Professional Documents

Culture Documents

PP User Manual - Production Order Life Cycle

PP User Manual - Production Order Life Cycle

Uploaded by

baljeet singhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PP User Manual - Production Order Life Cycle

PP User Manual - Production Order Life Cycle

Uploaded by

baljeet singhCopyright:

Available Formats

SAP ECC 6.

0 Implementation

Project: MARUTI

Atul Auto Ltd.

SAP ERP ECC 6.0 Implementation

Version 1.0

Training Manual

Production Planning & Control

[PP] - Production Order Life

Cycle

SAP Channel Partner

KPIT Cummins Infosystems Ltd

Hinjawadi, Pune

Subject: Production Order Life Cycle Page 1 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Document Information

Document Control:

Author Amit Chaubal / Sumant Sambrey

File Name Atul Auto Ltd._Training_Manual_PP.doc

Created 19th – Nov - 2011

Last Edited

Version Revision Revision Author

Date Description

V1.1 Amit Chaubal / Sumant Sambrey

Target Readership

Project Team

Subject: Production Order Life Cycle Page 2 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Purpose of the Document

This document captures in detail the transactional steps required in the SAP

system to be performed to meet the business requirements as envisaged in

the Business Blueprint phase. The screen shots along with rationale of all the

steps are also provided.

The documentation provides visibility to all project teams members on the

process flow in the system. This is very important due to the highly

integrated nature of SAP.

This training manual outlines the way, how the Production Planning &

Control (PP) Module should be executed for Atul Auto Ltd. as per the

requirement of their business scenarios.

Subject: Production Order Life Cycle Page 3 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Production order life cycle consists of production order creation, release ,

confirmation, settlements & technical completion:

1) Production Order from Planned order (MD04 / CO40)

2) Production Order creation (CO01)

3) Production order release (CO02)

4) Collective release of production orders (CO05N)

5) Printing of Shop floor papers (CO02)

6) Missing parts list against production order (CO24)

7) Production order confirmation (CO11N / CO15)

8) Goods receipt against production order (MB31)

9) Technical Completion of production order (CO02)

10) Mass processing of production orders (COHV)

11) Order information system (COOIS)

Production order life cycle

The MRP run creates planned orders for parts that are to be produced

internally. When the planned opening date is reached, these are converted to

production orders.

Business process overview

Process step Transaction Process Description

code

Planned order conversion to Independent Requirements for

MD04 / CO40

Production orders finished product is created.

Production order created

Production Order Creation CO01

manually.

Production Order Changes & CO02 Production Order changes &

release release.

Collective release of Production CO05N Production orders are released

Order collectively.

Missing parts list against

Missing Parts list CO24

Production Order is displayed.

Printing of Shop Floor papers CO02 Shop floor papers are printed.

Confirmation of production order CO11N / CO15 Production order is confirmed.

Goods Receipt against Production MB31 Goods Receipt w.r.t production

order order is done.

Subject: Production Order Life Cycle Page 4 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Process step Transaction Process Description

code

Production orders are technically

Technical Completion of orders CO02

completed.

Order Information system COOIS Production Order Report

PROCEDURAL STEPS

Via Transaction Code MD04 / CO40

The MRP run creates planned orders for parts that are to be produced

internally. When the planned opening date is reached, these are converted to

production orders.

Confirm your entries with Enter.

Subject: Production Order Life Cycle Page 5 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Double Click planned order to be converted, below screen will appear

To convert partial planned order, click

Enter Target quantity (quantity of the Production order to be created)

Click & Save

Subject: Production Order Life Cycle Page 6 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Message as below is displayed.

In CO40, Enter the planned order number. Steps after that remains same as

above.

Make the selection & press Enter (click Partial conv. During partial

conversion of planned order)

Subject: Production Order Life Cycle Page 7 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

To convert complete planned order, click

Save , message is displayed.

Subject: Production Order Life Cycle Page 8 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Via Transaction Code CO01

Production order can be created manual as required.

Confirm your entries with Enter.

Enter production order quantity, dates (finish date, start date will be

updated by backward scheduling)

Subject: Production Order Life Cycle Page 9 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Check Operation

Subject: Production Order Life Cycle Page 10 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Check BOM

Go to Production order header , initial screen will appear.

Check capacity availability

Check material availability

Run Cost Order

Schedule the order

Save , message is displayed.

Subject: Production Order Life Cycle Page 11 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Via Transaction Code CO02

The production order parameters are to be checked with Material availability n

other values. After this the Production order is released.

Subject: Production Order Life Cycle Page 12 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Confirm your entries with Enter.

Release order

Release with material shortage is possible giving information message as

below

Subject: Production Order Life Cycle Page 13 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Via Transaction Code CO05N

Confirm your selection & move to next tab

Subject: Production Order Life Cycle Page 14 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Execute

Select the orders to be released & select

Subject: Production Order Life Cycle Page 15 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Confirm the entries & click

Order released & message displayed as below.

Subject: Production Order Life Cycle Page 16 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Via Transaction Code CO02

If you want to print the shop floor papers from order carry out the following

steps.

Confirm your entries & press enter.

Subject: Production Order Life Cycle Page 17 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Via Transaction Code CO24

Shortage report / Missing parts list with respect to production orders can be

seen by following steps.

Confirm your selection & Execute

The above list can be transported to excel format.

Subject: Production Order Life Cycle Page 18 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Via Transaction Code CO11N / CO15

Confirm your entries with Enter

Subject: Production Order Life Cycle Page 19 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Click to check Auto-goods receipt on confirmation for

Sub assembly orders.

Confirm the entries & Save

Goods Movement are posted & message is displayed.

Subject: Production Order Life Cycle Page 20 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Via Transaction Code CO15

Order confirmation can be done collectively with above transaction. This step

is generally adopted during Assembly orders.

Select Partial / Final confirmation as required.

Subject: Production Order Life Cycle Page 21 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Click , to check Auto Goods issue / backflush

material for the Assembly orders.

Confirm the entries & Save

Order confirmation & goods movements are saved & message is displayed.

Subject: Production Order Life Cycle Page 22 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Via Transaction Code MB31

Goods Receipt against Production orders is to be done in case of the Final

Assembly. The separate activity enables us to declare each vehicle with colour

& Chassis number entries.

Confirm the entries & press Enter.

Select Vehicle Colour in the batch field & click

Subject: Production Order Life Cycle Page 23 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Confirm the entries & press

Serial number entry screen appear, click

Subject: Production Order Life Cycle Page 24 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Execute

List of serial number is displayed, select number & click

Confirm the entries & press

Subject: Production Order Life Cycle Page 25 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Save .Goods are posted & message is displayed.

Subject: Production Order Life Cycle Page 26 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

SAP ECC 6.0 Implementation

Project: MARUTI

Via Transaction Code CO02

Technical completion means ending a production order from a logistical

viewpoint. This function is usually used, if the execution of an order has to be

stopped prematurely or if the order could not be executed in the required

manner and open requirements for the order (reservations, capacities) should

be deleted. If an order is technically complete, you cannot change it. The

fields in the order are displayed but cannot be changed.

Save . Order is technically completed & message is displayed.

Subject: Production Order Life Cycle Page 27 of 27 Created by : Amit C / Sumant S

Created on : 19/11/2011

You might also like

- Remittance AdviceDocument30 pagesRemittance AdviceSureshNo ratings yet

- Fi Co Business Blue PrintDocument87 pagesFi Co Business Blue PrintVenu Gattamaneni0% (2)

- R&D Procedure - Control of Drawing Engg Specification P2Document1 pageR&D Procedure - Control of Drawing Engg Specification P2sumanNo ratings yet

- Sap s4 Hana Simple Finance Student Copy 1.19Document776 pagesSap s4 Hana Simple Finance Student Copy 1.19Surendra Peduru100% (1)

- Aim Methodology Activities and DocumentsDocument7 pagesAim Methodology Activities and DocumentsKiran NambariNo ratings yet

- Dashborad Reporting Using Bi: Amit Kumar Senapati PMP®Document11 pagesDashborad Reporting Using Bi: Amit Kumar Senapati PMP®M DhiwaherNo ratings yet

- Inter-Company Process in S - 4 HANA - SAP BlogsDocument17 pagesInter-Company Process in S - 4 HANA - SAP BlogsAbilash R100% (2)

- Oracle Fusion Cloud Financials R13 1Document7 pagesOracle Fusion Cloud Financials R13 1arun devaNo ratings yet

- Omfed CFP Sap PP End User ManualDocument118 pagesOmfed CFP Sap PP End User ManualDebasish GhoshNo ratings yet

- Sap Fico Notes FiDocument150 pagesSap Fico Notes FiMohammed Nawaz ShariffNo ratings yet

- Important Sap Fico QuestionsDocument33 pagesImportant Sap Fico Questionsswetha devarakondaNo ratings yet

- FI Project in SAPDocument75 pagesFI Project in SAPmani254722305100% (1)

- User Manual-SAP PP-RNAIPLDocument31 pagesUser Manual-SAP PP-RNAIPLramesh_lpkpnNo ratings yet

- IBM Global Services: User ExitsDocument30 pagesIBM Global Services: User ExitsRaul ThomasNo ratings yet

- Selection of Production VersionDocument7 pagesSelection of Production VersionBalanathan VirupasanNo ratings yet

- Implementing BADI For The Transactions VL02 & MM02: SAP Virtual/Onsite TrainingsDocument4 pagesImplementing BADI For The Transactions VL02 & MM02: SAP Virtual/Onsite TrainingsVamsi MohanNo ratings yet

- Quality Register: Project Name: Date: Release: Author: Owner: ClientDocument3 pagesQuality Register: Project Name: Date: Release: Author: Owner: ClientfarazNo ratings yet

- Competitive Analysis of Telecom IndustryDocument71 pagesCompetitive Analysis of Telecom Industryhemant1968767% (3)

- Batch Determination of Components in The Production Order in S - 4 1709 - SAP BlogsDocument17 pagesBatch Determination of Components in The Production Order in S - 4 1709 - SAP BlogskvarjunanNo ratings yet

- Adobeform Attachment WorkitemDocument20 pagesAdobeform Attachment Workitemrahaman.maNo ratings yet

- JPT GUI User Guide v1 1-EngDocument5 pagesJPT GUI User Guide v1 1-Engmehrdadgemini100% (1)

- PP BBPDocument20 pagesPP BBPSiva Sankar Mohapatra100% (1)

- Associative Ebom Mbom BP Flamy PublicDocument43 pagesAssociative Ebom Mbom BP Flamy PublicBinesh KumarNo ratings yet

- Combined Production Order Processing (DIMP) - SAP BlogsDocument17 pagesCombined Production Order Processing (DIMP) - SAP BlogsRashid KhanNo ratings yet

- Industry Foundation ClassesDocument40 pagesIndustry Foundation ClassesLokesh SharmaNo ratings yet

- Val BBP PP FinalDocument81 pagesVal BBP PP FinalAnonymous yahXGrlz8No ratings yet

- Odoo 10 ManufacturingDocument58 pagesOdoo 10 ManufacturingImenou Imen100% (4)

- PP User Manual - BOMDocument6 pagesPP User Manual - BOMbaljeet singhNo ratings yet

- PP User Manual - Chassis Number ManagementDocument19 pagesPP User Manual - Chassis Number Managementbaljeet singhNo ratings yet

- Ideation To Commercialization - DEMO SCRIPTDocument2 pagesIdeation To Commercialization - DEMO SCRIPTranvijayNo ratings yet

- Combined Production Order Processing (DIMP) - SAP BlogsDocument18 pagesCombined Production Order Processing (DIMP) - SAP BlogskesharNo ratings yet

- Order Split Without Product Cost Collector and By-ProductDocument14 pagesOrder Split Without Product Cost Collector and By-Productsrinivasa varmaNo ratings yet

- DMS User ManualDocument17 pagesDMS User Manualbaljeet singhNo ratings yet

- 4i9 s4cld2308 BPD en deDocument55 pages4i9 s4cld2308 BPD en deranjitan111No ratings yet

- BTE in Payment Run' and Dunning'Document22 pagesBTE in Payment Run' and Dunning'Arasumani Arumugam100% (1)

- Digital Manufacturing Accelerates Time To MarketDocument13 pagesDigital Manufacturing Accelerates Time To MarketRahul DeshpandeNo ratings yet

- Walldecals 120 1 PDFDocument50 pagesWalldecals 120 1 PDFerrahaNo ratings yet

- NC1801 Production and Operations Management - MODULE VDocument35 pagesNC1801 Production and Operations Management - MODULE VAakashNo ratings yet

- BCS GPIL PP Process Manual v1.0Document287 pagesBCS GPIL PP Process Manual v1.0sapppqmmanloNo ratings yet

- Chapter 01 - User ExitsDocument30 pagesChapter 01 - User ExitsSunil ReddyNo ratings yet

- Difference Between SAP47 & ECC 6Document3 pagesDifference Between SAP47 & ECC 6keyspNo ratings yet

- Tektronix - Group 3Document21 pagesTektronix - Group 3Utkarsh SharmaNo ratings yet

- Sap Ecc 5 & Ecc6Document3 pagesSap Ecc 5 & Ecc6mbraghumb9019No ratings yet

- Cognos Vs BODocument5 pagesCognos Vs BOKrishna Chaitanya KasturiNo ratings yet

- SNC-Setup Outsourced Manufacturing Scenario in SNCDocument22 pagesSNC-Setup Outsourced Manufacturing Scenario in SNCajay_agraNo ratings yet

- Payment ApprovedDocument37 pagesPayment ApprovedAnirbanNo ratings yet

- Lean Construction 3 InokumaDocument21 pagesLean Construction 3 Inokumainitiative1972No ratings yet

- 1.MPP PPTDocument64 pages1.MPP PPTNaveena SmilessNo ratings yet

- Helpfull SAP TcodesDocument70 pagesHelpfull SAP TcodesDiogo Max100% (2)

- gPsV5DcFP4MB5Vc0-SAP Product Lifecycle Management and Web UI The Good, The Bad, and The UglyDocument29 pagesgPsV5DcFP4MB5Vc0-SAP Product Lifecycle Management and Web UI The Good, The Bad, and The UglyPinaki RoyNo ratings yet

- Debugging Production Orders - ERP Manufacturing (PP) - SCN WikiDocument1 pageDebugging Production Orders - ERP Manufacturing (PP) - SCN WikiSandeepNo ratings yet

- Queryvision Guide To Installing and Configuring Ibm Cognos Analytics 11Document21 pagesQueryvision Guide To Installing and Configuring Ibm Cognos Analytics 11Adnan SherazNo ratings yet

- Implementing Menu Exits and Screen Exits in CJ92 Transaction (PS Module)Document14 pagesImplementing Menu Exits and Screen Exits in CJ92 Transaction (PS Module)Rahul GaikwadNo ratings yet

- Final Report: Project YONO by SBIDocument54 pagesFinal Report: Project YONO by SBIAayush KaushalNo ratings yet

- SAPReference FunctionDocument90 pagesSAPReference FunctionArnold_kat88No ratings yet

- Analysis and Comparison of BPM SoftwareDocument14 pagesAnalysis and Comparison of BPM Softwareqqvids100% (1)

- SAPReference 2Document134 pagesSAPReference 2Louay GhonaymNo ratings yet

- Sap ReferenceDocument79 pagesSap ReferenceAndreasJauchMeyrinchNo ratings yet

- 5 Steps To Bot Building Success v2017Document4 pages5 Steps To Bot Building Success v2017aravindiitNo ratings yet

- Configuration Steps in IDOC - SAP BlogsDocument19 pagesConfiguration Steps in IDOC - SAP BlogsmarianalarabNo ratings yet

- Workorder - Infosys Badi (Coois Modefication)Document9 pagesWorkorder - Infosys Badi (Coois Modefication)mohameds1988No ratings yet

- Exercises PS enDocument14 pagesExercises PS enjuanes ramirezNo ratings yet

- Create A Bloodborne Bosses Tier List - TierMakerDocument1 pageCreate A Bloodborne Bosses Tier List - TierMakerEL FLORESNo ratings yet

- Cheatsheet - MAQ SoftwareDocument1 pageCheatsheet - MAQ SoftwareArunima DasNo ratings yet

- IEEE Computer 2016Document124 pagesIEEE Computer 2016Arthur RossumNo ratings yet

- Resume Keerthana PG PDFDocument1 pageResume Keerthana PG PDFVivek GNo ratings yet

- Ic 695 Chs 007Document8 pagesIc 695 Chs 007Dilyalew DebreworkNo ratings yet

- Birth Registration SystemDocument6 pagesBirth Registration SystemAmit SheoranNo ratings yet

- Chetna 4 EastDocument15 pagesChetna 4 EastChetana SJadigerNo ratings yet

- 1 - IX Global English Presentation (SEPT 2022)Document36 pages1 - IX Global English Presentation (SEPT 2022)SHAM SUNDERNo ratings yet

- Resume Paula BulanDocument2 pagesResume Paula BulanKamote GamerzNo ratings yet

- Advanced Materials - 2018 - Hu - Memristor Based Analog Computation and Neural Network Classification With A Dot ProductDocument10 pagesAdvanced Materials - 2018 - Hu - Memristor Based Analog Computation and Neural Network Classification With A Dot ProductDiptanu DebnathNo ratings yet

- 3-0-1 Introduction To Email Student ManualDocument20 pages3-0-1 Introduction To Email Student ManualAnandNo ratings yet

- Implementing Bubble Sort AlgorithmDocument6 pagesImplementing Bubble Sort AlgorithmhariniNo ratings yet

- Help Ge Lunar ProdigyDocument96 pagesHelp Ge Lunar ProdigyMohammad El ArabNo ratings yet

- Data Structures and AlgorithmsDocument16 pagesData Structures and AlgorithmsAnh TuấnNo ratings yet

- Ipay88 Technical Spec V1.6.4Document31 pagesIpay88 Technical Spec V1.6.4Dmytro TsybenkoNo ratings yet

- Lecture 3 - 1 Dichotomy of Parallel Computing PlatformsDocument17 pagesLecture 3 - 1 Dichotomy of Parallel Computing PlatformswmanjonjoNo ratings yet

- Syllabus Course Number: MSCD 664 Course Title: Introduction To Nosql DatabasesDocument6 pagesSyllabus Course Number: MSCD 664 Course Title: Introduction To Nosql DatabasesUmaMaheswariShanmugamNo ratings yet

- Assignment Day13 Lesson10 JDBCDocument11 pagesAssignment Day13 Lesson10 JDBCaravind kumarNo ratings yet

- Resume Builder Project ReportDocument39 pagesResume Builder Project ReportPranav PatilNo ratings yet

- Data Sheet: Automotive Audio Bus A B TransceiverDocument2 pagesData Sheet: Automotive Audio Bus A B TransceiverЕвгений ИвановNo ratings yet

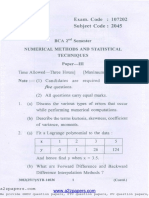

- Exam. Code: 107202 Subject Code: 2045: Five QuestionsDocument3 pagesExam. Code: 107202 Subject Code: 2045: Five QuestionsSatnam AzrotNo ratings yet

- Predicting Round and Game Winners in CSGODocument10 pagesPredicting Round and Game Winners in CSGORopyNo ratings yet

- Vmware Esx Server 3.5 Installation Guide: Devoloped By: KalamDocument24 pagesVmware Esx Server 3.5 Installation Guide: Devoloped By: KalamKarimulla KolimiNo ratings yet

- 1 - Introduction To HTML & CSSDocument26 pages1 - Introduction To HTML & CSSdanyNo ratings yet

- Student Internship MONITORING FORMDocument5 pagesStudent Internship MONITORING FORMAlrhazer SNNo ratings yet

- JTAC EMEA Overview 2019-PartnersDocument8 pagesJTAC EMEA Overview 2019-PartnersBenNo ratings yet