Professional Documents

Culture Documents

SAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELS

Uploaded by

karthi51289Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELS

Uploaded by

karthi51289Copyright:

Available Formats

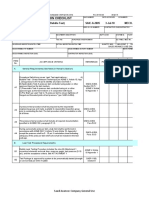

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.

00 30-Apr-18

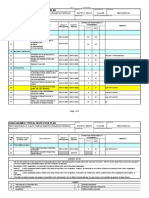

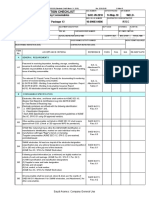

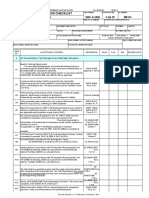

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Pre-Test Inspection of Pressure Vessels (All Applications,

SAIC-A-2025 3-Jul-18 MECH-

Including In-situ Testing of New Fin Fan Coolers)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Test Package Verification:

Test Diagram is submitted showing the following:

A) Limits of equipment to be tested incl. test manifold & equipment

included in the test.

A1 GI 2.102 Para

B) Test pressure of the system

5.1.2

C) Relief valve setting

D) Safety Instruction Sheet

• Hydrostatic testing for new vessels (field fabricated) shall be conducted

as per 32-SAMSS-004 and the original construction code.

Pneumatic test, when approved (refer to paragraph 5.4), shall be

conducted per UG-100 of ASME SEC VIII D1, or T-4 of ASME SEC VIII SAES-A-004,

A2 D2, whichever is applicable. Appendix F Item 3

• Pressure testing of small vessels shall be per the appropriate standard

as specified in 32-SAMSS-036.

• Hydrostatic testing for existing vessels shall be conducted per SAES-D-

008, Section 14.

A3 Procedure has been approved & meets the detailed requirements of GI 2.102 Para

SAIC-A-2001 (Review Procedure - Pressure Testing) 5.1.2

Verify drawing conformance of pressure vessel construction. Check all

32-SAMSS-004

nozzles, supports, attachments (orientation & dimension)

A4 Section 20

Systematically complete, verify & accept all drawings incl. details in

accordance with NMR-7919-1

A5 Verify complete code construction incl. support attachments. Repairs 32-SAMSS-004,

New & Pick-up (ID/OD) are accepted. ASME VIII, UG-99 (a) Section 16.1.1

If block valves are used for blocking or isolating hydro test sections, the

differential pressure across the valve seat shall not exceed the seat test SAES-L-150 Para

A6

pressure during the strength test and shall not exceed the rated seat 5.10

pressure during the tightness test.

The hydrotest pressure of all internally coated vessels, tanks or piping SAES-A-004,

shall be reviewed against the coating limitations as per SAES-H-001. On Appendix F Item

A7

completing the hydrostatic test, the pressure should be reduced gradually 17

to prevent decompression failure of the internal coating.

Weld Summary Record (SAEP-1160 Welding Database) was verified to

SAEP-1160 Para

indicate completion/acceptance of all weld joints, repairs, modifications &

A8 5.1 & SAES-W-

any applicable weld inspection reqmts (visual, NDE).

010, Section 16

Verify SAIC-W-2008 & SATR-W-2008 details as applicable

All required inspection & testing (RT, MT, PT, PWHT, PMI) has been

completed & inspection control sheet has been signed by SA. (ASME 32-SAMSS-004,

A9

VIII, UG-99, Para. A-2) Para 14.1.3

As applicable, an SAEP-1160 Welding Database is reviewed

Saudi Aramco: Company General Use

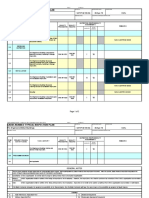

Safety Instruction Sheet (SIS) for vessels/equipment is complete & SAES-A-005,

A10

approved. Verify correct test pressure for system/equipment. Para. 4.2

Test Pressure at top of vessel is verified against the SIS and conforms

to the following ASME Section VIII code, as applicable:

Test pressure measured at the top of the vessel shall be:

16.3.11.1(a) For Division 1 vessels per UG-99(b):

PT=1.3 MAWP (S/ST)

16.3.11.1(b) For Division 2 vessels per 8.2.1:

SAES-A-004,

Greater of:

Appendix F &

i) PT = 1.43 MAWP

A11 32-

ii) PT = 1.25 MAWP (ST/ S)

SAMSS-004,

Where,

Section 16.3.11

PT is the minimum test pressure

S is the allowable stress at design temperature

ST is the allowable stress at test temperature

ST/S is the lowest ratio for the pressure boundary

materials, excluding bolting materials, of which

the vessel is constructed.

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechJagdishNo ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAUDIPIPINGMATTRACEDocument9 pagesSAUDIPIPINGMATTRACEMAZHARULNo ratings yet

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioNo ratings yet

- SAUDICHECK - WELD TRACKING DATABASEDocument5 pagesSAUDICHECK - WELD TRACKING DATABASEManoj KumarNo ratings yet

- Saudi Aramco Pressure Testing ProcedureDocument21 pagesSaudi Aramco Pressure Testing ProcedureDilshad AhemadNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-L-1003 29-Jun-17Document1 pageSaudi Aramco Inspection Checklist: SAIC-L-1003 29-Jun-17Zia ur RehmanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument11 pagesSaudi Aramco Inspection ChecklistleonysNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument2 pagesSaudi Aramco Typical Inspection PlanMAZHARULNo ratings yet

- Inspection ProcedureDocument13 pagesInspection ProcedureSantosh Kumar100% (1)

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- 01-SAMSS-049 Reinforced Thermoset Resin (RTR) Pipe, Fittings and Adhesive Packing, Handling, Transportation and Storage 21-FEB-2012 PDFDocument8 pages01-SAMSS-049 Reinforced Thermoset Resin (RTR) Pipe, Fittings and Adhesive Packing, Handling, Transportation and Storage 21-FEB-2012 PDFasiqnaNo ratings yet

- Saudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeDocument7 pagesSaudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeAnonymous S9qBDVkyNo ratings yet

- SAIC-A-2016 Rev 0Document2 pagesSAIC-A-2016 Rev 0philipyapNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- Ad 036821 001Document1 pageAd 036821 001AmolNo ratings yet

- Saudi Aramco System Lay-up ReportDocument2 pagesSaudi Aramco System Lay-up Reportdeepa narayan100% (1)

- Saudi Aramco Test ReportDocument4 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- A A A A A A: Saudi Aramco Inspection ChecklistDocument2 pagesA A A A A A: Saudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalDocument11 pagesSaudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument5 pagesSaudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliShahbaz AhmadNo ratings yet

- Saudi Aramco PMI checklist ensures alloy purityDocument5 pagesSaudi Aramco PMI checklist ensures alloy puritykarioke mohaNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- III. Applicable Codes & Standards for Aramco ProjectsDocument5 pagesIII. Applicable Codes & Standards for Aramco ProjectsZain Ali KidwaiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistphilipyapNo ratings yet

- New Floating Pontoon Coast Guard Construction InspectionDocument2 pagesNew Floating Pontoon Coast Guard Construction InspectionSabheeh AliNo ratings yet

- Saudi Aramco welding inspection planDocument12 pagesSaudi Aramco welding inspection planspravin231No ratings yet

- QMIS RFI RaisedDocument2 pagesQMIS RFI RaisedSulman YounasNo ratings yet

- Inspection Report Focused Cutting/Welding Flashback ArrestorsDocument2 pagesInspection Report Focused Cutting/Welding Flashback ArrestorsMansoor BabarNo ratings yet

- Saudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilDocument2 pagesSaudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalDocument12 pagesSaudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalAhdal NoushadNo ratings yet

- SAUDI ARAMCO PRESSURE TESTING PROCEDURE REVIEWDocument27 pagesSAUDI ARAMCO PRESSURE TESTING PROCEDURE REVIEWNaushad AlamNo ratings yet

- Saep 321Document25 pagesSaep 321AbdullahNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- SAIC-L-2035 Rev 6Document2 pagesSAIC-L-2035 Rev 6biplabpal2009No ratings yet

- SAIC-A-2009 Rev 2Document5 pagesSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- 175 320300Document1 page175 320300sridhar100% (1)

- SATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument13 pagesSATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground Pipelikarthi51289No ratings yet

- Saic H 2082Document8 pagesSaic H 2082jerin100% (1)

- SATIP-P-104-01 Rev 7 FinalDocument4 pagesSATIP-P-104-01 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Weekly Welder ReportDocument2 pagesWeekly Welder Reportkarthi51289No ratings yet

- Saic A 2025Document3 pagesSaic A 2025usmanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- SAIC-A-2025 Rev 6 Pre Test Pressure VesselDocument4 pagesSAIC-A-2025 Rev 6 Pre Test Pressure Vesselpookkoya thangal100% (1)

- SAIC-A-2026 Rev 6 Pre Test API TankDocument6 pagesSAIC-A-2026 Rev 6 Pre Test API Tankpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289No ratings yet

- SAUDI ARAMCO PNEUMATIC TEST INSPECTIONDocument4 pagesSAUDI ARAMCO PNEUMATIC TEST INSPECTIONpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 30-Apr-13 PipingDocument13 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 30-Apr-13 Pipingpookkoya thangalNo ratings yet

- Saic A 2011Document8 pagesSaic A 2011jerinNo ratings yet

- Saic A 2005Document10 pagesSaic A 2005karthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 InstDocument17 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 Instkarthi51289No ratings yet

- SAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTDocument4 pagesSAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 Civilkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 Civilkarthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 Mechkarthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 Mechkarthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 2016Document1 pageSaic A 2016karthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289No ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 2016Document1 pageSaic A 2016karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 Mechkarthi51289No ratings yet

- Haggis Exercise - Prosper - Updated 2007Document11 pagesHaggis Exercise - Prosper - Updated 2007Anonymous 3TyM2U3U4eNo ratings yet

- Principles of Gas-Solid FlowsDocument575 pagesPrinciples of Gas-Solid FlowsLiang Wenjia100% (3)

- Sample 4320Document11 pagesSample 4320Deepak Sharma100% (1)

- Vertical Pump Ranges: Sulzer PumpsDocument4 pagesVertical Pump Ranges: Sulzer Pumpsjhonny_restrepo001No ratings yet

- ASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorDocument6 pagesASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorsajuhereNo ratings yet

- Technical Data Styrofoam™ RTM-X: Extruded Polystyrene Foam XPS (EN13164) - Free From HCFC - Blue ColorDocument1 pageTechnical Data Styrofoam™ RTM-X: Extruded Polystyrene Foam XPS (EN13164) - Free From HCFC - Blue ColorHUGONo ratings yet

- Econex Brochurev 3 LRDocument2 pagesEconex Brochurev 3 LRekanayakeemdNo ratings yet

- Lab Report Experiment 1 - Rate of Reaction - 2021Document4 pagesLab Report Experiment 1 - Rate of Reaction - 2021Ye Woon LimNo ratings yet

- 02 - Radial Flow and Radius of InvestigationDocument16 pages02 - Radial Flow and Radius of InvestigationrogerNo ratings yet

- F April 2019: Course: Class NBR(S) : Slot: Time: Three Hours Max. Marks: 100Document1 pageF April 2019: Course: Class NBR(S) : Slot: Time: Three Hours Max. Marks: 100Sandhya SundarNo ratings yet

- Section 24 Neutralizing Filming AminesDocument3 pagesSection 24 Neutralizing Filming AminesSheikh SahabNo ratings yet

- LNG VS GTLDocument1 pageLNG VS GTLdishankmpatelNo ratings yet

- Numerical Modeling of Piano Key Weirs Using FLOW-3D: Results DiscussionDocument1 pageNumerical Modeling of Piano Key Weirs Using FLOW-3D: Results Discussionmary cabezasNo ratings yet

- Energies 15 04580 v2Document16 pagesEnergies 15 04580 v2ฉัตรประภา แวววงศ์No ratings yet

- FEC - Filter Media Pore Test Rig PDFDocument2 pagesFEC - Filter Media Pore Test Rig PDFAman KatiyarNo ratings yet

- PVC Piping Systems-PPFADocument40 pagesPVC Piping Systems-PPFAAmal KaNo ratings yet

- Domestic Water Booster Pump CalculationsDocument26 pagesDomestic Water Booster Pump CalculationsAnonymous BJ9omO100% (10)

- Chapter Glossary: Properties of Pure SubstancesDocument6 pagesChapter Glossary: Properties of Pure SubstancesyusufNo ratings yet

- ASPE Cross Connection ControlDocument13 pagesASPE Cross Connection ControlAngelo Mar MallariNo ratings yet

- Understanding Fluid Mechanics FundamentalsDocument8 pagesUnderstanding Fluid Mechanics FundamentalsKrishnaChaitanyaNo ratings yet

- Wall Thickness Calculation Followed B31.8 PDFDocument3 pagesWall Thickness Calculation Followed B31.8 PDFBPCL HCULOBS100% (1)

- Barchart Piping AllDocument30 pagesBarchart Piping AllSamuelTrinandoNo ratings yet

- WehoAntistatic LeafletDocument2 pagesWehoAntistatic LeafletSoldadura De Termoplasticos TuberiasNo ratings yet

- Metering Pumps Instruction Manual Milton RoyDocument14 pagesMetering Pumps Instruction Manual Milton RoyNakclean Water SolutionsNo ratings yet

- Vignesh (2015) - Reactor DesignDocument8 pagesVignesh (2015) - Reactor DesigngandurikNo ratings yet

- Distillation Iv Mccabe Thiele MethodDocument29 pagesDistillation Iv Mccabe Thiele MethodDaffa YezaldyNo ratings yet

- Powapak Air Ultra Operating ManualDocument45 pagesPowapak Air Ultra Operating ManualBenrub Flores75% (4)

- Design Fluidized Bed Reactor for Acrylic Acid ProductionDocument46 pagesDesign Fluidized Bed Reactor for Acrylic Acid Productionlily89% (9)

- Homework #8: CEE212 - Structural and Solid Mechanics Winter Semester 2014-2015Document2 pagesHomework #8: CEE212 - Structural and Solid Mechanics Winter Semester 2014-2015nageshNo ratings yet

- PreviewpdfDocument105 pagesPreviewpdfMd.Tanvir RahmanNo ratings yet