Professional Documents

Culture Documents

7140 - 7177 Valve Manual

Uploaded by

contactoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7140 - 7177 Valve Manual

Uploaded by

contactoCopyright:

Available Formats

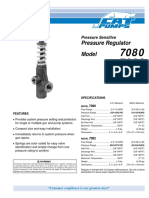

®

Brass Thermo Valves

Models 7140-7177

SPECIFICATIONS

U.S. Measure Metric Measure

130°F MODEL 7146

Max. Inlet Pressure............................125 PSI (8.6 BAR)

Inlet Port (7146)...........................1/4" NPTM (1/4" NPTM)

Bleed Port ......................................1/8" NPTF (1/8" NPTF)

Weight .................................................6.2 oz. (.17 kg)

Dimensions......................................3.0 x .88" (76 x 22mm)

145°F MODELS 7140, 7141, 7142

Max. Inlet Pressure............................125 PSI (8.6 BAR)

Inlet Port (7140)...........................1/4" NPTM (1/4" NPTM)

Inlet Port (7141)...........................3/8" NPTM (3/8" NPTM)

Inlet Port (7142)...........................1/2" NPTM (1/2" NPTM)

Bleed Port ......................................1/8" NPTF (1/8" NPTF)

Weight .................................................6.2 oz. (.17 kg)

Dimensions......................................3.0 x .88" (76 x 22mm)

FEATURES

165°F MODELS 7143, 7144, 7145

● Protects pump from premature failure of seals Max. Inlet Pressure............................125 PSI (8.6 BAR)

Inlet Port (7143)...........................1/4" NPTM (1/4" NPTM)

and cups by eliminating heat build-up in closed Inlet Port (7144)...........................3/8" NPTM (3/8" NPTM)

loop by-pass systems. Inlet Port (7145)...........................1/2" NPTM (1/2" NPTM)

Bleed Port ......................................1/8" NPTF (1/8" NPTF)

Weight .................................................6.2 oz. (.17 kg)

● Choice of three port sizes to allow convenient Dimensions......................................3.0 x .88" (76 x 22mm)

and easy installation into the by-pass loop.

180°F MODELS 7170, 7171, 7172

● Automatically seats during unloader/regulator Max. Inlet Pressure............................125 PSI (8.6 BAR)

Inlet Port (7170)...........................1/4" NPTM (1/4" NPTM)

pressure spikes to prevent liquid bleed. Inlet Port (7171)...........................3/8" NPTM (3/8" NPTM)

Inlet Port (7172)...........................1/2" NPTM (1/2" NPTM)

● Temperature protection without interruption Bleed Port ......................................1/8" NPTF (1/8" NPTF)

Weight .................................................6.2 oz. (.17 kg)

in flow. Dimensions......................................3.0 x .88" (76 x 22mm)

● Compatible with systems using either unloader 190°F MODELS 7175, 7176, 7177

or regulator valves. Max. Inlet Pressure............................125 PSI (8.6 BAR)

Inlet Port (7175)...........................1/4" NPTM (1/4" NPTM)

Inlet Port (7176)...........................3/8" NPTM (3/8" NPTM)

● Mount multiple Thermo Valves in-line to handle Inlet Port (7177)...........................1/2" NPTM (1/2" NPTM)

increased system flow. Bleed Port ......................................1/8" NPTF (1/8" NPTF)

Weight .................................................6.2 oz. (.17 kg)

● Optional By-Pass hose with Thermo Valve Dimensions......................................3.0 x .88" (76 x 22mm)

for quick, compact installation. The Thermo Valve must be installed with a pressurized pump inlet.

“Customer confidence is our greatest asset”

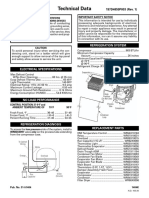

EXPLODED VIEW SELECTION: The Thermo Valve is a simple device designed to

be installed in the by-pass line of the regulating device when

the by-pass liquid is being recirculated to the inlet of the pump.

Bleed 1 This Thermo Valve is effective with either a pressure regulator or

Port an unloader.

2

3

INSTALLATION: Exercise caution when installing the Thermo

4

Valve as to not exceed the maximum inlet pressure of the valve

or the pump.

6 When installed in a Piston Pump application with the by-pass

routed directly to the inlet line, the maximum inlet pressure to

the pump is 40 PSI and a pressure reducing valve must be

installed between the Thermo Valve and pump inlet.

7

When installed in a Plunger Pump application with the

by-pass routed directly to the inlet line or inlet port, the

maximum inlet pressure to the pump is 60-70 PSI and a pressure

Inlet 8

Port

reducing valve must be installed between the Thermo Valve and

the pump inlet.

PARTS LIST Some regulating devices may have excessive pressure spikes

ITEM P/N MATL

DESCRIPTION MODEL USED QTY when in by-pass. The maximum inlet pressure to the Thermo Valve

1 — BB

Cap, Bleed All 1 is 125 PSI.

2 — NBR

O-Ring, Cap - Internal All 1

3 — DWasher, Back-up All 1

Caution should be exercised not to exceed 125 PSI in the by-pass

4 — NBR

O-Ring, Cap - External All 1 loop as this may cause harm to both the valve and the pump.

6 — CU

Power Pill-130°F 7146 1

— CU

Power Pill-145°F 7140, 7141, 7142 1

For convenience in installation, By-pass Hose and Thermo Valve

— CU

Power Pill-165°F 7143, 7144, 7145 1 assemblies are available for 1/4", 3/8" and 1/2" unloader connections.

— CU

Power Pill-180°F 7170, 7171, 7172 1

— CU

Power Pill-190°F 7175, 7176, 7177 OPERATION: As the system liquid is recirculated during the by-

7 — SSpring All 1 pass cycle, the temperature will increase. Frequent or prolonged

8 — BB

Body 1/2" NPT 7142, 7145, 7172, 7177 1 by-pass can result in extremely high temperature build-up. These

— BB

Body 3/8" NPT 7141, 7144, 7171, 7176 1 high temperatures cause premature failure of cups and seals.

— BB

Body 1/4" NPT 7140, 7143, 7146, 7170, 7175 1 Installing the Thermo Valve protects the pump against these

— 7090.40 —By-Pass Hose 2SF 1

w/7140 Thermo Valve (145°)

excessive temperatures. The power pill in the Thermo Valve

— 7091.41 — By-Pass Hose 4SF 1 detects the temperature rise in the liquid and compresses the

w/7141 Thermo Valve (145°) spring, opening the bleed port and dumping a portion of the over-

— 7092.40 — By-Pass Hose 2SFX 1 heated liquid.

w/7140 Thermo Valve (145°)

— 7093.42 — By-Pass Hose 5, 7, 15 PFR 1 The Thermo Valve is most effective when operating with ambient

w/7142 Thermo Valve (145°) temperature liquids and moderate GPM. As the incoming liquid

MATERIAL CODES (Not Part of Part Number): temperature increases, the quicker the by-pass liquid will reach its

BB=Brass CU=Copper D=Acetal NBR=Medium Nitrile (Buna-N) S=304SS temperature release point, forcing the Thermo Valve to bleed-off.

The higher the system GPM, the more heat generating energy is

TROUBLESHOOTING produced, also forcing the Thermo Valve to bleed-off. For

Problem Probable Cause Solution example, a 25 GPM system@130°F will activate the Thermo

Leaking at low ● Foreign material ● Check internal and external Valve much quicker than a 5 GPM system@90°F.

temperature or trapped o-rings on cap for cuts and fit and

non by-pass ● Damaged o-ring replace if worn or damaged. In high flow systems, it may be necessary to install multiple

operation through ● Check for deep cuts or imperfect- Thermo Valves to best prevent overheating the system.

bleed port ions on inner lip of cap where

o-ring seats. Because of the unique design of the Thermo Valve it will not bleed

● Damaged Power Pill ● Check for deep cuts or imperfect- liquid during a pressure spike from the regulator or unloader as it

ions on top lip of power pill which completely seats and shuts off the flow.

seats up to inner cap o-ring and

replace if damaged. The Thermo Valve must be installed with a pressurized

● Check for malfunctioning power pump inlet.

pill stem. Failure of stem to

expand and retract will prevent

opening and closing of valve. WARRANTY

Replace if worn.

90 Day Warranty

Leaks between ● Damaged o-ring ● Check external o-ring on cap and

body and cap replace if worn or cut. Refer to complete CAT PUMPS Warranty for further information.

World Headquarters CAT PUMPS (U.K.) LTD.

1 Fleet Business Park, Sandy Lane, Church Crookham

CAT PUMPS FLEET, Hampshire, GU52 8BF, England

1681 - 94th Lane N.E. Minneapolis, MN 55449 - 4324 Phone Fleet 44 1252-622031 — Fax 44 1252-626655

e-mail: sales@catpumps.co.uk

Phone (763) 780-5440 — FAX (763) 780-2958 N.V. CAT PUMPS INTERNATIONAL S. A.

e-mail: techsupport@catpumps.com Heiveldekens 6A, B-2550 Kontich, Belgium

www.catpumps.com The Pumps with Nine Lives Phone 32- 3- 450.71.50 — Fax 32-3- 450.71.51

e-mail: cpi@catpumps.be www.catpumps.be

International Inquiries CAT PUMPS DEUTSCHLAND GmbH

FAX (763) 785-4329 Buchwiese 2, D-65510 Idstein, Germany

Phone 49 6126-9303 0 — Fax 49 6126-9303 33

e-mail: intlsales@catpumps.com e-mail: catpumps@t-online.de www.catpumps.de

PN 993179 Rev B 5647

You might also like

- EliminatorDocument55 pagesEliminatorChristian ChumpitazNo ratings yet

- High-Security Mechanical Locks: An Encyclopedic ReferenceFrom EverandHigh-Security Mechanical Locks: An Encyclopedic ReferenceRating: 5 out of 5 stars5/5 (9)

- VickersDocument24 pagesVickersJose Angel Rodriguez100% (2)

- ProFlowEliminatorCertifiedManual PDFDocument24 pagesProFlowEliminatorCertifiedManual PDFintermountainwaterNo ratings yet

- DSA6 15M SidedoorDocument14 pagesDSA6 15M SidedoorДудла Станіслав100% (1)

- Ecr88 - 20009002-D CHNDocument720 pagesEcr88 - 20009002-D CHNDiego MontenegroNo ratings yet

- 1403E Under Over Stripper PDFDocument16 pages1403E Under Over Stripper PDFOvRrj AhmedNo ratings yet

- Stripper Packer DSV4 3.06 1 VentanaDocument12 pagesStripper Packer DSV4 3.06 1 VentanaValeria Sanchez100% (1)

- BOP-EU QuadDocument20 pagesBOP-EU QuadMarvin Omaña100% (2)

- AA4V125 Series 1 Service Parts ListDocument38 pagesAA4V125 Series 1 Service Parts ListTimon2005100% (1)

- Astm F477Document4 pagesAstm F477Hernando Andrés Ramírez Gil100% (1)

- Ficha Técnica Cat 1010 (1 Hojas)Document1 pageFicha Técnica Cat 1010 (1 Hojas)paulowillNo ratings yet

- 4.06 10M-15M Striper PackerDocument16 pages4.06 10M-15M Striper Packeroswaldo58100% (1)

- JSB 40G Part ListDocument6 pagesJSB 40G Part Listjose luis Olguín RiffoNo ratings yet

- Wilden Pump p8Document47 pagesWilden Pump p8RUBERTH ALEXANDER OCHOANo ratings yet

- Operation and Maintence Maunal of Boiler Feed PumpDocument131 pagesOperation and Maintence Maunal of Boiler Feed Pumpmanishsharmalnt100% (1)

- Pressure Regulator ModelDocument4 pagesPressure Regulator ModelJuan Pablo Palma PizarroNo ratings yet

- Pump Catalog: "The Pumps With Nine Lives"Document34 pagesPump Catalog: "The Pumps With Nine Lives"Hasan Syaiful INo ratings yet

- Denison Hydraulics Vane Pumps - Single, Double, Triple T6 Mobile ApplicationDocument35 pagesDenison Hydraulics Vane Pumps - Single, Double, Triple T6 Mobile ApplicationZoran Jankov100% (1)

- Graco Husky 716 Diaphragm Pump Data SheetDocument8 pagesGraco Husky 716 Diaphragm Pump Data SheetMROstop.comNo ratings yet

- Ficha Tecnica C 40Document1 pageFicha Tecnica C 40Abrar HussainNo ratings yet

- Phaser/1000 Series: Oil Pressure Relief Valve (With Balancer)Document1 pagePhaser/1000 Series: Oil Pressure Relief Valve (With Balancer)NikNo ratings yet

- 15 Frame Plunger Pump: Standard Brass ModelDocument4 pages15 Frame Plunger Pump: Standard Brass Modelmantilla7No ratings yet

- Cat Pumps Catalog PAGESDocument41 pagesCat Pumps Catalog PAGESMiguel Angel Santos PintadoNo ratings yet

- CLS100 Proportional Load Sensing Mobile Valve: Overhaul Manual / Trouble Shooting GuideDocument55 pagesCLS100 Proportional Load Sensing Mobile Valve: Overhaul Manual / Trouble Shooting GuideSOLID ENGENHARIA & PROJETOSNo ratings yet

- Graco XT Auto BrusurDocument4 pagesGraco XT Auto Brusurcav4444No ratings yet

- Graco Husky 3275 Diaphragm Pump Data SheetDocument8 pagesGraco Husky 3275 Diaphragm Pump Data SheetMROstop.comNo ratings yet

- Technical Data: Refrigeration SystemDocument2 pagesTechnical Data: Refrigeration SystemMiguel RamirezNo ratings yet

- Flowserve Actuator SizingDocument16 pagesFlowserve Actuator SizingalexmontellNo ratings yet

- Cat 3507 LDocument4 pagesCat 3507 LJordan aguilarNo ratings yet

- UntitledDocument37 pagesUntitledAilson Florencio LuzNo ratings yet

- Sample ValveDocument20 pagesSample ValveLuis Eduardo Aguilar Dueñas100% (1)

- ES56 Dual Combi BOPDocument24 pagesES56 Dual Combi BOPLismiantoNo ratings yet

- Airlift Performance ManualDocument36 pagesAirlift Performance ManualADRIAN SALAZAR MARTINEZNo ratings yet

- TESCOM 26-1000 Series (2015-11)Document6 pagesTESCOM 26-1000 Series (2015-11)BrianNo ratings yet

- Air Compressors 1Document59 pagesAir Compressors 1Rajesh SinsinwarNo ratings yet

- Texas Oil Tools: "DSH4" Side Door Stripper Packer 3.06" 10MDocument14 pagesTexas Oil Tools: "DSH4" Side Door Stripper Packer 3.06" 10Mjose perozoNo ratings yet

- Thermostatic Expansion Valves: Technical BrochureDocument12 pagesThermostatic Expansion Valves: Technical BrochuresenNo ratings yet

- Tech Data ZIS42D (31-51404) 197D4859P003-1Document2 pagesTech Data ZIS42D (31-51404) 197D4859P003-1Cesar Calderon GrNo ratings yet

- PDBO0A102Document24 pagesPDBO0A102LucioRimacNo ratings yet

- Ficha Tecnica 1006 GTDocument6 pagesFicha Tecnica 1006 GTJonhatan Duque RamirezNo ratings yet

- P 180 M S GX MotorDocument8 pagesP 180 M S GX MotorMohamed OmerNo ratings yet

- ScaDocument16 pagesScaAndres CarrascoNo ratings yet

- Accessory CatalogDocument42 pagesAccessory Catalogluis mirandaNo ratings yet

- ContinentalPVR50 70Document65 pagesContinentalPVR50 70Juan Carlos Bermudez CardenasNo ratings yet

- 3 1524 (1500)Document6 pages3 1524 (1500)mkNo ratings yet

- WH GXXTA SpecDocument1 pageWH GXXTA Specltovar01No ratings yet

- GFI ImpcoDocument21 pagesGFI ImpcoNikolai GeorgievNo ratings yet

- Advanced Series PLASTIC Pumps: Advance Your ProcessDocument47 pagesAdvanced Series PLASTIC Pumps: Advance Your ProcesscristinaleitonNo ratings yet

- PartnerDocument14 pagesPartnerLeo van GorkumNo ratings yet

- T-900 Series ManualDocument14 pagesT-900 Series ManualSonyer YFNo ratings yet

- PDFQ0A202Document12 pagesPDFQ0A202LucioRimacNo ratings yet

- RS68-120 MLN ManuelDocument28 pagesRS68-120 MLN ManuelUmar MajeedNo ratings yet

- 7 Frame SchematicDocument4 pages7 Frame Schematicab5951No ratings yet

- Flojet Jabsco RuleDocument11 pagesFlojet Jabsco RuleCarlos A. Galeano A.No ratings yet

- s4shr-Lp Spec SheetDocument2 pagess4shr-Lp Spec SheetedfabaroNo ratings yet

- S4SHR-LP Spec Sheet PDFDocument2 pagesS4SHR-LP Spec Sheet PDFedfabaroNo ratings yet

- 200b-917121-Chapter Two-SpecificationsDocument24 pages200b-917121-Chapter Two-SpecificationsindrajayaNo ratings yet

- Hybrid Pump Variable & Fixed Flow Double & Triple T6H Piston & Vane PumpDocument27 pagesHybrid Pump Variable & Fixed Flow Double & Triple T6H Piston & Vane PumpElias80100% (1)

- The Inverted Bucket Steam Trap: Energy Efficient Because It's So ReliableDocument4 pagesThe Inverted Bucket Steam Trap: Energy Efficient Because It's So ReliablesgrsthNo ratings yet

- P800 PX800 Adv PLS Eom 02 - 1Document48 pagesP800 PX800 Adv PLS Eom 02 - 1Smart SupplyNo ratings yet

- Tech HBDocument32 pagesTech HBGreg ReynekeNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Parker SizeTempratureApplicationMediaPressureDocument40 pagesParker SizeTempratureApplicationMediaPressuretrilemmaNo ratings yet

- Engineering Operation & Maintenance: Metal PumpDocument24 pagesEngineering Operation & Maintenance: Metal PumpMantenimiento Helados La FresitaNo ratings yet

- Sistema Electico y de Arranque GeneradorDocument51 pagesSistema Electico y de Arranque Generadoroctavio hernandez100% (1)

- Injector Sleeve Installation On 2008-2017 Detroit Diesel DD15 & 16 Diesel EnginesDocument2 pagesInjector Sleeve Installation On 2008-2017 Detroit Diesel DD15 & 16 Diesel EnginesIonut-alexandru IordacheNo ratings yet

- CLEVELAND 199-512 Repair Kit For Master Cylinder 10-30, 10-30A, 10-30C & 10-30DDocument6 pagesCLEVELAND 199-512 Repair Kit For Master Cylinder 10-30, 10-30A, 10-30C & 10-30DBrunoNo ratings yet

- Numa DTH P65 - ManualDocument22 pagesNuma DTH P65 - Manualsalvatore baldiNo ratings yet

- Válvulas-De-Seguridad-Proporcional-1 Parker PDFDocument12 pagesVálvulas-De-Seguridad-Proporcional-1 Parker PDFGuillermo de la Fuente SantiagoNo ratings yet

- Allis Chalmers Engine PartDocument47 pagesAllis Chalmers Engine Partphilippe gravierNo ratings yet

- SH-Coffee-Art Plus SPMDocument36 pagesSH-Coffee-Art Plus SPMdeclansmithknNo ratings yet

- V Rings Type ADocument3 pagesV Rings Type ACTN2010No ratings yet

- Ka 15 AccesoriosDocument87 pagesKa 15 AccesoriosNery AndrésNo ratings yet

- Service Kits For Sulzer Pumps and AgitatorsDocument8 pagesService Kits For Sulzer Pumps and AgitatorsPascal CoteNo ratings yet

- Hyva Valvula Volvo Volcadora PDFDocument2 pagesHyva Valvula Volvo Volcadora PDFricardo bueraNo ratings yet

- 2011 Bowen Fishing Tools Price BookDocument198 pages2011 Bowen Fishing Tools Price BookREGHIS HaouesNo ratings yet

- Mechanical Seals - Mechanical Seals For Pumps - Elastomer Bellows SealsDocument7 pagesMechanical Seals - Mechanical Seals For Pumps - Elastomer Bellows SealsChrist Rodney MAKANANo ratings yet

- Pump Specifications Elv Series Submersible Sump Pump With Oiltector ControlDocument7 pagesPump Specifications Elv Series Submersible Sump Pump With Oiltector ControlAnonymous PCsoNCt0mFNo ratings yet

- AngkutanDocument35 pagesAngkutanrahmandpNo ratings yet

- Grundfosliterature 1580Document284 pagesGrundfosliterature 1580Marko DjapicNo ratings yet

- Saver CF Conflow Oct 2005Document60 pagesSaver CF Conflow Oct 2005Matthew LipuscekNo ratings yet

- 06 636Document57 pages06 636muhammad aliNo ratings yet

- Hydraulic Cylinder Serie HV - MillerDocument96 pagesHydraulic Cylinder Serie HV - MillerroNo ratings yet

- Vajraa Technical ServicesDocument10 pagesVajraa Technical ServicesVipin RanaNo ratings yet

- Solex PDFDocument13 pagesSolex PDFDiego Alejandro Cobos CaballeroNo ratings yet

- EagleBurgmann HJ92N enDocument4 pagesEagleBurgmann HJ92N enJohnNo ratings yet