Professional Documents

Culture Documents

Practica de Laboratorio Intercambiadores en Inglés

Practica de Laboratorio Intercambiadores en Inglés

Uploaded by

Juan D. CastroOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Practica de Laboratorio Intercambiadores en Inglés

Practica de Laboratorio Intercambiadores en Inglés

Uploaded by

Juan D. CastroCopyright:

Available Formats

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

1. IDENTIFICATION

Engineering

ACADEMIC PROGRAM

Transport Phenomena

COURSE

Heat exchanger

LABORATORY PRACTICE

2. GENERAL LABORATORY SAFETY RULES

REACTIVE

Quantity Name Risk* Safety Rules Emergency control

measures

N/A water burns Use gloves, Use gloves to avoid

glasses, and a burns whit hot

laboratory coat water tubes

EQUIPMENT

Quantity Name Risk * Safety Rules Emergency control

measures

1 Concentric tube burns Lab coat, gloves Use gloves to avoid

heat exchanger burns whit hot

WL302 water tubes

1 Shell and tube burns Lab coat, gloves Use gloves to avoid

heat exchanger burns whit hot

water tubes

MATERIALES

Quantity Name Risk* Safety Rules Emergency Control

measures

none none None none None

*Risk: Physical risk type 1

Here are all the. the reagents, equipment, and materials to be used during the development of the practice

3. GOOD PRACTICES OF ENVIRONMENTAL SUSTAINABILITY IN WASTE MANAGEMENT TO

BE TAKEN INTO ACCOUNT WHEN DEVELOPING THE PRACTICE

Waste Hazardous waste Waste disposal Emergency control

classification * measure

No waste No waste n/a n/a

*Hazardous waste classification: follow the “Hazardous and chemical materials disposal and storage

classification guide”.

If there is no generated waste, you will write not applicable. (N/A)

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 1 de 14

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

4.1 OBJECTIVE

1. Use the concepts learned during the semester to understand the phenomenology of heat

exchangers.

2. Study phenomenology in heat exchangers.

3. Apply concepts of mass and energy balances.

4. Develop analytical thinking in chemical processes.

4.2 THEORETICAL CONCEPTS

4.2.1. The function of a heat exchanger: A heat exchanger is a device that facilitates the process of heat

exchange between two fluids that are at different temperatures. Heat exchangers are used in many

engineering applications, such as refrigeration, heating and air-conditioning systems, power plants, chemical

processing systems, food processing systems, automobile radiators, and waste heat recovery units. During

heat transfer, the fluids do not come into direct contact or mix. The heat transport from the hot fluid to the cold

fluid takes place through a thermally conductive separating wall.

4.2.2. Heat Exchanger principles: All types of heat exchangers operate using the same thermodynamic

principles and mechanism of heat transfer. These principles basically describe how thermal energy is

transferred at the macroscopic level. Three bodies are interacting in a heat exchanger system: the hot fluid,

the cold fluid, and the wall separating the two fluids. Energy flows from the hot fluid, through the wall or

barrier, and then into the cold fluid. The following are some thermodynamic principles that are useful to

understand how heat exchangers work:

• 4.2.3. Thermodynamics principles in a heat exchanger: The first law is referred to as the Law of

Conservation of Energy, which states that energy (in the form of heat and work) can neither be created nor

destroyed. It can only be transferred to another system or converted to one form or another. In heat

exchangers, this statement is translated by the heat balance equation written as:

(Heat In) + (Generation of Heat) = (Heat Out) + (Accumulation of Heat)

Assuming it operates in a steady-state flow that means that the thermal properties remain constant at all

points as time changes, and the system is adiabatic (perfectly insulated), the heat balance equation

simplifies to Heat In = Heat Out. This is one of the most basic equations which is used in the design and

operation of heat exchangers.

4.2.3. Mechanisms of Heat Transfer

The mechanism involved in the transfer of heat in heat exchangers is a combination of both conduction and

convection. The driving force of heat transfer is the temperature difference between two or more regions.

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 2 de 14

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

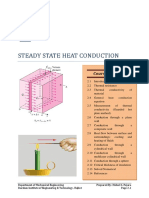

4.2.3.1. Conduction: . For heat exchangers, the conduction takes place on the wall separating the two

fluids. Fourier‘s Law of Heat Conduction states that the rate of heat transfer normal to the material‘s

cross-section is proportional to the negative temperature gradient. The proportionality constant is the

material‘s thermal conductivity.

4.2.3.2. Convection: Convection in heat exchangers occurs through the bulk motion of the fluid against the

surface of the wall, thus transferring thermal energy. This phenomenon is represented by Newton‘s Law of

Cooling which states the rate of heat loss is proportional of a body to the difference in the temperature of the

body and its surroundings (for this instance, the wall and the fluid).

During an operation of a heat exchanger with a conductive partition, heat is transferred from the hot fluid to

the cold fluid in this sequence:

1. 1.From the hot fluid to the adjacent surface of the wall by convection.

2. 2. Through the wall surface side by conduction.

3. 3. From the wall to the cold fluid by convection.

4.2.4. Flow configuration in a heat exchanger

• 4.2.4.1. Countercurrent Flow: In countercurrent flow heat exchangers, the process and utility fluid streams

flow in opposite directions. Countercurrent flow in heat exchangers is the most efficient and the most utilized

flow pattern. A large temperature difference of the fluids is almost maintained constant across the length of

the heat exchanger. This provides a more uniform heat transfer rate and minimizes thermal stress. It is also

possible for the cold fluid to have an outlet temperature close to the inlet temperature of the hot fluid

(highest temperature). This configuration requires less surface area compared to its co-current flow

counterpart.

•

•

• Co-current or Parallel Flow: In co-current or parallel-flow heat exchangers, the process and utility fluid

streams flow in parallel directions. It is suitable if the outlet temperatures of the two fluids are nearly the same

temperature. The temperature difference of the fluids is very large at the inlet and drastically decreases across

the length of the heat exchanger, which causes large thermal stress and eventual material failure. This

configuration has less efficiency compared to countercurrent flow.

•

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 3 de 14

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

• Cross Flow: In cross flow heat exchangers, the process and the utility fluids flow perpendicular to each

other. They are commonly used on systems with gas-liquid or vapor-liquid heat exchange, wherein the gas

or vapor is the process fluid. The liquid is contained in a tube and the gas flows outside those tubes.

Examples of a cross flow heat exchanger are steam condensers, radiators, and air conditioner evaporator

coils.

4.2.5. Types of heat exchangers

A heat exchanger is a broad class of heat transfer equipment

Recuperative Heat Exchangers

These types of heat exchangers are designed to have separate flow paths for the two fluids, wherein they

exchange heat simultaneously, utilize a conductive wall to separate the two fluids.

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 4 de 14

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

4.2.5.1 Double-pipe Heat Exchangers: Double-pipe heat exchangers, also known as a hairpin or jacketed

pipe exchanger, are the simplest type among the heat transfer equipment. They are made of two concentric

pipes with different diameters. The process fluid flows through the smaller inner pipe and the utility fluid flows

through the annular space between the two pipes. The wall of the inner pipe acts as the conductive barrier

between the two fluids wherein heat is transmitted. The countercurrent flow pattern is the most utilized, though

it may be configured to co-current flow.

Double pipe heat exchangers are suitable for heating or cooling small flow rates of fluids. They are cheap,

have a flexible design, and are easy to maintain. They can be constructed from pipes of the same lengths

interconnected with fittings at the ends to maximize floor space. However, they only operate at lower heating

duties compared to other heat exchanger equipment.

4.2.5.2 Shell and Tube Heat Exchangers: Shell and tube heat exchangers are composed of tubes arranged

in a bundle that is housed in a large cylindrical vessel called a shell. Similar to the double pipe heat exchanger,

the wall of the inner pipe acts as the conductive barrier. The process fluid flows in the tube side and the utility

fluid flows on the shell side.

Shell and tube heat exchangers are ideal for heating and cooling liquids with high flow rates, temperatures,

and pressures. To increase operational efficiency, they can be designed to have multiple passes wherein one

fluid comes in contact with the other several times.

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 5 de 14

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

4.2.5.3 Plate and Frame Heat Exchangers: These use a series of corrugated plates that are joined by either

a gasket, weld or braze to ensure that the two fluids do not mix. The plates have inlet and outlet ports on the

corner to allow passage of the fluid streams. The flow paths of the fluids are the spaces between the plates

and are arranged in alternating hot-cold-hot-cold fluid streams. Fluids flow in a countercurrent flow

configuration; the hot fluid flows down the plates while cold fluid flows up.

The design of the plate and frame heat exchanger creates a large heat transfer area, high turbulence, and

high fouling resistance. The overall heat transfer coefficient and efficiency are higher compared to tubular

heat exchangers. However, the high-pressure drop is encountered by the fluids due to high wall shear stress

that makes pumping costs expensive. It is also not advisable to be used if the fluids have high-temperature

differences.

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 6 de 14

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

4.5.2.4 comparison between the heat exchanger

4.3 METHOD

1 Record temperature curves · in parallel flow mode · in counterflow mode

2 Determine average heat flux for parallel flow and counterflow operation

3 Determine average overall heat transfer coefficients

The WL 302 trainer enables the study of the characteristic properties of heat transfer on the model of a

tubular heat exchanger. The heat transfer takes place in coaxially arranged tubes with the hot water passing

through the inner tube. Cold water flows in the outer tube. In doing so, the hot water emits some of its

thermal energy to the cold water. In experiments, both parallel flow and counterflow operation can be

demonstrated, with their different temperature curves. The non-linear temperature progression along the

tubular heat exchanger is demonstrated by measuring the water temperatures in both tubes at the inlet,

outlet and half of the transfer section. A measurement of the pipe wall temperature also allows the

investigation of convective heat transfer at the wall. In the experiment analysis, the important variables

such as heat flux, overall heat transfer coefficient and heat losses are determined. The closed hot water

circuit contains a tank with electrical heater and a pump. A thermostat keeps the hot water temperature

constant. The cold water is supplied and disposed of via the laboratory network. The flow rate and all

relevant temperatures are recorded. The measured values are read from digital displays and can be

transmitted simultaneously via USB directly to a PC, where they can be analysed using the software

included.

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 7 de 14

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

1. Adjust the desired Flow direction with valves 1,3,2,4. For parallel flow open valves 1

and 3, close valves 2 and 4.

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 8 de 14

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

2. For countercurrent flow open valves 2 and 4, close valves 1 and 3.

3. Parallel flow T4 cold water inlet, T6 cold water outlet, Countercurrent flow T6 cold

water inlet, T4 cold water outlet

Parallel flow Countercurrent flow

DATA TABLE

Counterflow configuration

Hot Water Flow Cold Water T4 °C T6 °C

(l/min) flow (l/min)

1

2

3

Parallel configuration

Hot Water Flow Cold Water T4 °C T6 °C

(l/min) flow (l/min)

1

2

3

Heat exchanger supply unit WL110

For this practice, you must:

1. compare the difference between heat exchangers

2. function and behavior of a tubular, Shell and tube, and plate heat exchanger during operation •

3. recording temperature curves in parallel flow operation, in counterflow operation

4. Calculation of mean heat transfer coefficient

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 9 de 14

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

CONFIGURATION EQUIPMENT SCHEME

HEAT EXCHANGER FOR THE PRACTICE

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 10 de 14

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

For the operation follow the lines and change the connections for counterflow or parallel flow

Tubular and Shell and tube heat exchanger Plate Exchanger

DATA TABLE

Counterflow configuration tube exchanger

Hot Water Flow Cold Water Cold water Hot water Middle

(l/min) flow (l/min) temperature temperature water

°C °C temperature

°C

1

2

3

Parallel configuration tube exchanger

Hot Water Flow Cold Water Cold water Hot water Middle

(l/min) flow (l/min) temperature temperature water

°C °C temperature

°C

1

2

3

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 11 de 14

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

Counterflow configuration shell tube exchanger

Hot Water Flow Cold Water Cold water Hot water

(l/min) flow (l/min) temperature temperature

°C °C

1

2

3

Parallel configuration Shell and tube exchanger

Hot Water Flow Cold Water Cold water Hot water

(l/min) flow (l/min) temperature temperature

°C °C

1

2

3

Counterflow configuration plate exchanger

Hot Water Flow Cold Water Cold water Hot water

(l/min) flow (l/min) temperature temperature

°C °C

1

2

3

Parallel configuration plate exchanger

Hot Water Flow Cold Water Cold water Hot water

(l/min) flow (l/min) temperature temperature

°C °C

1

2

3

4.4 CUESTIONARIO

1. the laboratory report must have a scientific article form

4.5 BIBLIOGRAFIC REFERENCES.

[1] J. M. Smith, H. C. V. Ness, and M. M. Abbott, Introduction to Chemical Engineering

Thermodynamics, 7th Edition, 7th edition. Boston, Mass.: McGraw Hill Higher Education, 2007.

[2] Y. A. Cengel, A. J. Ghajar, Heat and mass transfer fundamentals and applications, 5th

edition. New York: McGraw-Hill, 2014.

[3] Gunt WL302 series heat transfer in the tubular heat exchanger.

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 12 de 14

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

[4] Gunt WL110 series experiments of the fundamental of heat transfer.

[5] https://www.iqsdirectory.com/articles/heat-exchanger.html

EDUCATIONAL OUTCOME Resultados del aprendizaje

1. An ability to apply knowledge of 3. Management of industrial and laboratory

mathematics, science, and equipment

engineering 4. Energy balance calculations.

2. An ability to design and conduct 5. Equipment preparation and startup.

experiments, as well as to analyze

6. Preparation of PAPER-type report.

and interpret data

DEVELOP REVISE APPROVE

TEACHER COORDINATOR DIRECTOR

Jeffrey León Pulido Jeffrey León Pulido

Lina María Chacón Rivera

Date: 19/04/22 Date: 19/04/22 Date:19/04/2022

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 13 de 14

Versión: 0

FORMATO

Código: FRN-002-f1

GUIDELINE FOR LABORATORY PRACTICE Fecha: 26/01/2021

CHANGE CONTROL

DATE DESCRIPCIÓN DEL CAMBIO

19.04.2022 The laboratory guide is changed from Spanish to English

https://myrcc.rcc.mass.edu/ICS/103_lab_manual/mitosis-and-meiosis.html

https://www.iqsdirectory.com/articles/heat-exchanger.html

DOCUMENTO ORIGINAL FRN-002-f1 Pág. 14 de 14

You might also like

- 6 Series Counter Pressure AutoclaveDocument14 pages6 Series Counter Pressure AutoclavevivoNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Principles of Physics XI 2020 PDFDocument684 pagesPrinciples of Physics XI 2020 PDFululululululululu93% (15)

- Maintenance ManualDocument17 pagesMaintenance ManualSean ChanNo ratings yet

- ABCS of Fire Alarms Part 2Document3 pagesABCS of Fire Alarms Part 2doclap75No ratings yet

- Astm E337 15Document24 pagesAstm E337 15Yeferson Fabian Rico Osma100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- C 680 - 14Document29 pagesC 680 - 14Roberto Colonia100% (1)

- Fluent Tips and TricksDocument137 pagesFluent Tips and TricksalmohammadiNo ratings yet

- Shell & Tube JSA PDFDocument6 pagesShell & Tube JSA PDFAwinanto SaunNo ratings yet

- SOP Fire DrillsDocument8 pagesSOP Fire DrillsMayur WaghmareNo ratings yet

- Heated Breathing Tube - BMCDocument15 pagesHeated Breathing Tube - BMCremeshlogoNo ratings yet

- SCL 2022Document28 pagesSCL 2022alexiazavala40No ratings yet

- SCL Instruction Manual R2 09 18 PDFDocument28 pagesSCL Instruction Manual R2 09 18 PDFCLAUDIONo ratings yet

- Etia00 51710322 e StromboliDocument32 pagesEtia00 51710322 e StrombolimaidenjukaNo ratings yet

- Test On Vapor Compression Refrigeration-Batch 18Document4 pagesTest On Vapor Compression Refrigeration-Batch 18Ovini De SilvaNo ratings yet

- Guidelines For Fouling FactorsDocument8 pagesGuidelines For Fouling Factorsrajat vermaNo ratings yet

- AREA Introduction To EN 378 - For Publication - 0Document27 pagesAREA Introduction To EN 378 - For Publication - 0jorge rodriguezNo ratings yet

- Manual INCUBADORA THERMO 3110 PDFDocument104 pagesManual INCUBADORA THERMO 3110 PDFLuisa HernandezNo ratings yet

- DV-WC-0075 FPDocument20 pagesDV-WC-0075 FPSuresh KumarNo ratings yet

- Preface: About This PublicationDocument27 pagesPreface: About This PublicationRuben SantillanNo ratings yet

- Roto Vap SopDocument13 pagesRoto Vap Sopcristobal pascuaNo ratings yet

- Astm D7962 - 17Document3 pagesAstm D7962 - 17mancjaNo ratings yet

- Testo 557 Instruction ManualDocument28 pagesTesto 557 Instruction ManualSzabolcs KelemenNo ratings yet

- heat11-EXPLOSION PROTECTION in HTF-Plants WhitePaper PDFDocument12 pagesheat11-EXPLOSION PROTECTION in HTF-Plants WhitePaper PDFMomar Talla DiawNo ratings yet

- dm008205 enDocument6 pagesdm008205 enMusa ArysNo ratings yet

- Panel-Mounting Thermostats: Operating ManualDocument36 pagesPanel-Mounting Thermostats: Operating Manualremon thereminNo ratings yet

- Mettler HC103 Moisture Analyzer Quick Guide PDFDocument34 pagesMettler HC103 Moisture Analyzer Quick Guide PDFlab icNo ratings yet

- Towards Standard Testing Materials For High Temperature So - 2015 - Energy ProceDocument11 pagesTowards Standard Testing Materials For High Temperature So - 2015 - Energy Procepaween saetaeNo ratings yet

- Characterization of A Parabolic Trough Collector IAMDocument9 pagesCharacterization of A Parabolic Trough Collector IAMArshad AhmedNo ratings yet

- H VSD Series ManualDocument14 pagesH VSD Series Manualben.hamed.mouldiNo ratings yet

- D6745-11 (Reapproved 2015)Document6 pagesD6745-11 (Reapproved 2015)Albe CibiaNo ratings yet

- D 1610 - 00 - Rde2mtatmdaDocument2 pagesD 1610 - 00 - Rde2mtatmdaTarakJanaNo ratings yet

- SOP-Safety-01 (Working in Hot Environments)Document7 pagesSOP-Safety-01 (Working in Hot Environments)iswaraNo ratings yet

- Guidelines For Assessment of Temperature UniformitDocument4 pagesGuidelines For Assessment of Temperature UniformitGiaraf100% (1)

- D 3259 - 95 R01 - RdmyntkDocument2 pagesD 3259 - 95 R01 - RdmyntkEmre DalgicNo ratings yet

- Guidelines For The Protection of Pressurised Systems Exposed To Fire PDFDocument81 pagesGuidelines For The Protection of Pressurised Systems Exposed To Fire PDFhiginio.moro6182No ratings yet

- Yeast Tub Process Management SOP ExampleDocument6 pagesYeast Tub Process Management SOP ExampleJulissa CepedaNo ratings yet

- Itiot ExperimentDocument6 pagesItiot ExperimentShiv GuptaNo ratings yet

- Astm D1078 PDFDocument8 pagesAstm D1078 PDFJuan Carlos MejiaNo ratings yet

- Safe Use of Cryogenic MaterialsDocument28 pagesSafe Use of Cryogenic MaterialsJimmy Cuevas MonsalveNo ratings yet

- Ecourses - Ndri.res - in Moodle File - PHP 92 Lesson 22Document6 pagesEcourses - Ndri.res - in Moodle File - PHP 92 Lesson 22Amit Kr GodaraNo ratings yet

- 50HD (220V50HZ) 新款Document14 pages50HD (220V50HZ) 新款thaungmtNo ratings yet

- User Manual: RHF SeriesDocument21 pagesUser Manual: RHF Seriesسامح الجاسمNo ratings yet

- HEAT TRANSFER OIL SYSTEMS - Risk Engineering GuidelineDocument20 pagesHEAT TRANSFER OIL SYSTEMS - Risk Engineering GuidelineLuis PereiraNo ratings yet

- DNP SDS 049 Rev 0 V200Document11 pagesDNP SDS 049 Rev 0 V200Jair MontesdeocaNo ratings yet

- Astm e 337 - 02Document24 pagesAstm e 337 - 02vlong3003100% (2)

- 〈1228.1〉 DRY HEAT DEPYROGENATIONDocument4 pages〈1228.1〉 DRY HEAT DEPYROGENATIONlinh100% (1)

- Usp42-Nf37 202Document4 pagesUsp42-Nf37 202Mohamed Hassan100% (1)

- Clinical ThermometersDocument7 pagesClinical ThermometerssujudNo ratings yet

- Topic 8 (Fire Protection)Document16 pagesTopic 8 (Fire Protection)muhammadarifh7No ratings yet

- Avtc2231 Intro Aircraft Systems Laboratory: Letourneau UniversityDocument7 pagesAvtc2231 Intro Aircraft Systems Laboratory: Letourneau UniversityConnerNo ratings yet

- MSDS InglésDocument5 pagesMSDS InglésWendy CotoNo ratings yet

- Supporting Guidance (WAT-SG-85) : Application of Standards To Thermal DischargesDocument10 pagesSupporting Guidance (WAT-SG-85) : Application of Standards To Thermal DischargesSyllogos KireasNo ratings yet

- Cylinder Unit Hydrobox FTC BoxDocument14 pagesCylinder Unit Hydrobox FTC BoxkjulenNo ratings yet

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- Cryogenics Safety Manual: A Guide to Good PracticeFrom EverandCryogenics Safety Manual: A Guide to Good PracticeNo ratings yet

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringFrom EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNo ratings yet

- Fin HMTDocument12 pagesFin HMTbalakalees100% (1)

- Heat Transfer ConductionDocument4 pagesHeat Transfer ConductionFiras M YounisNo ratings yet

- Balloon Pop ExtravaganzaDocument8 pagesBalloon Pop Extravaganzaapi-381674437No ratings yet

- Conduction Convection RadiationDocument23 pagesConduction Convection Radiationsuhaila bakarNo ratings yet

- Science: Third Quarter - Module 6 Heat TransferDocument42 pagesScience: Third Quarter - Module 6 Heat TransferJonnah Faye Mojares100% (1)

- Energy Plus Getting StartedDocument74 pagesEnergy Plus Getting StartedAnderson FabricioNo ratings yet

- 01 - Manish Sharma Timilsina - Conduction Heat Transfer Beyond Fourier LawDocument10 pages01 - Manish Sharma Timilsina - Conduction Heat Transfer Beyond Fourier LawShrestha RishavNo ratings yet

- BLDG 6611 - Heat TransferDocument20 pagesBLDG 6611 - Heat TransferAnthony ReyNo ratings yet

- Sample Chapter 7 Therapeutic Mod Ali TiesDocument28 pagesSample Chapter 7 Therapeutic Mod Ali Tiesmdarif4ptNo ratings yet

- Composite Wall ExperimentDocument6 pagesComposite Wall ExperimentVillanNo ratings yet

- PC-FT 403: Lecture (5) byDocument95 pagesPC-FT 403: Lecture (5) byFT 19 Suparno DasNo ratings yet

- PDE NotesDocument96 pagesPDE NotesSamama FahimNo ratings yet

- Thermoregulation: Presenter: Dr. Faisal Djamil Sheriff, H58/38054/2020 Moderator: Dr. MuriithiDocument56 pagesThermoregulation: Presenter: Dr. Faisal Djamil Sheriff, H58/38054/2020 Moderator: Dr. MuriithiHarshilPatelNo ratings yet

- Steady State Heat Conduction: Course ContentsDocument48 pagesSteady State Heat Conduction: Course ContentsJainil GajjarNo ratings yet

- 2 Thermal Physics1Document18 pages2 Thermal Physics1Hakim Abbas Ali Phalasiya100% (1)

- Week 02Document49 pagesWeek 02Meriem OkhlasNo ratings yet

- EES Integration Example 3.2-1aDocument10 pagesEES Integration Example 3.2-1aNayef FtouniNo ratings yet

- Complete ReportDocument16 pagesComplete Reporterhamfatima3No ratings yet

- 11 ChapterDocument24 pages11 ChapterShashwat SahayNo ratings yet

- © Ncert Not To Be Republished: Activity 4.1Document14 pages© Ncert Not To Be Republished: Activity 4.1Kalpavriksha1974No ratings yet

- Catalog PYRO-CONTROLE 2008 (Valabil)Document64 pagesCatalog PYRO-CONTROLE 2008 (Valabil)Marian VinatoruNo ratings yet

- MindmapDocument1 pageMindmapSudhish ThapaNo ratings yet

- Conduction Tracing Versus Steam Jacketing 6-23-02Document5 pagesConduction Tracing Versus Steam Jacketing 6-23-02David FonsecaNo ratings yet

- DX DT K DX D: Aim: Calculate The Steady State Temperature Distribution in The RodDocument11 pagesDX DT K DX D: Aim: Calculate The Steady State Temperature Distribution in The RodSiddhartha Harsha OmmiNo ratings yet

- Thermal Analysis of Cables in Unfilled Troughs - Investigation of The IEC Standard (Leon2012)Document9 pagesThermal Analysis of Cables in Unfilled Troughs - Investigation of The IEC Standard (Leon2012)daegerteNo ratings yet

- Thermal Resistance: Asst. Prof. Krongkaew Laohalidanond (Dr.-Ing.)Document27 pagesThermal Resistance: Asst. Prof. Krongkaew Laohalidanond (Dr.-Ing.)oloNo ratings yet

- Chapter 12 Mechanical EngineeringDocument34 pagesChapter 12 Mechanical EngineeringM Singgih Iman SNo ratings yet