Professional Documents

Culture Documents

Data Sheetfor RLD30 VUFSeries

Uploaded by

yu8357305Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheetfor RLD30 VUFSeries

Uploaded by

yu8357305Copyright:

Available Formats

RLD 30V UF Series PTC Devices

RLD 30V UF Series PTC Devices

Description

The 30V UF series provides radial resettable overcurrent protection with holding

current from 0.9A to 9A. This series is suitable for applications with higher holding

currant and higher working voltage up to 30V.

Features

RoHS compliant and lead-free 30Vdc operating voltage

Halogen-free 40A maximum short current

Fast time-to-trip Meet all USB protection requirements

Applications

Powered USB for POS and IPC Computers & peripherals

USB hubs, ports and peripherals Automotive applications

General electronics Motor protection

Agency Approval and Environmental Compliance

Agency File Number Regulation Standard

E201431 2011/65/EU

R50103284 IEC 61249-2-21:2003

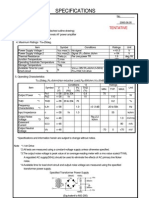

Electrical Characteristics

Maximum Agency

Resistance

Ihold Itrip Vmax Imax Pd typ Time To Trip Approval

Part Number Current Time Rmin R1max

(A) (A) (Vdc) (A) (W)

(A) (Sec.) (Ω) (Ω)

RLD30P090UF 0.90 1.80 30 40 0.6 4.50 5.9 0.070 0.220

RLD30P110UF 1.10 2.20 30 40 0.7 5.50 6.6 0.050 0.170

RLD30P135UF 1.35 2.70 30 40 0.8 6.75 7.3 0.040 0.130

RLD30P160UF 1.60 3.20 30 40 0.9 8.00 8.0 0.030 0.110

RLD30P185UF 1.85 3.70 30 40 1.0 9.25 8.7 0.030 0.090

RLD30P250UF 2.50 5.00 30 40 1.2 12.50 10.3 0.020 0.070

RLD30P300UF 3.00 6.00 30 40 2.0 15.00 10.8 0.020 0.080

RLD30P400UF 4.00 8.00 30 40 2.5 20.00 12.7 0.010 0.050

RLD30P500UF 5.00 10.00 30 40 3.0 25.00 14.5 0.010 0.050

RLD30P600UF 6.00 12.00 30 40 3.5 30.00 16.0 0.005 0.040

RLD30P700UF 7.00 14.00 30 40 3.8 35.00 17.5 0.005 0.030

RLD30P800UF 8.00 16.00 30 40 4.0 40.00 18.8 0.005 0.020

RLD30P900UF 9.00 18.00 30 40 4.2 40.00 20.0 0.005 0.020

新竹市科學工業園區工業東四路 24-1 號 No. 24-1 Industry E. Rd. IV, Hsinchu Science Park, Hsinchu 300, Taiwan.

TEL: +886-3-5643931 FAX: +886-3-5644624 http://www.pttc.com.tw

Page: 2 of 14 2018/10/25 Revision: Q

RLD 30V UF Series PTC Devices

Note on Electrical Characteristics

◼ Vocabulary

Ihold = Hold current: maximum current device will pass without tripping in 23ºC still air.

Itrip = Trip current: minimum current at which the device will trip in 23 ºC still air.

Vmax = Maximum voltage device can withstand without damage at rated current (I max)

Vop = Maximum continuous voltage device can withstand without damage at rated current (I max)

Imax = Maximum fault current device can withstand without damage at rated voltage (Vmax)

Pd typ = Typical power dissipated from device when in the tripped state at 23 ºC still air.

Rmin = Minimum resistance of device in initial (un-soldered) state.

R1max = Maximum resistance of device at 23 ºC measured one hour after tripping or reflow soldering of 260 ºC for 20 sec.

◼ Caution: Operation beyond the specified rating may result in damage and possible arcing and flame.

◼ Specifications are subject to change without notice.

新竹市科學工業園區工業東四路 24-1 號 No. 24-1 Industry E. Rd. IV, Hsinchu Science Park, Hsinchu 300, Taiwan.

TEL: +886-3-5643931 FAX: +886-3-5644624 http://www.pttc.com.tw

Page: 3 of 14 2018/10/25 Revision: Q

RLD 30V UF Series PTC Devices

Polymeric PTC Selecting Guide

◼ Determine the following operating parameters for the circuits:

Normal operating current (Ihold) ․ Maximum interrupt current (Imax)

Maximum circuit voltage (Vmax) ․ Normal operating temperature surrounding device (minºC/maxºC)

◼ Select the device form factor and dimension suitable for the application:

Surface Mount Device (SMD) ․ Axial Leaded Device (ALD) ․ Other Customized Form Factors

Radial Leaded Device (RLD) ․ DISC Device

◼ Compare the maximum rating for Vmax and Imax of the PPTC device with the circuit in application and make

sure the circuit’s requirement does not exceed the device rating.

◼ Check that PPTC device’s trip time (time-to-trip) will protect the circuit.

◼ Verify that the circuit operating temperature is within the PPTC device’s normal operating temperature range.

◼ Verify the performance and suitability of the chosen PPTC device in the application.

◼ Mechanical Stress

PPTC devices will undergo a thermal expansion during fault condition. If PPTC devices are installed or placed in an application where

the space between PPTC devices and the surrounding materials (e.g., covering materials, packaging materials, encapsulate materials

and the like) is insufficient, it will cause an inhibiting effect upon the thermal expansion. Pressing, twisting, bending and other kinds of

mechanical stress will also adversely affect the performance of the PPTC devices, and shall not be used or applied.

◼ Chemical Pollutants

Silicone-based oils, oils, solvents, gels, electrolytes, fuels, acids, and the like will adversely affect the properties of PPTC devices, and

shall not be used or applied.

◼ Electronic and Thermal Effect

PPTC devices are secondary protection devices and are used solely for sporadic, accidental over-current or over-temperature error

condition, and shall NOT be used if or when constant or repeated fault conditions (such fault conditions may be caused by, among

others, incorrect pin-connection of a connector) or over-extensive trip events may occur.

PTTC devices are different from fuses and, when a fault condition occurs, will go into high-resistance state and do not open circuit, in

which case the voltage at such PPTC devices may reach a hazardous level.

Operation over the maximum rating or other forms of improper use may cause failure, arcing, flame and/or other damage to the PPTC

devices.

Conductive material contamination, such as metal particle, may induce shortage, flame or arcing.

Due to the inductance, the operation circuits may generate a circuit voltage (Ldi/dt) above the rated voltage of PPTC devices, which

shall not be used under such circumstances.

◼ General

Customers shall evaluate and test the properties of PPTC devices independently to verify and ensure that their individual applications

will be met.

The performance of PPTC devices will be adversely affected if they are improperly used under electronic, thermal and/or mechanical

procedures and/or conditions non-conformant to those recommended by manufacturer.

Customers shall be responsible for determining whether it is necessary to have back-up, failsafe and/or fool-proof protection to avoid or

minimize damage that may result from extra-ordinary, irregular function or failure of PPTC devices.

Any and all responsibilities and liabilities are disclaimed if any item under this notice of warning is not complied with.

新竹市科學工業園區工業東四路 24-1 號 No. 24-1 Industry E. Rd. IV, Hsinchu Science Park, Hsinchu 300, Taiwan.

TEL: +886-3-5643931 FAX: +886-3-5644624 http://www.pttc.com.tw

Page: 4 of 14 2018/10/25 Revision: Q

RLD 30V UF Series PTC Devices

Average Time-to-Trip Curves

A= RLD30P090UF

M

B= RLD30P110UF

L

K

C= RLD30P135UF

D= RLD30P160UF

J

E= RLD30P185UF

I F= RLD30P250UF

H G= RLD30P300UF

H= RLD30P400UF

G I= RLD30P500UF

F

J= RLD30P600UF

E K= RLD30P700UF

D L= RLD30P800UF

C M= RLD30P900UF

B

新竹市科學工業園區工業東四路 24-1 號 No. 24-1 Industry E. Rd. IV, Hsinchu Science Park, Hsinchu 300, Taiwan.

TEL: +886-3-5643931 FAX: +886-3-5644624 http://www.pttc.com.tw

Page: 5 of 14 2018/10/25 Revision: Q

RLD 30V UF Series PTC Devices

Thermal Derating Curve

Thermal Derating Table

Recommended Hold Current (A) vs. Ambient Temperature (ºC)

Ambient Operation Temperature

Part Number

-40 ºC -20 ºC 0 ºC 23 ºC 40 ºC 50 ºC 60 ºC 70 ºC 85 ºC

RLD30P090UF 1.31 1.17 1.04 0.90 0.75 0.69 0.61 0.55 0.47

RLD30P110UF 1.60 1.43 1.27 1.10 0.91 0.85 0.75 0.67 0.57

RLD30P135UF 1.96 1.76 1.55 1.35 1.12 1.04 0.92 0.82 0.70

RLD30P160UF 2.32 2.08 1.84 1.60 1.33 1.23 1.09 0.98 0.83

RLD30P185UF 2.68 2.41 2.13 1.85 1.54 1.42 1.26 1.13 0.96

RLD30P250UF 3.63 3.25 2.88 2.50 2.08 1.93 1.70 1.53 1.30

RLD30P300UF 4.35 3.90 3.45 3.00 2.49 2.31 2.04 1.83 1.56

RLD30P400UF 5.80 5.20 4.60 4.00 3.32 3.08 2.72 2.44 2.08

RLD30P500UF 7.25 6.50 5.75 5.00 4.15 3.85 3.40 3.05 2.60

RLD30P600UF 8.70 7.80 6.90 6.00 4.98 4.62 4.08 3.66 3.12

RLD30P700UF 10.15 9.10 8.05 7.00 5.81 5.39 4.76 4.27 3.64

RLD30P800UF 11.60 10.40 9.20 8.00 6.64 6.16 5.44 4.88 4.16

RLD30P900UF 13.05 11.7 10.35 9.00 7.47 6.93 6.12 5.49 4.68

新竹市科學工業園區工業東四路 24-1 號 No. 24-1 Industry E. Rd. IV, Hsinchu Science Park, Hsinchu 300, Taiwan.

TEL: +886-3-5643931 FAX: +886-3-5644624 http://www.pttc.com.tw

Page: 6 of 14 2018/10/25 Revision: Q

RLD 30V UF Series PTC Devices

Physical Dimensions (mm.)

Fig. 1 Fig. 2 Fig. 3 Fig. 4 Fig. 5

A B C D E Y

Part Number Fig. Lead Dia.

(Max.) (Max.) (Typ.) (Min.) (Max.) (Typ.)

RLD30P090UF 7.4 12.2 5.1±0.7 7.6 3.0 1.0 3 0.51

RLD30P090UF-S 7.4 10.6 5.1±0.7 7.6 3.0 1.0 4 0.51

RLD30P110UF 7.4 14.2 5.1±0.7 7.6 3.0 1.0 3 0.51

RLD30P110UF-S 7.4 12.0 5.1±0.7 7.6 3.0 1.0 4 0.51

RLD30P135UF 8.9 13.5 5.1±0.7 7.6 3.0 1.0 3 0.51

RLD30P135UF-S 8.9 11.3 5.1±0.7 7.6 3.0 1.0 4 0.51

RLD30P160UF 8.9 15.2 5.1±0.7 7.6 3.0 1.0 3 0.51

RLD30P160UF-S 8.9 12.8 5.1±0.7 7.6 3.0 1.0 4 0.51

RLD30P185UF 10.2 15.7 5.1±0.7 7.6 3.0 1.0 3 0.51

RLD30P185UF-S 10.2 13.8 5.1±0.7 7.6 3.0 1.0 4 0.51

RLD30P250UF 11.4 18.3 5.1±0.7 7.6 3.0 1.0 3 0.51

RLD30P250UF-S 11.4 16.0 5.1±0.7 7.6 3.0 1.0 4 0.51

RLD30P300UF 11.4 19.2 5.1±0.7 7.6 3.0 1.2 3 0.81

RLD30P300UF-S 11.4 15.2 5.1±0.7 7.6 3.0 1.2 4 0.81

RLD30P400UF 14.0 22.0 5.1±0.7 7.6 3.0 1.2 3 0.81

RLD30P400UF-S 14.0 17.3 5.1±0.7 7.6 3.0 1.2 4 0.81

RLD30P500UF 14.0 25.6 10.2±1.0 7.6 3.0 1.2 3 0.81

RLD30P500UF-S 14.0 23.0 10.2±1.0 7.6 3.0 1.2 4 0.81

RLD30P600UF 16.5 26.8 10.2±1.0 7.6 3.0 1.2 3 0.81

RLD30P600UF-S 16.5 23.4 10.2±1.0 7.6 3.0 1.2 4 0.81

RLD30P700UF 19.1 28.6 10.2±1.0 7.6 3.0 1.2 3 0.81

RLD30P700UF-S 19.1 25.0 10.2±1.0 7.6 3.0 1.2 4 0.81

RLD30P800UF 21.6 31.1 10.2±1.0 7.6 3.0 1.2 3 0.81

RLD30P800UF-S 21.6 26.9 10.2±1.0 7.6 3.0 1.2 4 0.81

RLD30P900UF 24.1 31.6 10.2±1.0 7.6 3.0 1.2 3 0.81

RLD30P900UF-S 24.1 27.0 10.2±1.0 7.6 3.0 1.2 4 0.81

新竹市科學工業園區工業東四路 24-1 號 No. 24-1 Industry E. Rd. IV, Hsinchu Science Park, Hsinchu 300, Taiwan.

TEL: +886-3-5643931 FAX: +886-3-5644624 http://www.pttc.com.tw

Page: 7 of 14 2018/10/25 Revision: Q

RLD 30V UF Series PTC Devices

Recommend Pad Layout (mm)

A B D1 D2

Part Number

(Typ.) (Typ.) (Typ.) (Typ.)

RLD30P090UF 5.1 1.0 1.0 2.5

RLD30P110UF 5.1 1.0 1.0 2.5

RLD30P135UF 5.1 1.0 1.0 2.5

RLD30P160UF 5.1 1.0 1.0 2.5

RLD30P185UF 5.1 1.0 1.0 2.5

RLD30P250UF 5.1 1.0 1.0 2.5

RLD30P300UF 5.1 1.2 1.5 3.5

RLD30P400UF 5.1 1.2 1.5 3.5

RLD30P500UF 10.2 1.2 1.5 3.5

RLD30P600UF 10.2 1.2 1.5 3.5

RLD30P700UF 10.2 1.2 1.5 3.5

RLD30P800UF 10.2 1.2 1.5 3.5

RLD30P900UF 10.2 1.2 1.5 3.5

新竹市科學工業園區工業東四路 24-1 號 No. 24-1 Industry E. Rd. IV, Hsinchu Science Park, Hsinchu 300, Taiwan.

TEL: +886-3-5643931 FAX: +886-3-5644624 http://www.pttc.com.tw

Page: 8 of 14 2018/10/25 Revision: Q

RLD 30V UF Series PTC Devices

Wave Soldering Parameters

Profile Feature Condition (Note 1)

Average Ramp-Up Rate (Tsmax to TP) 4ºC/second max.

Preheat

-Temperature Min (Tsmin) 100ºC

-Temperature Max (Tsmax) 125ºC

-Time (Tsmin to Tsmax) 60-180 seconds

Peak Temperature (TP) 265ºC

Max Time at Peak Temperature (tP) 5 seconds

Ramp-Down Rate 6 ºC /second max.

Time 25ºC to Peak Temperature 5 minutes max.

Storage Condition (Note 2) 0ºC ~35ºC, ≦70%RH, 2 Years

Note:

1. If the wave soldering temperatures exceed the recommended profile, devices may not meet the performance requirements.

2. If the storage condition exceeds the suggest requirement or the storage time exceeds 2 years, then, 110°C/4hrs baking before wave

soldering assembly process is recommended to remove the residual moisture contained in the epoxy coating.

新竹市科學工業園區工業東四路 24-1 號 No. 24-1 Industry E. Rd. IV, Hsinchu Science Park, Hsinchu 300, Taiwan.

TEL: +886-3-5643931 FAX: +886-3-5644624 http://www.pttc.com.tw

Page: 9 of 14 2018/10/25 Revision: Q

RLD 30V UF Series PTC Devices

Environmental Specifications

Operating Temperature -40ºC to +85 ºC

Maximum Device Surface

125ºC

Temperature in Tripped State

+85ºC , 1000 hours

Passive Aging

±5% typical resistance change

+85ºC , 85%R.H. 1000 hours

Humidity Aging

±5% typical resistance change

MIL-STD-202 Method 107G

Thermal Shock +85ºC /-40ºC 10 times

-30% typical resistance change

MIL-STD-202, Method 215

Solvent Resistance

No change

MIL-STD-883C, Method 2007.1, Condition A

Vibration

No change

Moisture Sensitivity Level Level 1, J-STD-020C

Physical Specifications

P090UF-185UF: Tin-plated copper clad steel

Lead Material

P250UF-P900UF: Tin-plated copper

Soldering Characteristics Solderability per MIL-STD-202, Method 208E

Insulating Material Cured, flame retardant epoxy polymer meets UL94V-0 requirements.

新竹市科學工業園區工業東四路 24-1 號 No. 24-1 Industry E. Rd. IV, Hsinchu Science Park, Hsinchu 300, Taiwan.

TEL: +886-3-5643931 FAX: +886-3-5644624 http://www.pttc.com.tw

Page: 10 of 14 2018/10/25 Revision: Q

RLD 30V UF Series PTC Devices

Tape and Reel Specifications: EIA468-B/IEC60286-2

EIA IEC Dimensions

Dimension Description

Mark Mark Dim.(mm) Tol.(mm)

Carrier tape width W W 18 -0.5/+1.0

Hold down tape width W4 W0 11 min.

Top distance between tape edges W6 W2 3 max.

Sprocket hole position W5 W1 9 -0.5+0.75

Sprocket hole diameter* D0 D0 4 -0.32/+0.2

Abscissa to plane(straight lead) H H 18.5 +3.0

Abscissa to plane(kinked lead) H0 H0 16 +0.5

Abscissa to top P090UF-P185UF H1 H1 32.2 max.

Abscissa to top P250UF-P900UF H1 47.5 max.

Overall width without lead protrusion: P090UF-P185UF C1 42.5 max.

Overall width without lead protrusion: P250UF-P900UF 57

Overall width with lead protrusion: P090UF-P185UF C2 43.2 max.

Overall width with lead protrusion: P250UF-P900UF 58

Lead protrusion L1 l1 1.0 max.

Protrusion of cut out L L 11 max.

Protrusion beyond hold-down tape l2 l2 Not specified

Sprocket hole pitch: P090UF-P400UF P0 P0 12.7 +0.3

Sprocket hole pitch: P500UF-P900UF P0 P0 25.4 +0.5

Pitch tolerance 20 consecutive. +1

Device pitch: P090UF-P300UF 12.7

Device pitch: P400UF-P900UF 25.4

Tape thickness t t 0.9 max.

Tape thickness with splice t1 2.0 max.

Splice sprocket hole alignment 0 +0.3

Body lateral deviation Δh Δh 0 +1.0

Body tape plane deviation Δp Δp 0 +1.3

Ordinate to adjacent component lead*: P090UF-P400UF P1 P1 3.81 +0.7

Ordinate to adjacent component lead*: P500UF-P900UF 7.62 +0.7

Lead spacing: P090UF-P400UF F F 5.08 +0.8

Lead spacing: P500UF-P900UF F F 10.18 +0.8

Reel width P090UF-P300UF w2 w 56 max.

Reel width P400UF-P900UF w2 w 63.5 max.

Reel diameter a d 370 max.

Space between flanges less device* w1 4.75 -3.25/+9.25

Arbor hole diameter c f 26 +12.0

Core diameter* n h 91 max.

Box 56/372/372 max.

Consecutive missing places None

Empty places per reel 0.1%max.

新竹市科學工業園區工業東四路 24-1 號 No. 24-1 Industry E. Rd. IV, Hsinchu Science Park, Hsinchu 300, Taiwan.

TEL: +886-3-5643931 FAX: +886-3-5644624 http://www.pttc.com.tw

Page: 11 of 14 2018/10/25 Revision: Q

RLD 30V UF Series PTC Devices

Tape and Reel Specifications: EIA468-B/IEC60286-2 (Continued)

Fig. 1

Fig. 2

新竹市科學工業園區工業東四路 24-1 號 No. 24-1 Industry E. Rd. IV, Hsinchu Science Park, Hsinchu 300, Taiwan.

TEL: +886-3-5643931 FAX: +886-3-5644624 http://www.pttc.com.tw

Page: 12 of 14 2018/10/25 Revision: Q

RLD 30V UF Series PTC Devices

Marking on Device

Polytronics

Voltage rating

Trademark

Current rating & series code

Date code

Part Ordering Number System

RLD 30 P □□□ UF - □□

Packaging Style (B: Bulk; TA: Tape & Ammo; TR: Tape & Reel)

30Vdc Lead- Free Product Series

Holding Current Rating

Polytronics Symbol

Voltage Rating

Radial Leaded Device

新竹市科學工業園區工業東四路 24-1 號 No. 24-1 Industry E. Rd. IV, Hsinchu Science Park, Hsinchu 300, Taiwan.

TEL: +886-3-5643931 FAX: +886-3-5644624 http://www.pttc.com.tw

Page: 13 of 14 2018/10/25 Revision: Q

RLD 30V UF Series PTC Devices

Packaging Quantity

Part Number Ordering Code Bag Quantity Reelpack Quantity Ammopack Quantity

RLD30P090UF-B 500

RLD30P090UF RLD30P090UF-TR 2000

RLD30P090UF-TA 2000

RLD30P110UF-B 500

RLD30P110UF RLD30P110UF-TR 2000

RLD30P110UF-TA 2000

RLD30P135UF-B 500

RLD30P135UF RLD30P135UF-TR 2000

RLD30P135UF-TA 2000

RLD30P160UF-B 500

RLD30P160UF RLD30P160UF-TR 2000

RLD30P160UF-TA 2000

RLD30P185UF-B 500

RLD30P185UF RLD30P185UF-TR 2000

RLD30P185UF-TA 2000

RLD30P250UF-B 500

RLD30P250UF RLD30P250UF-TR 2000

RLD30P250UF-TA 2000

RLD30P300UF-B 500

RLD30P300UF RLD30P300UF-TR 2000

RLD30P300UF-TA 2000

RLD30P400UF-B 200

RLD30P400UF RLD30P400UF-TR 1000

RLD30P400UF-TA 1000

RLD30P500UF-B 200

RLD30P500UF RLD30P500UF-TR 1000

RLD30P500UF-TA 1000

RLD30P600UF-B 200

RLD30P600UF RLD30P600UF-TR 1000

RLD30P600UF-TA 1000

RLD30P700UF-B 200

RLD30P700UF RLD30P700UF-TR 1000

RLD30P700UF-TA 1000

RLD30P800UF-B 100

RLD30P800UF RLD30P800UF-TR 1000

RLD30P800UF-TA 1000

RLD30P900UF-B 100

RLD30P900UF RLD30P900UF-TR 1000

RLD30P900UF-TA 1000

新竹市科學工業園區工業東四路 24-1 號 No. 24-1 Industry E. Rd. IV, Hsinchu Science Park, Hsinchu 300, Taiwan.

TEL: +886-3-5643931 FAX: +886-3-5644624 http://www.pttc.com.tw

Page: 14 of 14 2018/10/25 Revision: Q

You might also like

- Datasheet For MUR1620Document6 pagesDatasheet For MUR1620WarungRobotika Milis100% (1)

- Motorola An 780ADocument6 pagesMotorola An 780ArobinsonsNo ratings yet

- stk-404-050 enDocument6 pagesstk-404-050 enNimrod ElsisuraNo ratings yet

- 1 Ss 133Document4 pages1 Ss 133inmooreaNo ratings yet

- Moc 3021Document7 pagesMoc 3021Juanpere2No ratings yet

- Rpi 352Document2 pagesRpi 352Nelson RodriguezNo ratings yet

- Silicon N-Channel MOS FET: ApplicationDocument5 pagesSilicon N-Channel MOS FET: ApplicationihsanjuNo ratings yet

- Diodo 2SJ76, 77, 78, 79 DatasheetDocument7 pagesDiodo 2SJ76, 77, 78, 79 Datasheetnaupas007No ratings yet

- STP80NF70: N-Channel 68 V, 0.0082, 98 A, TO-220 Stripfet™ Ii Power MosfetDocument13 pagesSTP80NF70: N-Channel 68 V, 0.0082, 98 A, TO-220 Stripfet™ Ii Power MosfetAsif IqbalNo ratings yet

- TLP190B: Telecommunication Programmable Controllers MOS Gate Driver MOS FET Gate DriverDocument5 pagesTLP190B: Telecommunication Programmable Controllers MOS Gate Driver MOS FET Gate DriverKhaiRul NiZam AnuarNo ratings yet

- FTD 2017Document5 pagesFTD 2017Alejandra SeguraNo ratings yet

- Ultrahigh-Speed Switching Applications: Package Dimensions FeaturesDocument5 pagesUltrahigh-Speed Switching Applications: Package Dimensions FeaturesGeta EnacheNo ratings yet

- UHF Low-Noise Amp, Wide-Band Amp Applications: FeaturesDocument4 pagesUHF Low-Noise Amp, Wide-Band Amp Applications: Featuresmark777markNo ratings yet

- STB80PF55 STP80PF55: P-Channel 55V - 0.016 - 80A - TO-220 - D PAK Stripfet™ Ii Power MosfetDocument13 pagesSTB80PF55 STP80PF55: P-Channel 55V - 0.016 - 80A - TO-220 - D PAK Stripfet™ Ii Power MosfetnotmikemikeNo ratings yet

- (XX) Furuno FS-1570 Technical Drawings PDFDocument15 pages(XX) Furuno FS-1570 Technical Drawings PDFGeta Enache50% (2)

- TLP 3526Document6 pagesTLP 3526santia6768No ratings yet

- Silicon PNP Epitaxial Planar Type: TransistorsDocument4 pagesSilicon PNP Epitaxial Planar Type: Transistorsscarp2moneyNo ratings yet

- Datasheet 2sk3067Document3 pagesDatasheet 2sk3067Neo SolisNo ratings yet

- 2 SK 3747Document4 pages2 SK 3747luis_h_t_79No ratings yet

- 24V - D3427 and 5V D3423Document14 pages24V - D3427 and 5V D3423Pradeeban NNo ratings yet

- Moc 3021Document8 pagesMoc 3021Adrian Jose Costa OspinoNo ratings yet

- MCR225 2FPDocument6 pagesMCR225 2FPLuis Francisco Gómez MottaNo ratings yet

- Digital Logic Ground Isolation Line Receiver Microprocessor System Interfaces Switching Power Supply Feedback Control Transistor InvertorDocument8 pagesDigital Logic Ground Isolation Line Receiver Microprocessor System Interfaces Switching Power Supply Feedback Control Transistor InvertorEdward CollinNo ratings yet

- Transistor k4100Document13 pagesTransistor k4100mjmg1100% (1)

- STK442 110Document4 pagesSTK442 110Ivan AsimovNo ratings yet

- STK442 110Document4 pagesSTK442 110Alfredo Valencia RodriguezNo ratings yet

- MAZ8xxx Series (DIodos Zeners)Document5 pagesMAZ8xxx Series (DIodos Zeners)Leandro PalmeiraNo ratings yet

- CPH 6316Document5 pagesCPH 6316bojan 2No ratings yet

- stk442 090Document4 pagesstk442 090edwingt09No ratings yet

- 2SJ79 P Mosfet Bordely AppDocument6 pages2SJ79 P Mosfet Bordely Appjeanpaul CAYTANNo ratings yet

- SMD2920 Surface Mount PTC Devices: Electrical CharacteristicsDocument8 pagesSMD2920 Surface Mount PTC Devices: Electrical CharacteristicsMisho MishoNo ratings yet

- Uvtop CatalogueDocument40 pagesUvtop CatalogueEdoardo AlbertiNo ratings yet

- 2 SK 4096Document5 pages2 SK 4096aldo_suviNo ratings yet

- SR3020PT - SR30150PT: FeaturesDocument2 pagesSR3020PT - SR30150PT: FeaturesGiovanni SanchezNo ratings yet

- Low Cost JFET Input Operational Amplifiers ADTL082/ADTL084: Preliminary Technical DataDocument6 pagesLow Cost JFET Input Operational Amplifiers ADTL082/ADTL084: Preliminary Technical Datadragon-red0816No ratings yet

- MOC30X0MDocument11 pagesMOC30X0MmersoigNo ratings yet

- Sanyo ICs STKs PDFDocument117 pagesSanyo ICs STKs PDFFreddy Monge BarbaranNo ratings yet

- DatasheetDocument8 pagesDatasheetlitodexNo ratings yet

- CD40106BE DatasheetDocument10 pagesCD40106BE DatasheetOscar GonzalesNo ratings yet

- Moc302x 5xDocument6 pagesMoc302x 5xMohammed ZiadNo ratings yet

- SF2500EX22Document4 pagesSF2500EX22zi_ming86No ratings yet

- B321 PDFDocument5 pagesB321 PDFperro sNo ratings yet

- 2 SC2236, NPNDocument4 pages2 SC2236, NPNnegrea_c8079No ratings yet

- 2SK 2508Document6 pages2SK 2508Abbas AliNo ratings yet

- TND017Document5 pagesTND017ajisetyo1990No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageFrom EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsFrom EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Premier Electronics - Stock ListDocument10 pagesPremier Electronics - Stock ListRushabhShahNo ratings yet

- Brochure SupresorDocument2 pagesBrochure SupresorselvamejiaNo ratings yet

- AB Cable Conection 10220005Document1 pageAB Cable Conection 10220005KS LaiNo ratings yet

- PIC32 Microcontroller Families: 32-Bit MicrocontrollersDocument7 pagesPIC32 Microcontroller Families: 32-Bit MicrocontrollersbolbolbilaloNo ratings yet

- 15EC35 - Electronic Instrumentation - Module 4Document33 pages15EC35 - Electronic Instrumentation - Module 4Anish AnniNo ratings yet

- Data SheetDocument13 pagesData SheetbhagvataNo ratings yet

- Magat Hydroelectric Power Project Philippines: Content/uploads/2013/07/shutterstock - 35516521.jpgDocument3 pagesMagat Hydroelectric Power Project Philippines: Content/uploads/2013/07/shutterstock - 35516521.jpgMishel P. FerolinoNo ratings yet

- DVD Receiver System: Service ManualDocument69 pagesDVD Receiver System: Service ManualGarlapati TrinadhNo ratings yet

- Service Manual: Published in Jul.'02 842DF110Document326 pagesService Manual: Published in Jul.'02 842DF110Soraphong NaknoppakoonNo ratings yet

- 3RW30 40Document38 pages3RW30 40Tiago SousaNo ratings yet

- Walsall Hazardous Area & Explosion Proof Electrical EquipmentDocument12 pagesWalsall Hazardous Area & Explosion Proof Electrical EquipmentAmiruddin Abdul RahimNo ratings yet

- Chapter 1Document21 pagesChapter 1iris33% (3)

- P170em EsmDocument122 pagesP170em EsmpukymottoNo ratings yet

- Banner S18UIADocument9 pagesBanner S18UIAXavieltNo ratings yet

- Syma x12 User ManualDocument11 pagesSyma x12 User ManualDecki IswandiNo ratings yet

- TT-BH046 User ManualDocument10 pagesTT-BH046 User ManualsanyolllNo ratings yet

- F200 Series Residual Current DevicesDocument2 pagesF200 Series Residual Current DevicesArtemNo ratings yet

- Method Statement For Fire Alarm SystemDocument4 pagesMethod Statement For Fire Alarm SystemNethajiNo ratings yet

- PVQ-1310 PV-C1320 PV-C1330W VV-1300 VV-1310W PV-C1340 PV-C1350W PV-C2010 PV-C2020 PV-C2030W VV-2000 PV-C2060 PDFDocument129 pagesPVQ-1310 PV-C1320 PV-C1330W VV-1300 VV-1310W PV-C1340 PV-C1350W PV-C2010 PV-C2020 PV-C2030W VV-2000 PV-C2060 PDFRobson RodriguesNo ratings yet

- High Power LASERDocument22 pagesHigh Power LASERVIJEESH PNo ratings yet

- Standard Heavy Duty Limit Switches FD/FP/FL: Options and Ordering CodesDocument9 pagesStandard Heavy Duty Limit Switches FD/FP/FL: Options and Ordering CodesNisar AhmedNo ratings yet

- RNO Analysis Mate V1 01Document93 pagesRNO Analysis Mate V1 01Manik KapoorNo ratings yet

- DiagnosticDocument16 pagesDiagnosticPrasanna Venkatesan100% (1)

- IEC Risk Assessment Calculator - 1Document1 pageIEC Risk Assessment Calculator - 1Sergio Aldo Enriquez LoriaNo ratings yet

- Cummins: Fault Code: 382 PID: S237 SPN: 626 FMI: 11Document4 pagesCummins: Fault Code: 382 PID: S237 SPN: 626 FMI: 11Enrrique LaraNo ratings yet

- Pages From Electrical Insulation For Rotating Machines - Design, Evaluation, Aging, Testing, and Repair-7Document5 pagesPages From Electrical Insulation For Rotating Machines - Design, Evaluation, Aging, Testing, and Repair-7Muhammad AsimNo ratings yet

- EN FANOXTD MANU SIA OCEFSecondaryDist SIAB-SPECIFIC-CT R032Document114 pagesEN FANOXTD MANU SIA OCEFSecondaryDist SIAB-SPECIFIC-CT R032arolnNo ratings yet

- Commscope r2hh 6533d r5Document4 pagesCommscope r2hh 6533d r5roy tanjungNo ratings yet

- Inspection ChecklistDocument2 pagesInspection ChecklistrobinrubinaNo ratings yet

- Artix-7™ Power, DDR2 Memory, Priced For Students.: Proudly Sponsored byDocument1 pageArtix-7™ Power, DDR2 Memory, Priced For Students.: Proudly Sponsored byIván Salazar BartoloNo ratings yet