Professional Documents

Culture Documents

Corrective Action

Corrective Action

Uploaded by

savanth jayaram0 ratings0% found this document useful (0 votes)

4 views1 pageThe document outlines steps to take when unacceptable leakage occurs during hydrostatic testing of HDPE pipes:

1. Identify the source of the leak and isolate the leaking section to prevent further damage.

2. Gradually reduce pressure and assess the severity of the leakage to determine the appropriate corrective measures.

3. Consider temporary repairs like sealing materials or clamps before implementing permanent repairs such as replacing damaged sections or welding in a spool piece. Monitor repairs and retest the system.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines steps to take when unacceptable leakage occurs during hydrostatic testing of HDPE pipes:

1. Identify the source of the leak and isolate the leaking section to prevent further damage.

2. Gradually reduce pressure and assess the severity of the leakage to determine the appropriate corrective measures.

3. Consider temporary repairs like sealing materials or clamps before implementing permanent repairs such as replacing damaged sections or welding in a spool piece. Monitor repairs and retest the system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageCorrective Action

Corrective Action

Uploaded by

savanth jayaramThe document outlines steps to take when unacceptable leakage occurs during hydrostatic testing of HDPE pipes:

1. Identify the source of the leak and isolate the leaking section to prevent further damage.

2. Gradually reduce pressure and assess the severity of the leakage to determine the appropriate corrective measures.

3. Consider temporary repairs like sealing materials or clamps before implementing permanent repairs such as replacing damaged sections or welding in a spool piece. Monitor repairs and retest the system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Oman Water Treatment Company SAOC

C.R.No. 1/34896/5

Doc No: C-06-23-AN-CAP-001

19.11.2023

CORRECTIVE ACTION PLAN FOR HDPE PIPE

LEAKAGE REPAIR AT YIBAL

If unacceptable leakage occurs during a hydrostatic test of an HDPE (high-density

polyethylene) pipe, it's important to take immediate corrective actions to address the issue.

Here are steps you can follow:

1. Identify the Source:

- Stop the hydrostatic test immediately and identify the source of the leakage.

- Conduct a visual inspection and use appropriate methods (such as pressure testing

instruments) to pinpoint the location of the leak.

2. Isolate the Leaking Section:

- If possible, isolate the leaking section of the HDPE pipe to prevent further leakage. This

may involve closing valves or using other isolation methods.

3. Reduce Pressure:

- Gradually reduce the pressure in the affected section to minimize the extent of the

leakage. This can help prevent further damage and make it easier to implement repairs.

4. Assess the Severity:

- Evaluate the severity of the leakage to determine the appropriate corrective measures. A

minor leak may have different solutions than a major rupture.

5. Temporary Repairs:

- Consider temporary measures to stop the leakage and allow for a controlled shutdown of

the hydrostatic test.

- Use appropriate sealing materials or clamps to temporarily stop the leak.

6. Prepare the Pipe Surface:

- Clean the area around the leak to ensure proper adhesion of repair materials.

- Remove any dirt, debris, or contaminants from the pipe surface.

7. Implement Permanent Repairs:

- Depending on the severity of the damage, this may involve replacing the damaged

section of the HDPE pipe or implementing a more robust repair solution.

- If the leak is in at Joint, cut the Joint with 500 mm both end.

- Weld the cut portion with a spool piece,

8. Monitor and Test:

- Monitor the repaired section for any signs of further leakage.

- If feasible, reinitiate a controlled hydrostatic test to verify the effectiveness of the repair.

9. Review and Learn:

- Conduct a thorough review of the incident to understand the cause of the leakage and

implement preventive measures to avoid similar issues in future tests.

Always consult with a qualified professional or the manufacturer of the HDPE pipe for

specific guidance on repairing and addressing leaks in your particular system. Following

industry best practices and safety guidelines is crucial during corrective actions in

hydrostatic testing scenarios.

P.O.BOX-93, RUSAYL, POSTAL CODE-124, SULTANATE OF OMAN. TEL: +968 24446514/ 5/ 9, FAX: +968 24446509

Web : www.owatco.com Emails : owatco@omantel.net.om, omanwtc@gmail.com

Doc Ref NO: OWATCO-F21-00

You might also like

- Method Statement For The Installation of Water Treatment PlantDocument12 pagesMethod Statement For The Installation of Water Treatment Plantafraz_xec89% (19)

- Method Statement - HVAC Duct Leakage Testing ProcedureDocument7 pagesMethod Statement - HVAC Duct Leakage Testing ProcedureSyed TouqeerNo ratings yet

- Astm F1417.aDocument6 pagesAstm F1417.aKelly Bates100% (2)

- Line BreakDocument30 pagesLine Breakmanoranjan singhNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Subsea Pipeline Design, Analysis, and InstallationFrom EverandSubsea Pipeline Design, Analysis, and InstallationRating: 3 out of 5 stars3/5 (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Hose Selection: Selection, Installation and Maintenance of Hose and Hose AssembliesDocument2 pagesHose Selection: Selection, Installation and Maintenance of Hose and Hose AssembliesAbdul JunaediNo ratings yet

- Astm F1041Document2 pagesAstm F1041Hernando Andrés Ramírez Gil100% (1)

- Api 653 Report-Hydrolic Test PDFDocument12 pagesApi 653 Report-Hydrolic Test PDFnaoufel1706No ratings yet

- INS - OUTS of HYDRO TESTINGDocument3 pagesINS - OUTS of HYDRO TESTINGJosh WhiteNo ratings yet

- Fsa PSJ 701 06 PDFDocument9 pagesFsa PSJ 701 06 PDFAshitava SenNo ratings yet

- TN021 Squeezing-Off Polyethylene Pipes July 2023Document3 pagesTN021 Squeezing-Off Polyethylene Pipes July 2023RicNo ratings yet

- Line BreakingDocument8 pagesLine BreakingkaremkokoNo ratings yet

- Fluid Sealing Standards For NMEJ StandardsDocument9 pagesFluid Sealing Standards For NMEJ Standardsamol1321No ratings yet

- Info Brief #8: Proper Squeeze-Off ProcedureDocument2 pagesInfo Brief #8: Proper Squeeze-Off Proceduremoch ardiansyahNo ratings yet

- Jones Hydrant OM 8-21-09Document6 pagesJones Hydrant OM 8-21-09RktBatamNo ratings yet

- Composite Hose InformationDocument3 pagesComposite Hose InformationXain ChaudharyNo ratings yet

- 13 PiggingDocument14 pages13 PiggingDaniel DamboNo ratings yet

- Hydrostatic and Settlement Tests ProcedureDocument12 pagesHydrostatic and Settlement Tests Procedureツ ツ100% (1)

- Care and Maintenance of HoseDocument3 pagesCare and Maintenance of HosehydrasearchNo ratings yet

- Procedure Natural Gas Piping Purging HazardsDocument4 pagesProcedure Natural Gas Piping Purging HazardsEko KurniawanNo ratings yet

- TN 46 Guidance Field Hydro Test Hdpe Pressure ConsiderationsDocument17 pagesTN 46 Guidance Field Hydro Test Hdpe Pressure ConsiderationsZohair AftabNo ratings yet

- TN 46Document23 pagesTN 46Khalil AhmadNo ratings yet

- Dead Leg Rupture HSE 20190829Document3 pagesDead Leg Rupture HSE 20190829kuraimundNo ratings yet

- Re-Welding, Expansion & HT ProcedureDocument6 pagesRe-Welding, Expansion & HT Proceduresuria qaqcNo ratings yet

- Mechanical PlugsDocument6 pagesMechanical Plugskategord0% (1)

- Pressure Testing of Pipelines: CR Asia GroupDocument7 pagesPressure Testing of Pipelines: CR Asia Groupvishal bailurNo ratings yet

- Field Hydrotest Manual UndergroundDocument8 pagesField Hydrotest Manual UndergroundPhuoc PhuNo ratings yet

- Preparing A Prover For A Water Draw CalibationsDocument3 pagesPreparing A Prover For A Water Draw CalibationsLeonel NavaNo ratings yet

- Installation / Operation / Maintenance Instructions Magnetic Level GaugeDocument6 pagesInstallation / Operation / Maintenance Instructions Magnetic Level GaugeHumayun NawazNo ratings yet

- A Good Practice Guide For The Electrofusion Jointing of Larger Diameter Polyethylene Pressure PipesDocument20 pagesA Good Practice Guide For The Electrofusion Jointing of Larger Diameter Polyethylene Pressure PipesHilal Al KhuzaimiNo ratings yet

- Alkazri - 2008 - A Quick Guide To Pipeline Engineering - 4 Pipeline Decommissioning and Industry DevelopmentsDocument9 pagesAlkazri - 2008 - A Quick Guide To Pipeline Engineering - 4 Pipeline Decommissioning and Industry DevelopmentsRUSSEL SAHDA MALAKANo ratings yet

- This Document Was Downloaded From The Penspen Integrity Virtual LibraryDocument20 pagesThis Document Was Downloaded From The Penspen Integrity Virtual LibraryGRANRICKYNo ratings yet

- Series 808Y Installation InstructionsDocument4 pagesSeries 808Y Installation InstructionsFEBCONo ratings yet

- Managing Ili ProjectsDocument13 pagesManaging Ili ProjectsuncleflowerNo ratings yet

- Manual DPCVDocument8 pagesManual DPCVbhaaskarNo ratings yet

- Boiler Hydrostatic TestingDocument2 pagesBoiler Hydrostatic Testingbonginkosi mathunjwaNo ratings yet

- BP - Tb0002inspection of Small-Bore Fittings and PipeworkDocument4 pagesBP - Tb0002inspection of Small-Bore Fittings and PipeworkMohd Khairul100% (1)

- DKK2462 Chapter 7Document15 pagesDKK2462 Chapter 7rawanisephiaNo ratings yet

- Furmanite Failure ModesDocument34 pagesFurmanite Failure ModespkannanNo ratings yet

- Nfpa 291 Hyd - Test PDFDocument11 pagesNfpa 291 Hyd - Test PDFJeff D. Agustin100% (1)

- Technical Service Bulletin: LG Water SolutionsDocument1 pageTechnical Service Bulletin: LG Water SolutionsCherifi ChawkiNo ratings yet

- Design Guidelines For Safety in Piping NetworkDocument15 pagesDesign Guidelines For Safety in Piping NetworkrvnesariNo ratings yet

- PVC Pipeline Design ManualDocument86 pagesPVC Pipeline Design ManualxkishanNo ratings yet

- Piping Tie-Ins The BasicsDocument4 pagesPiping Tie-Ins The BasicsashokNo ratings yet

- Rofi Operation and Maintenance ManualDocument3 pagesRofi Operation and Maintenance ManualSteve NewmanNo ratings yet

- Testing and Maintenacne of High Voltage Bushings PsmmCHAP-06Document24 pagesTesting and Maintenacne of High Voltage Bushings PsmmCHAP-06protectionwork100% (1)

- Sae J1273.02Document15 pagesSae J1273.02Igor Bastos100% (1)

- Sampling of Oil-Filled Power Apparatus Instructions: Why Sample?Document4 pagesSampling of Oil-Filled Power Apparatus Instructions: Why Sample?sajjad_pirzada100% (1)

- Procedure For Hydro Testing: Pressure TestDocument5 pagesProcedure For Hydro Testing: Pressure TestDevang ShahNo ratings yet

- Plumbing - Testing-and-CommissioningDocument26 pagesPlumbing - Testing-and-CommissioningMEONo ratings yet

- IADC Well Sharp WireLine UpdatedDocument143 pagesIADC Well Sharp WireLine UpdatedEmad ZakiNo ratings yet

- Troubleshooting Defects Hot Runner SystemDocument4 pagesTroubleshooting Defects Hot Runner SystemJorge MartinezNo ratings yet

- EconomicBenefits ValvesDocument4 pagesEconomicBenefits ValvesLuisPinda DazacolNo ratings yet

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsFrom EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsRating: 4.5 out of 5 stars4.5/5 (2)

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

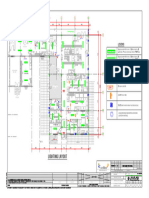

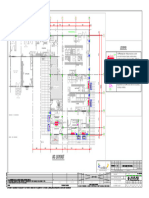

- Lek Kitchen Lighting LayoutDocument1 pageLek Kitchen Lighting Layoutsavanth jayaramNo ratings yet

- Lek Kitchen Ac LayoutDocument1 pageLek Kitchen Ac Layoutsavanth jayaramNo ratings yet

- 1200dia Vertical Tank-ModelDocument1 page1200dia Vertical Tank-Modelsavanth jayaramNo ratings yet

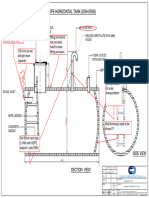

- 1800DIA. HORIZONTAL TANK - ModelDocument1 page1800DIA. HORIZONTAL TANK - Modelsavanth jayaramNo ratings yet

- 1800DIA. HORIZONTAL TANK - ModelDocument1 page1800DIA. HORIZONTAL TANK - Modelsavanth jayaramNo ratings yet

- 20201015111453920Document1 page20201015111453920savanth jayaramNo ratings yet

- Hydrotest Procedure C 6 23Document19 pagesHydrotest Procedure C 6 23savanth jayaramNo ratings yet

- Doc. No. Appendix D - HSE Risk Assessment 0 HDPE Pipe HydrotestDocument1 pageDoc. No. Appendix D - HSE Risk Assessment 0 HDPE Pipe Hydrotestsavanth jayaramNo ratings yet

- Hydrotest Check ListDocument2 pagesHydrotest Check Listsavanth jayaramNo ratings yet

- Hydrotest Pump CertificateDocument1 pageHydrotest Pump Certificatesavanth jayaramNo ratings yet

- Mcleod Gage ManualDocument11 pagesMcleod Gage ManualEzsilvasilva SilvaNo ratings yet

- Basic Guide To Calculating Falls and Gradients For Drainage - Basic Guide To Calculating Falls and Gradients For Drainage - Wyre CouncilDocument6 pagesBasic Guide To Calculating Falls and Gradients For Drainage - Basic Guide To Calculating Falls and Gradients For Drainage - Wyre Councilvenkateswara rao pothinaNo ratings yet

- Daikin Engineering Data VRV-WIII (2015)Document356 pagesDaikin Engineering Data VRV-WIII (2015)Adam Chan100% (1)

- Qa-Qc Multi Inspector CV (Welding-Painting-Ndt)Document7 pagesQa-Qc Multi Inspector CV (Welding-Painting-Ndt)mansih457No ratings yet

- FJM Odu Idu For Europe R410a 50hz Ver 1 1 TDBDocument221 pagesFJM Odu Idu For Europe R410a 50hz Ver 1 1 TDBEko RamadhaniNo ratings yet

- Venturi Tubes PDFDocument2 pagesVenturi Tubes PDFJericho Paulo RosalesNo ratings yet

- Calobri 12.10Document140 pagesCalobri 12.10Hal SkoglundNo ratings yet

- Cleaning Gauging Hydrautesting and Chemical CleaningDocument2 pagesCleaning Gauging Hydrautesting and Chemical CleaningJosephKaren LorzanoIlaganNo ratings yet

- 5599-9001-010EN0711 LumithermDocument45 pages5599-9001-010EN0711 LumithermGabriel RusuNo ratings yet

- Norma - Retaining Products: FIX HMKDocument8 pagesNorma - Retaining Products: FIX HMK井上孝平No ratings yet

- Kflex ST C0 TubesDocument8 pagesKflex ST C0 TubesDatashield InfoNo ratings yet

- C-SP-55-017 - Vertical Turbine PuDocument20 pagesC-SP-55-017 - Vertical Turbine PuEsteban Rios PitaNo ratings yet

- En 1435-RT PDFDocument24 pagesEn 1435-RT PDFKhwanas LuqmanNo ratings yet

- En 1253-1Document15 pagesEn 1253-1Zarko SretenovicNo ratings yet

- Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListDocument17 pagesSaudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListnadeemNo ratings yet

- Pipe Fittings and Port Adapters 5Document1 pagePipe Fittings and Port Adapters 5armin_kunosic9871No ratings yet

- FM 200 DesignDocument45 pagesFM 200 DesignNethajiNo ratings yet

- 3-A® Sanitary Standards - 17-11Document11 pages3-A® Sanitary Standards - 17-11CHRISTIAN ZAVALANo ratings yet

- 10-Air Conditioning Installations - Split Unit PDFDocument76 pages10-Air Conditioning Installations - Split Unit PDFsofyan_shahNo ratings yet

- Brochure Seamless Tubes For Hycy 20210525Document28 pagesBrochure Seamless Tubes For Hycy 20210525Carlos BenitezNo ratings yet

- 6300Document2 pages6300Ali BaigNo ratings yet

- GuidePDF-263553 PDFDocument6 pagesGuidePDF-263553 PDFlongkhanhckNo ratings yet

- 2GR FE ExhaustDocument5 pages2GR FE ExhaustLuks FernandezNo ratings yet

- Transmital Log - ACTIVE1Document40 pagesTransmital Log - ACTIVE1Hafeez AhmedNo ratings yet

- Solidworks Routing ToolsDocument22 pagesSolidworks Routing ToolsMichaelDelCastilloNo ratings yet

- Fisher 1098 Egr Pilot OperatedDocument34 pagesFisher 1098 Egr Pilot OperatedDavid Jesus Mejias LlanosNo ratings yet

- Nit 1005 Mab Amd 1Document95 pagesNit 1005 Mab Amd 1Pradeep KumarNo ratings yet

- 1.variable Spring Hanger or Variable Effort SupportDocument4 pages1.variable Spring Hanger or Variable Effort SupportMayur MandrekarNo ratings yet

- Tube and Pipe Inventor PDFDocument15 pagesTube and Pipe Inventor PDFBemvilac BritoNo ratings yet

- 1818 - KMBD-4500-10000 Installation Operation Maintenance Repair Manual - Mechanical Vacuum BoostersDocument32 pages1818 - KMBD-4500-10000 Installation Operation Maintenance Repair Manual - Mechanical Vacuum BoostersahmedNo ratings yet