

materials, excluding bolting materials, of which

the vessel is constructed.

Saudi Aramco: Company General Use

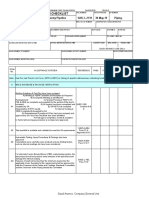

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Pre-Test Inspection of Pressure Vessels (All Applications,

SAIC-A-2025 15-Nov-17 MECH-

Including In-situ Testing of New Fin Fan Coolers)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

B Field Verification/Pre-Test Inspection of Vessel

SAES-A-004

B1 Vents shall be provided at all high points in the tested system as needed Para 5.14.1

Temporary supports shall be installed prior to hydrostatic testing, and

flushing of the piping if they were determined to be required per

SAES-A-004,

B3 SAES-L-150. These supports shall not be removed until after the system

Para.5.15.2

has been fully drained. The structural support system for stacked

equipment shall be verified for hydrostatic loads prior to testing.

All threaded joints and faying surfaces shall be seal welded by a

continuous fillet weld (required weep holes shall be left unwelded). SAES-W-010,

B4

Connections or attachments designed for periodic removal may be Para. 11.15.1

exempted from seal welding.

Weld Summary Record was verified to indicate completion of all weld SAES-W-010,

B5

joints & applicable weld inspection reqmts (visual and NDE). Para. 15.2

No acceptance of pressure testing shall be made prior to postweld heat 32-SAMSS-004,

B6

treatment. Section 16.3.4

Prior to final inspection and ressure testing, the inside and outside of the

32-SAMSS-004,

B7 vessel shall be thoroughly cleaned of all slag, scale, dirt, grit, weld spatter,

Section 16.2.9

paint, oil, etc.

Vessel Trim (associated piping) receives a strength test except in Utility

services and less when a service test can be conducted. SAES-L-150,

B8

Note: Vessel Trim piping pressure tests are often Para. 5.3

overlooked

B9 Sampling piping systems are pressure tested as an integral part of the

SAES-L-150,

New equipment to which it is connected.

Para. 5.6

All welded attachments provide with telltale holes shall be pneumatically

32-SAMSS-004,

tested at minimum 70 kPa (10 psi) prior to heat treatment and vessel

B10 Section 16.3.5,

pressure testing. Telltale holes must not be plugged during the vessel

16.3.6

pressure test.

The use of shellacs, glues, lead, etc., on gaskets during testing is

32-SAMSS-004,

B11 prohibited. No paint or primer shall be applied to a vessel prior to

Section 16.3.7

hydrostatic testing.

Hydrostatic pressure testing shall be performed with gaskets and

bolting identical to those required in service and as specified on the 32-SAMSS-004,

B12

data sheet. These gaskets may be used as service gaskets if the bolted Section 16.3.9

joint is not disassembled after completion of hydrostatic pressure testing.

B13 Metal temperature shall monitor throughout pressure vessel during 32-SAMSS-004,

New pressure test as per 32-SAMSS-004 Section 16.3.13

Vertical vessels tested in horizontal position are supported such that

32-SAMSS-004,

B14 primary stresses in any part of the vessel do not exceed 90% of minimum

Section 16.3.14

specified yield strength of the vessel material.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Pre-Test Inspection of Pressure Vessels (All Applications,

SAIC-A-2025 15-Nov-17 MECH-

Including In-situ Testing of New Fin Fan Coolers)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Horizontal vessels shall be tested while resting on their permanent 32-SAMSS-004,

B15

support saddles without additional supports or cribbing. Section 16.3.15

Equipment or parts that are cladded shall be hydrotested with water 32-SAMSS-031,

B16

having chloride content not greater than 50 ppm. Para. 10.2.1

Fin fan exchangers shall be strength tested as specified below:

a) New fabricated fin fan coolers to be strength tested in accordance with

32-SAMSS-011.

b) Modified or repaired fin fan coolers shall be strength tested in SAES-A-004,

B17 accordance with the Safety Instruction Sheet (SIS). Appendix F

c) In-situ pressure testing shall be conducted in reference to Appendix G. Item 4

This is applicable to new and repaired or modified fin fan coolers that

passed the shop strength test then transported to site.

Jacketed Vessel exams & hydrotest sequence are planned and detailed in

design & during hydrotesting (per test procedure).

A) Inner vessel construction &

hydrotesting is completed prior to installation and hydrotesting of outer

SCH Q, (Project

B18 jacket . B) Construction

Specific)

sequence allows 100% visual inspection of welds during hydrotest. Jacket

design & installation is carefully planned.

[Reference: ASME VIII, UG-99 sect. (e)]

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-A-004, General Requirements for Pressure Testing, 7 Jan 2016)

2. SAES-A-005, Safety Instruction Sheet, (21 March 2010)

3. SAES-D-008, Repairs, Alterations, and Re-rating of Process Equipment (30 June 2012)

5. SAEP-1160, Tracking and Reporting of Welding, NDT and Pressure Testing for Capital Projects. (10 July 2011)

6. SAES-W-010, Welding Requirements for Pressure Vessels (15 May 2016)

7. 32-SAMSS-031, Manufacture of Clad Vessels and Heat Exchangers. (2 Nov, 2011)

8. 32-SAMSS-004, Manufacture of Pressure Vessels (30 June 2014)

9. ASME Section VIII, Division 1 - Rules for Construction of Pressure Vessels (Latest Edition)

10. ASME Section VIII, Division 2 - Rules for Construction of Pressure Vessels, Alternative Rules (Latest Edition)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

BER

ACTOR

RE-INSP DATE

Saudi Aramco: Company General Use

BER

ACTOR

RE-INSP DATE

Work Verified

Work Verified

Work Verified

YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Piping ChecklistDocument3 pagesSaudi Aramco Piping ChecklistphilipyapNo ratings yet

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- SAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTDocument2 pagesSAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTnisha_khanNo ratings yet

- Saes A 007 PDFDocument29 pagesSaes A 007 PDFsindalisindiNo ratings yet

- Saes A 010Document32 pagesSaes A 010hyderabadNo ratings yet

- SAIC-A-2001 - Review Procedure - Pressure Testing (All Applications)Document13 pagesSAIC-A-2001 - Review Procedure - Pressure Testing (All Applications)walidNo ratings yet

- Saes Z 004Document40 pagesSaes Z 004nadeem100% (1)

- 01 Samss 010Document12 pages01 Samss 010Ahmed Shaban KotbNo ratings yet

- 01 Samss 010Document12 pages01 Samss 010Ahmed Shaban KotbNo ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDocument4 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechJagdishNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistm4metzNo ratings yet

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocument2 pagesSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNo ratings yet

- SAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSDocument2 pagesSAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- 01 Samss 012 2014Document10 pages01 Samss 012 2014lhanx2No ratings yet

- Aramco Receiving Inspection Checklist for Air-Cooled Heat ExchangerDocument13 pagesAramco Receiving Inspection Checklist for Air-Cooled Heat ExchangerjerinNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- 01-SAMSS-016 Qualification of Plates For Storage Tanks and Pressured Equipment For Resistance To Hydrogen-Induced CrackingDocument14 pages01-SAMSS-016 Qualification of Plates For Storage Tanks and Pressured Equipment For Resistance To Hydrogen-Induced CrackingJoni Carino SuniNo ratings yet

- 01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentDocument13 pages01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentAbdul HannanNo ratings yet

- Samss 023Document10 pagesSamss 023Subin RoshanNo ratings yet

- SAUDI ARAMCO PNEUMATIC TEST CHECKLISTDocument3 pagesSAUDI ARAMCO PNEUMATIC TEST CHECKLISTரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 ElectDocument6 pagesSaudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 Electkarthi51289No ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Saic A 2011Document8 pagesSaic A 2011jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Saes A 011 PDFDocument20 pagesSaes A 011 PDFcywahaNo ratings yet

- Verify Saudi Aramco Test Equipment SafetyDocument6 pagesVerify Saudi Aramco Test Equipment SafetyEagle SpiritNo ratings yet

- Selecting Tube Inserts For Shell-and-Tube Heat ExchangersDocument7 pagesSelecting Tube Inserts For Shell-and-Tube Heat Exchangerskamranonline999No ratings yet

- Saes A 005 PDFDocument32 pagesSaes A 005 PDFAdnanAtifNo ratings yet

- Saic A 2011Document5 pagesSaic A 2011Anonymous 4e7GNjzGWNo ratings yet

- SAIC-A-2009 Rev 0Document3 pagesSAIC-A-2009 Rev 0philipyapNo ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 Mechkarthi51289No ratings yet

- 1 Hornos RotatoriosDocument493 pages1 Hornos RotatoriosAnonymous iI88LtNo ratings yet

- Chloro Alkali PlantDocument11 pagesChloro Alkali PlantsimaproindiaNo ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- Crack & Thermal Checks - Wal & SlabsDocument3 pagesCrack & Thermal Checks - Wal & SlabsMuhammad IshaqNo ratings yet

- SAIC-A-2005 Rev 5 Leak TestDocument4 pagesSAIC-A-2005 Rev 5 Leak Testpookkoya thangalNo ratings yet

- Saic A 2025Document3 pagesSaic A 2025usmanNo ratings yet

- SAIC-A-2025 Rev 6 Pre Test Pressure VesselDocument4 pagesSAIC-A-2025 Rev 6 Pre Test Pressure Vesselpookkoya thangal100% (1)

- SAIC-A-2026 Rev 6 Pre Test API TankDocument6 pagesSAIC-A-2026 Rev 6 Pre Test API Tankpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 30-Apr-13 PipingDocument13 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 30-Apr-13 Pipingpookkoya thangalNo ratings yet

- SAUDI ARAMCO PNEUMATIC TEST INSPECTIONDocument4 pagesSAUDI ARAMCO PNEUMATIC TEST INSPECTIONpookkoya thangalNo ratings yet

- SAIC-A-2009 Rev 6 Test EquipmentDocument5 pagesSAIC-A-2009 Rev 6 Test Equipmentpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289No ratings yet

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- SAIC-A-2009 Rev 7Document4 pagesSAIC-A-2009 Rev 7sajidazmi.amuNo ratings yet

- Saic A 2005Document10 pagesSaic A 2005karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechAbdul HafeezNo ratings yet

- SAIC-A-2005 Rev 8Document4 pagesSAIC-A-2005 Rev 8Syed ImranNo ratings yet

- SAIC-A-2026 Rev 2Document5 pagesSAIC-A-2026 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2002 Rev 8Document5 pagesSAIC-D-2002 Rev 8Syed ImranNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 Mechkarthi51289No ratings yet

- SAIC-A-2011 Rev 6 Pressure TestDocument8 pagesSAIC-A-2011 Rev 6 Pressure Testpookkoya thangalNo ratings yet

- SAIC-A-2013 Rev 6 Hydro PipeDocument6 pagesSAIC-A-2013 Rev 6 Hydro Pipepookkoya thangalNo ratings yet

- Saic A 2010Document13 pagesSaic A 2010jerinNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechaneeshNo ratings yet

- Saudi Aramco Pre-Pressure ChecklistDocument2 pagesSaudi Aramco Pre-Pressure ChecklistnadeemNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- SAIC-L-2095 Rev 7Document6 pagesSAIC-L-2095 Rev 7Jaseel KanhirathingalNo ratings yet

- SAIC-A-2010 Rev 8Document13 pagesSAIC-A-2010 Rev 8Syed ImranNo ratings yet

- SATR-A-2007Document2 pagesSATR-A-2007razzak.me.enggNo ratings yet

- Saic D 2022Document7 pagesSaic D 2022sureshNo ratings yet

- Saudi Aramco pneumatic test checklistDocument5 pagesSaudi Aramco pneumatic test checklistpookkoya thangalNo ratings yet

- Saudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 ElectDocument6 pagesSaudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 Electkarthi51289No ratings yet

- Satr A 2007Document2 pagesSatr A 2007usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechphilipyapNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistDilshad AhemadNo ratings yet

- Satr A 2007Document2 pagesSatr A 2007Shahzad HussainNo ratings yet

- Saudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 Mechkarthi51289No ratings yet

- 12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Document30 pages12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Abdul HannanNo ratings yet

- RFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREADocument4 pagesRFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREAAbdul Hannan100% (1)

- RFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREADocument4 pagesRFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREAAbdul Hannan100% (1)

- 12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Document30 pages12e-C01 Rfis & Hprs Log Updated 28-Jan-2024Abdul HannanNo ratings yet

- Saes Z 008Document47 pagesSaes Z 008nadeemNo ratings yet

- Saep 13 PDFDocument25 pagesSaep 13 PDFAnonymous 4IpmN7OnNo ratings yet

- Saes A 100Document6 pagesSaes A 100nadeemNo ratings yet

- Saes Z 010Document16 pagesSaes Z 010nadeemNo ratings yet

- Saes A 102Document22 pagesSaes A 102nadeemNo ratings yet

- 01 Samss 005 PDFDocument5 pages01 Samss 005 PDFjojo_323No ratings yet

- 09-SAMSS-060 Packaging Requirements For CoatingsDocument4 pages09-SAMSS-060 Packaging Requirements For CoatingsAbdul HannanNo ratings yet

- 02 Samss 010Document7 pages02 Samss 010balajiNo ratings yet

- 01 Samss 005 PDFDocument5 pages01 Samss 005 PDFjojo_323No ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechAbdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Final Inspection of Intumescent Fireproofing Application SAIC-B-2010 15-Nov-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Inspection of Intumescent Fireproofing Application SAIC-B-2010 15-Nov-17 MechAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 15-Nov-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 15-Nov-17 MechAbdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Module 1 - Introduction To ChemistryDocument10 pagesModule 1 - Introduction To ChemistryJhun Lerry TayanNo ratings yet

- Materials: The Critical Raw Materials in Cutting Tools For Machining Applications: A ReviewDocument48 pagesMaterials: The Critical Raw Materials in Cutting Tools For Machining Applications: A ReviewRAJIV GandhiNo ratings yet

- TitationDocument2 pagesTitationapi-222503660No ratings yet

- Low Well Productivity SolutionsDocument17 pagesLow Well Productivity SolutionsjeedNo ratings yet

- StructuralDocument40 pagesStructuralStephanie Joy Delos Reyes67% (3)

- Standards For Corrosion RatesDocument2 pagesStandards For Corrosion RatesHai LeNo ratings yet

- Cafco FENDOLITE MIIDocument8 pagesCafco FENDOLITE MIINelloNo ratings yet

- SOIL COLLOIDS PROPERTIESDocument4 pagesSOIL COLLOIDS PROPERTIESAbhishekNo ratings yet

- 04 Unit Operations in Food Processing Contact Equilibrium Separation Processes-3: ExtractionDocument15 pages04 Unit Operations in Food Processing Contact Equilibrium Separation Processes-3: Extractionjackson100% (1)

- Technical Calculation and Estimators Man Hour Manual Marko Bulics 20031Document107 pagesTechnical Calculation and Estimators Man Hour Manual Marko Bulics 20031Jake 1No ratings yet

- Coarse Aggregate Specific GravityDocument16 pagesCoarse Aggregate Specific GravityJudy Tan0% (1)

- BBS IntroDocument15 pagesBBS IntroKaushal KumarNo ratings yet

- Instruction manual for welding machineDocument4 pagesInstruction manual for welding machine7AMOOD ASALNo ratings yet

- Boiler Paint Resists 550°CDocument1 pageBoiler Paint Resists 550°CnanoNo ratings yet

- Astm d5778 12Document20 pagesAstm d5778 12farquinNo ratings yet

- Thesis Huifei JinDocument170 pagesThesis Huifei Jintaufiqishak09No ratings yet

- Unfolding The CausticumDocument78 pagesUnfolding The CausticumSk Saklin MustakNo ratings yet

- ME 601 - Stress Analysis Assignment 1 - Review of Strength of Materials Due Date: 27/07/2015, at The Beginning of The ClassDocument6 pagesME 601 - Stress Analysis Assignment 1 - Review of Strength of Materials Due Date: 27/07/2015, at The Beginning of The Classfatty acidNo ratings yet

- Heat Transfer TextbookDocument3 pagesHeat Transfer Textbookapi-3800348100% (1)

- ReportDocument14 pagesReportAnh Lương QuỳnhNo ratings yet

- Muntinlupa City Ordinance 10-109Document7 pagesMuntinlupa City Ordinance 10-109Joy Dawis-Asuncion0% (1)

- Analysis and Simulation of Mini Pyrolysis Reactor For Conversion ofDocument5 pagesAnalysis and Simulation of Mini Pyrolysis Reactor For Conversion ofDidit Setyo PamujiNo ratings yet

- 4 Chapter Liquids and Solids McqsDocument6 pages4 Chapter Liquids and Solids McqsAáwáíź Jútt0% (1)

- CH 03Document37 pagesCH 03amir joudehNo ratings yet

- Antigen-Antibody Interactions: The Basis of Immune RecognitionDocument3 pagesAntigen-Antibody Interactions: The Basis of Immune RecognitionTinku MeherNo ratings yet

- Microwave Transistors - MESFETDocument19 pagesMicrowave Transistors - MESFET陳加穎No ratings yet