Professional Documents

Culture Documents

Best Practices in Cleaning Internal Surfaces of High Pressure Boilers

Best Practices in Cleaning Internal Surfaces of High Pressure Boilers

Uploaded by

Lakshminarayan0 ratings0% found this document useful (0 votes)

9 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views3 pagesBest Practices in Cleaning Internal Surfaces of High Pressure Boilers

Best Practices in Cleaning Internal Surfaces of High Pressure Boilers

Uploaded by

LakshminarayanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

s72018 Best Practices in Clearing Internal Surfaces of High Pressure Boilers

‘essenical zon

pwatce

SlucalEooen

+ SechenlEpetng

* Chctel Emineiog

1 ates cone

1 Comme Aslesoos

+ pn betacaos

1 Rae Daur ene

+ Marne Enonescna

aie Eaisson

uenasi. 8 Ste Sens

tendarneefsheoy

on

Cleaning High Pressure Boiler Internal Surfaces

High pressure boilers need very clean inter surfaces. The pre-commissionng cleaning inves

Alla bol out to remove any oly matrals, Acid Cleaning ocean up ml scales and Steam

‘lowing to clea superbestr,rheatr, and piping. Pos-commitioning cleaning is specifi to each

boise

igh pressure boilers are designed to produce steam at specified quay Improper steam quality

a lead to tube fulresn the boiler, 5 well as turbine bade dateage, resulting in large avaiabiity

Toss The cleaning of intra! surace of high pressure boiler ea be grouped int vo main mothod,

tne pre-commsstoning an the other postcommssoning cleaning.

Pre-commissioing cleaning

During manufacturing of seamless steel bes, «quantity of mil seals sre bound be formed and

‘some ofthese can remain inside. Daring fabrication ad eestion ofthe pressure pas, some arpoust

‘foi and prease can alo get into the tube surface apt fom the weld slg and other materia

“Taking all of tose nfo consideration, the pre-sommissioning cleaning has three major stops

‘© Alkali oil out - hich is fo removing th land grease From the internal sufce.

© Aci cleaning for removing the ml scale nthe intral surface, Hoth ai cleaning en alkal

‘oi-ou are done for ll water-touched surface.

‘Sica blowing - Inthe ease of supe heaters, reacaters, and steam pipes, they are cleaned by

steam Blowing

Alkali boi-out

‘This operation in boilers is taken up afer hyd esting ofthe oilers compleed and the oil

burners are commissioned. Alkaline Mush s cased out before the Boilers taken for elk bil

ut risa practice o mechasically remove the oil and grease wherever posse. The dum atersals

are insted before stat of aia Boil ou. Normally sd:um carbonate a sodium posphate m2

fsa quanity along witha detergent to about 0.05 to 0.!% by volume ae used for alka bilo.

[Afr the boil out solution is added the drum levels checked though a gauge glass and confined

before fring the Bose. Te Biles brought 0 20 kl square in about 8 hours ime Keeping

mind the ae of pressure aise and emperature raise ellowed fr cold startup. The dru level

‘maintained at normal level during this operation. After abou ou: hours at pressure, the fie is hut

‘doors andthe boiler is ellowed to cool, This ensures the sludge settle down and the oiler blow down

iscarned out using the bottom dain. Care shouldbe taker t maintain the drums water level with i

the visible range of gauge glass, Tha operation i done forfour tines toa total of about 16 hous,

Solution samples ar takes at epularimte-vals, and if the orginal concerti drops to half oF

‘below, chemicals ae aed to bring back the concetaon. The oiler then drained fer the damn

metal temperature is below 90 degree . The boiler is then rinsed with clea rinse water and fushed.

Acid cleaning

May methods are used by diferent oiler makers to clean the mill cle and rust inside the rbe

Surface Is very important tha this petation sctred out by an experienced and rliable agen.

“The methods used are circulating aid method ard soaking method,

hits: brghthubenginsering.com/powerplants/37629-cleaning-high-pressure-bolle-ntemab surfaces!

18

si72018 Best Practices in Clearing Internal Surfaces of High Pressure Boilers

Inthe eate ofthe ctculating method, extemal acid cleaning pumps ae use to Keep the acid in

cirulation. However inthe case of soaking method the acd kept stationary for a specified time

May combinations of acids ae used for this purpose. The most popular acid is 5% bydroclore

‘acid with inibtors that aze used to mbibit the action of acd the cleaned surface ofthe ube. Te

Superbester tubes shouldbe plugged ard water Filled and mniined under positive presse so that

‘the acid vapors do not enter the tube surface. The boiler is drsineg under nogen t& postive

‘pressure tht need to protect she incr Virgin sefce, The sludge rvaing (rom mil scales

lin rst will have tobe flashed from the bottom headers. The boiler then goes though passivation

operation to ensure a proietve layer formation inside the ube sures

‘Steam blowing

Stcam blowing is used wo clean the super heater oils andthe stcam pipes like main steam and

reheater pipes. There ae two methods used for steam bowing: continous blowing and intermittent

‘lowing. tn bot asc, the idea isto ctete a disturbatice onthe surface ofthe tube or pipe wel

above that is possible ding the peak load operation ofthe boiler. [is sen that at a pressre of

‘ound 40 ky em squued, the internal surface ofthe super heater and steam pipes at subjected to

‘suet a dsusbance that any loosely adhering materials dislodged when the ea is allowed to blow

tutto the aotephece The completion of tears blowing is declared i te target plate of turbine

blade material kept a the predefined pont is fre ror ny indenttion is within lowed mts, To

complete the steams blowing Ia super bat, rete, steam pipes, ee, ter bowing is done in

‘ore than ome stg,

Post-operatonal cleaning

During operation boilers aceumulate deposits aside the tube surface depending upon the quality of

‘water chemistry maintained, Once the bolers have operated for about ive years then itis 8 g008

practice to tak tube samples fom the igh hea Mux ein and evaluate Gem for intcral epost

‘Tho samples retaken fro all he four walls ofthe bote fama walls and ested forthe emount of

{zpos andthe chemistry of deposit The deposit quant is above 0 mgm squared then the

tubes termed diy and acid leaning is recommended. The typeof acid to be used fr cleaning will

Akepend upon the chemistry and adherence of the deposits othe tube surface. Ith deposit contains

‘copper ftom the pr-bole system, dn this bas toe ist removed. The other ingredients of te

epost ae removed subsequent. Hee the post operational cleaning can have few stages of acid

‘leasing To decide tis, tube samples taken ate sujoctd toa cleaning isin he lb using the actual

eid tempertre tie and sage planned tthe sit, sed on the rele ofthe cleaning he lb

fd fesul thre achieved, the faa secommenation is gies othe bole weet

Related Articles on thie Site

hits: brghthubenginsering.com/powerplants/37629-cleaning-high-pressure-bolle-ntemab surfaces!

218

si72018 Best Practices in Clearing Internal Surfaces of High Pressure Boilers

SUBSCRIBE & FOLLOW:

RELATED TOPICS:

: rag Pere

Fuaecrane yer

anutcairgTshroay

Tweets oy ge

“ew Pn Engrg asin

Tus ae nsoee by eres

wt eincngnsna toroneers on

BH Engineering

{DEH Eraeerng

ip dolls: STEM vs. Spars.

Winer ae we fvestng?

‘oulyiniad0nGUGe eolge Recholarenps

aston

SIGNUP FOR EMAILS

Choc sup ra sar»

Atos BHEngnowng Tomer

conse ue ry Paley

éseine With Us Cony

hits: brghthubenginsering.com/powerplants/37629-cleaning-high-pressure-bolle-ntemab surfaces!

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Boiler Performance and Air Pre-Heater PluggingDocument3 pagesBoiler Performance and Air Pre-Heater PluggingLakshminarayanNo ratings yet

- Boiler Performance TestingDocument4 pagesBoiler Performance TestingLakshminarayanNo ratings yet

- Low Drum Level in Boiler Operation - How To HandleDocument3 pagesLow Drum Level in Boiler Operation - How To HandleLakshminarayanNo ratings yet

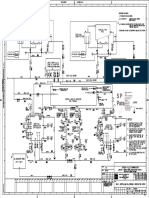

- PID Lube Oil R01-CertifiedDocument1 pagePID Lube Oil R01-CertifiedLakshminarayanNo ratings yet

- 1264 1270 1 PBDocument8 pages1264 1270 1 PBLakshminarayanNo ratings yet

- Servo Therm Synthetic Fluid OilDocument1 pageServo Therm Synthetic Fluid OilLakshminarayanNo ratings yet

- Boiler Waterwall Tubes and Condenser Tube Leakage in Power PlantsDocument3 pagesBoiler Waterwall Tubes and Condenser Tube Leakage in Power PlantsLakshminarayanNo ratings yet

- Why Economizer and Air Pre-Heaters Are Provided in BoilersDocument3 pagesWhy Economizer and Air Pre-Heaters Are Provided in BoilersLakshminarayanNo ratings yet

- How To Run A Coal Fired Boiler at The Best EfficiencyDocument3 pagesHow To Run A Coal Fired Boiler at The Best EfficiencyLakshminarayanNo ratings yet

- Safety Valves in Boiler SystemDocument3 pagesSafety Valves in Boiler SystemLakshminarayanNo ratings yet

- Chemical Regime in Water Quality Management of High Pressure Boiler PlantsDocument3 pagesChemical Regime in Water Quality Management of High Pressure Boiler PlantsLakshminarayanNo ratings yet

- Tube Failures in High Pressure BoilersDocument3 pagesTube Failures in High Pressure BoilersLakshminarayanNo ratings yet

- Reliability PresentationDocument111 pagesReliability PresentationLakshminarayanNo ratings yet

- Mejia Ph-II, 500mw, Vol-1 CepDocument339 pagesMejia Ph-II, 500mw, Vol-1 CepLakshminarayanNo ratings yet

- Furnace Wall Blowers Optimization in BoilersDocument3 pagesFurnace Wall Blowers Optimization in BoilersLakshminarayanNo ratings yet

- A Study On 500 MW Coal Fired Boiler Unit's Bowl Mill Performance Through Coal Sampling and Characterization: CPRI's ExperienceDocument6 pagesA Study On 500 MW Coal Fired Boiler Unit's Bowl Mill Performance Through Coal Sampling and Characterization: CPRI's ExperienceLakshminarayanNo ratings yet

- Esp CommgDocument16 pagesEsp CommgLakshminarayanNo ratings yet

- Concentration Control of Silica in Water ChemicalDocument6 pagesConcentration Control of Silica in Water ChemicalLakshminarayan100% (1)

- 1 - Boiler Tube FailuresDocument55 pages1 - Boiler Tube FailuresLakshminarayan100% (1)

- Case Study On Minimum Flow Through Cep Recirculation LineDocument5 pagesCase Study On Minimum Flow Through Cep Recirculation LineLakshminarayanNo ratings yet

- Condensate Polishers Add Operating Reliability and FlexibilityDocument17 pagesCondensate Polishers Add Operating Reliability and FlexibilityLakshminarayanNo ratings yet

- Clean Air Flow TestDocument4 pagesClean Air Flow TestLakshminarayanNo ratings yet

- COMMISSIONING Question PaperDocument9 pagesCOMMISSIONING Question PaperLakshminarayanNo ratings yet

- Air Pre HeaterDocument7 pagesAir Pre HeaterLakshminarayanNo ratings yet

- Design Features of Advanced Ultrasupercritical Plants, Part IIIDocument20 pagesDesign Features of Advanced Ultrasupercritical Plants, Part IIILakshminarayanNo ratings yet

- Competitive Coal - Power Line MagazineDocument8 pagesCompetitive Coal - Power Line MagazineLakshminarayanNo ratings yet

- Controlled Circulation PumpDocument5 pagesControlled Circulation PumpLakshminarayanNo ratings yet