Professional Documents

Culture Documents

Contractor's Proposal

Contractor's Proposal

Uploaded by

Dream 2 Rose0 ratings0% found this document useful (0 votes)

21 views41 pagesOriginal Title

6. Contractor's Proposal

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views41 pagesContractor's Proposal

Contractor's Proposal

Uploaded by

Dream 2 RoseCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 41

CONTRACTOR’S PROPOSAL

FOR

LOC NINH 1 SOLAR POWER PLANT (200MWp)

Engineering, procurement, construction, supply,

Installation, testing & commissioning

Dated: 24 May, 2020,

‘TABLE OF CONTENT

1, PROJECT DESCRIPTION..

2, PV SYSTEM

24 PV Array System

22 PV module,

2.3 Inverter and box transformer

2406 Combiner Box.

2. Calculation ofthe optimal angie of photovolaie modules

26 PY aray layout

3. ELECTRICAL SYSTEM..

3.1 Grounding and Lighning Protection.

8.2 Cable Laying Instalaton Method

23 Lighting Systems

54 Substation Communication system,

35 CCTV system...

4. CONTROLAPROTECTION SYSTEM..

4. SCADA System,

4.2 Metecrological stations

5. CIVIL WORK.

5.1 General 7

5.2 Site Clearance & Freperation

5.3 Stuctxe

5.4 Architecture

55 Road

5. Water Supply and Orsinage and Sewage Treatment Syste,

6. FIRE ALARM ANO FIREFIGHTING SYSTEM...

7. ANNEXES sen

|AINEX-I CODES AND SIANUARUS

ANNEX.02 PERFORANCE TESTS.

[ANNEX-08 INSPECTIONGS, TESTING AND COMMISSIONING

[ANNEX.OM BILL OF GJANTITIES (EQUIPMENT AND MATERIALS)

ANNEX0S BILL OF QUANTITIES (CIVIL WORKS).

ANNEX-06 PVSYST SIMULATION CALCULATION,

LOCI SOLAR OME ANT ao)

1. PROJECT DESCRIPTION

Loc Nh 12.8 solar powerplants planned fo be bultin Loc Ni, Tinh Binh Phu, wth @

‘esigned total installed capacty of $49.9984 Mp (DC). Thre are three PV ds, each with

2 capacty of 199.08 MW, 198.88 NAP and 149.8384 RAN, as doa in the follow tabla

4

‘Table 11 Overview of nal capacty

nunerot | Meet! | cir | AC inst

Pan | Pvmoau | oy lat ag | cope | canmaty | None

reaper | Sretaonants | | “tw

— - Faupment

oem | 454500 0 woos | sors | “oie

pret

teennn2 | ese 00 0 woos | ters

teens | se0ae0 8 woores | was

Toa | 12eseco ° ‘senstea | 51075

2. PV SYSTEM

2.4 PV Array System

Solar system designed in Loc Nin 1 solar powerplant consists of 464,500 ploves (2440.Np

Monocystaine soon ipece), such a the above table 1.11. In order to factate the

connection, the projct provided with 20 sats &.2SMW PV power generation unis in oa

Lec Ninh 4 solar power slant hove 30 photovaliae power generaton uns. Each unt is

Cequioped with one 6:25 NWA Box transformer and two sets 3128 KW cantralze Inverters,

and twenty-four 2-ivone DC bghining protectan combiner boxes, Each combiner box is

comected to less than 22 photovoltaic module stings, and each photovtaic module sting is

comectedin sates wih 3¢ photovoltaic modules. On the whole, each unt provides 262-254

sets PV arrays withthe 2x30 arrangement. Every furor treo 6.25 MW units connect fo the

hey: bult 220 RY eop up cubtation for ono cu ofthe 3 HY eurenteatoton tne. Dip

angle ofthe PV arrays 10:The PY aay system votage is 1800 Voc.

2.2 PV module

‘Atleast 440W¥p Menc-cytln scon PV mori is applied to the Project. According tothe

Cfcioncy reduction rte fe the 30-year operation petod ofthe plant, the minimum power

‘generation rates of 82.52% and 82.5% stall be guaranteed ae the opeaton for 10 years

‘and 30 years.

Table 22-1 ain Paramore of PY Module

z

ria

LOCIVNH 1 SOLAR POWER PLANT 00H)

=n im eam

+ | Tee tree ons scan

2 | eect prance

21 | Sania rowerauaa i) 0

22_ | oastsonertowerc Mo on

23. | Weaie eco OH we

24_|Peksovrvatine wee

25 [Peak poer cent 0) ‘0x7

20 | openctadvtge mor

27 | shots crt ‘0x7

28. | Tremevinan vtge fay 0 ‘eves

3 | treme pane

21 Rata oping topes tal 6) ra

32 | Temper coe eso cutee) soo

33. | fenpute coat operat vatge i aa

4 | Temperature coeficent ef peak power (SK) a3

“| tects

“| Bmersin at em ‘ec 608585

42 | wean oa) od

43 | eearntrg mr aa

“| ere ctorncon fincin box rer

78 [Fane mari ——-

5 [Ope condo

2a enperne iewermere

Noa The parameters We above able ae only used nthe bidding scheme aie Hage,

and the fal parameters vil be based on the purchased equipment parameters

2.3 Inverter and box tranaformer

234 tnvertar

‘Tho unit capacty snot ess than 625M, each unt has 2 sets atleast 3. 125MW centralized

inverters,

“Table 23-4 Man Paramtreof ols than 6:25 HW (29.1264) verter

Oct + ScLAR POWER RANT ont)

im con ro canon

esrumepvoiege | teow | Rat oumarowr | — ata

‘i Pa iar eps

evar 7

_voltageystarting vokage output power ee KW

wperiateaeare® | arson | Masini odeteunos | arian

Tinie ee | 7A | _Feledgoinge | SPE oie

wer gary | Noverman | Gatvotnge ange | oie

Nashaew DoF]

em aa | Rewdgitegns | Sale

Micra o6 hort aq meron | app

caret wwanmagcepny | 2225

Moin Operating temperature

‘effclencylefficlencyin | 39.%96.7% | P* “ee 36-600

OTA

~eoow [canna | Reatseranet

= —

Ta

coaenets | trowtar | po printonand ting | eavbrodutn

arg

Sig SEOANTGN 00 OY doo sp ag alana ROTOR

"Note: The parameters in he above table are only used inthe bang scheme at his stage,

‘and the na parameters wile based on the purchased equipment parameters

2.3.2 Box transformer

()95kV Tanstormer

‘Te box transformer has one no less than 6250 kVA transformer, $510 65-0.6RV, ro ese

than 6250 KYA transformer, double. spit winding ot-immersed transformer, copper core

winding,

opacity: >B25MVA

Reted vole at HV site: 35kV

Rated vatage at Vso: 063K

{(heoordng tothe inverter tpt val)

“Transformation rato: 5282 570 63.0 634

Connection group: Dyttytt

‘Stort-crout mpedancs: 6% (According to the IEC 60076 standard)

(2)854V Ring Main Unit

‘Tha high-voltage si of tho transfocmer i csanscted toa group of metsl-enclosed SF6

Insulation ring network caoinet equipment (RMU) tough a medium-votage cable. This

‘equipment is equipped wth wo load switch cabinets and one vacuum cra breaker cabinet

LOCUM 5 SOAR POWER PLANT (2004)

‘The veltage love i 35AV the current is 630A, and the shoc-oreultcurent fs 20KA (1s)

Compliant with global safey and gid code,

“The Contractor willkep the ttalinstaled capac ofthe Box transformer of hs project

changed,

Note: Considering the equipment upgrade and replacement of each invertor

‘manufacturer, there are two capacity specifications of 6.25MW and 6.8MW (2 sets

34M), The specific parameters need tobe determined according tothe equipment

procurement; the contractor will determine the total capacity ofthe inverter No leas

than 618.76.

2.4 DG Combiner Box

Its demandes 1°65 protocion class to satsy the need af eutlook insaation and usage as

\wel as SPO protection frst power power supply system. Cable grand in-out terminal,

‘maximum PV array vitae 1500 Ve 22 inputs Fuse with hlder type, DC ckcit breaker, OC

‘SPO, satfpowered, cure! mentoring foreach string, PY vetage monitor and SPO fake

‘monitoring must be Indes in DC combiner box also

2. Calculation ofthe optimal angle of photovoltaic modules

According to the feast study report, the annual average radiation at ste area i 1847.58

‘env? and input the radiation int the PV system sofware fo simulate the radiation at ste

‘ares, When the optimal angle of the photovollc modules Is 10 degres, the loss on the

Inained surface ofthe PY modula isthe smallest. The amount of radiation receved isthe

largest The photovoltaic power generation dung the operaton ofthe photovolaie power

station fs shown in the PVsyst siulation resus inthe Annex 08: PVSYST SIMULATION,

CALCULATION.

26 PV array layout

“The photovoltaic power pent is died info 3 plots, The PV fled area of Loc Ninh 1 projct

‘covers an area of about 29 hectares. In ord to avoid shadows, the pitch of the component

‘subaraysin each block (fent and back edges ofthe PY module array) is 5400 ~ 6000,

3. ELECTRICAL SYSTEM

3.4 Grounding and Lightning Protection

Grounding and lightning design shall conform to the Intute of Electcal and Elbctroncs

Enginors standard IEEE 60/2000 "Guide for Safety in Gri station Grounding “and IEC

£2205"The bahtning protecioninemational standard

LOC HIN SOLAR POWER ANT 20)

3.14 Grounding of the PY Aray for Lighting Protection

‘Grouncing and ightning design shall conform tothe insttte of Electical and Elecrones

[Engineers standard IEEE 80/2000 "Guile for Safety in Grid station Grounding” and IEC

623057Tho ightring proton international standard’ or equivalent

Photovotac (PV) lghining amesters ofthe installed solar pane! area (Photovoltaic: PV)

witb designed and manufactured in accordance wih system features suchas: rik density,

‘rect Ightning power, elecscty voltage, scale ofthe system.

= The stel bar of foundation pla aso wil be mainly taken as dee ighningprotactive

earthing for PV aay of ie power station,

= The S05 mm# gavanlzed fat steal shal be lad around the equipment as the

‘rounding gid forth transformer and inverter, andthe 2.6m-ong 050 steal tube with

hot galvanzing shalbe lida the verical grcunding electrode.

“The PY modula ram is connected to tha bracket through the pressure block,

‘The PY Combiner box davies are connected to the bracket grounding eystem network

‘trough a 50 mn? plastic copper wie.

‘The wesc and tzaneformer are connected to bracket grounding system network

through 55 mn galvanized flat tee,

The photovoltaic medues shal be conecad fo the bracket by passing blocks the

Photovaltsic fed brackets shall be connected by 404 mm? galvanzad fat seal and

is realy connected with the main grounding network. Lightning protection systom and

fre extinguishing sytem in photovoltaic area should mat requirements of Vtnam

EVN and IEEE 80-2000 standard

The earthing resistance of PV arays not greater than 4 0.

~ Allightrng protector for Inete station, MDB station, Lightning protection of the PV

fled shall be use Faraday type connected with soparate ground system from PV. The

‘earthing resistance isnot higher han 40

- Uhting protection tthe photovoae fo, Lightning proteton ofthe PY filed shall be

‘early steamer type connected wih separate ground system from PV. The earthing

resistance isnot higher than 20.

3.2 Cable Laying Installation Method

The photovoitalc mostule connection in the Fel! area uses OCTS0NV photovoltaic special

‘ables. The DC cable belweon the combiner box and tho contrakzed inverter use the

‘single-core 120mm aluminum core cable ts votage ove is 1.8(9KV. 38KY collector Ines

sea combination of overtead wes and cables, of which the MV cable use the engle-core

‘70-300? sluinum core cable, ts votag levels 26(35)k

‘AC auxllary pover for other systems shall be supped from station sevice transformer

sine

LOCK) SOLAR ONES ANT oma)

connected sirecty from 35¢V cotecton Ine or rom extemsl22kV tne of EVN,

PV cables shal be aie in HOPE cont an OC cables shale la in doc burial made,

‘38k current colecton line cables shall be overhead type and the cables In transformer

sation sal be laid trough cable lade. Fiber optic shal be installed overnead, Meanwhte,

cables from S8KV RMU to 36KV colton line and communication cable shall be lis in

HDPE underground cordit ard the cables in 20k substation shall be lid though cable

trench or cable tubes in tet butal mode.

3.8 Lighting Systems

The indoor and outdoor lighting system of220KV substation aque for substation, inverter

station and other buldingsis expected to use indoor LED ohn coin, wall hanging or

ater types. The projct shoul be complet Intemational standards.

3.4 Substation Communication system

13.441 SDH Synchronous Optical Transmitter

The 220KV Substation project would had be equipped with 1 sel of SDH optical transmission

Cequiprnent, 1+ configuration of main equipment such as optical interface boar, and 2 sats

of scheduling data networ< equipment. The comesponding SDH optical interface board is

‘added tothe opposite power grid substation

3.42 Communication prtoco! for SCADAEMS

“The SCADATEMS signals tough te gateway wil use the IECEO87O-5-106

‘communication protool procedure 104),

“The transmission channel for SCADNEMS signals of Loc Nin(t-3) solar powerplant

uses the IECS0670-£-104 communication protocol procedure 104) fr transmission of

9 and 2.

3.43 Hotline IP Phone information channel

‘At Loc Ninh 1-28 solar powerplant, the IP phones connected by Ethernet channel rom the

IP phone connected to Switch, Router, FE conection of SOH Optical Transmission

Equipment to Ad and A2

3.5 CCTV systom

Monitoring objects ofthe shotoveii ik COTY eystem shall inckide:Bnx transformer anc

-rvetter- Photovoltaic fl video informaton is sent othe substation CTV system tough

optical cables.

“The 220KV substation CCTV system has reserved the communication socess interface

forthe photovolta eld CTY system,

Pe 4

Loci 1 SAR POWER ANT OHNE

4, CONTROL& PROTECTION SYSTEM

4.1 SCADASystem

PV power generation's one performs realtime Information (neuding: boxy transformer,

combiner box, inverter). Bay level can work independently in case of falure of elation level

and network. The desig othe system folows SCADA and RELAY protocols with EVN,

Monitoring system for? Fld shouldbe abo tobe meritored up t sting level (current,

voltage, power and daily energy generator). The status and alarm of each signa shall be

realme cisplay, System shall be clang atleast:

Current deviation and alarm tunction (comparison between the string in each combiner

box)

Power output precestion according to EVN requement.

~ Geographical display to show PV aray area avaiable with fault deniiaton and

tivated alarm information.

Monitoring and contr system for PV and substation shal be separate system for both

hardware and sowere,

‘The 220KV substation SCADA systom has reserved the communication acoessinertace

forthe photovotae le SCADA system.

4.2 Meteorological stations

The Loc Ninh 1 solar powerplant project is provided with 8 ses of metaoroogical stations for

lonvronmental monitoring, and each metecrolescal station Is composed of wind speed

sensor, wind erection sensor, 2 sels of pyranometr (horizontal and i at last, PY module

temperature and ambient temperature measuring probe, control box and suppor, to measure

parameters such as ambient temperature, wind speed, wind dreton andiradiation tnt,

lis S485 communication interface can be comected to tho monitoring system of

rK-connected supansion and cetrol device for eal-me recording of environmental data,

5. CIVIL WORK

5.1 General

‘According to TGVNZ7S7:1995, the Design wind speed Is considered to ba 24mis (average

‘ind speed at height of tOm within tOmin,

‘The lowest point of te PV modules about 0.8m above ground

‘tis preliminary ceterined thatthe photovoltaic suppor base adopts a PHC-300.A pipe

plo, the photovoic cuppa adopts a stcel structure, and the main fame adopts 2968

LOCKS} SOLAR ROWER A ANT 20200)

stool

65.2 Site Clearance & Preparation

‘The sie clearance and land leveling as wel as the ernoval and throw-away of roots wil be

one by the Employer. Land leveling should moet he following roqurements

-Backll ofthe site shoulé be wel graded sand, gravel or sol, the maximum $22 of

backfl cannot be greater than 200 mm.

Tha compaction coficiert shouldbe noes than 0.92, expansive soll nc and so with

‘roan matter content greater han 5% camo! be used a fling.

“Tho slopo ofthe sito should not be greator than 234,

“The Contractor is ony responsible for minor eveng

5.3 Structure

5.31 Fixed PV mounting structure and Foundation

‘The PY mounting stuctueare designed with consideration gwen fo dead load, ve load. The

dead load includes weight of PY madule and dead weight of PV mounting structure: the Ive

load includes wind load end rainwater load, with the design wind speed of 26 mls. PV

mounting structure are of fixed type and made of C2358 stel, which mainly consist of main

beam, purine, column, dlagonal, connecting bots and cther bots, Modules and purines,

purines and main beams, nan beams and columns are botad. The columns are connected

vit the foundation through foundation bots. The selection ofthe structure section shouldbe

‘determined a the construction deal stage according to the technology andthe construction

schadhle

According to prlimnay geological report and hydrological data ia the FS, the foundation

of PV mounting structure wil use PH-300-A pipe pl, the dlameter of pos SOD mm. AL this

stage, the lngth of PHC-200-A lef 3.0m with 2.0m underground.

Final, the clamter an length ofthe PHC pipe plo should be detained according to

‘he detail geotechnical rept and the stat load test ofthe pile

6.2.2 Foundation of transformer and invertor

‘Cunezete box fou is evelyn fre Furnan of vansore a net

5.3.3 Fencing of PV Site Area

Only one fence i st forth works inthe form oft

Lavre-mesh simple fence, with height of

2.5 morsel wee moh,

5.3.4 Collector Line Works

35KY collector ines adopt wo laying methods: overhead and cable rect burial, Reinorcad

concrete foundation for tre tower of overhead bre, The slope of cable trench shal be

‘excavated by 1:0; after excavation, tench bottom shall be cleaned and tampod, and

#

4?

LOCIUNH # SOLAR POWER PANT (amu)

100mm fe sand shal te paved above and below the postion for cable laying, and

seqrogaton (rks or tin concrete plates orang tapes or her ype segregation) sha

be setabove cates forprotecton.and meet he requrements of Vietnam EVN's standard

5.4 Architecture

One Warehouse wit 8a of 1000 ser,

“Main guard nouse 1 nos

-Simall guard house 4 ros.

-Natch tower 6m height 1908

Project banner 1 nos.

5.5 Road

A he PV fled, the with ofthe main oad of he infernal road ofthe Loe Ninh 1 solar power

plat ie 6.0 m, and the wlth of the branch rosd le 4.0 m, graded macadam pavement ie

Adopted. The intemal readis designed asa combination of permanent and temporary works

tomes the requirements & construction, equipment transportation ard maintenance

‘The access read conrectng withthe loca oad Is about 1.0 km i otal length and &.0 m

In width, with graded grave pavement.

‘Te table must be cleared within the scope of foad land. The requrements are a=

fotos

(The rubbish, xgaric residues and surface humus sol, tur, erop roots and topsoll

thin the cad land area sal be removed, and tho tops plantod shal be stacked ina

esignated spol yard. After the site is cleaned up, it shouldbe relled before fling to

rake the compactnes meet the specified requirement

{2)To fil the embankment, the humus sail thin the range ofthe foundation ofthe

roadbed shouldbe compltely excavated andthe pte hauls be filed and compacta;

In addtion, the pits win the range ofthe roadbed shouldbe fled and compacted,

5.6 Wator Supply and Crainage and Sowage Treatment Systom

1) Water Source

‘The water used in te booster station comes from the underground, The 220kV

substation project cil a deep wel inthe 20KV substation,

2) Wator Supply Systm

‘The domestic water supply system has used complete sets of equipment, and the

{acities include deep wel, water tanks, water supply pumps.

3) Photovoltaic module cleaning system

‘There is no clearing equiment in the PV power station. The frefahting system piping

atvork can be usad se PV madul lasing

zs

Loc np 1 SOLA owe ANT pom)

4) Drainage Systom in Substation aes

For the drainage system inthe operation management area, 2 indepandont facies are

proved forthe air drainage and domestic sewage discharge,

2) Rainwater Drainage

Rainwater drainage inudes the cainage of oo rarwatr rainwater inthe sto area and

In cable trenches.

Rainwater on the bulng root Is cllectod by rainwater hopper, then drcted trough

rainwater ser pipe, fraly dscharged trough the ground rainwater eich. Through the

raiewater inlet andthe rainwater pipe bred outdoor, ramatr Inthe ste area is cotected

and discharged outs,

“Through pipsne, rarwater in the cable tench is drained to the rainwater drainage

‘system inside the substation,

b) Domestic sonage sischargo

“Tho domestic sewage systom consists of sewage pipes, sewage Inspection wes, and

septic tanks (efectve volume is about 2m"). The domestic sewage at each water point is

colbctd int the sepictrk through the sewage pipeline, and after the saptc tanks seed,

iis regualy cleared by spacial vehicles

'5) Drainage system cf photovottac plant

“The drainage dich of photovoliae plant areas mally arranged along the road, fofowing

‘allonal method and local sandarés with rtum paris of 20 years

Drainage systom shallbe concrete orstne lng.

6. FIRE ALARM AND FIREFIGHTING SYSTEM.

In the project, fre hydrants wil be sot up next to the main roads in the photovoltaic power

Plant area. At the same tie, fe-fghting systems ere equipped with fe-ghting pipes and

fre pumps, each set of photo-wllaic power unit transformer and inverter reom is equipped

With 2 sot of COs fre extinguishers firefighting deve, The fkefgting piping network can be

used as PV module cleaning,

7. ANNEXES

ANNEX-01 CODES AND STANDARDS

‘The project wil conform tothe applcable requiem ofthe latest exon of the fotbwing

standards orto recognized equat

aT

LOCOS SOLAR POWER A ANT ota)

feces tli silicon terrestrial photovoltaic (PV) modules

£0 60068 ireuetaltesing - Par 1: General and guidance

= a Tao Coe BRO ROTO an

at of power convorar for Use h phatovotale power aye

FEC621002 | part2: Particular requirements for inverters

otoraai (PV) systoms = Requirements fo tstng,

fc enas-+ camentstion and maintenance — Pat: Grid comected

ystems — Documentation, commissioning tests and inspection

kaw 2ar2o0arait [Becrity ofthe National Assembly (14/2/2004)

aw 2arzo eran a PUTS ane aaEMTETNG a Humbe OARS OTHE

fect aw of the National Assembly (20/112012)

| rToN-18-21-2006|

[ectrc Equipment Norm

freculatons ans

hachncal standards

Thetntegated contol system, protection sytem

-onfigration, protecting technical spectficaton for ines and

[rok vansformer station of EVN

forms and decres|

ent processes, which relate to ovthoad power Vanamissin|

jreiar ang te regulation on GSibutedeletetyaystom Tesued

ISITE-BCT _ by the Minty of industry and Trade (MOIT) (1111/2015)

ruler arng projec development and model power purchase

fivzotzrrr-8cT _byreaments applied to solar power projects (12/08/2017)

jeceane Tet procedure of sanding proventon

FEEE 1647 Fornecconnecton test of dibuted Enagy soca

JEEECOZ01S [aot Satay HAC Sutton Grande

vw carer ba opal oi aoc, esa RT

tone esd he miso ast and Tada

arorreact fistos

rear Peon is aoa oT aol aa SSSR

kozovwrrccr_[eosta0.

a

euterents and phe coo equtenerts for HV eupent

tia

Jcen0se fans votes

Jecetnee Senay atone wastomers

FECECOSO __[Sees)rtenaonal eocrlecical vcabiay

(Sees Insulation coordination

zx

Loci SoxAPoWeR ANT omit)

feceoo7e Seis) Power transformers

| Series) Palwnylciorda muted cabs oated volagos up

fc e027 andincluding 450/750

lec coos ndictrs of neue cables

lec ease )ietesna Equipment and'SCADA

jecenass Sores) Electical relays

jecoazer Sees) Elects cables —Galeulaton ofthe curent rath

lec eases Low-votage ebcicalinstatations

EO 60528 ted nicke-cacmium prismatic rechargeable shoe coll

Jeabal measuring Waneducor Tr convening a Slocieal

weal ants to analogue or digtal slgnsle

mon teat matode formulating and shosihing ator of

fea ocr cables and optical cables

fEC 60808 |Bhor-circuit currents in three-phase a.c, systems

EC 60047 ‘Serios) Low votage switchgear and contol gear |

‘Saree Shor creut coments in de aulary metalation

comes PSs wate

[EC61096-1 Poworinstatatons excoeding 1 KV ac. Pat 1: Commen los

jEC 62040 {Series} Uninterruptible Powe System

Tgn-wlage sitchgear and contol gear = Part 200; AC

[EC62271.200 fetatenclosed switchgear and contro gar fr rated vatoges

ove 1 kV ane p to ai including 62 KV

|ece2s05 [Series Protection against lining

[Fre fatting

Trcvw zoza.1996 Pe Brveniion and proctor Balk and srucures —

sgn requirements

righting system ~Ganeral requirement for Gaughs,

fewer onan ten

[FOvN 5738:2001 Fire warning system — Design requirements

[FEW 7435-7 Fre pretection potable and wheeled fre extinguishers

[Pv inaataton

Fodralntalatons of buldings Part 7-772. Requroments for

JEc90364-7 712 kpecsa installation or ocatons- Solar photovaale (PV) power

ols

fec.e2548 Photovotac (PV) arays— Desion requirements

Cui 1 SOLAR POWER AN zou

EceaTIe srmcaia corosion tasting of photovolae (PV) modules

[Ponnecors To BG applica i PS Safety requirements and

Ec 62a62:2014

11506212008 [onnectos for PV aysiem

fresaoes [Balance eystom of PV

je 6an26 ond lors of ulated cables

esis on elie and apical Tre cables undor We condons =

Jec603s2-1-2 Part 1.2: Testor vaca fame propagation for a single insuate|

ro cable «Procedure for 1 RW pre-mivad ame

Frvs0s1e eo cates tr patra syst

Jecewor bata cxrosintesng of phatovotao PW romies

JEcc1720 __ Preowtae PV mds qalfeaton

is

(EVN 27S7-1005 _[ondsand lets Deskn standard

oa Wasa Biking Cae Nr Pyar & Cave Daa for

.200ex0 __feonsucion

aidnce for determination of ae Copan of We wind

Jose unser Tovi 2737:1008

gh of stucures for eainquake relsancos: Pant General

ON 8-201 amperage

Ign of sutures for earthquake reatancos: Pa

[mst 2201 ne ing sas ond prc secs

TOWN 55752072 fel eructires —Osegn standard

“uw oananoxa” PUP Sander Test eto n situ Tor pits under at

pressive lad

Asce7-10 mn design loads for buldings and other structures

5 EN 1900, 2002 ass of Stuctural Design

|Eurocede 1 Aone on sirucures — Part 1 General actions

lbenstes, ser-weigt moosed ads tr bukangs "|

IEwoccde 1- Actions on sruciures — Part 3: General actions

(OxD 2291909,

5 ads

[Eurocedo 1: Aatons on srucures — Part 1 General aeons

fi991-7.42005 [Wired actions

EN ‘urocede 3 — Desig of steel ruclures — Part -71 General

995-1-1:2008 ‘and ules for busing

fsen urocede f Acions on erucures — Par T-7 General ules ae

[962-1-1:2003 fue for bulsings

LOC MI SOLAR POWER ANT 200

sen

fses-t22008

Treen 3 — Design of Seal srucuTes — Pan TE Goward

Jes — Structural

redeson

51070085: 2007Eoeado 3 Des of stoeetuctures

Part & Ping

BS EN 14199:2005

ution of special geotechnical workemicopies

EEE St 691-2001

EEE Gunde er Tansmison Structure Foundation Dewan and

resing

Loctun + soxae pon Ns (ci)

ANNEX.02 PERFORMANCE TESTS

1. Purpos

1) This Schedule sets forth the basis for the dotormination of the Performance

Acceptance Tet (PAT) incidngscoeptance eftera,

2) The objective of et perfomance tess fs 10 prove thal the Project ie capable of

‘generating enorny as expected

2. Contractor's Responsbiliies

1) Perform al checks, calraton, measurements for all measuring equipment involved

thetest

2) Clean and maintain all pyranometers as required by the local environmental

condtons; daly leaning fs required during PAT.

3) Acquire data, perfom caleiatlons and present resus

4) Maintain an accurate record ofa plant vents, fa

‘er montoring system inclting he start ad endl of each event

5) Provide ful access to the Project's sto, al maintenance records, actuty logs,

colected data and real-time data from SCADA tothe Over:

£8) Notify the Owner onthe Intended stat date ofeach test period at last 5 busine

‘days porto commance the each test prio,

2. Detaled Technical Report

1) Upon completion of each test, the Contractor wil provide to the Owner a detailed

{echnical report, the "Perfsmance Test Repot’,indcating thatthe Project, as designed,

constructed and commissioned, has generated the requted energy in order to moet the

performance citer descized below

2) The Perormance Test Report wil provide evidence that al tests have boon

satsfaconly completes ard wil present the test preparation, dala source, calculation and

results ofthe test Calcutn worksheet in Excel format and allnecessary PVayst fas wil be

prowded together wih Perlman Test Report fr review,

3) The report wil also provide detsis of any noted defclency and corecive action

cared ou ding the tox periods.

4) The Owner wil view the Performance Test Report and provise writen comments to

the Contractor, it any, within 10 business days, which the Contractor will asonaby aderess

4. Performance Tests

1) PAT Period

“The PAT Perod wil commence ona dat ater al the following acties have Bean fly

complete:

‘Al commissioning ant slar-up actives have been successfuly completed and all

1 dowmtime fram equipment

LOCH 1 SOLAR PONER ANT oma)

deficiencies potently affecting energy generaton performance have been fly resolved;

‘The Projects synctrerized to the Local Ut ie:

[Al modules forthe project have been installed onthe stuctore a exposed to sunlight

{or atleast 15 days;

‘A visual inspection ofthe modules has been conducted to make sure that they ae in a

reasonable sate of teaniness and in particular fee from constructon residues (2, mud,

cust);

Solar metering equipment has boon completely installed and calbvated:

‘Al pyranometers we been calibrated and cleaned as par manufacturers

recommendatons;

All temperature senso’s have been Instaled and calibrated; and

‘The SCADA system fly operational and Owner has access to all operational data,

2) The PAT Period wi consist of at least 7 days nthe aggregate where al th follwing

conditions are met for ach day

‘Te global horizontal radiance is an average of 400 Wim? fr each how for at least

hours pe day,

“eal dally radiation onthe horizontal planes atleast 2k,

‘Any equipment outage or curtaiment that resis in a lass of energy exceed tothe gr

‘or oss the necessary performance data during dayight hous shorter than 15 minutes per

day in tho aggregate

‘The PAT Period wil te extended by one day for any day on wich al the conditions

above ae not met

3) Method of Measurement

Data collection by the SCADA system will commence at 12:00AM and end at 11'53PM

‘on each test day, averaged on a 5 minute Interval

‘The average value of each meteorological and electrical measurement relevent 1 the

perfomance test wil be recorded as 8 time stamped fle andthe historical series ofa data

points wil be avatable as a single, comma-separated values fle (CSV), the "Measurement

Data’. Relevant data shal include Plane of Array (POA) and Global Horizontal (GH!)

radiance, ambient teperture, and onary fecorded a the revere meter,

No ata points receded during the Test Period and compiled in the ofignal

Measurement Data fe wal be remaved o filed with other data at anytime,

No uncertainties or conection factors wil be apliod tothe Measurement Data

4) Data Analysis

‘All measured data mist be from the Measurement Data fle, adequate quality checks

shall be cad out to ersure that measurement data satisies the Test Period contions

radiance is measure by the horizontal (SHI pyranometers fr tracker systems, and by

vyt

Loci» soxar Pow LAN oct)

lao of aay (POA) pyranameters for eed tt systems

‘Where moce than one meteorological stations instated a a Project the aritametic mean

forthe recorded parameter wil bo used

Fer PAT, the olling datapoints aa be excluded from the Data Analysis (but not rm

the Measurement Data fe

_—The global havizontl radiance is below 100 Win?

_—The S-minute average iralance ders by mare than 10% fom the average radiance

forthe hour centered abou: that 5-minute petiod,

5) Cateulation

‘The Performance Ratio calculation formula is

Productioneneray

Expected energy

Performance Ratio (PR)

Tai SEE cent Oreo)

‘Aer the Data Anaya, the recorded data for actual meteorological conditions during the

“Test Parod wl be inputints the Tost PVsyst Model

‘The expected eneray generation forthe Test Period (expressed in Kh) as calculated by

‘ho Tost PYeyst Modo, willbe called E>.

“The actual energy production forth project over the samo paiod (expratsod in KWh)

vill be read from the projects revenue meter, and wil be called Eueren. Aur enegy

consumption forthe substzion isnot to bo included win Eyer=. Al other ausllary energy

consumed inthe project shal be included (inverters, trackers, vansformers et)

6) PAT Remedy and Retest

‘The Contactor has the follwing options the project does not pass PAT, ori the

Contractor elects o terminate the PAT before the completion ofthe Test Pri

“The Contractor may al the Contractor's sole discretion and cost, eae! fo remedy any

home It believes caused the Project fo fall the PAT and subsequently repeat tho PAT in

econ wih his Schedule. For ean, such test wil run fr the same duration and wil

be subject tothe same consiions as sel forth in this Schedule,

It the Contractor eleds not to remedy, ori the Project does not pass the PAT for

Contractor's reasons after tree (8) altompts to remedy and retest, the PAT wil be considered

felled and the perfomance liquidated damages shall apply. However, the Project does not

pass tho PAT forthe Employer or EVNS reasons, the Contractor shall no longer be lable for

Loc hui 7 SOLAR POWER RANT 2040)

the performance guarante thereat

The Contracor wil have maximum 20 days for remedy and retest stating from end of

PAT Peto

Loc Wnt # SOLAR FONE PLANT aH)

‘ANNEX-03 INSPECTIONGS, TESTING AND COMMISSIONING.

1. Functional Testing

44, Seriatizing

Provide Project drawings that include PV sting wing, combiner box elctreal

principe te, electrical system single tne et;

‘Record al combines boxes serial numbers and indeate zone locations within Project

Record al Inverters sor umbers and indleate zone locations within Projet

Record al medium vllage transformer serial numbers, and inverter serial number(s)

to.which each is comected

Record a Neteontogical Weather Stations serial numbers and Indicate zone

locations within Projet

1.2. PV Stings Open Citclt Voltage Test (Voc)

‘Measurement of Vac of each and every string is required to ensure that al stings

have the same nunber of Nodules connected anc correct poany. This is intended to

‘check the correct instalation ac wel a the balanced performance of tho arrays, This

“Toss notintanded as a measure of Module or aay perfomance,

“Test wil be in accordance with Standard: IEC 62446 Grd Connected Photovoale

‘Systems. Minimum Requirements for Systom Oocumentation, Commisioning Tocts

and Inspection.

+ Open the Combiner box DG disconnect and remove all string fuses in the

‘combiner box

‘+ Measure the open circu voitge ofeach sting onthe we side of he fuso holier.

4+ Aflr massuremant and recording of each sting Voe, replace the fuses back to the

1..PV String Cables

Perform sting cable related electra! tests including ensuring proper connactity of

strings on each combiner box according te sting tables,

44, AC MY Cables -Elocrcal Tests

‘Conduct insulation resistance test performed individual on each conducts, with al

‘other conductors and shields grounded, Ensure all AC MV cable tested for isolation

OCI 5 SOLAR ROWER ANT oN)

resistance before commissioning the inverter and utity Interconnection, Where

_appleabe performance a shill-conthuiy test on each pawor cable,

1.5. Metering Systom — Electrical Tests

[Ensue correct messurement and indation by applying voltage or curent to each

‘analog input; corect operation and setting of each auxary inpuoutput festure

(vechanical relay, gta and analog); and conf measurements ad indications aro

consistent with loads present afer intl system energization.

416. Grounding & Lightning Protection

Very thatthe groanding end ghining protection system is compliant vith design

ravings. The grounding system shall comply with eloctical system code 2s

Intorprotod by tho EVN requirements

2, Inspection

24. General Visual and Mechanical inspections

Ingpect the visual and mechanical sttbutes of each ofthe folowing components

‘nctuing the nameplate deta consistency with drawings and speciation, physical

‘and mectanical condition, the unit clearness, certificate, the anchorage, elgnment,

rcunng and cla ances per manufectixing an instalation eqtsemerts

2.2. PV Module Visual Inspections

PV panels to be ssualy inspected and recorded upon receipt, prior to and post

instalation onthe aay racking,

Pre and post installa inspection Procedure should document the flowing

~ Contractor shal viualy inspect the mesile packaging upon receipt. Any damage

shall be documented by the Contractor, Contractor shall nat be required to unpack

andlor incviually hspect each module. At such time if any damage is discovered

Contractor shall immeditaly nati Clot. Cnt and Contactor wl work together to

‘etemin the source of the damage and responsi.

~Visualy inspect each module to determine th presence er absence of anomalies or

defects. Optical magnifcaton isnot required. Visual inspection 1 not intended to

replace the Factory Acceptance Quality Measures, but is intended to improve the

‘overall quality ofthe netalation. Such anomalies or defects should nctuc, but are

not ites to

Loc nni 1 SOLA ROMER BAN (024

++ Shipping Damage (document damaged packaging prior o unpacking and damage

to modules ater unpacking)

+ Insalaon Darger

1 Broken, cracked, etched, scratched, wrinkled, oF tm extemal surfaces,

++ Broken, cracked or fully electrical iterconnections.

+A photovtaic 28 touching another cal r the module frame.

++ Missing, peeling, or éamaged metal layers on cell surfaces, and any ational

snomalies or defects specieg by the user

— Record the results ofthe visual nspecton so that any changes that occur dung

subsequent testing can be ented.

2.3. Marking and Labeting

‘The marking onal of the wees and cables used in the solar farm shall be in compliance with

‘he local letra stardard, Al electrical equipment used in he Projet shal be labeled

th safoy signage,

24. Racking Array and Module Mounting Inspections

{Visual inspection of Mechanical insta

ion

~ Inspect PY rack assomblies and wire tray assembles to ensure there ae no loose

serens oF attach,

Inspect PV meduleintatation to ensure modules are installed wth unform spac.

~ Inspect all PV modules and clamps ane ensure they are fastened to racking system

8 per module man facturer and racking manufactrer instalation specieations

Ensure no loose sews and stachments, spacing is per the module manufactuos

(uideines and unfarm spacing and al fastened components.

(iVisual inspecticn of Electical instalation

~ Visually inspect any plug and recoptacle connectors between the PV modules to

censure they are fly engaged an fee fom unde stress;

= Visually inspect the aay fo ensure module and rack to rack grounding has been

inetaled

~ Check to see that al wing is neat and wall supported

Loc + SOLAR ROWER ANT nat)

2.5. Combiner Box ~ Electrical Inspections

‘The constuctor n addtion to General Visual and Mechanical Inepection

Requirements, inspect cabnety (visual, mechanical ae electrical), tightness of pole

rmounteg hardware, al ground bonds, electrical comedtions, contnuty from box

conectors to posive fuse blocks and negative terminals;

26, Box ranstormer andinverter ~ Visual, Mechanical and Electical Inspections

~The constructor ensures ll transformers (ew-vatage step-up to intermediate,

secondary step-up to gid and grounding) have been tested atthe factory and

‘ocumentes prose arvng al projet ste per appicabiestandars.

~The constructor inspect the folowing adtional tems operation of alarm, carta, and

trip excite fom tempertue indeatrs,coxect liquid level i tank (ol level) and

temperature, de-evergized tap-changer poston & lef as spectied, no signs of

‘overheating with primary and secondary connections, bushings and nsultors are

‘Goan, check ol love and temperature, sot transformer taps to rated voltage, 3s

_snscifed, cil lake and excessive rusting, coxrect ype.

In sition to General Visual and Mechanical Inspecton requirements, inspect the

folowing adational tems: al ground cables cornectod and torqued, all empty holos

have been plugged, and ensure weather and rodent prof

27. Cleult Breakers ~ Visual and Mechanical Inspections

In action to General Vaual and Mechanical Inspection requirements, inspect the

folowing addtional tems: ckeut breaker size & (ype comesponds to. drawings,

‘coordinator study, and aderess for microprocessr-communicaton packages, correct

28, Relays ~ Visual and Mechanical Inspections.

In adtion to Genel Visual ané Mechanical Inspecton requirements, inspect the

folowing sdtional tems; modeVstyelseal number, fmarelsotwere revision, and

‘ated control volag recordad, very oporation of lightening diodes, displays, &

targets, passwords for all access levels recorded, font panel clean and foreign

‘material removed tem case, an relay sen scoorcance wih coordination study

2. Lightning Arrests -Visual and Mechanical Inspections

In addon to General Visual and Mechanical Inspection requirements, inspect the

folowing edaional ts: ground lead on each device i indvidualy attached to a

‘round bus or grourd electrode and elcticaly connected and recorded, applicable,

x

&

LOC NHS SOLAR POWER A ANT Zoo)

2.40, UPS~Visual ane Mechanica Inspections

| dation to Genera! Visual and Mechanica Inspecton requrements, inspect the

coating fans,

‘241, Cables - Visual end Mechanical Inapections

In addition to General Visual and Mechanical Inspecton requemeonts, Inspect the

follwing addtional tems: cable data comparison wit dravings and specications,

compression-appie connectors for earest cable match & bndentation, coroct

Identification & arrangements and cable jacket insulation and conto,

3. Commissioning

34. SCADA System

‘AISCADA systems used in the project shal be tested and accepted as fotos:

~ Contin compliance vith the Litys SCADA recuirements

~ Very communication with each Inverter

~ Conti measurement eadngs from inverters per specication

~ Conf status reacings fom auliary equipments per spectcation

~ Communication Ramos log-in, tp access) tested

~ Connection tothe Usity, if applicable, needs to be tested

~ Alvatables measured by the SCADA system have to be validated, not ony readings

‘rom the inverters eadings from the recomibiner boxes and from the weather stato,

forexampi, sive have tobe checked

~ Acabinels are dan of dust and debi,

~ Alvluesesplaye on screens ae valid and scale correct.

‘3.2. Communication System

Cconfm compliance wi the U's Canto an Telecemmunication equrements

ty testing requirements are successtuly completed

~ Ethernet equipmentinstales

~ Network programming competed

~ PRC Equipment Verification

Loca 1 SOLAR ROMER AV (200)

~ Confirm reviewed stings applied to relay

Functional tats ofthe SCADA, commands from both the Human Machine Interfaces

and trough the web intrace

£33. Protection and Contre! Equipment

‘The constructor Al Protection & Contol EqupmentiSystoms shal be tested and

‘documented in the Contractor's Final Functonal Test Report and shall be in

accordance to appabe standards,

~ Perform insuationsesitance tests fom each ckeut to the grounded frame in

accordance with Manufacturers published data

~ Apply voltage or curent toa analog inputs and very correct registration of he relay

rete unetion.

Chock functional operation of each element used inthe protacion scheme,

~ Conf the Functinal Operation a flows:

1+ Under Votage Relay

4+ Instantaneous Overeurent Relay

Time Overcuret

+ Overvetage Reay

+ Directional Ovecurent Relay

4 Frequency Relay

+ Contr! Verifcaton

34, Power Factor Contro System

‘A Power Qualty miler shal be Instaled wih adequate settings. Volage or current

‘hall be applied as appropiate to each analog input. Aor inital system energization,

‘cont that the monauroments and Inoatlons are consistent wh loads presen

Ensure thatthe PLE and network equpmest are installed and programmed, Verify

PLC and inverter communication, Very control, setting and timings according to

loading (feity producer). Ensure that the Power Factor Cent! system meets the

EWNs quirements

'35.Contro Verfiea

erty the operation of al active digit! Inputs, oxtput contact, infemel ogi funtion

Used in the poecion scheme, and te reseting of a minimax recorders,

L

4 4

oon 1 so.Ane POWER ANT oni)

communication sts, faut counters; events sequence recorder, and event

recorders,

3.6, Testing of Interconnection

«The systems Grd interconnection and protections systems shal be tested and

accepted in accordance with the EVN's requirements,

ancew

Pa wscomien | et

‘ahvxed

Fa TORTS HOT asanapecenieo| any

‘oost'nvseseaecn| MONE) ayy

ore

10091 +020} gow asl yay

aupreishioouoy! “dNngrre mee

snptiston asso anoe

“diygrie sno sed ences

1woudnbe peu amionoia) LP

neu -ejoweied oaveasoneg “80 Pa

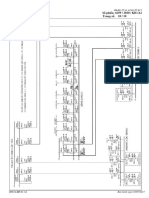

181 uoWdinbe BunooujBue Arewd ouN0e13 I e1eeL

9 yo Ssancud sup BuUNp WoREZHELY BOIS 810A Sk RUNS

(S1vRISLVW GNY LN3WdIND’) S3LLUNWND JO 7118 ¥O-XENNY

GEE LIVEN ES BAGS THIN GOT

ce | spls0e usps] yas p909|

ed wubadamsaneW | P0560)

nisoezowseien

‘osseous eoiono Soa 99 sBHIN Une | FT

rsa

» | soysovossanay | ©Eb

sauzrarsuonacenen | gg

we | wn TUN] emma} ze

‘ero pmuisoor3 | ey | wy suuperezi| —aneonal ret

>.e1e htt opin,

ponsiogeoeren

Tonorerse piso eonioa mea] Ey

i nee srt

recs

ave

ot | | ana se natty) "Spon | v1

sovendu ye nica | Jere

ar

Pi mung seed

papeuo marae)

vy smoueredeomoea | RO | wn | wontons cow | ay

(TART TENET APTOS TARGET

ped oxo au,

sunuuunnysopneueg,

meen iesrovon

Ud aoatoa uenuysoer eoegustll] vex

saa iwskowen ecu

dog iy wenn ser

‘buoy Busecay

‘nvSEOWebeH0N,

ou

vosswsuesl | 964

peaUano 58

"yes 950 buy

‘uno Bupioooy

tunuunry sopr@ueg,

INISEOW ENON,

we ox j0 aby

‘ua Bupioooy

uunuunry sejnpue9,

RISEOW BEAN,

go oun 0 3644

‘or Bupiocoy AISEOW eEEHOA

a poigolez suport} yoo1e 2990800] 2,

2.05+.0'e0ue! snjeoduo), YMSIOAASAHMN | ASE J0, 960

yse/sz0¥. 9810"

eyeuily sejowresed e2uewopog wn wondioseq owen

“on

we

OE INE MOT IOS TFT

‘aide eRUENED

‘vojoeixd BUN

sues reauien |

Ju yop fare ey PSA crore | ee

ce 4 | sus yor feaeseH pemUeVED | a9 SRN | ey

r $305 FS eH PORE SaaS

on | 1 [amarosienmwrremeeo| aeoehomen| FFE

Supuncig | ¥b

oge sore

owns sojoursed ooue us ” 7 wwondus a oN

S nat joued ‘wn dosed wen | en

‘RDEV OT TOS T NOT

FST_DoyeE Tanod Sera

SrniAe SS Ime

‘eid GOV, £2 (WO8-GAT 611200

‘openve “ZHOrE=ndO “slno-penb) ogi © iso} | HOW, woREN same cevoncto

sy} uowdnbe Buyeauibue Arepucsss jea1noeIa z-¥ O1GEL

EE TE SOT TOS TN TOT

x

LOCKE) SOLAR POWER RANT oun)

ANNEX-05 BILL OF GUANTITIES (CIVIL WORKS)

ee

CEE

Se em

a

— «| fon

=

=.

7 [Berens

Soleiaaeie

a

13 everer

a ae

— a

a a

a

eT aaa

——— =a

on olan

a =f

———

142 | cable tutes)

a =e

so “ee

oa alarms

Sea vce appa, | pp

17 Sour acto of PV Fat ea

Simpeenca PV ft wo in| 80 [mnie oce

1 | Fudaton tahnrgrod

Earth vers wearin m | am

oath ers beektlg m | a80

Lear corrects m | wo

Fourdsin cont G0 m | ao

Gitar [as

co [Risepmaeaanst com oa

110 | bawage cro ae won| 0a

1. [ sos oat tte im [10

1:2 [onto acne in| ae

119 [Bang Pv ste

187 | Warehouse [too | Sefeer Fae

‘182 [man quattone es [ tote tonr fame

1138 | nat guru mo [4 [Setar

1184 | Wath ovr vee [tame

OCI 1 SOLAR POnER FANT 2a)

ANNEX-06 PVSYST SIMULATION CALCULATION

4x

PVSYST v6.75) 910420] Pace 15

Grid-Connected System: Simulation parameters.

Project: LoeNinht

Geographical site Lectin ccouey Vietnam

Suan atte 1160" Longiude 10848" &

Tire tne ns LegalTine Tine zone UTe7 Alte 8D

‘Abed 020

Mateo dat: Lectin Hetaonrm 72 (1001-2010), Sate100%-Syrhate

‘Simulation variant: New simulation varlant

‘Sinton dato 30420 19410

Simulation forthe 40th year of operation

Simulation parameters Syste type United sheds

Collctor Pane Orientation me aims

Sheds contguration Ne. otsbeds 5 nines sheds

‘shade spacing 580" Colledor wists 00m

Inactive band Tep 0027 Bator 02m

‘Shing tnt sre LUmtprotla ange 26°” Groundoov.Reto{@CR) 87.8%

Models used ‘Transposon Paez Dine Pete, Metener

Horizon Free Horton

Near Shadings tual snscngs of shads

BV Bray Characteristics

PV module Siero Medal LRA-T2NPH AON now

‘Cictom paramos dofiniton Manuiocrr Long Soar

‘wanserot PV maces Ineetos So modes Impure 15180 stings

Tolsmonber of PV modes Np mosules 454500" _UnitNem Power 40>

‘ray bal power Nomial(STC) 198880 KiYp ALoperstng cond, 180484 Kp (40°C)

‘ay operating enacts (0° C) ‘Umpp 2 Timp 1280078

‘otto edule on SH et

Inverter Model EP126HAUDAO2

"Cision parameters coiton anuactrer Shorg

contact ‘opera Volage BIOI800V UntNom, Power 3125 kc

ax power 928°C) 3894 SE

love pa eet verare 60 une Tot Poe 187500 kWlac

‘Promento 407

PV Ara loss factors

‘ray Soling Losses oss Fracton 10%

‘Thema Loss factor Uc (cons) 280 Win K ‘vind) 0.0 Wnt Kms

Weg Oi Loss Global erayres, 0073 mOAm Los Fracton 1.0% at STC

Sete Dito toes Vet Oop O7 oes Frcton 0.1% STC

LUD ntcod Depradaton le Fraeton 10%

Mose ally toes ls Facton 0.7%

Mose Wismateh Losses oe Fracfon 0S at MPP

Suing Meta oss le Fracion 0.10%

ode erage dagen ar20 10 Lows foctor 04 Sioa

Mmalc du To degadaon pS depunson 04 Klyear Vine RMS deport 0.4 Soar

Bx

pvsyst vers aioaz0 | Page28

Grid-Connected System: Simulation parameters |

Ineldonce oct (AMY: User dened AW rele

‘system oss factors

[AC los, anata econ ‘ora votage 20H

ees: 240000 mn? 200m Lose Frasfon 0.1 Yat STC

ster uanfomer Iron a (24H cannaaon) 167020 W lec Frcaon 0.1% at STC

Recbvfndscie losses 203mOhm Loss Facton 10% at STC

naval of 5ystm 36 ays, 3 pre Tine rcion 1.0%

eet needs Unis tod ai)

‘uae oss cmlat ane) 30000". tom Power tesh, 0.0 KA

PVSYST V85| aioaz0 | Page 3

Grid: Connected Syetom: Main recults

Project: LocNinht

‘Simulation variant: Now simulation variant

‘Simulation for theft year of operation

Main eyetom paramatr= ‘Syst pa Untied sheds

PV Fad Oretaton ‘Shots depstion tt 1 xiputh

Pv meses Model LR&TOHPH-ANON-now "Prom 440\%p

Pv rey Ne ofmadtiea 454500 Pom tea! 199900 kw

Ione ‘Model EP125HKUD02 "Prom 125k ae

Irv pack No ofunts. 60.0 Prom toa! 187500 KW 9c

Users eed rst ad (oi)

ain simulation resus |

Systm Producten Produced Energy S105K3 MWhiyear Specie prod. 1553 KNAW

New smatin vation

PvsyST vers iso420] Page as

Grid-Connected Syetem: Loss diagram

Project Lochinht

‘Simulation variant: New simulation variant

‘Sinulatin forthe 10th year of operation

Main system parameters System type United sheds

PV Fd Oretaon ‘Stats eosion tt 1 inuth

Pv modes Model UR472HPH-AtON-neN "Prom 440 Wp

Pv ray Ne.otmedies 454500, Pom ot! 129960 Kp

vere ‘Model EPI25HAUDO2 |” Prom S125KW ac

rte pock No.of units 600 Pom 3! 187500 KW 9c

Users ods one dh)

ose gr ore te whole ee

‘ta neem ca plane

wr Sarg arn ee

at caren gota

‘anger oer

‘ay oni ney (ST fe)

‘eae epadeon oy)

Pe dito

tn tyne

Logins aettin

SIT ST

cite

ey Sa

‘evar Lee ce epeton te)

‘Sat Lone vr ina age

‘Sere volgen

‘stan, oe)

‘Stara

nay ected i

PVSYST v6.75 taoaz0| Pages

Grid-Connected System: P50 - P80 evaluation

Projeot : LooNinht

‘Simulation variant: New simulation variant

‘Simulation forthe 10th your of operation

Main system paramotrs ‘ipo Unlimited sheds

PY Fit Omntaton ‘Shade pection at 1 imu

Pv mado Model LR&-T2HPHA¢ON-naw Poo 440 Np

Pv roy Neofmiies. 454500 Pom tal 198060 kw

lover Model EP21254AUD02 "Prom Saeki ae

Inver pack N,ofunts 600 Prom ol 187500 KW se

Users eds Untinios ea ()

Evaluation of the Production probaly forcast

‘The probably dstbuton fe system produconfrcast or dfoontyearsis mainly dependoré

on th moto deta sod forthe sult, and depands onthe olor choices

Moto dal source etoorerm 72 (100-2010), Set=100%

Melo a ed Monty eerogen Stic Mulla erage

‘Spectid Devaton ‘tmsto change 00

Yeartojearvatily Varies 25%

‘Tho probably dtibton varices depending on smo oytom paramos uncealnes

Species Deaton PV male redeinghparamelere 1.0%

Inver ofieny ncaraniy 05 %

Soling and misnacn ureeransoe 10%

Dogadaion montanty 10%

(loa! varity tao + sytem) Variance 3.1% (qusdate sun)

pool roductnprobsbilly Variaiey 987240

Ps Hoe MWh

oo 2anzeo twWh

Pos Zaeei6 mn

Probability detribution

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Control & Protection DiagramDocument1 pageControl & Protection DiagramDream 2 RoseNo ratings yet

- NTVH 6259-2020 (C21, Duong Day 277, 278 Tram Binh Long 2, 273, 274, 275, 276 Loc Tan) TLDocument1 pageNTVH 6259-2020 (C21, Duong Day 277, 278 Tram Binh Long 2, 273, 274, 275, 276 Loc Tan) TLDream 2 RoseNo ratings yet

- Contract AgreementDocument9 pagesContract AgreementDream 2 RoseNo ratings yet

- General ConditionsDocument106 pagesGeneral ConditionsDream 2 RoseNo ratings yet

- Particular ConditionsDocument45 pagesParticular ConditionsDream 2 RoseNo ratings yet

- Supplymental Agreement - Loc Ninh 1Document6 pagesSupplymental Agreement - Loc Ninh 1Dream 2 RoseNo ratings yet

- SchedulesDocument76 pagesSchedulesDream 2 RoseNo ratings yet

- TCVN 6306-1-2015Document82 pagesTCVN 6306-1-2015Dream 2 RoseNo ratings yet

- Loa-Ln1Document1 pageLoa-Ln1Dream 2 RoseNo ratings yet

- Employer's RequirementsDocument7 pagesEmployer's RequirementsDream 2 RoseNo ratings yet

- Project Verification Report v3.1Document32 pagesProject Verification Report v3.1Dream 2 RoseNo ratings yet

- Test Dinh Ky SPCDocument16 pagesTest Dinh Ky SPCDream 2 RoseNo ratings yet

- Thiết bị hạ áp tcvn6592-2-2000Document129 pagesThiết bị hạ áp tcvn6592-2-2000Dream 2 RoseNo ratings yet

- Tính Cap DT1Document1 pageTính Cap DT1Dream 2 RoseNo ratings yet

- DrawingsDocument11 pagesDrawingsDream 2 RoseNo ratings yet

- 200102.HLS.DT3. TỔN THẤT ĐIỆN ÁP VÀ TỔNG THẤT CÔNG SUẤT - HIỆU CHỈNH CÁPDocument8 pages200102.HLS.DT3. TỔN THẤT ĐIỆN ÁP VÀ TỔNG THẤT CÔNG SUẤT - HIỆU CHỈNH CÁPDream 2 RoseNo ratings yet

- TCVN 9358 2012Document52 pagesTCVN 9358 2012Dream 2 RoseNo ratings yet

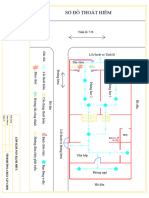

- So do thoat hiem Lớp mầm non Hạnh Phúc ĐNai1 ModelDocument1 pageSo do thoat hiem Lớp mầm non Hạnh Phúc ĐNai1 ModelDream 2 RoseNo ratings yet

- tcvn5844-1994 Cáp Trug ÁpDocument13 pagestcvn5844-1994 Cáp Trug ÁpDream 2 RoseNo ratings yet

- TCVN 9358 2012Document52 pagesTCVN 9358 2012Dream 2 RoseNo ratings yet

- Thiết Bị Hạ Áp Tcvn6592!2!2000Document78 pagesThiết Bị Hạ Áp Tcvn6592!2!2000Dream 2 RoseNo ratings yet

- M C L CDocument1 pageM C L CDream 2 RoseNo ratings yet

- tcvn5844 1994Document7 pagestcvn5844 1994Dream 2 RoseNo ratings yet

- TCVN 6610 3 Iec 60227 3Document16 pagesTCVN 6610 3 Iec 60227 3Dream 2 RoseNo ratings yet

- Lớp mầm non Hạnh Phúc - Tình huống cháy 1Document2 pagesLớp mầm non Hạnh Phúc - Tình huống cháy 1Dream 2 RoseNo ratings yet