Professional Documents

Culture Documents

Annals 2013 2 04

Uploaded by

Aleksandar GrkicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annals 2013 2 04

Uploaded by

Aleksandar GrkicCopyright:

Available Formats

1.

Orlin STOYANOV

DEVELOPMENT AND TESTING A DIESEL ENGINE

DIAGNOSTIC SYSTEM

1.

UNIVERSITY OF RUSE, BULGARIA

ABSTRACT: The purpose of this study is to develop a system for diagnostics of a diesel engine. In the

article are presented curves, which describe the characteristics of the crankshaft angular velocity

variation in transient state, and the fluctuations of the rotation at idle speed which are described as

parameters for diagnosing these types of engines. The obtained results indicate that this method can

find practical application in the diagnosis of diesel engines. This will allow the implementation of

perspective methods for diagnostics of these types of engines, for which modern diagnostic tools are

inapplicable due to their design features.

KEYWORDS: Diagnosis, angle velocity, acceleration, diagnostic system

INTRODUCTION

The diagnostic systems can be described as the sum of diagnostic tools, diagnosed object and

contractor (operator).

The main stages in the development of diagnostics systems are:

choice of object for diagnosis;

definition of diagnostic parameters which will be measured;

development and testing the system used for measuring the diagnostic parameters;

data processing and analysis of measured parameters;

defining the normative values of diagnostic parameters;

development of algorithms for diagnostics.

The diagnostic systems can be divided into two groups:

systems for control of the performance and the reliability of the technical processes;

systems for definite detection of faults based on type, size and location.

PRINCIPLE OF OPERATION OF THE SYSTEM

Since the system is developed to control the performance and the reliability, as well as to

locate the faults in the diagnosed object, it is required that this system is to measure the value of the

current angular velocity, angular acceleration and cyclic crankshaft speed fluctuation of diesel

engines. The system is designed for diagnostics of diesel engines used in road construction and

agricultural machinery.

The calculation of the current angular velocity and the angular acceleration is based on signals

received from the inductive transducer mounted against the flywheel ring gear. To determine the

current value of the angular velocity and the angular acceleration the duration of the impulses

generated by the transition of two successive flywheel teeth along the sensor are measured. Obtained

in this way, the impulse of unknown duration tx, is filled with signals of known constant frequency

with period Te, received from clock generator. The impulse duration of the measurements is

determined with the following the mathematical relation:

M=tx / Te

where: tx – impulse with unknown duration, Te – constant frequency

At maximum engine speed 3000min-1, the frequency is:

Fmax = 3000/60 = 50 Hz;

T =20ms

For flywheel is with 144 teeth

txmin = 20ms/144 = 138μs

At minimum engine speed 300 min-1

Fmin = 300/60 = 5 Hz;

Т =200ms

txmax = 200ms/144 = 1380μs.

© copyright FACULTY of ENGINEERING ‐ HUNEDOARA, ROMANIA 37

ANNALS OF FACULTY ENGINEERING HUNEDOARA – International Journal Of Engineering

The precision required is taken into account when determining the cyclical fluctuation of the

crankshaft speed. The clock generator’s frequency is determined according to the calculations given in

Table 1. It is estimated that using a clock generator with a frequency of 8MHz gives the required

accuracy for the conducted measurements. The memory capacity used for intermediate data storage

was also subject of consideration when designing the system.

Table 1. The clock generator’s frequency

nmax = 3000 nmin=300

Fген Te

min-1 min-1

1MHz 1 μs 138 1380

2MHz 0.5 μs 276 2760

4MHz 0.250 μs 552 5520

8MHz 0.125 μs 1104 11040

10MHz 0.1μs 1380 13800

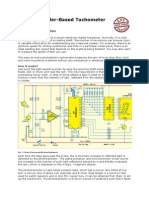

The system is based on single-chip microcontroller ATMEL – АТ89C51. It consists of the following

components: microcontroller ATMEL – АТ89C51, 32kB external memory RAM62256, 16 bit

programmable timer PIT8254, 7474 D-type flip-flop, clock frequency generator - 8MHz, RS232

driver/receiver MAX232, Programmable Peripheral Interface - PPI8255, control panel, display unit and

primary transducer (Fig.1).

Figure 1. Block scheme of the device

The signal frequency received from the transducer is a function of the speed. The length of

each impulse is uneven due to the fluctuation of the crankshaft speed.

The measurement unit is the programmable interval timer PIT 8254, which perform timing and

counting functions. The two channels of clock inputs Clock0 and Clock1 of Timer0 and Timer1, work

successively over time. Nth Impulse tx generated by Nth tooth is measured by Timer0, and N+1 tooth by

Timer1. Each Impulse tx obtained from the sensor allows trough Gate0 or Gate1 the counting of the

Timer0 or Timer1.

D-flip-flop 7474 is set in counter mode. The inverted output Q is connected directly back to the

Data input giving the device “feedback”. It works as a binary divider for frequency division and shifts

the timers input channels. Nth impulse triggers Q and N+1 pulse triggers Q . This triggers the

countdown through Gate0 and Gate1. It allows entry of the reference pulses with period Te from the

clock generator respectively to Timer0 and Timer1.

Available for reading during the measurement of Nth impulse in Timer1 is N-1 pulse (past event),

respectively when measuring pulse N+1, Timer0 reads Nth pulse.

At the end of each period of the input impulse an interruption INT0 is activated. This

interruption serves for reading the completed period from Timer0 and Timer1. A program redirects

the signal reading from Timer0 to Timer1. The resulting number, dimensionless value M, is stored in

sequential order in the external memory. The RAM capacity of 32kB allows 16 384 records.

The parallel interface PPI8255 is a general-purpose I/O interface used to connect the eight

digits, seven segment digital external display unit to the system bus. By pressing the "display" button

38 Tome XI (Year 2013). Fascicule 2. ISSN 1584 – 2665

ANNALS OF FACULTY ENGINEERING HUNEDOARA – International Journal Of Engineering

the data stored in the memory system is displayed successively from 0 to 16,383th measurement. The

function of this peripheral equipment is to help verifying the system’s proper work. Redundant clock

generator with referenced frequency, which simulate signal from the sensor, is used to control the

operation of the measuring system.

When the “measurement” button is pressed, the system goes into a standby. The actual

recording begins when the system receive the signal which simulates the TDC position of the

crankshaft. When the measurement is initiated, a yellow LED indicator lights up. When the system

memory is full, the LEDs are deactivated, which show that the process of data recording is completed.

During the measurement, the process cannot be interrupted (except by hardware Reset of the CPU).

The recorded data can be latter transferred to a PC through COM port.

EXPERIMENTAL RESULTS

The parameter that describe most precisely the diesel engine overall technical condition is the

change in the angular acceleration of the crankshaft during transient state (from idle to maximum

engine speed). Figure 2 shows the engine D240 curve characteristics of the angular velocity change

obtained using the date from the developed device.

Figure 2. Curve of crankshaft angular velocity characteristic in transient state

Another main parameter used to determine the technical condition of the diesel engine is the

internal-cyclical fluctuation (irregular rotation of the crankshaft for one cycle of the engine) at idle

speed. Faults and malfunctions of individual engine cylinders alter the internal cyclical rotation which

leads to fluctuations. The type of a malfunction or failure can be determined by the curve resulted

from the experiments. In order to smooth out the crankshaft fluctuations, the experimental curve is

processed with a moving average filter.

Figure 3. Visualization of the experimental curve (1) after the first (2) smoothing

with moving average filter

Figure 3 presents the experimental curve (1) and curve (2) resulted after first smoothing by

moving average filter. For more accurate analysis on the curve is applied second smoothing, presented

in Figure 4.

Tome XI (Year 2013). Fascicule 2. ISSN 1584 – 2665 39

ANNALS OF FACULTY ENGINEERING HUNEDOARA – International Journal Of Engineering

Figure 4. Visualization of the experimental curve after the first (1) and second (2) smoothing

with moving average filter

CONCLUSIONS

The obtained results indicate that this method can find practical application in the diagnosis of

diesel engines. This will allow the implementation of perspective methods for diagnostics of these

types of engines, for which modern diagnostic tools are inapplicable due to their design features.

For this purpose, it is necessary to carry out further studies in order to determine the

invariance, sensitivity and normative values of diagnostic parameters which will be used.

REFERENCES

[1.] Гарипов, Е. Идентификация на системи, Идентификация чрез непрекъснати модели. ТУ,

София, 2007.

[2.] Karakehayov Z., K. Christensen, O. Winther, Embedded Systems Design with 8051

microcontrollers, Marcel Dekker, 1999.

[3.] Каракехайов З., С. Григоров, Едночипови микрокомпютри. София, 1992.

[4.] Цонев Р., П. Даскалов, Ц. Драганова, Методи за теоретично изследване. Русе, 2010

ANNALS of Faculty Engineering Hunedoara

– International Journal of Engineering

copyright © UNIVERSITY POLITEHNICA TIMISOARA,

FACULTY OF ENGINEERING HUNEDOARA,

5, REVOLUTIEI, 331128, HUNEDOARA, ROMANIA

http://annals.fih.upt.ro

40 Tome XI (Year 2013). Fascicule 2. ISSN 1584 – 2665

You might also like

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- DC Motor System Identification and Speed Control Using dSPACE ToolsDocument14 pagesDC Motor System Identification and Speed Control Using dSPACE ToolsIhab BenayacheNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- TP 02004Document4 pagesTP 02004hyarub9No ratings yet

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsFrom EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNo ratings yet

- CNC MachinesDocument52 pagesCNC Machinespranav sharmaNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- RPM IndicatorDocument39 pagesRPM IndicatorAnkur PatelNo ratings yet

- Digital TachometerDocument5 pagesDigital TachometerSARATH SASINo ratings yet

- CNC System: 2.1 Machine StructureDocument5 pagesCNC System: 2.1 Machine StructurePilar García SímbalaNo ratings yet

- Direct Torque ControlDocument4 pagesDirect Torque Controlsf111No ratings yet

- Computer Numeric Control: Prof. J. Ramkumar Department of Mechanical Engineering IIT KanpurDocument48 pagesComputer Numeric Control: Prof. J. Ramkumar Department of Mechanical Engineering IIT KanpurHassnain MohdNo ratings yet

- Computer Numeric Control: Prof. J. Ramkumar Department of Mechanical Engineering IIT KanpurDocument48 pagesComputer Numeric Control: Prof. J. Ramkumar Department of Mechanical Engineering IIT KanpurAjay VermaNo ratings yet

- CncDocument48 pagesCncabdifatah.nadir.snu.eduNo ratings yet

- Engine Status Monitoring System Using Real Time Clock (ds1307)Document4 pagesEngine Status Monitoring System Using Real Time Clock (ds1307)International Journal of computational Engineering research (IJCER)No ratings yet

- Identification of Torsional Vibration Features in Electrical Powered Rotating EquipmentDocument9 pagesIdentification of Torsional Vibration Features in Electrical Powered Rotating EquipmentHasan PashaNo ratings yet

- Modal Analysis and Condition MonitoringDocument5 pagesModal Analysis and Condition Monitoringbidyutkr30100% (2)

- Triac Application NoteDocument10 pagesTriac Application Notewizardgrt1No ratings yet

- Familiarization With and Performance Check Of, Vibration Testing & Measuring EquipmentDocument33 pagesFamiliarization With and Performance Check Of, Vibration Testing & Measuring EquipmentOmar Saleem100% (1)

- Electro-Hydraulic Controller Functional DescriptionDocument8 pagesElectro-Hydraulic Controller Functional DescriptionvesridharNo ratings yet

- The Design of Soft Starter For AC Motors Based On Single Neuron PI RegulatorDocument5 pagesThe Design of Soft Starter For AC Motors Based On Single Neuron PI RegulatorMega Firdausi NuzullaNo ratings yet

- EHTC Functional DescriptionDocument8 pagesEHTC Functional Descriptionveer_s100% (2)

- IR TachometerDocument10 pagesIR TachometerMohammed Abdulrahman MossaNo ratings yet

- Tech OmeterDocument6 pagesTech OmeterdannycbsNo ratings yet

- 05 - Electro - Hydraulic ControllerDocument7 pages05 - Electro - Hydraulic Controllerwildhoney1979No ratings yet

- 3 Waukesha Gas Engine Maintenance ManualDocument75 pages3 Waukesha Gas Engine Maintenance ManualMamunNo ratings yet

- Dynamic Performance and Analysis of Direct Torque Control Method Based On DSP For PMSM DrivesDocument5 pagesDynamic Performance and Analysis of Direct Torque Control Method Based On DSP For PMSM DrivesRaspy ReddyNo ratings yet

- Data Acquisition: Detectors: TransducersDocument11 pagesData Acquisition: Detectors: TransducersVasile RaduNo ratings yet

- High - Performance Adaptive Intelligent Direct Torque Control Schemes For Induction Motor DrivesDocument24 pagesHigh - Performance Adaptive Intelligent Direct Torque Control Schemes For Induction Motor Drivesmechernene_aek9037No ratings yet

- MCR The Modular Compact Rheometer SeriesDocument20 pagesMCR The Modular Compact Rheometer SeriesKAKAWNo ratings yet

- Technical Feedback EhtcDocument9 pagesTechnical Feedback EhtcPrashant Kumar ChoudharyNo ratings yet

- Position Control of Hybrid Stepper MotorDocument36 pagesPosition Control of Hybrid Stepper MotorAditya ChaudharyNo ratings yet

- Speed Regulation and Torque Ripple Minimization of Induction Motor by DTC With PI and Fuzzy Logic ControllerDocument6 pagesSpeed Regulation and Torque Ripple Minimization of Induction Motor by DTC With PI and Fuzzy Logic ControllerVijay KumarNo ratings yet

- A54 2 Korzeniewski Improved Algorithms of Direct Torque Control MethodDocument11 pagesA54 2 Korzeniewski Improved Algorithms of Direct Torque Control MethodMohamed Elsaid El ShallNo ratings yet

- Signal Processing To Reduce The Effect of Gear DynamicsDocument7 pagesSignal Processing To Reduce The Effect of Gear DynamicsEric BechhoeferNo ratings yet

- Mech Vibrartion Lab2Document13 pagesMech Vibrartion Lab2Edryna AntasyaNo ratings yet

- Mochammad Ilham K - 240110150003Document15 pagesMochammad Ilham K - 240110150003Lambok SinagaNo ratings yet

- NAPS04 Paper OBTorDocument5 pagesNAPS04 Paper OBTorMiguel Paca CentellasNo ratings yet

- (212142518) Stepper Motor Control Using MicrocontrollerDocument4 pages(212142518) Stepper Motor Control Using MicrocontrollerraghavthakurjiNo ratings yet

- Speed Control of BLDC Motor Using DSP: 1 4 1 JNTUH Hyderabad, India 2 JNTUH Hyderabad, IndiaDocument5 pagesSpeed Control of BLDC Motor Using DSP: 1 4 1 JNTUH Hyderabad, India 2 JNTUH Hyderabad, IndiapravnkumarNo ratings yet

- Direct Torque Control of Induction Motor Using Artificial Neural NetworkDocument7 pagesDirect Torque Control of Induction Motor Using Artificial Neural NetworkMohamed SomaiNo ratings yet

- 3-Phase AC Motor Control With V/HZ Speed Closed Loop Using The DSP56F80XDocument24 pages3-Phase AC Motor Control With V/HZ Speed Closed Loop Using The DSP56F80Xrutu_jnecNo ratings yet

- The Drive Design of The STM32-based Brushless DC Motor: Song Wang, Wang Guo, Wenqiang DunDocument9 pagesThe Drive Design of The STM32-based Brushless DC Motor: Song Wang, Wang Guo, Wenqiang DunMarco LisiNo ratings yet

- Direct Torque Control For Induction Motor Using Intelligent Artificial Neural Network TechniqueDocument7 pagesDirect Torque Control For Induction Motor Using Intelligent Artificial Neural Network TechniqueInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Simplified SVPWM Algorithm For VectorDocument4 pagesSimplified SVPWM Algorithm For VectorPrudhvi RajNo ratings yet

- Jeas 0408 94Document7 pagesJeas 0408 94Jun Chee LimNo ratings yet

- PROBLEM STATEMENT FOR TEMPERATURE CONTROL OF POLYHOUSESDocument36 pagesPROBLEM STATEMENT FOR TEMPERATURE CONTROL OF POLYHOUSESAbhishek SinghNo ratings yet

- Semester Project "Computer Numerical Controlled Machine": Ee332 Control Systems Lab - CNC MachineDocument19 pagesSemester Project "Computer Numerical Controlled Machine": Ee332 Control Systems Lab - CNC MachinezakiNo ratings yet

- High Performance Direct Torque Control of Induction Motor Drives Using Space Vector ModulationDocument9 pagesHigh Performance Direct Torque Control of Induction Motor Drives Using Space Vector ModulationMefisto ElNo ratings yet

- Adaptive Bandwidth Approach ON DTC Controlled Induction MotorDocument9 pagesAdaptive Bandwidth Approach ON DTC Controlled Induction MotorijicsjournalNo ratings yet

- Design of A Low-Cost Contact-Less Digital - Like PDFDocument3 pagesDesign of A Low-Cost Contact-Less Digital - Like PDFMed MaxNo ratings yet

- Design and Implementation of A Digital TachometerDocument3 pagesDesign and Implementation of A Digital TachometerInnovative Research Publications0% (1)

- Speed Control of Single Phase Induction Motor Using Infrared Receiver ModuleDocument6 pagesSpeed Control of Single Phase Induction Motor Using Infrared Receiver ModuleSanjay ShelarNo ratings yet

- Speed Measurement Trainer GuideDocument16 pagesSpeed Measurement Trainer Guidehydromec_indiaNo ratings yet

- Direct Torque Control ExplainedDocument7 pagesDirect Torque Control ExplainedAnjana SudarsananNo ratings yet

- 99 000 RPM Contact Less Digital TachometerDocument11 pages99 000 RPM Contact Less Digital TachometerHemanth Kumar K SNo ratings yet

- Mechatronics CEP 2 Designing Control System For Suspension SystemDocument12 pagesMechatronics CEP 2 Designing Control System For Suspension SystemFaizan SamdaniNo ratings yet

- Design of The Sine Wave Generating Circuit Based On The Atmega128A MicrocontrollerDocument5 pagesDesign of The Sine Wave Generating Circuit Based On The Atmega128A MicrocontrollerhamidNo ratings yet

- Thesis Modeling of Two Rotor MIMO SystemDocument68 pagesThesis Modeling of Two Rotor MIMO SystemEyad Al-MohatwaryNo ratings yet

- DC Motor With Speed and Current Closed Loops, Driven by eTPU On MCF523xDocument44 pagesDC Motor With Speed and Current Closed Loops, Driven by eTPU On MCF523xSalman HabibNo ratings yet

- BITS Pilani Hyderabad Campus Engineering Optimization ProblemsDocument6 pagesBITS Pilani Hyderabad Campus Engineering Optimization ProblemsHemanthReddyOntedhuNo ratings yet

- Readynas Os 6.2: Software ManualDocument241 pagesReadynas Os 6.2: Software ManualLA-ZOUBE GAELNo ratings yet

- Vishay Siliconix: Features ApplicationsDocument4 pagesVishay Siliconix: Features ApplicationsJuan CarlosNo ratings yet

- Khaled Yousef CVDocument2 pagesKhaled Yousef CVYusuf ZayedNo ratings yet

- 2 Introduction To Structured Programming and Problem SolvingDocument7 pages2 Introduction To Structured Programming and Problem SolvingA DeshpandeNo ratings yet

- Wk-3802w 1ge+1fe+wifi Dual Mode OnuDocument9 pagesWk-3802w 1ge+1fe+wifi Dual Mode OnupilemkuNo ratings yet

- DVCon Europe 2015 TA1 5 PaperDocument7 pagesDVCon Europe 2015 TA1 5 PaperJon DCNo ratings yet

- As-Interface Network Trouble Shooting GuideDocument16 pagesAs-Interface Network Trouble Shooting Guideenrique benitezNo ratings yet

- Network Interface Converter Net-01X (03X) Owner's Manual 2010-01Document12 pagesNetwork Interface Converter Net-01X (03X) Owner's Manual 2010-01Joshua KaukungwaNo ratings yet

- Software Requirements Specification New FINALDocument15 pagesSoftware Requirements Specification New FINALArñäv VarshneyNo ratings yet

- Vulnerability Analysis and Penetration Testing Project ReportDocument15 pagesVulnerability Analysis and Penetration Testing Project ReportSuba LakshmiNo ratings yet

- Cloud Services For SAP Ariba SolutionsDocument24 pagesCloud Services For SAP Ariba SolutionsLucas DutraNo ratings yet

- Christopher Celio, Krste Asanovic, David PalersonDocument35 pagesChristopher Celio, Krste Asanovic, David PalersonkbkkrNo ratings yet

- Cyber Crime Trend in Bangladesh, An Analysis and Ways Out To Combat The ThreatDocument8 pagesCyber Crime Trend in Bangladesh, An Analysis and Ways Out To Combat The ThreatShahriarNo ratings yet

- Yokogawa DCS System Maintenance Procedures - Inst ToolsDocument31 pagesYokogawa DCS System Maintenance Procedures - Inst ToolsCarlos Jimenez100% (1)

- Day 2 TaskDocument4 pagesDay 2 TaskYaathriganNo ratings yet

- Attacking Hypervisors Via Firmware and Hardware: Alex Matrosov (@matrosov)Document44 pagesAttacking Hypervisors Via Firmware and Hardware: Alex Matrosov (@matrosov)Никита СанкинNo ratings yet

- Install Mountain Lion HackintoshDocument14 pagesInstall Mountain Lion HackintoshCI WongNo ratings yet

- A BIG collection of Unix/Linux ‘grep’ command examplesDocument11 pagesA BIG collection of Unix/Linux ‘grep’ command examplesDaniel GomezNo ratings yet

- SCCM Driver Pack ListDocument3 pagesSCCM Driver Pack ListSwitlana RemetskiNo ratings yet

- Adoption of Cloud Computing in UAEDocument4 pagesAdoption of Cloud Computing in UAEengrrhasanNo ratings yet

- Perform Bus Topology and Star TopologyDocument14 pagesPerform Bus Topology and Star TopologyYagnik SakhiyaNo ratings yet

- Issue149 enDocument57 pagesIssue149 enNick PolaNo ratings yet

- Chapter 3: Service Models: Phan Nguyen Ky Phuc November 13, 2018Document3 pagesChapter 3: Service Models: Phan Nguyen Ky Phuc November 13, 2018ManhNo ratings yet

- Final Report Csc264Document26 pagesFinal Report Csc264ALIA MAISARAH ABDUL RAHMANNo ratings yet

- SAP Digital Vehicle HuDocument46 pagesSAP Digital Vehicle Husuhas.kandeNo ratings yet

- BAPIDocument28 pagesBAPIPRASHANT KUMARNo ratings yet

- Emerging Markets in Voluson S8t BT22Document18 pagesEmerging Markets in Voluson S8t BT22Badr Ibrahim Al-QubatiNo ratings yet

- Salvador Gec MMW Final ExaminationDocument5 pagesSalvador Gec MMW Final ExaminationLucky Jewel Rose SalvadorNo ratings yet

- Install Odoo 11 on Ubuntu 16.04 in 14 StepsDocument13 pagesInstall Odoo 11 on Ubuntu 16.04 in 14 StepsRusdi AdamNo ratings yet

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Tensor Technology Guide: Tensor Ring Benefits and UsesFrom EverandTensor Technology Guide: Tensor Ring Benefits and UsesRating: 5 out of 5 stars5/5 (2)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Autophagy in Health and DiseaseFrom EverandAutophagy in Health and DiseaseBeverly RothermelNo ratings yet

- Environmental and Health and Safety Management: A Guide to ComplianceFrom EverandEnvironmental and Health and Safety Management: A Guide to ComplianceRating: 4 out of 5 stars4/5 (2)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 4.5 out of 5 stars4.5/5 (2)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesFrom EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo ratings yet

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet