Professional Documents

Culture Documents

BioShine - Oysterlead Nature Plast EN

BioShine - Oysterlead Nature Plast EN

Uploaded by

magudelomoncadaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BioShine - Oysterlead Nature Plast EN

BioShine - Oysterlead Nature Plast EN

Uploaded by

magudelomoncadaCopyright:

Available Formats

Empresas Aliadas: Introductory video

elaborated by our

commercial partner

OYSTERLEANTM, A BIOMARINE WASTE TRANSFORMED INTO

A PACKAGING MATERIAL TO REPLACE FOSSIL PLASTICS

Plastic

Oysterlean + Pelltes = Packaging

Lic. Santiago Almeida

MKT & Sales NaturePlast Ec.

1 of 2 Telf: +593 98 343 3040

Comparison of

environmental impact

of fossil vs. organic

raw materials

How to be more sustainable and reduce the environmental impact of plastic packaging?

Flexible packaging demands our attention from three main life cycle areas:

- Reuse: Developments that extend the useful life of plastic packaging.

- Recycle: Processes to recover this valuable material for new products.

- Renew: Progressive substitution of organic raw materials over traditional non-renewable ones.

Oysterlean by NaturePlast

Oysterlean is a final product resulting from the refinement of a biomarine waste material from seashells. The shells

are collected, refined and transformed into pellets that are made adaptable and viable for use by the plastic

packaging industry. The potential of a bio-renewable resin capable of replacing petroleum-based plastics in

progressive percentages up to 100% bio-renewable.

The carbon footprint of Oysterlean is about five times lower than that of conventional plastics (PE and PP).

Since more than 75% of Oysterlean is a biomarine waste from shell culture, the bioregeneration cycle of this

material is 4-6 months until it becomes waste.

Bio-Marine Plastic

Processing Oysterlean Producer Retailer Final Client

Waste Pelltes

Supply Chain

We have worked to create solid alliances with the Ecuadorian industry for the development and supply of flexible

packaging capable of meeting the highest quality standards required by the floriculture industry.

Lic. Santiago Almeida

MKT & Sales NaturePlast Ec.

2 of 2 Telf: +593 98 343 3040

You might also like

- FileDocument2 pagesFileHola Hola71% (7)

- QMRE Business Plan Digital PDFDocument50 pagesQMRE Business Plan Digital PDFSourabh WaghNo ratings yet

- European Polymer Journal 61 (2014) 285-299 PDFDocument15 pagesEuropean Polymer Journal 61 (2014) 285-299 PDFEstudiante2346No ratings yet

- KSU Trumpet Syllabus 2017Document72 pagesKSU Trumpet Syllabus 2017Vini EbiNo ratings yet

- Introduction To Business Combination - Lesson1Document37 pagesIntroduction To Business Combination - Lesson1Eunice MiloNo ratings yet

- Erlang - DefinitionDocument19 pagesErlang - DefinitionNathan MillsNo ratings yet

- Plastic Has A Problem Is Chemical Recycling The SolutionDocument12 pagesPlastic Has A Problem Is Chemical Recycling The SolutionTomGaliciaNo ratings yet

- Plastimark SpADocument2 pagesPlastimark SpASadeq NeiroukhNo ratings yet

- Design Thinking WorkshopDocument20 pagesDesign Thinking WorkshopKilian DuchesneNo ratings yet

- Plastic Energy - BASF Dialog ForumDocument12 pagesPlastic Energy - BASF Dialog ForumRajesh100% (1)

- Envronment RelationsDocument18 pagesEnvronment RelationsYogiNo ratings yet

- Polystyrene Recycling System - StyromeltDocument2 pagesPolystyrene Recycling System - StyromeltDuncan HarrisonNo ratings yet

- Who Says Leather Is Harmful For The PlanetDocument2 pagesWho Says Leather Is Harmful For The PlanetDhanny S OktafiantoNo ratings yet

- Pyrolysis of Plastic Waste - Opportunities and ChallengesDocument17 pagesPyrolysis of Plastic Waste - Opportunities and Challengesgavin meadeNo ratings yet

- Polymer Testing: Material PropertiesDocument7 pagesPolymer Testing: Material PropertiesSoffi SyarofahNo ratings yet

- Chemistry Plastic BreakdownDocument9 pagesChemistry Plastic BreakdownAndre ThomasNo ratings yet

- Project Management (HRMA 40023) : Office of The Vice President For Academic Affairs College of Business AdministrationDocument9 pagesProject Management (HRMA 40023) : Office of The Vice President For Academic Affairs College of Business Administrationkayla watanabeNo ratings yet

- PLASTICSDocument8 pagesPLASTICSAMNA NISARNo ratings yet

- Trioloop FlyerDocument2 pagesTrioloop Flyerapi-480490345No ratings yet

- Plastic Free PackagingDocument10 pagesPlastic Free PackagingmramininiNo ratings yet

- Liveable Cities Lab - Circular EconomyDocument38 pagesLiveable Cities Lab - Circular EconomyarmagnetoNo ratings yet

- FOOPAK CATALOG Rev Update - CompressedDocument36 pagesFOOPAK CATALOG Rev Update - CompressedRudy NASUHANo ratings yet

- ArmaPET From Bottle To Foam 01Document7 pagesArmaPET From Bottle To Foam 01Somnath SekarNo ratings yet

- GUUNDocument36 pagesGUUNTimoty James PaulinNo ratings yet

- PlasticsDocument69 pagesPlasticsMyrna TabernillaNo ratings yet

- Abstract 2Document8 pagesAbstract 2Beni PrasetyoNo ratings yet

- Active Packaging Fromchitosan-Titanium Dioxide Nanocomposite Filmfor Prolonging Storage Life of Tomato FruitDocument7 pagesActive Packaging Fromchitosan-Titanium Dioxide Nanocomposite Filmfor Prolonging Storage Life of Tomato Fruitkumari svgNo ratings yet

- Development of New Automobile Components Based On Thermoplastic Elastomers From Recycled Polyethylene and Natural RubberDocument8 pagesDevelopment of New Automobile Components Based On Thermoplastic Elastomers From Recycled Polyethylene and Natural RubberInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Buildings: Thermo-Mechanical Properties of A Wood Fiber Insulation Board Using A Bio-Based Adhesive As A BinderDocument15 pagesBuildings: Thermo-Mechanical Properties of A Wood Fiber Insulation Board Using A Bio-Based Adhesive As A BinderBatuhan DerNo ratings yet

- Avigloplast Com The Future of Circular Economy Breaking Barriers in Pet Thermoform RecyclingDocument4 pagesAvigloplast Com The Future of Circular Economy Breaking Barriers in Pet Thermoform RecyclingAVI Global PlastNo ratings yet

- Aira Krish MoreteDocument2 pagesAira Krish MoreteAira Krisha100% (1)

- India-BrandAuditReport FinalDocument40 pagesIndia-BrandAuditReport FinalozanNo ratings yet

- Hdpe Particle SizeDocument11 pagesHdpe Particle SizeMadiha ZaimuriNo ratings yet

- Product Type/ Year 1 2 3 4 5 Key PointsDocument1 pageProduct Type/ Year 1 2 3 4 5 Key PointsRiturajPaulNo ratings yet

- 72 175 1 SMDocument5 pages72 175 1 SMIvan Fadhillah 2010242014No ratings yet

- Mixed Plastics Film Laminate Recycling - Need of The HourDocument4 pagesMixed Plastics Film Laminate Recycling - Need of The HourLê Lâm BìnhNo ratings yet

- Sportswear Giant Set To Tap Indian Firm'S Pet Project To Cut Virgin Plastic UseDocument14 pagesSportswear Giant Set To Tap Indian Firm'S Pet Project To Cut Virgin Plastic Usenelson vargheseNo ratings yet

- Thermosets Vs Thermoplastics - AIP Precision Machining - Daytona, FLDocument3 pagesThermosets Vs Thermoplastics - AIP Precision Machining - Daytona, FLMFNo ratings yet

- Thermosets Vs Thermoplastics - AIP Precision Machining - Daytona, FLDocument3 pagesThermosets Vs Thermoplastics - AIP Precision Machining - Daytona, FLMFNo ratings yet

- Ran J. Sharon President & CeoDocument19 pagesRan J. Sharon President & CeoLuan NguyenNo ratings yet

- 2021 - Unzipping Polyester-For A Cleaner FutureDocument2 pages2021 - Unzipping Polyester-For A Cleaner Futureliliacul2000No ratings yet

- Monteiro 1998Document9 pagesMonteiro 1998Erick BaezNo ratings yet

- Type The Document TitleDocument10 pagesType The Document TitleaadiNo ratings yet

- Elevate Your Sustainability Strategy With The Righ PackagingDocument10 pagesElevate Your Sustainability Strategy With The Righ PackagingSaddam BousbataNo ratings yet

- Microbial Degradation of Plastics-1Document10 pagesMicrobial Degradation of Plastics-1Jovin princeNo ratings yet

- Polymer Engineering Sci - 2023 - Aydogdu Emir - Effect of Mastic Gum Integration On Improvement of Polylactic AcidDocument12 pagesPolymer Engineering Sci - 2023 - Aydogdu Emir - Effect of Mastic Gum Integration On Improvement of Polylactic AcidsilviofratariNo ratings yet

- The Most Cost Effective Tray Sealing Solution On The MarketDocument2 pagesThe Most Cost Effective Tray Sealing Solution On The MarketAlezNgNo ratings yet

- Step 4 - Identify Recovery OptionsDocument8 pagesStep 4 - Identify Recovery OptionsDulmar QuinteroNo ratings yet

- Design and Construction of A PET Extrusion Machine For Production of Insulation MaterialDocument8 pagesDesign and Construction of A PET Extrusion Machine For Production of Insulation Materialahmed titoNo ratings yet

- Trabajo Teórico YeniferDocument8 pagesTrabajo Teórico YeniferLidia DelgadoNo ratings yet

- Plastic Recycli NG Survey: Under Supervision Of: Dr. Ibrahim El-FahamDocument43 pagesPlastic Recycli NG Survey: Under Supervision Of: Dr. Ibrahim El-FahamCao LongNo ratings yet

- Compañy Projet Englihs (Sena)Document8 pagesCompañy Projet Englihs (Sena)Lidia DelgadoNo ratings yet

- Quotation: "Solid Waste Management Waste Water Treatment Preventive Maintenance Specialist"Document26 pagesQuotation: "Solid Waste Management Waste Water Treatment Preventive Maintenance Specialist"Walter SorianoNo ratings yet

- Sayani Chatterjee 19F040 Shaon Roy 19F041Document18 pagesSayani Chatterjee 19F040 Shaon Roy 19F041sharathNo ratings yet

- Dairy Packaging Industry'S Scandal in Vietnam: What Should Be DoneDocument10 pagesDairy Packaging Industry'S Scandal in Vietnam: What Should Be DoneMinh Long NguyễnNo ratings yet

- CSR - Excessive Plastic by FMCGDocument14 pagesCSR - Excessive Plastic by FMCG23P051ShubhamNo ratings yet

- 10 1002@app 50020Document13 pages10 1002@app 50020dhy182No ratings yet

- US VERSION - ElevateYourSustainabilityStrategywiththerighpackagingDocument10 pagesUS VERSION - ElevateYourSustainabilityStrategywiththerighpackagingSaddam BousbataNo ratings yet

- Plastics Technology PracticeDocument35 pagesPlastics Technology Practicerizaazari4530100% (2)

- Recycling Plastic Marine LitterDocument36 pagesRecycling Plastic Marine LitterYong JiangNo ratings yet

- Revise Chap 12Document14 pagesRevise Chap 12RACHEL DAMALERIONo ratings yet

- Properties and Applications of Compostable Starch-Based Plastic MaterialDocument5 pagesProperties and Applications of Compostable Starch-Based Plastic Materialsuroyo bimantoroNo ratings yet

- Recycled Polyester: Manufacturing, Properties, Test Methods, and IdentificationFrom EverandRecycled Polyester: Manufacturing, Properties, Test Methods, and IdentificationNo ratings yet

- ISO 31000:2018 Structure: Session - 2 (A)Document35 pagesISO 31000:2018 Structure: Session - 2 (A)kanchana rameshNo ratings yet

- BE Computer and IT Advanced Unix Programming, Artificial Intelligence and Expert SystemDocument41 pagesBE Computer and IT Advanced Unix Programming, Artificial Intelligence and Expert SystemJ DNo ratings yet

- Small Porch SwingDocument26 pagesSmall Porch SwingEngr Saad Bin SarfrazNo ratings yet

- Bi (English) - Business Plan FormatDocument17 pagesBi (English) - Business Plan FormatnityaNo ratings yet

- MASTER 2.3-Fragmentation MeasurementDocument40 pagesMASTER 2.3-Fragmentation MeasurementAlvaroNo ratings yet

- Application Access To People Data/Hub Process Flow: Identityaccessrequ Ests@yale - EduDocument1 pageApplication Access To People Data/Hub Process Flow: Identityaccessrequ Ests@yale - EduSanjeev SharmaNo ratings yet

- Gas Phase Catalysis by ZeolitesDocument36 pagesGas Phase Catalysis by ZeolitesHenrique SouzaNo ratings yet

- Eggbeater 1 Exploded View JAN22CDocument1 pageEggbeater 1 Exploded View JAN22CAlejandroz GonzalezNo ratings yet

- Ch1 SolutionsDocument12 pagesCh1 Solutionsocean2012cosmicNo ratings yet

- CH #2 NumericalsDocument3 pagesCH #2 NumericalsMs Noor ul AinNo ratings yet

- WCM - Yamashina - 05 - Professional Maintenance - Chapter - 3 - ADocument100 pagesWCM - Yamashina - 05 - Professional Maintenance - Chapter - 3 - ACíceroNo ratings yet

- 120 Days Schedule Rev.GDocument1 page120 Days Schedule Rev.Ghash117No ratings yet

- Chapter-1: Introduction About InternshipDocument57 pagesChapter-1: Introduction About InternshipSalman gsNo ratings yet

- Chapter 1 MEDocument5 pagesChapter 1 MEsubuhana20067No ratings yet

- Sensors: Proof of Concept of Scalable Integration of Internet of Things and Blockchain in HealthcareDocument22 pagesSensors: Proof of Concept of Scalable Integration of Internet of Things and Blockchain in HealthcareEmna BoussoffaraNo ratings yet

- MSDS Radiator CoolantDocument10 pagesMSDS Radiator CoolantFauzy AL RahmanNo ratings yet

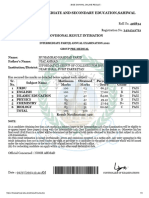

- Result PASS: Board of Intermediate and Secondary Education, SahiwalDocument1 pageResult PASS: Board of Intermediate and Secondary Education, SahiwalAsad Ali ChaudharyNo ratings yet

- Standard Operating Procedure: StorageDocument2 pagesStandard Operating Procedure: Storagesunny mgxNo ratings yet

- Engineering Guidelines For The Evaluation Penstocks TypicalDocument23 pagesEngineering Guidelines For The Evaluation Penstocks TypicalWanderson WadjôNo ratings yet

- Institute of Finance Management: Chuo Cha Usimamizi Wa FedhaDocument3 pagesInstitute of Finance Management: Chuo Cha Usimamizi Wa FedhaDaud M EmmanuelNo ratings yet

- Modbus RTUExtendDocument2 pagesModbus RTUExtendrifaiNo ratings yet

- SM Midterm ExamDocument7 pagesSM Midterm ExamKurt Morin CantorNo ratings yet

- Child Friendly School S High School 1Document17 pagesChild Friendly School S High School 1Roy C. EstenzoNo ratings yet

- Give An Example of A Government-Created Monopoly. Is Creating This Monopoly Necessarily Bad Public Policy? ExplainDocument8 pagesGive An Example of A Government-Created Monopoly. Is Creating This Monopoly Necessarily Bad Public Policy? ExplainMasri Abdul Lasi100% (1)

- 7 - Class 7Document81 pages7 - Class 7Zum BiiNo ratings yet

- How To Edit A PanelView Plus (ViewME) MER FileDocument6 pagesHow To Edit A PanelView Plus (ViewME) MER FileRafael Pertile CarneiroNo ratings yet