Professional Documents

Culture Documents

8rice Postharvest Handling

Uploaded by

Rouge Winters0 ratings0% found this document useful (0 votes)

3 views1 pageOriginal Title

8Rice-Postharvest-Handling

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 page8rice Postharvest Handling

Uploaded by

Rouge WintersCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Rice Postharvest Handling

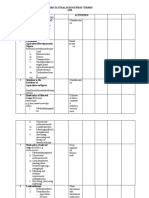

1. Postharvest System • Grain damage should be 6. Paddy aggregation and

• The postharvest system consists of a set minimised during threshing as storage

of operations from harvest to damaged grain is much more • This involves bulking of paddy

consumption.

Roots of rice crop infested

prone to attack by insects and rice by cooperative societies,

• An efficient postharvest system aims to moulds. farmer groups and millers.

minimise losses and maintain quality of 7. Milling

4. Cleaning grain after threshing

the harvested crop until it reaches the Fig1. Threshing of paddy • This is the process of removing

Factsheets for Rice Production, East Africa

• Cleaning paddy rice after threshing Source: Rice MAPP

final consumer. husks and bran from paddy rice

improves its storability, milling

• Rice postharvest system consist of the to produce white rice grains.

following operations: (a) Harvesting, (b) output, and quality, and hence its

market value. • Milling of paddy rice in Kenya is

Threshing, (c) Cleaning threshed grain

• Cleaning removes impurities such done by commercial rice millers;

(d) Drying, (f) Aggregation and storage,

as straws, chaff, weed seeds, and smallholder millers in village

(g) Milling (h) value addition (i)

Marketing. leaves, pods, sticks, broken grain, mills.

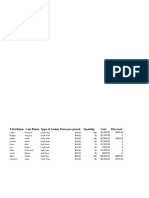

Fig 2.Winnowing of paddy 8. Marketing

• Postharvest losses in rice are estimated stones and other foreign matter. rice

at 30-40% due to inefficient postharvest • Cleaning is often done manually • In Kenya, rice is marketed through

Source: Daily Nation

handling operations. by winnowing. (a) Government agencies

2. Harvesting • Insect damaged and mouldy grain (National Irrigation Development

• Harvesting is the process of collecting are removed by hand picking. Authority, National Cereals and

mature rice crop from the field. 5. Drying of threshed paddy Produce Board, Lake Basin

3. Threshing Development Authority); (b)

• Rice paddy should be dried to a

• Threshing separates the grain from the Fig 3. Drying of paddy rice Marketing cooperatives; (c) Private

moisture content of 13-14% for

chaff, and produces paddy rice (threshed on concrete floor companies; and (d) small-scale

safe storage and milling.

grain with hulls). Source: Lusike Wasilwa traders.

• Sun drying is commonly used by • All the rice produced in Kenya is

• Threshing should be started immediately spreading the paddy on tarpaulins Dryness is checked using

after harvesting (within 24 hours after consumed locally, with a major

over a given period to dry. moisture meters. Dry production gap. Kenya imports

harvesting). • Small-scale driers can also be grain (13-14% moisture)

• In Kenya, threshing is done manually 90% of its rice from Vietnam, India

used. also breaks easily when and Pakistan.

and also by use of paddy threshers. bitten between the teeth.

Contact experts: Wayua, F (Francis.Obuoro@kalro.org); Otipa M; Wasilwa, L; Changalwa, C; Mutiga, S. (BeCA ILRI); Nyongesa. O. (IRRI);

Mugambi; C; Kimani; J; Ochieng, V; Ngari, B; Zhou, B (IRRI)); Mitchell T. (OSU); Wang, G. L .(OSU); Were, V (TSL); Ouedraogo, I. (INERA);

Rotich, F (UoEm); Correll, J. C. (UARK) and Talbot, N. J. (TSL). E-Guide for Rice Production in East Africa (2019)

You might also like

- Harvesting, Threshing, Drying, Storing, and MillingDocument15 pagesHarvesting, Threshing, Drying, Storing, and Millingrichard babasNo ratings yet

- Post Harvesting - Cereals, Pulses, OilseedsDocument56 pagesPost Harvesting - Cereals, Pulses, OilseedsArunNo ratings yet

- Unit 07 Agriculture - HighlightedDocument25 pagesUnit 07 Agriculture - HighlightedM.IbrahimNo ratings yet

- Qasim Bin Azam 2020-Ag-2465Document8 pagesQasim Bin Azam 2020-Ag-2465Ameer HamzaNo ratings yet

- Design and Testing of Improved Village-Type Dehuller-Degerminator For Dry-Milling Process of CornDocument6 pagesDesign and Testing of Improved Village-Type Dehuller-Degerminator For Dry-Milling Process of CornBelanja BelanjaNo ratings yet

- AME-Chap12-Harvesting EquipmentDocument9 pagesAME-Chap12-Harvesting EquipmentJordan YapNo ratings yet

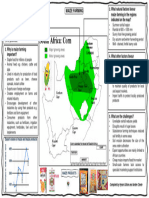

- Notes Maize FarmingDocument1 pageNotes Maize FarmingSabelo james BhembeNo ratings yet

- Notes - Maize FarmingDocument1 pageNotes - Maize Farmingndlovuazanda9No ratings yet

- EPAR UW 204 Wheat Ethiopia 07272012Document21 pagesEPAR UW 204 Wheat Ethiopia 07272012Balcha bulaNo ratings yet

- New Poster2Document1 pageNew Poster2emelarthur10No ratings yet

- Ginning: F 54. Recommended Gin Machinery For Machine-Stripped and Machine-Picked CottonDocument3 pagesGinning: F 54. Recommended Gin Machinery For Machine-Stripped and Machine-Picked CottonKathirrveluSubramainanNo ratings yet

- Rice Milling SystemDocument151 pagesRice Milling SystemPrince Oludare AkintolaNo ratings yet

- Paddy Drum SeederDocument2 pagesPaddy Drum SeederVrphalanivelNo ratings yet

- SCM-M Javid Nawaz-30234-Assignmnt#1Document5 pagesSCM-M Javid Nawaz-30234-Assignmnt#1Engr Muhammad Javid NawazNo ratings yet

- Harvesting, Threshing, Drying, StoringDocument18 pagesHarvesting, Threshing, Drying, StoringAntonio Jarligo Compra100% (1)

- Milling and Processing - IRRI Rice Knowledge BankDocument4 pagesMilling and Processing - IRRI Rice Knowledge BankCarl RondillaNo ratings yet

- Post Harvest ParametersDocument14 pagesPost Harvest ParametersManeth Muñez CaparosNo ratings yet

- 05/20/2021 Footer Text 1Document9 pages05/20/2021 Footer Text 1Keerthana ENo ratings yet

- 0 - Unit 7 AgricultureDocument27 pages0 - Unit 7 AgricultureAbdullah LateefNo ratings yet

- Basmati Rice Manufacturing ProcessDocument4 pagesBasmati Rice Manufacturing ProcessShamli Karumannil100% (1)

- B 1 - Basics of Beekeeping - 190613Document8 pagesB 1 - Basics of Beekeeping - 190613sam000678No ratings yet

- Central Visayas Seaweeds Constraints and OpportunitiesDocument10 pagesCentral Visayas Seaweeds Constraints and OpportunitiesRosas PagtooNo ratings yet

- Rationale: Per Capita Wheat Comsumption in Selected CountriesDocument4 pagesRationale: Per Capita Wheat Comsumption in Selected CountriesCesar VieyraNo ratings yet

- Milling of RiceDocument18 pagesMilling of RiceArush SidanaNo ratings yet

- Processing From Gin To Fabric PDFDocument12 pagesProcessing From Gin To Fabric PDFKannan KrishnamurthyNo ratings yet

- 6a Rice and Other Crop Processing Machinery CompressDocument140 pages6a Rice and Other Crop Processing Machinery CompressArman RiveraNo ratings yet

- 6a. Rice and Other Crop Processing MachineryDocument140 pages6a. Rice and Other Crop Processing MachineryNiño Evangelista FranciscoNo ratings yet

- 11 Review Notes Harvesting and ThreshingDocument16 pages11 Review Notes Harvesting and ThreshingtrishaNo ratings yet

- Abuteffera 20133252337 Thresher Write Up A 2005Document7 pagesAbuteffera 20133252337 Thresher Write Up A 2005BetyNo ratings yet

- Abuteffera 20133252337 Thresher Write Up A 2005Document7 pagesAbuteffera 20133252337 Thresher Write Up A 2005BetyNo ratings yet

- Abuteffera 20133252337 Thresher Write Up A 2005Document7 pagesAbuteffera 20133252337 Thresher Write Up A 2005BetyNo ratings yet

- Prospects & Challenges of Organic Cotton in BangladeshDocument36 pagesProspects & Challenges of Organic Cotton in BangladeshAhsan AryanNo ratings yet

- Select and Operate Farm Equipment 2 A4Document3 pagesSelect and Operate Farm Equipment 2 A4JaideHizoleSapul100% (2)

- Rice Milling: Poonam DhankharDocument9 pagesRice Milling: Poonam DhankharWeare1_busyNo ratings yet

- Rice Milling: Poonam DhankharDocument9 pagesRice Milling: Poonam DhankharNikhilesh KumarNo ratings yet

- Rice Milling: Poonam DhankharDocument9 pagesRice Milling: Poonam DhankharRajnand SinghNo ratings yet

- Rice Milling: Poonam DhankharDocument9 pagesRice Milling: Poonam DhankharWeare1_busyNo ratings yet

- Maize - Dry MillingDocument9 pagesMaize - Dry MillingAFIFAH AMIRATUL MUFIDAHNo ratings yet

- Select and Operate Farm Equipment 2Document3 pagesSelect and Operate Farm Equipment 2JaideHizoleSapul100% (15)

- Updated Cassava Starch Industry ReportDocument16 pagesUpdated Cassava Starch Industry ReportChrin KimrongNo ratings yet

- Cotton Textile IndustryDocument24 pagesCotton Textile IndustryZonish BakshNo ratings yet

- Lecture 11. Rice Milling TechnologyDocument16 pagesLecture 11. Rice Milling TechnologyDuy Nguyen VuNo ratings yet

- Lab 5 Abe 421Document6 pagesLab 5 Abe 421Theresa CostalesNo ratings yet

- Dar-Minsaad Subproject Completion ReportDocument8 pagesDar-Minsaad Subproject Completion ReportMark Hariss Coresis NomenNo ratings yet

- Vivas Basabeiii Abp32d Rice and Other Crop Processing MachineryDocument69 pagesVivas Basabeiii Abp32d Rice and Other Crop Processing MachineryArman RiveraNo ratings yet

- 1Document12 pages1PRAVEEN KUMARNo ratings yet

- Lecture 13. Tuber Starch ProcessingDocument10 pagesLecture 13. Tuber Starch ProcessingDuy Nguyen VuNo ratings yet

- Notes Rice Milling & Quality Control Affecting Quality ..Document7 pagesNotes Rice Milling & Quality Control Affecting Quality ..tcmittal69100% (1)

- RICE MILL MACHINERY AND EQUIPMENT - PPTX v111Document60 pagesRICE MILL MACHINERY AND EQUIPMENT - PPTX v111diomedes pataniNo ratings yet

- CPAR VALENCIA v.1Document81 pagesCPAR VALENCIA v.1kimmy maravillas100% (1)

- Agriculturalsciencefirst Termss One Week Topic/ Content Activities Meaningandimportanceof AgricultureDocument5 pagesAgriculturalsciencefirst Termss One Week Topic/ Content Activities Meaningandimportanceof AgricultureOgechiNo ratings yet

- Brochure GM Oat Technology 2017 enDocument8 pagesBrochure GM Oat Technology 2017 enArlette ReyesNo ratings yet

- Daily Current Affairs + PIB Summary (9 Feb 2024)Document6 pagesDaily Current Affairs + PIB Summary (9 Feb 2024)koushik royalNo ratings yet

- Agriculture NotesDocument16 pagesAgriculture NotesBHAVYA SACHDEVANo ratings yet

- 2.5 Research Paper - Machinery Mechanization - Harvesting and Threshing MachineDocument29 pages2.5 Research Paper - Machinery Mechanization - Harvesting and Threshing MachineArman RiveraNo ratings yet

- IGP TableDocument2 pagesIGP TableRalph Aldrin F. VallesterosNo ratings yet

- Harvesting & Threshing ModuleDocument56 pagesHarvesting & Threshing ModulejerryNo ratings yet

- Principles and Methods of Rice MillingDocument12 pagesPrinciples and Methods of Rice MillingMary - Ann Andal100% (1)

- ANIMAL FEED PLANT ModelDocument1 pageANIMAL FEED PLANT ModelRouge WintersNo ratings yet

- Flores Icc AssignmentDocument2 pagesFlores Icc AssignmentRouge WintersNo ratings yet

- ABE-321 ActivityDocument10 pagesABE-321 ActivityRouge WintersNo ratings yet

- Flores Icc Activity 2 &3Document2 pagesFlores Icc Activity 2 &3Rouge WintersNo ratings yet

- 07-Pineapple Processing PDFDocument20 pages07-Pineapple Processing PDFNicasio Perez Lim Aquino100% (1)

- FLORES, LORVEN - ABE-321 - ActivityDocument23 pagesFLORES, LORVEN - ABE-321 - ActivityRouge WintersNo ratings yet

- ABE-321 ActivityDocument8 pagesABE-321 ActivityRouge WintersNo ratings yet

- AB315 Properties of AB MAterials For Student PDFDocument66 pagesAB315 Properties of AB MAterials For Student PDFRouge WintersNo ratings yet

- ABE 315 - Module 1 - CoursepackDocument7 pagesABE 315 - Module 1 - CoursepackRouge WintersNo ratings yet

- New Understandings of How Dielectric Properties of Fruits and Vegetables Are Affected by Heat Induced DehydrationDocument16 pagesNew Understandings of How Dielectric Properties of Fruits and Vegetables Are Affected by Heat Induced DehydrationRouge WintersNo ratings yet

- ABE 315 - Module 2 - CoursepackDocument18 pagesABE 315 - Module 2 - CoursepackRouge WintersNo ratings yet

- Sustainability Indicators For Livestock Farming. A Review: Agronomy For Sustainable Development April 2012Document18 pagesSustainability Indicators For Livestock Farming. A Review: Agronomy For Sustainable Development April 2012Rouge WintersNo ratings yet

- Case Study MaterialsDocument22 pagesCase Study MaterialsRouge WintersNo ratings yet

- 1 5jolyDocument16 pages1 5jolyRouge WintersNo ratings yet

- Perspectives of The Livestock Sector in The Philippines: A ReviewDocument14 pagesPerspectives of The Livestock Sector in The Philippines: A ReviewRouge WintersNo ratings yet

- Tiny Rails Africa GuideDocument32 pagesTiny Rails Africa GuideMatthewNo ratings yet

- Fundamentals of Food Technology: A Course Module inDocument36 pagesFundamentals of Food Technology: A Course Module inEddilyn BunielNo ratings yet

- Antifungal Food ListDocument1 pageAntifungal Food ListKristina KavalinNo ratings yet

- Rabobank Grains-and-Oilseeds-Map-2021 Apr2021 DIGITALDocument1 pageRabobank Grains-and-Oilseeds-Map-2021 Apr2021 DIGITALolivier.hanne64No ratings yet

- Fotos Cajas RapidasDocument13 pagesFotos Cajas RapidasJemay OspinaNo ratings yet

- ANALISIS LAMA WAKTU PANGKAL BATANG TEBU (Saccharum Officinarum L.) Tertinggal Di Lahan Terhadap Nilai RendemenDocument5 pagesANALISIS LAMA WAKTU PANGKAL BATANG TEBU (Saccharum Officinarum L.) Tertinggal Di Lahan Terhadap Nilai RendemenelenaNo ratings yet

- Evaluation of Monocropped and Intercropped Grain Legumes For Cover Cropping in No-Tillage and Reduced Tillage Organic AgricultureDocument12 pagesEvaluation of Monocropped and Intercropped Grain Legumes For Cover Cropping in No-Tillage and Reduced Tillage Organic AgricultureMaría Paz Dos SantosNo ratings yet

- Prepare Vegetable DishesDocument28 pagesPrepare Vegetable DishesThea Jeonieesa GarayNo ratings yet

- The Legumez StoreDocument7 pagesThe Legumez StoreAkia GibsonNo ratings yet

- Agriculture of BiharDocument2 pagesAgriculture of Biharbhaviksinghsengar26No ratings yet

- Mahanandi Carrot CakeDocument19 pagesMahanandi Carrot CakeDivyanshBansalNo ratings yet

- Bio-Fertilizer Possibilities and Scope in NepalA ReviewDocument5 pagesBio-Fertilizer Possibilities and Scope in NepalA ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Inventory & Orderlist TBS Catering Services - 2022 4e Kwarta (ESTONIA)Document6 pagesInventory & Orderlist TBS Catering Services - 2022 4e Kwarta (ESTONIA)Ardian AlifyantoNo ratings yet

- Veg Station (M) SDN BHD: InvoiceDocument1 pageVeg Station (M) SDN BHD: Invoicedila fauziNo ratings yet

- Daftar Vegetables Vocabulary Tentang Nama Sayuran Dalam Bahasa InggrisDocument7 pagesDaftar Vegetables Vocabulary Tentang Nama Sayuran Dalam Bahasa InggrisFitri yaniNo ratings yet

- Trans by Line Item Shipping ReportDocument7 pagesTrans by Line Item Shipping ReportAdrian UlloaNo ratings yet

- Oriya To English Translations of Popular IngredientsDocument6 pagesOriya To English Translations of Popular IngredientsKailash Chandra Pradhan100% (1)

- Padhle 10th - Social Science - AgricultureDocument21 pagesPadhle 10th - Social Science - AgriculturePriyanshu VNo ratings yet

- Jess 104Document20 pagesJess 104Samasthita Ghosh twozerosixninefivetwozeroNo ratings yet

- PLU Deskripsi QTY Harga TotalDocument6 pagesPLU Deskripsi QTY Harga TotalkekburokNo ratings yet

- Glossary of Cereals-Grains in English and Hindi, Indian Cereals GrainsDocument48 pagesGlossary of Cereals-Grains in English and Hindi, Indian Cereals GrainsBhagwat ThakkerNo ratings yet

- CommodityShipments (PivotTables PivotCharts)Document27 pagesCommodityShipments (PivotTables PivotCharts)Ana Lorraine DalilisNo ratings yet

- ASSIGNMENT M.Sc. SEED PRODUCTIONDocument1 pageASSIGNMENT M.Sc. SEED PRODUCTIONFuzail RasheedNo ratings yet

- Plant-Based Protein Cheat SheetDocument1 pagePlant-Based Protein Cheat SheetKumar PalojiNo ratings yet

- Vegetables PoemsDocument8 pagesVegetables PoemsHG KachinNo ratings yet

- Fatty Acid Composition of Some Major OilsDocument18 pagesFatty Acid Composition of Some Major OilsChoice OrganoNo ratings yet

- Soap Saponification Value ChartDocument11 pagesSoap Saponification Value ChartLovely ChopraNo ratings yet

- Composicion de LupinoDocument5 pagesComposicion de Lupinomayeli montañez perezNo ratings yet

- Breeding Field Crops and Vegetables in Croatia: ReviewDocument13 pagesBreeding Field Crops and Vegetables in Croatia: ReviewDora ZidarNo ratings yet

- Mutu Fisik, Kimia Dan Organoleptik Buah Tomat (Lycopersicum Esculentum Mill.) HASIL PELAPISAN Berbagai Jenis Pati Selama PenyimpananDocument9 pagesMutu Fisik, Kimia Dan Organoleptik Buah Tomat (Lycopersicum Esculentum Mill.) HASIL PELAPISAN Berbagai Jenis Pati Selama PenyimpananDian BolonNo ratings yet