Professional Documents

Culture Documents

GetTempFile Ashx

GetTempFile Ashx

Uploaded by

Michelle SilvaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GetTempFile Ashx

GetTempFile Ashx

Uploaded by

Michelle SilvaCopyright:

Available Formats

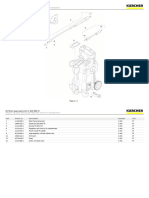

CE Mark HT-400™ Pump Maintenance and Repair Manual

Table 6.1—HT-400 Pump Fastener Torque Values*

Friction 0.078 0.110 0.200 0.078 0.110 0.200

Copper Moly- Copper- Moly-

Oil Oil

Thread -based based based based

Fastener

Diameter

Torque

in. n (ft-lb) (ft-lb) (ft-lb) (N-m) (N-m) (N-m)

FE attaching stud into power

1.000 14 146 200 350 198 271 475

end PE (all)

Nut to FE attaching stud (not

1.000 14 733 810 1026 993 1099 1391

more than 1/2 turn of nut)

Nut to FE attaching stud on

1.000 14

BEARCAT PUMP ONLY (do 750 830 1051 1018 1125 1425

not exceed 1/2 turn of nu)t

Top TB 1.375 12 1089 1500 2640 1476 2034 3579

Bottom TB 0.750 16 147 200 348 199 271 472

Discharge flange stud to FE 1.000 14 146 200 349 197 271 474

Nut to discharge flange stud 1.000 14 321 440 770 435 597 1044

1.000 14

PR TB to X-head 229 314 550 311 426 746

1.000 14

PR retainer to pushrod TB 188 257 450 254 349 610

Plunger TB to pushrod

1.000 14 146 200 350 198 271 475

retainer

1.000 14

Plunger Nose to Plunger TB 104 143 250 141 194 339

Connecting rod cap bolt 0.750 10 97 130 220 131 176 298

Gear support flange 0.500 13 38 50 84 51 68 114

Gear support thrust plate 0.500 13 45 60 101 61 82 137

PE 2x to 3x Bolt and Nut 0.625 11 132 175 296 179 238 401

PE 2x to 3x Bolt only 0.625 11 117 155 262 158 210 355

Suction header stud 0.625 11 75 100 168 102 135 228

Suction header nut 0.625 11 113 150 253 153 203 343

Allison transmission nut 2.000 16 573 800 1430 776 1085 1938

Grizzly™ pump input flange 0.500 13 57 75 127 77 102 172

* PR=Pushrod * X-head=Cross-head

* TB=Tie-Bolt * PE=Power End

* FE=Fluid End

6-2 Standard Fluid End Maintenance and Repair September 2008

You might also like

- HTB1YUPsGpXXXXbhXpXX PRXFXXXBDocument89 pagesHTB1YUPsGpXXXXbhXpXX PRXFXXXBFabio Andres Plata TorresNo ratings yet

- 744fe 855fe Parts Cata June11Document119 pages744fe 855fe Parts Cata June11manish yadav100% (2)

- Saint Gobain Prise List 01.02.2020Document9 pagesSaint Gobain Prise List 01.02.2020jaya prakash0% (1)

- KKK K14 K16Document6 pagesKKK K14 K16Cesar Riquelme100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Torpedo Catalogue 2016Document16 pagesTorpedo Catalogue 2016Cristobal Ordoñez50% (2)

- Service PartsDocument6 pagesService Partsslam9No ratings yet

- Montabert HC109Document14 pagesMontabert HC109Yiğit Erpak100% (2)

- Alliance Filter Cross Reference PDFDocument1 pageAlliance Filter Cross Reference PDFluisxxx1No ratings yet

- Assly.:-Assembly Sub.:-Sub Assembly 1 of 6: Sl. No. Quantity Article No. Unit Price Main Assly. Sub. Item DescriptionDocument6 pagesAssly.:-Assembly Sub.:-Sub Assembly 1 of 6: Sl. No. Quantity Article No. Unit Price Main Assly. Sub. Item DescriptionDarshana ChathurangaNo ratings yet

- 9853 6666 20h - COP 1840EX Version E (2012)Document156 pages9853 6666 20h - COP 1840EX Version E (2012)Rıfat Bingül100% (2)

- SpareParts 2010.10 enDocument17 pagesSpareParts 2010.10 enBehnam Ashouri100% (1)

- Motor and Gear G500 S8000 4kW LL, 5,5kW LL, 11kW and 11kW LL - Parts List - 2020Document1 pageMotor and Gear G500 S8000 4kW LL, 5,5kW LL, 11kW and 11kW LL - Parts List - 2020Centrifugal SeparatorNo ratings yet

- 600 KN Towing Winch ManualDocument173 pages600 KN Towing Winch ManualMartellusNo ratings yet

- Auto Coner 338 Engineer ReportDocument14 pagesAuto Coner 338 Engineer ReportSudhakar ReddyNo ratings yet

- Gearbox: Ecosplit I-IiDocument12 pagesGearbox: Ecosplit I-IiDpr OranNo ratings yet

- ShortSpareHD511P 15209600Document2 pagesShortSpareHD511P 15209600rizky anshoriNo ratings yet

- ShortSpareHDS818 4C - 11749000 1Document2 pagesShortSpareHDS818 4C - 11749000 1Abush GezuNo ratings yet

- Conn11a - Id MarkupDocument1 pageConn11a - Id MarkupAbdul basithNo ratings yet

- FORD CamsDocument10 pagesFORD CamsMystic BikerNo ratings yet

- BENDIX TF 550 750 PartesDocument2 pagesBENDIX TF 550 750 PartesJime CastroNo ratings yet

- MR 50,58,63 Parts Manual-2013Document26 pagesMR 50,58,63 Parts Manual-2013acanutrNo ratings yet

- Madass Parts ManualDocument59 pagesMadass Parts ManualDario Gabriel Coz RojasNo ratings yet

- SAB202 SparesdwgDocument17 pagesSAB202 Sparesdwgsalamaquinasf5100% (1)

- Conn9b - Id MarkupDocument1 pageConn9b - Id MarkupAbdul basithNo ratings yet

- Remanufactured Transmissions, Spare Parts, and Kits Catalog: 6S-750 Diesel UnitsDocument11 pagesRemanufactured Transmissions, Spare Parts, and Kits Catalog: 6S-750 Diesel UnitsFernando CabildoNo ratings yet

- Parts - List For Type: SLH-4GDocument5 pagesParts - List For Type: SLH-4Gtomas andres gonzalez mancillaNo ratings yet

- Ket Data SlowmovDocument42 pagesKet Data Slowmovslamet supriyadiNo ratings yet

- HP700 Rock-Machinery Parts ListDocument2 pagesHP700 Rock-Machinery Parts Listxin daiNo ratings yet

- A .4 Front Axle - Multi Disc Brake Schaffer 4350ZDocument3 pagesA .4 Front Axle - Multi Disc Brake Schaffer 4350ZSergeyNo ratings yet

- Conn7a - Id MarkupDocument1 pageConn7a - Id MarkupAbdul basithNo ratings yet

- Leistritz Re Eng L3 Pump WebDocument4 pagesLeistritz Re Eng L3 Pump WebChuong DongNo ratings yet

- Cost Report Part Time Description Qty Total Price GST Rate' GST Wheel AssemblyDocument3 pagesCost Report Part Time Description Qty Total Price GST Rate' GST Wheel AssemblyRadhe shamNo ratings yet

- Bearing Items InformationDocument1 pageBearing Items InformationAhmed Hassan Abo AsemNo ratings yet

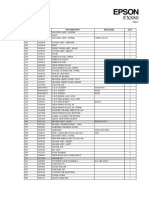

- FX 880Document5 pagesFX 880Nma ColonelnmaNo ratings yet

- Document 1Document3 pagesDocument 1Lucas sckuvieNo ratings yet

- HALLDE SpareParts RG-250 GBDocument3 pagesHALLDE SpareParts RG-250 GBjozsefhvNo ratings yet

- NB: PART NO. RATIONALISATION - 10 Digit Part Nos. in Brackets Are The Old Numbers For Otherwise Identical ItemsDocument7 pagesNB: PART NO. RATIONALISATION - 10 Digit Part Nos. in Brackets Are The Old Numbers For Otherwise Identical ItemsNma ColonelnmaNo ratings yet

- Stylus C80 Parts List and Diagram PDFDocument14 pagesStylus C80 Parts List and Diagram PDFDeniskoffNo ratings yet

- Coursework 1Document8 pagesCoursework 1petramariakjaloNo ratings yet

- Socket Weld Fittings CatalogDocument2 pagesSocket Weld Fittings CatalogstelioskoNo ratings yet

- Ferrofluid Feedthrough Catalog 2Document6 pagesFerrofluid Feedthrough Catalog 2germoal1468No ratings yet

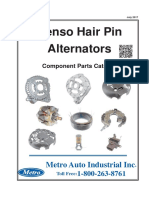

- Denso Hair Pin Parts CatalogDocument84 pagesDenso Hair Pin Parts CatalogrustyNo ratings yet

- SAB163 MK4 SparesDocument7 pagesSAB163 MK4 SparesYutt WattNo ratings yet

- OGL Culver Details 6+000 To 9+000Document5 pagesOGL Culver Details 6+000 To 9+000Bscpl Repalle to EeppurpalemNo ratings yet

- Chief 20partsDocument5 pagesChief 20partsEdgar ReikiNo ratings yet

- Sup 0014Document33 pagesSup 0014Tomy lee youngNo ratings yet

- Angle Grinder 3 601 C88 171 GWS 7-115 230V, GBDocument3 pagesAngle Grinder 3 601 C88 171 GWS 7-115 230V, GBmichaelmangaaNo ratings yet

- Fig.z 04 TTTG PN16 DN15-200 F4-F5Document1 pageFig.z 04 TTTG PN16 DN15-200 F4-F5d k70No ratings yet

- Parts List 8443B255DDocument2 pagesParts List 8443B255DЕвгенийNo ratings yet

- Roofmaster Light - Parts List V4.2Document16 pagesRoofmaster Light - Parts List V4.2AmeniNo ratings yet

- SAB 202 Parts List LASTDocument12 pagesSAB 202 Parts List LASTsalamaquinasf5No ratings yet

- Heavy Duty Industrial FanDocument16 pagesHeavy Duty Industrial FanAli MarsousiNo ratings yet

- NB: PART NO. RATIONALISATION - 10 Digit Part Nos. in Brackets Are The Old Numbers For Otherwise Identical ItemsDocument11 pagesNB: PART NO. RATIONALISATION - 10 Digit Part Nos. in Brackets Are The Old Numbers For Otherwise Identical ItemsAivars LīpenītsNo ratings yet

- Ficha Tecnica MOTOR BALDORDocument11 pagesFicha Tecnica MOTOR BALDORcarlos.castillo.ing.1No ratings yet

- Sink WDocument2 pagesSink WJake GlaxNo ratings yet

- In-Line Injection Pump Parts: Item Description Qty Part NumberDocument3 pagesIn-Line Injection Pump Parts: Item Description Qty Part NumberanilNo ratings yet

- Conn8b - Id MarkupDocument1 pageConn8b - Id MarkupAbdul basithNo ratings yet

- PLL 1737Document2 pagesPLL 1737pankarvi6No ratings yet

- Honda Wave 100, 100S 2005Document88 pagesHonda Wave 100, 100S 2005hwahydNo ratings yet

- NB: Part Number Rationalisation - 10 Digit Part Numbers in Brackets Are The Old Numbers For Otherwise Identical ItemsDocument6 pagesNB: Part Number Rationalisation - 10 Digit Part Numbers in Brackets Are The Old Numbers For Otherwise Identical ItemsNma ColonelnmaNo ratings yet

- Sluice Valve With ISI MarkDocument3 pagesSluice Valve With ISI Markatul.mankarNo ratings yet

- Listadepartes rc2-510 061112 1352202133 85Document2 pagesListadepartes rc2-510 061112 1352202133 85sri ganesh RNo ratings yet

- A200 Ion Users Manual Rev1Document151 pagesA200 Ion Users Manual Rev1Fido DidoNo ratings yet

- Catalogo X10R - 32Document2 pagesCatalogo X10R - 32Walter FormigoniNo ratings yet

- LPK1613 709 46Document8 pagesLPK1613 709 46amitsonuksmsNo ratings yet

- 3 Electrical P120 6VDocument28 pages3 Electrical P120 6Vmalte winbaldNo ratings yet

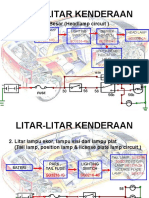

- Litar-Litar Kenderaan (Simulator)Document7 pagesLitar-Litar Kenderaan (Simulator)Fakhrul Helmi MieNo ratings yet

- Honda Civic EXDocument34 pagesHonda Civic EXJacinto BlancoNo ratings yet

- Shing Ling SL-700 Part BookDocument81 pagesShing Ling SL-700 Part BookRATSITOHARA EricNo ratings yet

- Fiat Doblo Panorama 2016 Owner's ManualDocument323 pagesFiat Doblo Panorama 2016 Owner's ManualZaki YoussifNo ratings yet

- GWM Haval Portfolio and List of Accessories and Merchandise Updated 1Document4 pagesGWM Haval Portfolio and List of Accessories and Merchandise Updated 1dboibreeNo ratings yet

- Target Hydrautech Private LimitedDocument21 pagesTarget Hydrautech Private LimitedSandeepNairNo ratings yet

- EN How To Change Front Brake Pads On Toyota Auris E15 Replacement GuideDocument22 pagesEN How To Change Front Brake Pads On Toyota Auris E15 Replacement Guideorban.jozsef.david2No ratings yet

- Spare Parts List: Hydraulic BreakerDocument16 pagesSpare Parts List: Hydraulic BreakerWilfredo MundarayNo ratings yet

- September '95: 26.32 FR CARRARO AXLE REF. 130880 For "MATBRO" Spare Parts ListDocument9 pagesSeptember '95: 26.32 FR CARRARO AXLE REF. 130880 For "MATBRO" Spare Parts ListCommaTECH Iasi 3No ratings yet

- Parts Manual: CascadeDocument14 pagesParts Manual: Cascadedanylo.msgNo ratings yet

- TSeries B242DDocument182 pagesTSeries B242DArgopartsNo ratings yet

- 2020 Front Suspension Oil Air Coil Token Specification EnglishDocument25 pages2020 Front Suspension Oil Air Coil Token Specification EnglishMarcin CinasNo ratings yet

- Free Wheeling Hub MaintenanceDocument28 pagesFree Wheeling Hub MaintenanceVitor RamosNo ratings yet

- BRENO Lights 2020 2021Document16 pagesBRENO Lights 2020 2021林永康No ratings yet

- Part Number Part Name Supply Date Supply Time Unloadi NG Loc Usage LOC Quantit YDocument3 pagesPart Number Part Name Supply Date Supply Time Unloadi NG Loc Usage LOC Quantit YTutejaNo ratings yet

- APT 160 Paving Breaker Parts BreakdownDocument1 pageAPT 160 Paving Breaker Parts BreakdownMikeNo ratings yet

- Spare PartsDocument4 pagesSpare PartsMariano GimenezNo ratings yet

- Page 1 of 4 Merimen E-Claims: Johor BahruDocument4 pagesPage 1 of 4 Merimen E-Claims: Johor BahruKhairul Arif Abd LatifNo ratings yet

- 98Document2 pages98StuartBohmNo ratings yet

- Right Parts Right Points: THE For The of Your JourneyDocument6 pagesRight Parts Right Points: THE For The of Your JourneyRodion Kamyshenko100% (1)

- Parts Catalog Option DetailDocument2 pagesParts Catalog Option DetailDmytro PichkurNo ratings yet