Professional Documents

Culture Documents

Zero Air For Gas Chromatography: Market Application Publication

Uploaded by

Srinivasan RaviOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zero Air For Gas Chromatography: Market Application Publication

Uploaded by

Srinivasan RaviCopyright:

Available Formats

Zero Air for Gas

Chromatography

Market Application Publication

Background:

Flame ionization detection (FID), a com-

monly used detection technique for gas

chromatography which involves passing a

separated sample through a hydrogen-air

flame to ionize a sample, is considerably

more sensitive than thermal ionization for a

broad range of compounds. FID is typically

used to detect volatile organic compounds

to nanogram levels. The air for the flame is

added to the detector after the separation

and the sensitivity is dependent on the abil-

ity of the detector to discriminate between

the background signal and the signal from

the compound(s) of interest. Zero Air, which

contains <0.1 ppm of hydrocarbons, is typi-

cally used as the oxidant.

In many laboratories, Zero Air is synthetic

air provided by an expensive high-pressure

gas cylinder. While this is a satisfactory

method, the use of an in-house generator to

provide Zero Air for FID detection is safer,

more convenient, more reliable and more

economical than the use of high pressure

cylinders. An in-house Zero Air generator is

completely automatic and requires a mini-

mum of maintenance.

Features and Benefits:

• Generates UHP Zero Air with total • Extremely low cost of operation,

hydrocarbon concentration (THC) no hidden costs (demurrage,

to <0.05 ppm maintaining inventory). Payback

• Low hydrocarbon concentration period typically less than one year

i n c re a s e s t h e a c c u r a c y a n d • Operates on a 24 hrs./day,

sensitivity of FID detection 7 days/week basis with minimum

• Eliminates buying and installation of maintenance

bulky and hazardous compressed • Models available to provide zero air

air tanks to up to 66 FID’s

• Prevents running out of gas during

instrument operation

MAP_ZeroAirForGC.indd 1 7/25/2012 11:29:27 AM

Application: Case Study:

UHP Zero Air systems for Gas Chromatog- Dr. Mike Jordan of Agriculture Canada FID detector is powered up on a continuous

raphy provided by Parker Balston Zero Air (Kentville, NS, Canada), who analyzes vola- basis on and an analytical measurement can

Generators employ a four step process in- tile anaerobic compounds in fruit samples be made whenever required. The detectors

cluding filtration, hydrocarbon removal, cool- reported that the use of an in-house gas are now calibrated on a periodic basis that

ing and final filtration to produce the required generator allows his laboratory to keep the is convenient to the analysis schedule. This

level of purity. Two stages of high efficiency FID detectors on their GC’s powered up on protocol saves a considerable amount of

coalescing pre-filtration are employed to re- a 24/7 basis. Previously, the detectors were time and maximizes laboratory efficiency.

move oil and particulate contamination. The powered up only when analyses were to be In-house generation of the gas also elimi-

air is then passed through a heated catalysis performed to minimize the consumption of nates the need for periodic changing of the

module to oxidize hydrocarbons into carbon the gas cylinders which were high in cost. gas tank, which also required recalibration

dioxide and water. The air is then cooled and When the FID was powered up, it was neces- of the FID. An additional benefit of less

passed through a final membrane filter to sary to recalibrate the FID before analytical frequent calibration is that it is no longer

remove all particles >0.01 micron. measurements could be taken and a signifi- necessary to train each technician in the

cant amount of time was expended before calibration process.

measurements could be taken. Since the

installation of an in-house gas generator, the

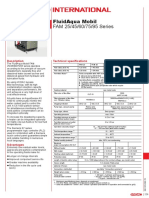

Specifications:

Zero Air Generators 75-83 HPZA-3500 HPZA-7000 HPZA-18000 HPZA-30000

Outlet Hydrocarbon

Concentration (as Methane) <0.1 ppm <0.05 ppm <0.05 ppm <0.05 ppm <0.1 ppm

Outlet Zero Air Flow Rate 1 L/min 3.5 L/min 7.0 L/min 18 L/min 30 L/min

Min/Max Air Pressure 40/125 psig 40/125 psig 40/125 psig 40/125 psig 40/125 psig

Pressure Drop @ Max Flow Rate 4 psig 4 psig 4 psig 4 psig 4 psig

Max Inlet Air Temperature 78°F (25°C) 78°F (25°C) 78°F (25°C) 78°F (25°C) 78°F (25°C)

Inlet/Outlet Ports 1/4” NPT 1/4” NPT 1/4” NPT 1/4” NPT 1/4” NPT

Startup Time for Specified

Hydrocarbon Concentration 45 min 45 min 45 min 45 min 45 min

Electrical Requirements(1) 120 VAC/60 Hz, 120 VAC/60 Hz, 120 VAC/60 Hz, 120 VAC/60 Hz, 120 VAC/60 Hz,

0.5 Amps 2 Amps 2 Amps 4 Amps 4 Amps

Dimensions 10”W x 3”D x 12”H 11”W x 13”D x16”H

(25cm x 8cm x 30cm) (27cm x 34cm x 42cm)

Shipping Weight 7 lb. (3 kg) 41 lbs. (19 kg) 41 lbs. (19 kg) 41 lbs. (19 kg) 41 lbs. (19 kg)

Ordering Information

Description Model Number

Zero Air Generator 75-83, HPZA-3500, HPZA-7000, HPA-18000, HPZA-30000

Maintenance Kit Model 75-83: MK7583 HPZA Models: MK7840

Installation Kit IK76803

Preventive Maintenance Plan 75-83-PM, HPZA-3500-PM, HPZA-7000-PM, HPZA-18000-PM, HPZA-30000-PM

Extended Support with 75-83-DN2, HPZA-3500-DN2, HPZA-7000-DN2, HPZA-18000-DN2, HPZA-30000-DN2

24 Month Warranty

Notes: 1. Electrical requirements are for North America; see product catalog and voltage appendix for electrical and plug configurations for locations outside North America.

© 2010, 2012 Parker Hannifin Corporation MAP Zero Air GC-A Reprinted Aug 2012

Parker Hannifin Corporation

Filtration and Separation Division

242 Neck Road

Haverhill, MA 01835

phone 800 343 4048 or 978 858 0505

fax 978 556 7501

www.labgasgenerators.com

MAP_ZeroAirForGC.indd 2 7/25/2012 11:29:27 AM

You might also like

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Filtros Sealkeen Emflon IIDocument2 pagesFiltros Sealkeen Emflon IItheflamebearerNo ratings yet

- FM CODEL GCEM40xx Ap12 PDFDocument6 pagesFM CODEL GCEM40xx Ap12 PDFCandi.nntppNo ratings yet

- Transformer Oil - DGA - From Sampling To AnalysisDocument47 pagesTransformer Oil - DGA - From Sampling To Analysislbk50100% (4)

- PBDocument6 pagesPBdalton2003100% (1)

- Arde Respira Ç ÃoDocument8 pagesArde Respira Ç ÃoSuprimentos IndaloNo ratings yet

- Novasulf HG400: On Line Hydrogen Sulphide Gas AnalyserDocument2 pagesNovasulf HG400: On Line Hydrogen Sulphide Gas Analysersyifa hananiaNo ratings yet

- PSA Oxygen Generator: Typical ApplicationsDocument2 pagesPSA Oxygen Generator: Typical ApplicationsRajdeepsinhNo ratings yet

- Dräger X-Pid 9000/9500 Multi-Gas Detection: Sensor Unit Integrated Photoionisation Detector (PID) Control UnitDocument8 pagesDräger X-Pid 9000/9500 Multi-Gas Detection: Sensor Unit Integrated Photoionisation Detector (PID) Control UnitShubham SharmaNo ratings yet

- ATI Aerosol Photometer & Aerosol Generator Basics: NAFA Meeting April 18, 2012 Scottsdale, AZDocument41 pagesATI Aerosol Photometer & Aerosol Generator Basics: NAFA Meeting April 18, 2012 Scottsdale, AZDivyansh BansalNo ratings yet

- Transformer TestsDocument54 pagesTransformer TestsMohammedSaadaniHassani75% (4)

- CO2 System PresentationDocument23 pagesCO2 System PresentationPankaj PandeyNo ratings yet

- Compressed Air Dryer Installation GuideDocument17 pagesCompressed Air Dryer Installation GuidelwinooNo ratings yet

- 6890 GC Site Preparation ChecklistDocument4 pages6890 GC Site Preparation Checklistigor_239934024No ratings yet

- FMGCEM40xx Series: Flue Gas AnalyserDocument6 pagesFMGCEM40xx Series: Flue Gas AnalyserMeindert gerssenNo ratings yet

- DTV Zero Purge Compressed Air DryersDocument4 pagesDTV Zero Purge Compressed Air DryersgauravvtyagiNo ratings yet

- ANALYTICS International: Hydrocarbon Analyser Thermo-FID PTDocument4 pagesANALYTICS International: Hydrocarbon Analyser Thermo-FID PTSumeet Sisir SarkarNo ratings yet

- Baseline THA Series 9000 - BrochureDocument2 pagesBaseline THA Series 9000 - Brochurecpl2304No ratings yet

- How To Increase Crude Throughput in Desalter ApplicationsDocument28 pagesHow To Increase Crude Throughput in Desalter ApplicationsAnonymous bHh1L1No ratings yet

- Development of Emission Factors From API 622 - 624 Test Data - Buzz Harris - Bronson PateDocument23 pagesDevelopment of Emission Factors From API 622 - 624 Test Data - Buzz Harris - Bronson PateratnakarpatilNo ratings yet

- Xylem Introduction To Sanitaire AerationDocument46 pagesXylem Introduction To Sanitaire AerationOscar GarciaNo ratings yet

- Daniel Compact Prover: ProversDocument12 pagesDaniel Compact Prover: ProversCarlos EduardoNo ratings yet

- Compact Prover Datasheet PDFDocument12 pagesCompact Prover Datasheet PDFMary Soledad Huarcaya EspinoNo ratings yet

- Signet 2536 Rotor-X Paddlewheel Flow SensorsDocument6 pagesSignet 2536 Rotor-X Paddlewheel Flow SensorsMETHOR SERVICE GROUPNo ratings yet

- Transformer Tests: Oil Tests and On-Line Monitoring Can Increase Transformer Life ExpectancyDocument50 pagesTransformer Tests: Oil Tests and On-Line Monitoring Can Increase Transformer Life ExpectancyMadalena SaraivaNo ratings yet

- Analizador HACHDocument4 pagesAnalizador HACHJADNo ratings yet

- Model 201C VOC Analyzer With PID or FID Detector 613Document8 pagesModel 201C VOC Analyzer With PID or FID Detector 613Dr. John " Jack" driscollNo ratings yet

- PS1411 DC StandardsDocument5 pagesPS1411 DC StandardsGiovanny MosqueraNo ratings yet

- Quincy - DesicantAirDryers 002 0617Document12 pagesQuincy - DesicantAirDryers 002 0617mc indusrial servicesNo ratings yet

- Eurofid Extractive AnalyzerDocument8 pagesEurofid Extractive AnalyzerCristian FernandezNo ratings yet

- Centrox: PSA Oxygen GeneratorDocument2 pagesCentrox: PSA Oxygen GeneratorRon PoteNo ratings yet

- Procal 2000 IR Emissions AnalyserDocument4 pagesProcal 2000 IR Emissions AnalyserMeindert gerssenNo ratings yet

- Portable Oxygen DeviceDocument70 pagesPortable Oxygen DevicemadhurNo ratings yet

- Sonimix 2106 Gas Dilution Calibrator: Key Benefits Accuracy Stability ApplicationsDocument2 pagesSonimix 2106 Gas Dilution Calibrator: Key Benefits Accuracy Stability ApplicationsДмитрий ТарасенкоNo ratings yet

- Portable FIDDocument4 pagesPortable FIDJennifer MaclachlanNo ratings yet

- PRPP 2013 Crude Oil PropertiesDocument7 pagesPRPP 2013 Crude Oil PropertiesMohamed AlaaNo ratings yet

- Plug LX-15T and LX-30T Liquefaction PproductsDocument2 pagesPlug LX-15T and LX-30T Liquefaction PproductsLiu YangtzeNo ratings yet

- Dry Desciccant Engineering ReferenceDocument18 pagesDry Desciccant Engineering ReferenceMinh TranNo ratings yet

- Condensate - Recovery - Solutions SB S71 02 ENDocument16 pagesCondensate - Recovery - Solutions SB S71 02 ENpxpingenieriaNo ratings yet

- PCUG BaltimoreDocument36 pagesPCUG BaltimoreJoseph RileyNo ratings yet

- Engineered Nitrogen Generator Systems - E4Document8 pagesEngineered Nitrogen Generator Systems - E4herdin56No ratings yet

- En7613 5 03 19 - Fam25 - 95 PDFDocument8 pagesEn7613 5 03 19 - Fam25 - 95 PDFhamsterNo ratings yet

- En7613 5 03 19 - Fam25 - 95 PDFDocument8 pagesEn7613 5 03 19 - Fam25 - 95 PDFhamsterNo ratings yet

- RS384 - Precision Nitrogen Standard Data Sheet Rev 5 RSID 384 EN LRDocument2 pagesRS384 - Precision Nitrogen Standard Data Sheet Rev 5 RSID 384 EN LRtofy kiNo ratings yet

- PSA Oxygen Generator: FeaturesDocument2 pagesPSA Oxygen Generator: FeaturesMukesh DubeyNo ratings yet

- Direct Cold Plasma: The Innovative Answer To Odour Control in The Food and Feed IndustryDocument4 pagesDirect Cold Plasma: The Innovative Answer To Odour Control in The Food and Feed IndustryInternational Aquafeed magazineNo ratings yet

- Chlorine Dioxide Generator Systems: Capacity OverviewDocument2 pagesChlorine Dioxide Generator Systems: Capacity OverviewOchoa Para La BandaNo ratings yet

- 2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFDocument9 pages2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFfawadintNo ratings yet

- Donaldson Report11Document8 pagesDonaldson Report11aimsNo ratings yet

- PL-3900 Battery Room Ventilation SystemDocument2 pagesPL-3900 Battery Room Ventilation SystemismailayarNo ratings yet

- Fral FDW62 Spec SheetDocument1 pageFral FDW62 Spec SheetmoisturecarevidsNo ratings yet

- HEPA Filter Leak Test PDFDocument34 pagesHEPA Filter Leak Test PDFjoe bloggs100% (1)

- Online Training Module: R410a & R32 Refrigerant SystemsDocument77 pagesOnline Training Module: R410a & R32 Refrigerant Systemsazlinna ujangNo ratings yet

- Signet 515 Rotor-X Paddlewheel Flow Sensors: FeaturesDocument6 pagesSignet 515 Rotor-X Paddlewheel Flow Sensors: FeaturesJonhatan SilvaNo ratings yet

- R410a GuideDocument18 pagesR410a Guideapi-19789368No ratings yet

- HEPA Filter Leak Test PDFDocument38 pagesHEPA Filter Leak Test PDFEhsan BadarNo ratings yet

- Generator Hydrogen PurggingDocument8 pagesGenerator Hydrogen PurggingsambhuNo ratings yet

- Boilers EmissionDocument2 pagesBoilers EmissionGopinath KaliyaperumalNo ratings yet

- Paper, 49th Annual Syp, ADDocument12 pagesPaper, 49th Annual Syp, ADPhilNo ratings yet

- Biofuge Fresco 100V-120V Green EnglishDocument70 pagesBiofuge Fresco 100V-120V Green EnglishAndrew Holmes80% (5)

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- EPR Vs EPDMDocument1 pageEPR Vs EPDMSrinivasan RaviNo ratings yet

- Self Control - In.spiritual - Practice ImersonDocument98 pagesSelf Control - In.spiritual - Practice ImersonTodorov Shabanski TodorNo ratings yet

- Ashtavakra Gita EbookDocument60 pagesAshtavakra Gita EbookJayraj08No ratings yet

- The Vedanta SutrasDocument399 pagesThe Vedanta Sutrasapi-3716165No ratings yet

- Internal Tooth Lockwasher SpecificationDocument2 pagesInternal Tooth Lockwasher Specificationsharkdude1134100% (1)

- Ab HumidityDocument1 pageAb HumiditySrinivasan RaviNo ratings yet

- Gate ValveDocument3 pagesGate ValveSrinivasan RaviNo ratings yet

- 2 Days ShiftDocument8 pages2 Days ShiftSrinivasan RaviNo ratings yet

- Ab HumidityDocument1 pageAb HumiditySrinivasan RaviNo ratings yet

- 2 Days ShiftDocument8 pages2 Days ShiftSrinivasan RaviNo ratings yet

- 38 Study On Corrosion Failure Analysis and Mechanism of Stainless Steel Pipe Welding Joint in Seawat PDFDocument6 pages38 Study On Corrosion Failure Analysis and Mechanism of Stainless Steel Pipe Welding Joint in Seawat PDFSrinivasan RaviNo ratings yet

- 5 MicrobiallyInfluencedCorrosionDocument5 pages5 MicrobiallyInfluencedCorrosionSrinivasan RaviNo ratings yet

- Astm Standards: S. NO. Description Standard No. No. of CopiesDocument1 pageAstm Standards: S. NO. Description Standard No. No. of CopiesSrinivasan RaviNo ratings yet

- True Love is Accepting What IsDocument4 pagesTrue Love is Accepting What IsSrinivasan RaviNo ratings yet

- Ashtavakra Gita EbookDocument60 pagesAshtavakra Gita EbookJayraj08No ratings yet

- Arunakirinatar Aruliya "Tiruppukaz" Part 1 (Verses 1-330)Document259 pagesArunakirinatar Aruliya "Tiruppukaz" Part 1 (Verses 1-330)StallinNo ratings yet

- Washer Lock HicollarsplitDocument1 pageWasher Lock HicollarsplitSrinivasan RaviNo ratings yet

- Washer Lock HicollarsplitDocument1 pageWasher Lock HicollarsplitSrinivasan RaviNo ratings yet

- 07 Leakage RedDocument10 pages07 Leakage RedSrinivasan RaviNo ratings yet

- A Guide To Shaft SealsDocument5 pagesA Guide To Shaft SealsSrinivasan RaviNo ratings yet

- Washer Lock Hicollarsplit PDFDocument1 pageWasher Lock Hicollarsplit PDFSrinivasan RaviNo ratings yet

- LappingDocument25 pagesLappingSrinivasan Ravi100% (1)

- Internal Tooth Lockwasher SpecificationDocument2 pagesInternal Tooth Lockwasher Specificationsharkdude1134100% (1)

- 2 Days ShiftDocument8 pages2 Days ShiftSrinivasan RaviNo ratings yet

- Er.Sulthan's Ayurvedic Home RemediesDocument321 pagesEr.Sulthan's Ayurvedic Home Remediesarunram86100% (2)

- Biodiesel: An Alternative Fuel Made From Plants and AnimalsDocument8 pagesBiodiesel: An Alternative Fuel Made From Plants and AnimalsSrinivasan RaviNo ratings yet

- Washer Lock HicollarsplitDocument1 pageWasher Lock HicollarsplitSrinivasan RaviNo ratings yet

- Er.Sulthan's Ayurvedic Home RemediesDocument321 pagesEr.Sulthan's Ayurvedic Home Remediesarunram86100% (2)

- Cathodic ProtectionDocument2 pagesCathodic ProtectionSrinivasan RaviNo ratings yet

- Lecture 4 Scab Formation On Castings SurfacesDocument57 pagesLecture 4 Scab Formation On Castings SurfacesLuis Arturo RamirezNo ratings yet

- Kinetics of Particles Lecture Note (2nd Newton Law)Document40 pagesKinetics of Particles Lecture Note (2nd Newton Law)Ainni MazlanNo ratings yet

- Sampling TechniquesDocument17 pagesSampling TechniquesDebjyoti SanyalNo ratings yet

- WLP and DLP3 Aug. 30 Sep. 3 Earths Internal StructureDocument4 pagesWLP and DLP3 Aug. 30 Sep. 3 Earths Internal StructureMariel LolincoNo ratings yet

- J Surfcoat 2004 10 056Document6 pagesJ Surfcoat 2004 10 056Iwan NovalNo ratings yet

- 414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si UnitsDocument3 pages414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si UnitsGuruh Mehra MulyanaNo ratings yet

- Al Farawati1997Document10 pagesAl Farawati1997NURUL FAIKA JNo ratings yet

- UntitledDocument99 pagesUntitledBhuvanNo ratings yet

- Astm D 3341Document4 pagesAstm D 3341Manuel GuzmanNo ratings yet

- Niog Plates2Document12 pagesNiog Plates2YVAN GUEEN M. NIOGNo ratings yet

- Prism Pa Nitrogen Membrane SeparatorsDocument8 pagesPrism Pa Nitrogen Membrane SeparatorsjosalkNo ratings yet

- Electrical Property of Ceramic and PolymerDocument32 pagesElectrical Property of Ceramic and PolymerbawokeNo ratings yet

- Grit ChamberDocument3 pagesGrit Chambergaur_shashikant4432No ratings yet

- Qualis Eng II PDFDocument30 pagesQualis Eng II PDFChris_Oliveira85No ratings yet

- Widmanstätten StructuresDocument3 pagesWidmanstätten StructuresdantegimenezNo ratings yet

- BYK FL-TI1 FloorCoatings enDocument16 pagesBYK FL-TI1 FloorCoatings enKinhNguyenNo ratings yet

- European Steel and Alloy Grades: About Us EN 10025-2Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10025-2farshid KarpasandNo ratings yet

- Effective atomic numbers of organic compoundsDocument7 pagesEffective atomic numbers of organic compoundsHala SweetNo ratings yet

- Ethylene GlycolDocument8 pagesEthylene GlycoljeswinNo ratings yet

- Rubiag 13Document1 pageRubiag 13ChérubinNo ratings yet

- Aluminum Bronze Properties and ApplicationsDocument3 pagesAluminum Bronze Properties and ApplicationsAbbasNo ratings yet

- CM113P - 12.22.19 - Activity - MirasolDocument3 pagesCM113P - 12.22.19 - Activity - MirasolElle KateNo ratings yet

- Savelyev - Physics - A General Course - Vol 2 - MirDocument529 pagesSavelyev - Physics - A General Course - Vol 2 - MirFabioNo ratings yet

- Photosynthesis HSBDocument5 pagesPhotosynthesis HSBMs. ButeNo ratings yet

- Temperature and Kinetic TheoryDocument48 pagesTemperature and Kinetic TheoryTimofejs MaksimovsNo ratings yet

- Ica 2 Reviewer For MidtermDocument17 pagesIca 2 Reviewer For Midtermjohn kyleNo ratings yet

- Earthwork Quantities: Calculation of VolumesDocument15 pagesEarthwork Quantities: Calculation of VolumesJane AsasiraNo ratings yet

- Acs Energyfuels 7b03733Document12 pagesAcs Energyfuels 7b03733Dinesh JoshiNo ratings yet