Professional Documents

Culture Documents

Hysical Distance Between Equipment: 4.3.1 GASL 1200

Uploaded by

Frank FungOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hysical Distance Between Equipment: 4.3.1 GASL 1200

Uploaded by

Frank FungCopyright:

Available Formats

Operation Instruction

Kilnloq system

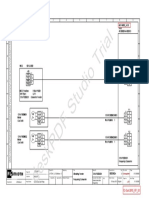

4.2 PHYSICAL DISTANCE BETWEEN EQUIPMENT

Between Gas Monitoring Unit (GMU) and Available length of heated sample line is Total

probe length of hose minus 4 meters (LHeated Hose total –

4m).

Each additional meter will increase the system

response time with one second.

Between Probe and Probe Cooling Probe Cooling should be placed as close to the

KilnLoq probe as possible. (customer

installation)

Between probe and Utility Air Recommended length of air pipe is max. 4 m.

(customer installation)

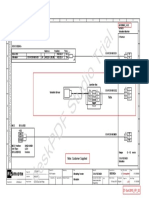

For further information see layout drawing “KilnLoq: System view”.

4.3 ENCLOSURES

Depending on system layout the Gas Monitoring Unit (GMU) could be a “GASloq

1200” or a GASloq CUBE. Furthermore the Kilnloq system can be supplied with at

Field Cabinet. Where the GMU description differs in this manual the text is marked

“GASloq 1200”, “GASloq CUBE” or "Field Cabinet".

More details about system layout are found in the layout drawings

4.3.1 GASLOQ 1200

This is the compact GMU version with all components installed in one cabinet. Electrical

components i.e. PLC, breakers, relays etc. are mounted on the back plate while gas

analyzers and other gas components are mounted in a swing-frame to achieve easy

accessibility.

4.3.2 TECHNICAL INFORMATION ENCLOSURE GASLOQ 1200

See layout drawing: 1200: Cabinet, 1200: Component layout, 1200: swing-frame

Dimension:

Dimensions l x w x h: 1200x 600 x 2100 mm.

Dimensions seaworthy package l x w x h: 1420 x 800 x 2280 mm.

Foundation: 4x12mm for 12mm expansion bolts

Weight:

Weight, dry: Approximately 400 kg.

Weight seaworthy package gross dry: Approximately 570 kg.

Temperatures:

Ambient temperature: 5°C to 40°C

Storage temperature: -15°C to 55°C under roof

Placement:

Analyzer housing In a dust- and vibration-free (max +- 0.04 mm

at 5 to 55 Hz. 0.5 g at 55 to 150 Hz) and well-

ventilated room of min. 6 m2.

Connections:

Gas connections: 6 / 10 mm PVDF fittings.

Drawing no: KilnLoq-400-10 Page 9 of 72

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- FM CODEL GCEM40xx Ap12 PDFDocument6 pagesFM CODEL GCEM40xx Ap12 PDFCandi.nntppNo ratings yet

- 3119-600series Rev2 0912 LRes PDFDocument8 pages3119-600series Rev2 0912 LRes PDFAlper Emrah SakalsızNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- P.1.87.01 Linear Heat Detection CableDocument5 pagesP.1.87.01 Linear Heat Detection CableMartin LlontopNo ratings yet

- Daikin VRV IV CatalogueDocument46 pagesDaikin VRV IV CatalogueNathan Vo100% (5)

- Zeeweed Pressurized Ultrafiltration: Model Zw1500Document2 pagesZeeweed Pressurized Ultrafiltration: Model Zw1500Praveen KumarNo ratings yet

- Duct Detector InstallationDocument6 pagesDuct Detector InstallationBinu SulochananNo ratings yet

- High Temperature Ultrasonic TestingDocument3 pagesHigh Temperature Ultrasonic TestingCarlos Bustamante100% (1)

- Insulation For Flowlines and RisersDocument23 pagesInsulation For Flowlines and Risersvpandya1981No ratings yet

- 6 Channel Long Distance Drone Gun Jammer: Model No.: TX-Q06Document5 pages6 Channel Long Distance Drone Gun Jammer: Model No.: TX-Q06Raul CostiniucNo ratings yet

- Laminar Flow ManualDocument16 pagesLaminar Flow ManualJOSHUA KETERNo ratings yet

- Fire Fighting SystemDocument17 pagesFire Fighting SystemAshutosh NayakNo ratings yet

- AMS ANALITICA-AIRFLOW PUF BrochureDocument2 pagesAMS ANALITICA-AIRFLOW PUF BrochureShady HellaNo ratings yet

- Kilnloq Datasheet 270910 PDFDocument40 pagesKilnloq Datasheet 270910 PDFFranz Alegria50% (2)

- DustGuard Spec Sheet V2-ENDocument3 pagesDustGuard Spec Sheet V2-ENrubenNo ratings yet

- Picoflow: Continuous Ow Measurement at Low Solid/Air RatiosDocument4 pagesPicoflow: Continuous Ow Measurement at Low Solid/Air RatiosDuc Duong TichNo ratings yet

- Manual ZG0 EngDocument16 pagesManual ZG0 Engeeng_nnabilNo ratings yet

- XRS5 ManualDocument24 pagesXRS5 ManualEric MaldonadoNo ratings yet

- Operator's Manual: 10 Minute 3,800 RPM 5 Minute 1,800 RPMDocument6 pagesOperator's Manual: 10 Minute 3,800 RPM 5 Minute 1,800 RPMPablo SalcedoNo ratings yet

- GSL 1100X6Document19 pagesGSL 1100X6Adolfo LopezNo ratings yet

- Black Eagle Hose BE 4466-UKDocument44 pagesBlack Eagle Hose BE 4466-UKmhollowayNo ratings yet

- Polycold Edwards Data Sheet Maxcool 4000HDocument2 pagesPolycold Edwards Data Sheet Maxcool 4000HAndrea Veronica Hernandez AmatoNo ratings yet

- Polycold Edwards Data Sheet Maxcool 4000HDocument2 pagesPolycold Edwards Data Sheet Maxcool 4000HadrianioantomaNo ratings yet

- TDS NF-334pDocument2 pagesTDS NF-334pamp.kaunasNo ratings yet

- ITP Steam TurbineDocument4 pagesITP Steam Turbinecandra trisilawatiNo ratings yet

- ProReact Digital LHD Installation InstructionsDocument11 pagesProReact Digital LHD Installation InstructionsAlexandru CraiovanNo ratings yet

- Hvac Comparisons Tech-CommDocument4 pagesHvac Comparisons Tech-Commpsn_kylmNo ratings yet

- DP33 NemaDocument3 pagesDP33 NemaAnonymous w63sFQiQNo ratings yet

- Gas Turbines Note PDF 10220 en Us 2005 1Document4 pagesGas Turbines Note PDF 10220 en Us 2005 1PhongNo ratings yet

- Operating Manual: Infrared Point Gas Detector GD10-P00Document28 pagesOperating Manual: Infrared Point Gas Detector GD10-P00bango7886No ratings yet

- Ketapang Coal Fired Power Plant Ash Handling Operation ManualDocument24 pagesKetapang Coal Fired Power Plant Ash Handling Operation ManualKulata IrminaNo ratings yet

- CLS50Document16 pagesCLS50sopan saNo ratings yet

- Atex Ii 3 G Wdg-Hpii SeriesDocument4 pagesAtex Ii 3 G Wdg-Hpii SeriesEsteban Alejandro CatrilNo ratings yet

- Manual Zaf-Zdaf EngDocument20 pagesManual Zaf-Zdaf EngIulian TitaNo ratings yet

- SOLAS Fire ExtinguisherDocument6 pagesSOLAS Fire ExtinguisherRavi GuptaNo ratings yet

- Pbe1202 PDFDocument2 pagesPbe1202 PDFMarco LondonNo ratings yet

- Trace Dissolved Oxygen Sensor: Model 499A TrdoDocument4 pagesTrace Dissolved Oxygen Sensor: Model 499A TrdoNIRINTSOA Samoelinica Nanah SidonieNo ratings yet

- Olympus Thickness GagesDocument8 pagesOlympus Thickness GagessukimeNo ratings yet

- Procal 2000 IR Emissions AnalyserDocument4 pagesProcal 2000 IR Emissions AnalyserMeindert gerssenNo ratings yet

- g3620 Sgoas Brochure 2012Document4 pagesg3620 Sgoas Brochure 2012Khasin FuadiNo ratings yet

- Cold Venting As API 521 To Discharge HCDocument4 pagesCold Venting As API 521 To Discharge HCkenoly123100% (1)

- Roots Comodities, Rev. Technical DescriptionDocument56 pagesRoots Comodities, Rev. Technical Descriptionnu.arabiaNo ratings yet

- CO2 System PresentationDocument23 pagesCO2 System PresentationPankaj PandeyNo ratings yet

- Zero Air For Gas Chromatography: Market Application PublicationDocument2 pagesZero Air For Gas Chromatography: Market Application PublicationSrinivasan RaviNo ratings yet

- Pentair Rotary Valve Whole House Carbon Filter ManualDocument28 pagesPentair Rotary Valve Whole House Carbon Filter Manualsquadron2k19No ratings yet

- C413-Line 3 ManualDocument80 pagesC413-Line 3 ManualGenrry Alejandro Echaccaya CuroNo ratings yet

- CSI-195C Radiant Panel BrochureDocument5 pagesCSI-195C Radiant Panel BrochureNitin ShenoyNo ratings yet

- GES-18 MKII - Free Fall LifeboatDocument7 pagesGES-18 MKII - Free Fall LifeboatFiqri Permana MohamadNo ratings yet

- Owner & Operator's Manual: ModelsDocument16 pagesOwner & Operator's Manual: ModelskmpoulosNo ratings yet

- 80010735V01 PDFDocument2 pages80010735V01 PDFClaudia Vergara CaloguereaNo ratings yet

- 9.0 Dust Collection SystemsDocument15 pages9.0 Dust Collection SystemsNol BarandonNo ratings yet

- Agilent 6890n DatasheetDocument5 pagesAgilent 6890n DatasheetMayar SayedNo ratings yet

- Through Circulation Dryer: Used ForDocument4 pagesThrough Circulation Dryer: Used ForYosses Sang NahkodaNo ratings yet

- Mech3005 Lab1112 Fancoil PDFDocument5 pagesMech3005 Lab1112 Fancoil PDFbilal almelegy100% (1)

- North EastDocument6 pagesNorth EastVikash TrivediNo ratings yet

- Technical Specifications For 33 KV Xlpe Insulated Underground Cables 1. ScopeDocument22 pagesTechnical Specifications For 33 KV Xlpe Insulated Underground Cables 1. Scopethumula.rameshNo ratings yet

- Smoke Detector - Duct Mounted Housing - DNRWDocument6 pagesSmoke Detector - Duct Mounted Housing - DNRWrhomadonaNo ratings yet

- 20210921-02 Ecology UnitDocument3 pages20210921-02 Ecology UnitQNBNo ratings yet

- 5.5.2 P H S L: Ower Connection To Eated Ample INEDocument1 page5.5.2 P H S L: Ower Connection To Eated Ample INEFrank FungNo ratings yet

- Pag 102Document1 pagePag 102Frank FungNo ratings yet

- Pag 104Document1 pagePag 104Frank FungNo ratings yet

- Arning Hazardous VoltagesDocument1 pageArning Hazardous VoltagesFrank FungNo ratings yet

- Pag 103Document1 pagePag 103Frank FungNo ratings yet

- 591 - Pagina 6Document1 page591 - Pagina 6Frank FungNo ratings yet

- 591 - Pagina 5Document1 page591 - Pagina 5Frank FungNo ratings yet

- 591 - Pagina 2Document1 page591 - Pagina 2Frank FungNo ratings yet

- 591 - Pagina 3Document1 page591 - Pagina 3Frank FungNo ratings yet

- 591 - Pagina 7Document1 page591 - Pagina 7Frank FungNo ratings yet

- Grundfosliterature 458842354Document12 pagesGrundfosliterature 458842354Frank FungNo ratings yet

- 591 - Pagina 8Document1 page591 - Pagina 8Frank FungNo ratings yet

- 591 - Pagina 4Document1 page591 - Pagina 4Frank FungNo ratings yet

- Eng 132213Document2 pagesEng 132213Frank FungNo ratings yet

- Wm3096 ProgrammingDocument15 pagesWm3096 ProgrammingFrank FungNo ratings yet

- The Secret of Forgiveness of Sin and Being Born Again by Pastor Ock Soo Park 8985422367Document5 pagesThe Secret of Forgiveness of Sin and Being Born Again by Pastor Ock Soo Park 8985422367Justinn AbrahamNo ratings yet

- Assignment 1 SolutionDocument11 pagesAssignment 1 SolutionKash TorabiNo ratings yet

- Lazard Levelized Cost of Storage v20Document46 pagesLazard Levelized Cost of Storage v20macNo ratings yet

- BagbagtoDocument3 pagesBagbagtoJayson Valentin EscobarNo ratings yet

- Mechatronic ApplicationsDocument31 pagesMechatronic ApplicationsDevice SamsungNo ratings yet

- Sow and Learning ObjectivesDocument14 pagesSow and Learning ObjectivesEhsan AzmanNo ratings yet

- AS Film Production Lesson.Document13 pagesAS Film Production Lesson.MsCowanNo ratings yet

- Sense and NonsenseDocument263 pagesSense and NonsenseAbdulRehmanKhilji100% (1)

- December 2022 Issue: More Transparency, P S An R T e R o M, y C en Ar P P, y PDocument24 pagesDecember 2022 Issue: More Transparency, P S An R T e R o M, y C en Ar P P, y Pwpp8284No ratings yet

- Safe Use of Power Tools Rev0Document92 pagesSafe Use of Power Tools Rev0mohapatrarajNo ratings yet

- How To Install Mesa (OpenGL) On Linux Mint - 6 StepsDocument2 pagesHow To Install Mesa (OpenGL) On Linux Mint - 6 Stepsankitfrnd45No ratings yet

- Chapter 4Document20 pagesChapter 4Vandan GundaleNo ratings yet

- Scriptcase MacrosDocument6 pagesScriptcase MacrosMeliana WangNo ratings yet

- Cure Jealousy WorksheetsDocument20 pagesCure Jealousy WorksheetsSelina CothrenNo ratings yet

- English Paper 1 Mark Scheme: Cambridge Lower Secondary Sample Test For Use With Curriculum Published in September 2020Document11 pagesEnglish Paper 1 Mark Scheme: Cambridge Lower Secondary Sample Test For Use With Curriculum Published in September 2020ABEER RATHINo ratings yet

- Manual de Caja Eaton Fuller ET20113Document22 pagesManual de Caja Eaton Fuller ET20113Juan Gomez100% (3)

- Tata Motors - Strategic ManagementDocument16 pagesTata Motors - Strategic ManagementVaishakh MenonNo ratings yet

- Smartpilot s1 s1g Service ManualDocument30 pagesSmartpilot s1 s1g Service Manualmalte winbaldNo ratings yet

- Unit 5-People Should Manage Nature-Ts-Planning Guide-Grade 5Document1 pageUnit 5-People Should Manage Nature-Ts-Planning Guide-Grade 5api-457240136No ratings yet

- CH 11 International TradeDocument20 pagesCH 11 International TradeSANTU GHORAINo ratings yet

- Acid Bases and Salts Previous Year Questiosn Class 10 ScienceDocument5 pagesAcid Bases and Salts Previous Year Questiosn Class 10 Scienceclashhunting123123No ratings yet

- Case AnalyzerDocument19 pagesCase AnalyzeranuragNo ratings yet

- Monorail Hoist SystemDocument17 pagesMonorail Hoist SystemypatelsNo ratings yet

- EmbOS GenericDocument324 pagesEmbOS Genericbogd33No ratings yet

- Parafusos PT SemblexDocument10 pagesParafusos PT SemblexSBonderNo ratings yet

- Semi Formal Asking To Borrow BooksDocument75 pagesSemi Formal Asking To Borrow BooksPei Cheng WuNo ratings yet

- PURL Questions and AnswersDocument3 pagesPURL Questions and AnswersSHAHAN VS100% (5)

- BronchiolitisDocument5 pagesBronchiolitisreshianeNo ratings yet

- Plastics Library 2016 enDocument32 pagesPlastics Library 2016 enjoantanamal tanamaNo ratings yet

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Casing and Liners for Drilling and Completion: Design and ApplicationFrom EverandCasing and Liners for Drilling and Completion: Design and ApplicationRating: 5 out of 5 stars5/5 (3)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Oil: An Overview of the Petroleum IndustryFrom EverandOil: An Overview of the Petroleum IndustryRating: 4.5 out of 5 stars4.5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- An Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsFrom EverandAn Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsNo ratings yet

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationFrom EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationRating: 4.5 out of 5 stars4.5/5 (2)

- 100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonFrom Everand100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)