Professional Documents

Culture Documents

Disa KW Working Chart

Uploaded by

Sayan Naskar0 ratings0% found this document useful (0 votes)

1 views2 pagesOriginal Title

Disa Kw Working Chart

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views2 pagesDisa KW Working Chart

Uploaded by

Sayan NaskarCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

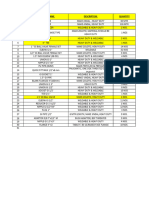

MECHNICAL MAN ELECTRICAL MAN

SI.NO. DATE WORK DESCRIPTION START TIME COMPLETE TIME

POWER REQUIRMENT POWER REQUERMENT

Assembly on machine for loose component.

Support cable traning system.

Support for distance sensor.

Railing.

1 1/29/2024 Inoculation system with load cell.

50 KN load cell mixing .

Cheeking of encoder cable.

Fixing one trolley and chainto cable traling system.

Fixing of encodeeer cable to traling.

Mechanical centerline measurement

with referance to disa line.

Instalation of cable trailing system & its

connection at both end.

Connection of distance sensor .

2 1/30/2024

Fixing of tower light & connection.

Connection to inoculation system .

After all connection power jb panel.

A.C fixing ( panel ac).

Fixing of refecter plate coloum.

Fixing of laddle pick up station.

Power up panel & check all electrical working.

with softworee persion further testing .

3 1/31/2024 Encoder fixing of disa indexing line/ cable routing

& connection .

With soft. Person setting of limit switch for machine.

Checking operation (basic with) softwere.

Laddle lining & readyness.

Calibration of hopper sensor .

Ccalibration of hopper load cell.

Calibration of laddel load cell.

Calibration of laddel sensor.

4 2/1/2024 Calibration of distance sensor.

Fixing of optrix sensor .

Placing of scada pc & checking its communication .

Checking of encodder (disa pash) signal.

Checking of dry scquence in scmi-auto-mode.

Pending activity of calibration or auto trial.

5 2/2/2024 Trial to take for with metal for laddels.

5 2/2/2024

Checking of optrix cameraa.

You might also like

- Abed Haimbodi's CV: Skilled Electrical EngineerDocument7 pagesAbed Haimbodi's CV: Skilled Electrical EngineerAbed Abi LemNo ratings yet

- Edc Lab 2Document10 pagesEdc Lab 2i222200 Muhammad AhmedNo ratings yet

- MC MINQ0416 Mine ElectricianDocument13 pagesMC MINQ0416 Mine Electriciandwarka prasadNo ratings yet

- Mod. C20-E2/EV: Testing Module of Electricity 2Document1 pageMod. C20-E2/EV: Testing Module of Electricity 2lusoegyi 1919No ratings yet

- Method of Statement For Power Cables: Owner/Client Consultant ContractorDocument7 pagesMethod of Statement For Power Cables: Owner/Client Consultant ContractorPandrayar MaruthuNo ratings yet

- Meters Requirement NigeriaDocument16 pagesMeters Requirement NigeriaMatousNo ratings yet

- Microprocessor-Based Distance Relay for EHV/UHV LinesDocument95 pagesMicroprocessor-Based Distance Relay for EHV/UHV Linesyand_carlosNo ratings yet

- Electrical Engineering Lab ManualDocument99 pagesElectrical Engineering Lab Manualvenkata karthikNo ratings yet

- Electrical Engineering: KCT College of Engg and Tech. Village Fatehgarh Distt - SangrurDocument23 pagesElectrical Engineering: KCT College of Engg and Tech. Village Fatehgarh Distt - SangrurNishant SaxenaNo ratings yet

- Checkfire 210 Detection and Actuation System: FeaturesDocument6 pagesCheckfire 210 Detection and Actuation System: FeaturesMatias EduardoNo ratings yet

- Relay & HV Lab Manual - 2020 Latest-1Document43 pagesRelay & HV Lab Manual - 2020 Latest-1uncensored unofficialNo ratings yet

- Mod. C24/EV: Ac/Dc Switching Power SupplyDocument2 pagesMod. C24/EV: Ac/Dc Switching Power Supplylusoegyi 1919No ratings yet

- H N Nagamani - 2017 - On-Line Diagnostic Technique For Monitoring Partial Discharges in Capacitor BanksDocument4 pagesH N Nagamani - 2017 - On-Line Diagnostic Technique For Monitoring Partial Discharges in Capacitor BanksdennyyusufNo ratings yet

- Applying IEC 60909, Fault Current CalculationsDocument6 pagesApplying IEC 60909, Fault Current CalculationsgayarthrichandranNo ratings yet

- Technical Submittal - Electrical ModificationDocument8 pagesTechnical Submittal - Electrical ModificationsaravananNo ratings yet

- Electronic Workshop & PCB Lab: Manual (NEC-352)Document20 pagesElectronic Workshop & PCB Lab: Manual (NEC-352)biswajit7sarkarNo ratings yet

- IJRPR263Document4 pagesIJRPR26319tk1ao222 md faisal aliNo ratings yet

- Lab Manual: Shree Ramchandra College of Engineering, Lonikand, Pune - 412 216Document43 pagesLab Manual: Shree Ramchandra College of Engineering, Lonikand, Pune - 412 216jatindraNo ratings yet

- S29 PDFDocument284 pagesS29 PDFPawan Shyamsundar GadewadNo ratings yet

- Ko Aung Ko HtayDocument128 pagesKo Aung Ko HtaylinkerNo ratings yet

- Presentation - Non-Domestic Electrical Installation Safety CodeDocument39 pagesPresentation - Non-Domestic Electrical Installation Safety CodeTommy YapNo ratings yet

- 6305-El-Etp-7010-A00 Ac DBDocument18 pages6305-El-Etp-7010-A00 Ac DBvicesuza87No ratings yet

- BR - 821 040 - Product Brochure - Cable Test Vans and Systems - ENDocument15 pagesBR - 821 040 - Product Brochure - Cable Test Vans and Systems - ENEmre BENGINo ratings yet

- An Outlook of Electrical & Power Industry Case StudiesDocument9 pagesAn Outlook of Electrical & Power Industry Case StudiesZineddine BENOUADAHNo ratings yet

- SGP Lab Manual PDFDocument17 pagesSGP Lab Manual PDFdanish fareedNo ratings yet

- SGP Lab ManualDocument17 pagesSGP Lab Manualshreemanti75% (4)

- 6837 ControllingAutoreclosing BK 20171106 WebDocument7 pages6837 ControllingAutoreclosing BK 20171106 WebbrunoscarpaNo ratings yet

- EV Charging Campaign Design Guide ControlDocument16 pagesEV Charging Campaign Design Guide ControlNikolas KyriakidisNo ratings yet

- Selectivity Catalog Domestic 291015Document12 pagesSelectivity Catalog Domestic 291015Samarendu BaulNo ratings yet

- Carmel Polytechnic College: AlappuzhaDocument52 pagesCarmel Polytechnic College: AlappuzhaefrfNo ratings yet

- Gedac Electric: Factory Acceptance Test For Low Voltage PanelsDocument11 pagesGedac Electric: Factory Acceptance Test For Low Voltage PanelsMohammad YaseeenNo ratings yet

- Circuit Breaker Analyzer & Timer CAT126D: DescriptionDocument7 pagesCircuit Breaker Analyzer & Timer CAT126D: Descriptionkenlavie2No ratings yet

- Applying IEC 60909 Fault Current Calculations PDFDocument6 pagesApplying IEC 60909 Fault Current Calculations PDFsam alNo ratings yet

- Method Statement For AC PANELDocument6 pagesMethod Statement For AC PANELkamilNo ratings yet

- Commissioning Tests for IDMT RelayDocument6 pagesCommissioning Tests for IDMT RelayVishal PatelNo ratings yet

- Recloser NOJA Power OSM15 27 38 Product Guide en PDFDocument12 pagesRecloser NOJA Power OSM15 27 38 Product Guide en PDFAlex B. MolinaNo ratings yet

- Selecting Arrester MCOV-UcDocument9 pagesSelecting Arrester MCOV-Ucjose GonzalezNo ratings yet

- 40-SDMS-02A: Saudi Electricity CompanyDocument70 pages40-SDMS-02A: Saudi Electricity Companymusleh19No ratings yet

- Electronics Device Manual (NEC-354) : Department of Electronics & Communication EngineeringDocument58 pagesElectronics Device Manual (NEC-354) : Department of Electronics & Communication EngineeringE-Biz NetworkNo ratings yet

- IPEC2018 DidtDocument7 pagesIPEC2018 DidtWitold PaczyńskiNo ratings yet

- The Oxford Polytechnic: Log SheetDocument9 pagesThe Oxford Polytechnic: Log SheetAnonymous EayGj0No ratings yet

- A New PMU-Based Fault Location Algorithm For Series Compensated LinesDocument14 pagesA New PMU-Based Fault Location Algorithm For Series Compensated Linessameerpatel15770No ratings yet

- Omogoye .O.S, Ogundare .A.B, Ojo .F.Epage 1Document7 pagesOmogoye .O.S, Ogundare .A.B, Ojo .F.Epage 1kalu chimdiNo ratings yet

- Smart Grid Testing: ApplicationDocument3 pagesSmart Grid Testing: ApplicationTayyab ZubairNo ratings yet

- CM Eng Smart Connectors ZeliskoDocument20 pagesCM Eng Smart Connectors ZeliskoLong Đạt NguyễnNo ratings yet

- Electrical Machines IIDocument61 pagesElectrical Machines IIPriya SurvacyNo ratings yet

- Electrical InterfaceDocument11 pagesElectrical InterfaceS.KAMBANNo ratings yet

- Auto Relay Setting GTRC2005Document24 pagesAuto Relay Setting GTRC2005Levi FondaNo ratings yet

- LT PN - BDDocument27 pagesLT PN - BDDarshit VyasNo ratings yet

- Power Wave Advanced Module & Advanced Module Aluminum: Operator'S ManualDocument34 pagesPower Wave Advanced Module & Advanced Module Aluminum: Operator'S ManualnikolovskidareNo ratings yet

- Technical Proposal For Setting Up A Model Substation For TrainingDocument14 pagesTechnical Proposal For Setting Up A Model Substation For Trainingjigyesh sharmaNo ratings yet

- Be8261 BeeieDocument82 pagesBe8261 BeeieMohammed OvaizNo ratings yet

- INVERTA (Three Phase) User ManualDocument24 pagesINVERTA (Three Phase) User ManualDario MontillaNo ratings yet

- Sat Procedure For MV SWGR Panels PDFDocument4 pagesSat Procedure For MV SWGR Panels PDFAmr ElkadyNo ratings yet

- Fault Location in Power Transformers During Impulse TestsDocument6 pagesFault Location in Power Transformers During Impulse TestsMozar CostaNo ratings yet

- Compact City PDFDocument4 pagesCompact City PDFpatricio aguirreNo ratings yet

- Electrical Equipment Installation and Maintenance Lesson PlanDocument13 pagesElectrical Equipment Installation and Maintenance Lesson PlanFerdinand OrquinaNo ratings yet

- HandShaking - Signal DISA MypourDocument1 pageHandShaking - Signal DISA MypourSayan NaskarNo ratings yet

- Span Water Line Indent MaterialDocument1 pageSpan Water Line Indent MaterialSayan NaskarNo ratings yet

- HandShaking - Signal DISA MypourDocument1 pageHandShaking - Signal DISA MypourSayan NaskarNo ratings yet

- Standard Unit WeightDocument1 pageStandard Unit WeightSayan NaskarNo ratings yet

- PIC16F161X Press Presentation November 2014Document28 pagesPIC16F161X Press Presentation November 2014Dream CatcherNo ratings yet

- 2014-16 Transmission CVT Fluid Change - Corolla (k313)Document16 pages2014-16 Transmission CVT Fluid Change - Corolla (k313)Repuestos Maceira100% (2)

- Product data sheet specifications analog voltmeter VLTDocument2 pagesProduct data sheet specifications analog voltmeter VLTSajid AkhterNo ratings yet

- 1 N 52 XXBDocument2 pages1 N 52 XXB81968No ratings yet

- Electrical Measurement and Measuring InstrumentsDocument1 pageElectrical Measurement and Measuring InstrumentsvinodsingoriaNo ratings yet

- ACP Panel Fixing AnalysisDocument8 pagesACP Panel Fixing AnalysisARYA100% (1)

- EE 330 HOMEWORK 4 TRANSMISSION LINE PROBLEMSDocument2 pagesEE 330 HOMEWORK 4 TRANSMISSION LINE PROBLEMSeng2011techNo ratings yet

- 028-Dehaco Water Distribution Skid - 3 (030408)Document3 pages028-Dehaco Water Distribution Skid - 3 (030408)brat.jose2023No ratings yet

- Hidráulica BásicaDocument210 pagesHidráulica BásicaAlfredo GalarzaNo ratings yet

- Varun Patil ProjectDocument22 pagesVarun Patil Projectpatil samrudhiNo ratings yet

- Schiavi Enc Met Page088Document1 pageSchiavi Enc Met Page088Adel AdelNo ratings yet

- Common Computer Connector TypesDocument36 pagesCommon Computer Connector TypesDaisy Mangahas BaleriteNo ratings yet

- FocusDocument65 pagesFocusRoberto Sanchez67% (3)

- 1483 E IMS 8 StorageDocument10 pages1483 E IMS 8 StorageJuan Manuel Pescador ReyesNo ratings yet

- Kx-Tda0103xj Kx-Tda0104xj Kx-Tda0108xj Kx-Tda0103x Kx-Tda0104x Kx-Tda0108xDocument134 pagesKx-Tda0103xj Kx-Tda0104xj Kx-Tda0108xj Kx-Tda0103x Kx-Tda0104x Kx-Tda0108xrobert orecisNo ratings yet

- APC Back-Ups 350Document2 pagesAPC Back-Ups 350Justin EndacottNo ratings yet

- PBD655 DatasheetDocument2 pagesPBD655 DatasheetSergeyNo ratings yet

- Ob 2223 HCDocument11 pagesOb 2223 HCRivaldyNo ratings yet

- Inspection of Crank Pin Bearing Inspection On The Main EngineDocument2 pagesInspection of Crank Pin Bearing Inspection On The Main EngineEzhil AnNo ratings yet

- 1040363-014 Rev 01 Technical Data BookDocument209 pages1040363-014 Rev 01 Technical Data BookBui Chi TamNo ratings yet

- Large Generator Course InfoDocument8 pagesLarge Generator Course Inforosario.md1052No ratings yet

- Mindray BC 2800 Service ManualDocument108 pagesMindray BC 2800 Service Manualcarlos enriquezNo ratings yet

- Skateboard Deck and Truck Parts GuideDocument5 pagesSkateboard Deck and Truck Parts GuideNik Syukriah AminNo ratings yet

- 2022.02 ROBOTBAS Building Automation SystemsDocument52 pages2022.02 ROBOTBAS Building Automation SystemsamurjiantoNo ratings yet

- TA8428K Datasheet en 20100223Document15 pagesTA8428K Datasheet en 20100223Richard Andrianjaka LuckyNo ratings yet

- Et&s-Mep Materail SpecificationDocument1 pageEt&s-Mep Materail Specificationneng oudomNo ratings yet

- Branson 25 Series Tractor Operator ManualDocument25 pagesBranson 25 Series Tractor Operator ManualPMV DeptNo ratings yet

- Digital Clock Using ArduinoDocument14 pagesDigital Clock Using Arduinoshivanshu67% (3)

- Joystick Control Plumbing - H PatternDocument3 pagesJoystick Control Plumbing - H PatternricardoNo ratings yet