Professional Documents

Culture Documents

CB-CON-03-1.0 - RS232 Control With C-Bus Network Automation Controller - 5500NAC

Uploaded by

vanlang87Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CB-CON-03-1.0 - RS232 Control With C-Bus Network Automation Controller - 5500NAC

Uploaded by

vanlang87Copyright:

Available Formats

Basic / Advanced / Expert

Configuration Guide

How to control RS-232 enabled

devices with C-Bus Network

Automation Controller – 5500NAC

Including connection to C-Bus Groups

How to control RS-232 with C-Bus Network Automation Controller – 5500NAC

CB-CON-03-1.0

Safety Information

Important Information

Read these instructions carefully before trying to install, configure, or operate this software. The

following special messages may appear throughout this bulletin or on the equipment to warn of

potential hazards or to call attention to information that clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label indicates that an electrical

hazard exists which will result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided,

can result in death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, can

result in minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this signal word.

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 2 / 19

Please Note

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of the

use of this material.

A qualified person is one who has skills and knowledge related to the construction, installation, and

operation of electrical equipment and has received safety training to recognize and avoid the hazards

involved.

Safety Precautions

WARNING

HAZARD OF INCORRECT INFORMATION

• Do not incorrectly configure the software, as this can lead to incorrect

reports and/or data results.

• Do not base your maintenance or service actions solely on messages

and information displayed by the software.

• Do not rely solely on software messages and reports to determine if

the system is functioning correctly or meeting all applicable standards

and requirements.

• Consider the implications of unanticipated transmission delays or

failures of communications links.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 3 / 19

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information that is contained herein. If

you have any suggestions for improvements or amendments or have found errors in this publication,

please notify us.

No part of this document may be reproduced in any form or by any means, electronic or mechanical,

including photocopying, without express written permission of Schneider Electric.

All pertinent state, regional, and local safety regulations must be observed when installing and using

this product. For reasons of safety and to help ensure compliance with documented system data,

only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions

must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2017 Schneider Electric. All rights reserved

Revision Number Created by Date

1.0 Project Services AU 1/03/2017

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 4 / 19

Table of Contents

1 Introduction .......................................................................................................................................... 6

1.1 Real World Use ............................................................................................................................... 6

1.2 Competencies ................................................................................................................................. 7

1.3 System prerequisites ...................................................................................................................... 7

2 Design .................................................................................................................................................... 8

2.1 Hardware Connections ................................................................................................................... 8

3 Configuration ....................................................................................................................................... 11

3.1 Communication configuration ......................................................................................................... 11

3.2 LUA RS-232 commands ................................................................................................................ 12

3.3 Including RS-232 commands into C-Bus Networks ........................................................................ 14

3.4 Connection setting and testing ....................................................................................................... 16

3.5 RS-232 connections & adding additional (RS-232) ......................................................................... 17

4 Conclusion ........................................................................................................................................... 18

5 Appendix .............................................................................................................................................. 19

5.1 Glossary ......................................................................................................................................... 19

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 5 / 19

1 Introduction

This configuration guide describes how to setup the C-Bus Network Automation Controller’s built in RS-232

interface for communication with 3rd party devices represented by a “Barco brand” projector. The wiring, its

initial settings and basic troubleshooting is described. Association with C-Bus groups and the incorporation

of controlled devices to the scenes is also explained.

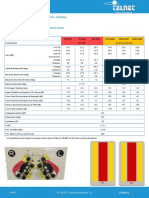

Sample image of “5500NAC” RS-232 connections

1.1 Real World Use

The real world applications for using a 5500NAC to interface to RS-232 equipment are many and varied.

The RS-232 interface is still one of the most preferred methods of communication between AV, HVAC

products that do not support either Ethernet, some proprietary Bus connection or a software API.

RS-232 can provide control and information exchange of:

• Projectors and displays

• Amplifiers, AV receivers and active speakers

• VRV/VRF Centralized Air Conditioners, heat pumps and other HVAC technologies

• Meteorological stations and other Sensing equipment.

NOTE: This list displays only a sample of some of the devices that can be controlled using this interface.

• User case 1: Connection of common RS-232 devices through most used connectors.

• User case 2: Configuration of BARCO CRWQ-62B projector and 5500NAC for communication over RS-

232.

• User case 3: Simple command for switching of BARCO CRWQ-62B projector ON.

• User case 4: Including control of BARCO CRWQ-62B projector control into the scenes.

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 6 / 19

1.2 Competencies

There are a few necessary competencies to follow procedures mentioned in this configuration guide. It is

mandatory to have knowledge of C-Bus commissioning via C-Bus ToolKit, basic 5500NAC configuration

knowledge, fair knowledge of the RS-232 interface and its settings and of Lua scripting language in the

scope described in the Product manual.

1.3 System prerequisites

Software / Product name Version Description/ Download link

Hercules setup utility 3.2.6 RS-232 / RS-485 serial comms “packet sniffer”

C-Bus Toolkit for NAC 1.15.0 http://www.schneider-electric.com.au

Table 1: System prerequisites

Part Number Device ID Description

C-Bus Network

5500NAC C-Bus Network Automation Controller

Automation Controller

Plug Pack 5500NAC Power supply 24Vdc 1.25A Plug Pack (Generic brand)

CRWQ-62B BARCO CRWQ-62B WQXGA, single chip DLP projector

Converter cable, used for temporary connection of

RS-232 to USB “Type

UCAB232 your PC to the 5500NAC RS-232 port for

A” converter

diagnostics and testing

Table 2: List of used

Hardware

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 7 / 19

2 Design

2.1 Hardware Connections

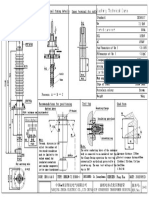

There are 2 typical connections commonly used for RS-232 control:

1/ 9 pin DE/DB9 serial plug

Picture 1: 9 pin DB/DE 9

connector

Please note that only 3 of the pins are used for the 5500NAC - RXD, TXD and GND.

The other remaining pins are either not connected at all or some may be used as float control. If a

device needs float control or is powered by any other pin aside from the RXD, TXD or ground, a USB to

RS-232 converter is typically required.

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 8 / 19

2/ 3.5 mm Stereo Audio jack connection

Picture 4: 3.5 mm audio jack connector

Picture 5: 5500NAC terminals connection

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 9 / 19

Baud Rate Maximum RS-232 Cabling Distance Recommendations

57600 5 metres

28800 10 metres

NOTE: Typically the maximum distance for RS-232 control is 15metres. By using special “low

capacitance” cables full speed communication can be maintained over longer distances (dependent upon

the cable characteristics)

Table 3: 5500NAC RS-232 terminals connection

It is a requirement that the cable pins ‘cross or are transposed’ to ensure that TX = transmitting pin

will be connected to the RX = receiving pin on the other end of the cable:

Picture 6: RS-232 ‘cross’

connection

Please note: 5500NAC is using a standard RS-232C interface with a signal level of ±12 Vdc.

If you wish to use a device with a different voltage level, for example RS-232TTL with signal level ±5Vdc, then

an additional hardware converter must be used, to ensure proper function and prevention of damage of the

5500NAC or connected device(s). Check the manual of the device you wish to connect to first.

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 10 / 19

3 Configuration

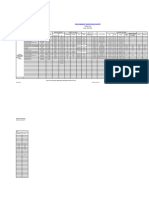

3.1 Communication configuration

First thing, refer to the manufacturer’s documentation for the device that you wish to control. The

5500NAC will need to be configured to suit the existing manufacturer settings. RS-232 control is

enabled in the BARCO CRWQ-62B projector by default. Communication settings must be included in

the RS-232 control script:

Table 4: Connection parameters

Sample Script for opening the RS-232 port and setting its parameters, flushing the buffer should also be

done in case of any read / unsent / leftover data):

-- Include library before calling serial functions

if not port

then

require('serial'

)

-- Setting port parameters and open serial

port port = serial.open('/dev/RS232', {

baudrate = 19200,

databits = 8,

stopbits = 1,

parity =

'none',

duplex =

'full'

})

-- Flushes any read/unsent

bytes port:flush()

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 11 / 19

3.2 LUA RS-232 commands

Data can be sent to the RS-232 port, however it does depend on the controlled hardware device itself. A

list of supported commands is typically provided by the device manufacturer. Table 4 displays a sample

from the BARCO CRWQ-62B projector’s instruction manual:

Table 5: sample list of RS-232 control

codes

Note:

The serial module will send out data in a “string format”.

ASCII format:

To send commands in an ASCII format instead, please use the following code sample:

-- Write data to serial

port port:write('Powr

1')

To send raw data, please view the following code segment:

-- Write data to serial port

msg = string.char(0x49, 0x52, 0x47, 0x42, 0x5F, 0x5F, 0x5F,

0x31) port:write(msg)

The data being written to the serial port is treated as a string, on the serial port side it is read as raw data.

This means that any raw data being sent must be written as an ASCII equivalent. Refer to the code

segment above, consider if you wished to send the raw data number ‘49’. To achieve this, it must be

written in an ASCII format. Using an ASCII “look up table” the equivalent ASCII format is ‘I” which is (0x49)

in hexadecimal. The serial port does not read this as ASCII and will recognize these characters to

represent the number ‘49’.

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 12 / 19

Data can also be read from the RS-232 port. Below we see an example of an alert in the 5500NAC alert

when confirmation from the projector is received:

-- Read data from serial port

if port:read() == 'Powr 1'

-- Send alert when condition matched

then alert('Projector is

ON') end

The RS-232 port should then be closed, when it is no longer needed:

-- Closing serial

port port:close()

Complete code sample for switching the BARCO CRWQ-62B projector to “ON”:

-- Include library before calling serial functions

if not port

then

require('serial'

)

-- Setting port parameters and open serial

port port = serial.open('/dev/RS232', {

baudrate = 19200,

databits = 8,

stopbits = 1,

parity =

'none',

duplex =

'full'

})

-- Flushes any read/unsent

bytes port:flush()

-- Write data to serial port corresponding to the projector’s manual

msg = string.char(0x7E, 0x30, 0x30, 0x30, 0x30, 0x20, 0x31,

0x0D) port:write(msg)

-- Closing serial

port port:close()

end

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 13 / 19

3.3 Including RS-232 commands into C-Bus Networks

The following sample, displays how to include commands to switch ON/OFF the BARCO CRWQ-62B

projector when mapped C-Bus groups change state.

You will need to create an object for use in controlling the projector:

Picture 7: Scene object properties

You can control the projector through C-Bus groups with the use of an ‘Event script’:

Picture 8: Object link to the event script

3.3.1 Script to control a projector’s on/off status with a C-Bus group

When the following script runs, it will check if the “C-Bus group state” is “on” or the C-Bus level is anywhere

from 1 through 255 (ie: ON, but dimmed), and will send an “on” command to the projector. It will also check

if the C-Bus group state is “off” or the level = 0, and will send an “off” command to the projector.

You will be able to put the projector object into a scene and turn it on / off and it will integrate with other C-

Bus interfaces, if you wish to use different C-Bus levels for triggering commands you will need to edit the

code and use the “C-Bus Level command”, please refer to the “Helper functions” in the 5500NAC for further

information.

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 14 / 19

value = getCbusState(0,100,1)

--if the cbus group is off, turn off the projector

if value == false then

if not port then

require('serial')

-- Setting port parameters and open serial port

port = serial.open('/dev/RS232',

{

baudrate = 19200,

databits = 8,

stopbits = 1,

parity = 'none',

duplex = 'full'

})

port:flush()

end

-- Write data to serial port Projector OFF

msg = string.char(0x7E, 0x30, 0x30, 0x30, 0x30, 0x20, 0x30, 0x0D)

port:write(msg)

port:close()

--if the cbus level is on, turn on the projector

elseif value == true then

if not port then

require('serial')

-- Setting port parameters and open serial port

port = serial.open('/dev/RS232',

{

baudrate = 19200,

databits = 8,

stopbits = 1,

parity = 'none',

duplex = 'full'

})

port:flush()

end

-- Write data to serial port Projector ON

msg = string.char(0x7E, 0x30, 0x30, 0x30, 0x30, 0x20, 0x31, 0x0D)

port:write(msg)

port:close()

end

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 15 / 19

3.4 Connection setting and testing

For connection setting and testing, a number of utilities can be used. Freeware “Hercules” software utility is

one of them:

http://www.hw-group.com/products/hercules/index_en.html

A RS-232 to “USB Type A” cable is required. An ASIX UCAB232 cable was used in this example. This

cable has two LEDs which provide indication of “incoming / outgoing” communications.

Picture 10: ASIX UCAB232 cable

When connected and properly configured, a PC can both receive commands from 5500NAC and send

commands to a controlled device for testing purposes. A sample of a “sent control code” with confirmation

from the projector is – hexadecimal code 4F 4B at the end = OK in ASCII.

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 16 / 19

Picture 11: Hercules utility environment with received code

3.5 RS-232 connections & adding additional (RS-232)

The 5500SHAC RS232 Physical port address is located in:

“Configurator > Utilities > System > Status > System Status > Serial Ports ‘/dev/RS232’.

The picture below shows the RS232 port in the 5500SHAC as the first port. As mentioned before this is only a

3 wire connection on the 5500SHAC (COM, RX, TX).

If the device you wish to control requires hardware “flow control”, then it will need a 4 wire RS-232 connection.

To provide this 4th wire, you would need to add a compatible USB<>RS-232 adaptor that will give you the

additional connections. This will also work through an external USB hub (with its own external hub power), so

that you can connect multiple USB adaptors onto the one USB connection on the 5500SHAC.

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 17 / 19

The picture below also shows the 3rd port as a “FTDI chipset” USB<>RS232 adaptor, this was plugged into the

USB-A slot on the 5500SHAC. The 5500SHAC auto detects the FTDI chipset USB device and adds it to the

GUI (does not require a refresh /re-load / etc for screen to update).

Having separate adaptors also allows you to specify individual baud rates to each USB adaptor according to

what your equipment needs.

4 Conclusion

5500NAC can be used as a gateway / interface for control of RS-232 devices using C-Bus devices / wall

controls / touchscreens / Tablets (via 5500NAC Dashboards).

Proper settings and connection is imperative for correct functionality. It is critical to get valid sets of codes

from the manufacturer of the device as all manufacturers are different.

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 18 / 19

5 Appendix

5.1 Glossary

The following table describes the acronyms and defines the specific terms used in this document.

Abbreviation Description

RS-232 Telecommunications standard for binary serial communications between

devices

bd Baud = unit for transmitted symbols per seconds

hexadecimal Positional number system with base of 16

ASCII American Standard code for Information Interchange

Schneider Electric (Australia) Pty Ltd Schneider Electric (New Zealand) Ltd

Customer Care Australia: Customer Care New Zealand

Phone 1300 369 233 Phone 0800 652 999

Email: customercare.au@schneider-electric.com Email: sales@nz-schneider-electric.com

33 – 37 Port Wakefield Rd 38 Business Parade South

Gepps Cross, South Australia East Tamaki 2013

Australia, 5094 Auckland, New Zealand

How to control RS-232 with C-Bus Network Automation Controller - 5500NAC

CB-CON-03-1.0 Page 19 / 19

You might also like

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- AN001 spaceLYnk Integration Using BACnet v2.0Document19 pagesAN001 spaceLYnk Integration Using BACnet v2.0anupamNo ratings yet

- Industrial Network Security: Securing Critical Infrastructure Networks for Smart Grid, SCADA, and Other Industrial Control SystemsFrom EverandIndustrial Network Security: Securing Critical Infrastructure Networks for Smart Grid, SCADA, and Other Industrial Control SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Application Note: Advanced Techniques in VisualizationDocument21 pagesApplication Note: Advanced Techniques in Visualizationruben_rodriguez_61No ratings yet

- InduSoft Application Design and SCADA Deployment Recommendations for Industrial Control System SecurityFrom EverandInduSoft Application Design and SCADA Deployment Recommendations for Industrial Control System SecurityNo ratings yet

- Application Note: Tunable WhiteDocument34 pagesApplication Note: Tunable Whiteruben_rodriguez_61No ratings yet

- The Real Product Safety Guide: Reducing the Risk of Product Safety Alerts and RecallsFrom EverandThe Real Product Safety Guide: Reducing the Risk of Product Safety Alerts and RecallsNo ratings yet

- ManualDocument32 pagesManualAugusto Francisco Diaz LaraNo ratings yet

- Untitled PDFDocument192 pagesUntitled PDFthomasNo ratings yet

- User Manual: Com'X 510 Energy ServerDocument136 pagesUser Manual: Com'X 510 Energy ServerGoran JovanovicNo ratings yet

- EasyLogic™ PM2200 SeriesDocument86 pagesEasyLogic™ PM2200 SeriesMiguel Huaccha ArmasNo ratings yet

- EasyLogic EM72X0Document78 pagesEasyLogic EM72X0Alex PereiraNo ratings yet

- User Manual: Com'X 510 Energy ServerDocument136 pagesUser Manual: Com'X 510 Energy ServerwafiikNo ratings yet

- User Manual: Easylogic™ Dm6000H / Dm6200H SeriesDocument50 pagesUser Manual: Easylogic™ Dm6000H / Dm6200H SeriesLucio SalesNo ratings yet

- Manual DM6000Document52 pagesManual DM6000thiago silvaNo ratings yet

- QGH1329903 02 enDocument70 pagesQGH1329903 02 enfadliNo ratings yet

- RS 082020 SE - GutorPxW UserGuideDocument56 pagesRS 082020 SE - GutorPxW UserGuideNicolas VegaNo ratings yet

- Nha2778902 11 enDocument96 pagesNha2778902 11 enRagil AnggaNo ratings yet

- M221 Modbus Master ExampleDocument20 pagesM221 Modbus Master ExampleMuhamad Gusti MaulanaNo ratings yet

- EasyLogic™ PM2100 series-EN PDFDocument92 pagesEasyLogic™ PM2100 series-EN PDFMiguel Huaccha ArmasNo ratings yet

- 7ML02-0305-02 8650 Switchboard Installation GuideDocument104 pages7ML02-0305-02 8650 Switchboard Installation GuideAlejo MiraNo ratings yet

- PM5500 User GuideDocument142 pagesPM5500 User Guidewilber chiclla jaraNo ratings yet

- ATV312 Programming Manual en BBV46385 04Document127 pagesATV312 Programming Manual en BBV46385 04Faruk PatelNo ratings yet

- 7ML02-0305-01 (2) Contador de EnergiaDocument102 pages7ML02-0305-01 (2) Contador de EnergiaLindomar SalazarNo ratings yet

- ATV12 User Manual EN BBV28581 03 PDFDocument133 pagesATV12 User Manual EN BBV28581 03 PDFPrabha PrabhakarNo ratings yet

- User Manual: Easylogic™ Pm2100 SeriesDocument92 pagesUser Manual: Easylogic™ Pm2100 SeriesBinh Thai HYNo ratings yet

- User Manual: Easylogic™ Pm2100 SeriesDocument92 pagesUser Manual: Easylogic™ Pm2100 SeriesRoxanneNo ratings yet

- SCHNEIDER Conext Tool Manual Usuario Rev A ENDocument130 pagesSCHNEIDER Conext Tool Manual Usuario Rev A ENwasco plantNo ratings yet

- Manual ION8650Document104 pagesManual ION8650Manuel Lavado SilvaNo ratings yet

- How Can I Implement SCD6000 With IPMCC and Control Software TVDADocument113 pagesHow Can I Implement SCD6000 With IPMCC and Control Software TVDAEdwinNo ratings yet

- Managing Alarms in SCADA Expert Vijeo Citect 7.5Document84 pagesManaging Alarms in SCADA Expert Vijeo Citect 7.5phongNo ratings yet

- PM3200 Series User ManualDocument82 pagesPM3200 Series User ManualНиколай МухаNo ratings yet

- MachineExpert Basic ReleaseNotes enDocument34 pagesMachineExpert Basic ReleaseNotes enFranklin Alfredo Colmenares MarchanNo ratings yet

- Vijeo Citect - Quick Start Tutorial - Part 1 Ver D PDFDocument97 pagesVijeo Citect - Quick Start Tutorial - Part 1 Ver D PDFAlex Chua Kok KeongNo ratings yet

- SCADAPack 32P ControllerDocument54 pagesSCADAPack 32P ControllerAnonymous VLoHH2No ratings yet

- PME 8.1 Installation - IT Infrastructure Preparation GuideDocument13 pagesPME 8.1 Installation - IT Infrastructure Preparation GuideVinicius AlmeidaNo ratings yet

- User Manual: Powerlogic Pm5300 SeriesDocument120 pagesUser Manual: Powerlogic Pm5300 SeriesSáng Bùi QuangNo ratings yet

- SmallEnergyMonitoringSystem TVD v1.0Document31 pagesSmallEnergyMonitoringSystem TVD v1.0VũDuyTânNo ratings yet

- Eav15107 En10Document124 pagesEav15107 En10Youssef El AjraouiNo ratings yet

- PME - DC - Ed - Commissioning - Guide 7EN02-0385-00Document142 pagesPME - DC - Ed - Commissioning - Guide 7EN02-0385-00VicNo ratings yet

- Schneider 5330Document122 pagesSchneider 5330cttam812No ratings yet

- User Manual: Powerlogic Pm5300 SeriesDocument114 pagesUser Manual: Powerlogic Pm5300 Seriesade widiNo ratings yet

- Schneider Scadapack Controller Quick Start ManualDocument15 pagesSchneider Scadapack Controller Quick Start ManualMike McKayNo ratings yet

- Conzerv™ Em64Xxh Series: User ManualDocument64 pagesConzerv™ Em64Xxh Series: User ManualSindhuKumarNo ratings yet

- Power Manager 1.3 Design GuideDocument57 pagesPower Manager 1.3 Design GuideGutus NirwantoNo ratings yet

- User Manual: Conzerv EM6400NG+Document70 pagesUser Manual: Conzerv EM6400NG+Shailesh YdvNo ratings yet

- Vijeo Citect Quick Start Tutorial Part 1Document97 pagesVijeo Citect Quick Start Tutorial Part 1frenchcmmNo ratings yet

- ATV12 User Manual en BBV28581 05Document143 pagesATV12 User Manual en BBV28581 05Bima Richardo SihombingNo ratings yet

- CitectSCADA - Quick Start Tutorial - Part 1Document89 pagesCitectSCADA - Quick Start Tutorial - Part 1Adit GilaNo ratings yet

- A9MEM3115 User ManualDocument134 pagesA9MEM3115 User ManualispiracscribdNo ratings yet

- Cyber Security For Automation Systems - v1.0 - Training ManualDocument53 pagesCyber Security For Automation Systems - v1.0 - Training ManualjacobnamoonNo ratings yet

- How Can I : Improve Motor Management With iPMCC - V3.1Document72 pagesHow Can I : Improve Motor Management With iPMCC - V3.1Kiran ReddyNo ratings yet

- User Manual: Easylogic Em64Xxh SeriesDocument68 pagesUser Manual: Easylogic Em64Xxh SeriesNandgulab Deshmukh0% (1)

- PLC - m258 - Performance PackagingDocument151 pagesPLC - m258 - Performance PackagingUlisses AlbuquerqueNo ratings yet

- Ats22 User Manual en Bbv51330 04Document85 pagesAts22 User Manual en Bbv51330 04Luis RolaNo ratings yet

- Modicon PAC Engineering and Operation SoftwareDocument64 pagesModicon PAC Engineering and Operation SoftwareEEngineNo ratings yet

- EcoStruxure Modicon Builder V3.1Document145 pagesEcoStruxure Modicon Builder V3.1jairoberNo ratings yet

- Modicon M580 Quick Start - v1.0 - Training ManualDocument169 pagesModicon M580 Quick Start - v1.0 - Training Manualaryan_iust0% (1)

- b0700gd KDocument25 pagesb0700gd KAlia RedhaNo ratings yet

- NHA2778902-00 - User ManualDocument66 pagesNHA2778902-00 - User Manualหนุ่ม วัยทองNo ratings yet

- 590 Safety ManualDocument54 pages590 Safety ManualTaz Juan G100% (2)

- Aastha ConsultingDocument4 pagesAastha Consultinghkzn groupNo ratings yet

- DS ANT TNA352A33rDocument3 pagesDS ANT TNA352A33rEdelNo ratings yet

- ISO 817 2014 Amd 2 2021Document10 pagesISO 817 2014 Amd 2 2021EdwinMedinaBejaranoNo ratings yet

- 1.1 Notes - Functional Elements of An InstrumentDocument4 pages1.1 Notes - Functional Elements of An InstrumentB. MeenakshiNo ratings yet

- PCP - VersionDocument33 pagesPCP - VersionKiran JoshiNo ratings yet

- Isms ServicesDocument2 pagesIsms ServicesDoanh DoanhNo ratings yet

- BR4144A.8 英 (conector)Document1 pageBR4144A.8 英 (conector)Victor GuzmanNo ratings yet

- Design, Development and Characterization of Resistive Arm Based Planar and Conformal Metasurfaces For RCS ReductionDocument15 pagesDesign, Development and Characterization of Resistive Arm Based Planar and Conformal Metasurfaces For RCS Reductionfereshteh samadiNo ratings yet

- Safety CVDocument13 pagesSafety CVJ Russel DichosoNo ratings yet

- A Brief History of Communications PDFDocument166 pagesA Brief History of Communications PDFIbrahim G. GordilsNo ratings yet

- Passive Optical Network of Company ECIDocument39 pagesPassive Optical Network of Company ECIKundan VanamaNo ratings yet

- Procurement Monitoring Report JuneDocument2 pagesProcurement Monitoring Report JuneKaJong JaclaNo ratings yet

- Satyam Eye Hospital - Google SearchDocument1 pageSatyam Eye Hospital - Google SearchRajeshwar GargeNo ratings yet

- TK371 Plano ElectricoDocument2 pagesTK371 Plano ElectricoCarlos IrabedraNo ratings yet

- Web Development ProposalDocument7 pagesWeb Development ProposalTaiwo PraiseNo ratings yet

- Create A System Repair Disc !Document13 pagesCreate A System Repair Disc !deenNo ratings yet

- Omv Lo SR2 XMSLC ZD KDocument9 pagesOmv Lo SR2 XMSLC ZD KAsad AhmedNo ratings yet

- Concrete Business in A BOXDocument35 pagesConcrete Business in A BOXDessalegn GaminiNo ratings yet

- Welcome Letter - RobotStudio School Edition - 107670Document1 pageWelcome Letter - RobotStudio School Edition - 107670Meche HerztNo ratings yet

- Ncpre BombayDocument5 pagesNcpre BombaySingh SranNo ratings yet

- Contract Management SAPDocument5 pagesContract Management SAPRitesh Singh0% (1)

- SG 8Document2 pagesSG 8sindhu67% (6)

- Hec Boq SubconDocument25 pagesHec Boq SubconSHRIYA POWERNo ratings yet

- MP3 Active/Passive Chassis: Installation & Operation ManualDocument46 pagesMP3 Active/Passive Chassis: Installation & Operation ManualLuis Carlos SolanoNo ratings yet

- Block Diagram: (LCR System: On)Document2 pagesBlock Diagram: (LCR System: On)blogexplosivo1547No ratings yet

- Installation Procedure For Version 4.2.12.00 - Release 4.2Document54 pagesInstallation Procedure For Version 4.2.12.00 - Release 4.2Talhaoui ZakariaNo ratings yet

- Combined Cycle Power Plant - Summary StudyDocument3 pagesCombined Cycle Power Plant - Summary StudydndudcNo ratings yet

- IIT Bombay Spoken Tutorials For ICT Training in Schools: Value To The SchoolDocument2 pagesIIT Bombay Spoken Tutorials For ICT Training in Schools: Value To The SchoolmanaliNo ratings yet

- CTXM-M FTXM-M 3PEN393186-10J Operation Manuals EnglishDocument48 pagesCTXM-M FTXM-M 3PEN393186-10J Operation Manuals EnglishAllf AllfNo ratings yet