Professional Documents

Culture Documents

HI121 - Installation Instructions PDF

Uploaded by

Fabrizzio IschaberOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HI121 - Installation Instructions PDF

Uploaded by

Fabrizzio IschaberCopyright:

Available Formats

Installation Instructions

Model HI121 Thermal Detector

Figure 1 HI121 Thermal Detector

These instructions are written in accordance with the important! The detector placements shown on these

installation guidelines of NFPA 72, National Fire Alarm Code, drawings were chosen after a careful evaluation of the area

and CAN/ULC-S524, The Installation of Fire Alarm Systems. being protected. Siemens Industry, Inc.'s extensive

experience in design of the system assures the best detector

CAUTION placement by following these drawings.

Detection Device Storage

DO NOT install this detection device until all SPECIFICATIONS

construction is completed. Environmental

Operating Temperature: 32OF (0OC) to 100OF (38OC)

DO NOT store this detection device where it can be Humidity: Up to 95% RH, non condensing

contaminated by dirt, dust, or humidity. Air Pressure: No effect.

Alarm Temp: 135OF (57OC)

DETECTOR PLACEMENT Electrical

Locate the HI121 on the ceiling, at least 4 inches from the Voltage: 16-27 VDC

side walls. For an ideal, smooth ceiling condition, place the Ripple: 3V peak-to-peak

detectors at a maximum center spacing of 50 feet (2500 Supervisory Current: 100μA max

square feet), 25 feet from side walls or room partitions. For Alarm Current: 30-50mA

FM Approved installations this detector has an RTI rating Start-up Time: 30 seconds max

of QUICK, which allows a maximum center spacing of 20

feet (400 square feet). Locate detectors 10 feet from side DETECTOR WIRING

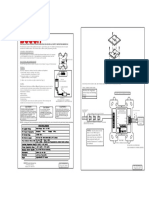

walls or room partitions. The HI121 should be connected as shown in Figure 2 using

the separate mounting base, Model DB-11. Follow the

Actual job conditions and sound engineering judgment

control panel wiring connection drawing installed on the

should be used to determine detector spacing. Consider

inside face of each control panel cover. See DB-11

environmental factors including ambient temperature

instruction, P/N 315-094193, for base mounting. Duplicate

fluctuation, and the nature of the fire hazard. Room or area

wiring information is also in the Installation, Operation, and

configuration and ceiling type (sloped or flat, smooth or

Maintenance Manual provided with every control panel.

beamed) also dictates placement.

Note any limitations on the number of detectors and

Should questions arise regarding detector placement, follow restrictions on the use of remote devices permitted for

the drawings provided and/or approved by Siemens Industry, each circuit.

Inc. or by its authorized distributors. This is extremely

WARNING: CONNECT DETECTOR ONLY TO CIRCUITS SPECIFIED IN DETECTOR

AND PANEL LITERATURE OR SYSTEM MAY NOT OPERATE.

DB-11/DB-11E DB-11/DB-11E

[NO REMOTE DEVICE] [WITH REMOTE DEVICE(S)]

+

SEE REMOTE DEVICE INSTRUCTIONS

1b FOR WIRING DETAILS: 1b

TO INITIATING +

CIRCUIT OF INSTALLATION

SIEMENS 1a 1b DEVICE INSTRUCTIONS

INDUSTRY, INC. 5 6 RR-11 P/N 315-094924

CONTROL PANEL

RLC-11, RLW-11 P/N 315-094925

6 RSAC-11, RSAW-11 P/N 315-094926 -

(SEE CAUTION 1) 5 ADB-11 P/N 315-096162 5

-

CAUTION: MULTIPLE REMOTE DEVICES

END OF

LINE

1. Do not use looped wire under base terminal 5. If remote devices are supported by the initiating circuit, DEVICE

(NOTE

Break wire run to provide supervision of each detector/base may have up to 2 remote devices POLARITY

connection. with the following configurations and restrictions only: WHEN

APPLICABLE)

Remote Remote

2. When a remote relay is used to control a critical Device 1 Device 2 Restrictions

system function, the relay and its associated RR-11 RLC-11, RLW-11 See Caution 2

RR-11

detector and optional module(s) must be the RLC-11, RLW-11 RSAC-11, RSAW-11 See

RSAC-11, RSAW-11 Caution 2

Wire from base to

ONLY devices on the initiating circuit. RLC-11, RLW-11 RLC-11, RLW-11 RSAC-11/RSAW-11

to RL-11

Figure 2 Installation and Wiring Diagram for HI121 Conventional Detector

A6V10281365_a_en_-- Siemens Industry

Industry,, Inc.

Building Technologies Di

echnologies vision

Division

INSTALLATION / REMOVAL OF DETECTOR

TO INSTALL:

• Rotate detector counterclockwise while gently pressing 30°

on it until the detector drops fully into base.

• Then rotate the detector clockwise until it stops and

locks in place. Insert optional locking screw (Order

30°

Model LK-11).

TO REMOVE: Figure 3 HI121 with Figure 4 TM121 Test

Loosen locking screw, if installed. Then rotate the detector TM121Test Magnet Magnet Placement

counterclockwise until stop is reached. Pull detector out

of base.

Detector and control panel functionality can also be tested

using the TM121 test magnet as shown in Figure 3. Place

LED INDICATOR OPERATION

the magnet in the specific area at the bottom of the detector

The HI121 contains an LED indicator capable of flashing

that is shown in Figure 4 for at least 5 seconds with the

either one of three distinct colors: green, yellow, or red.

The microprocessor-based detector checks that its critical colored side towards the centered LED. The detector will

electronics are operating. send an alarm to the panel.

Based on the results of these checks, the LED indicator WARNING: Testing with the magnet only tests the circuit,

flashes as follows: it does not test the detector’s sensing ability.

Flash WARNING: The TM121 test magnet is a strong magnet

Flash Interval that can be harmful to pacemaker wearers and to those

Color Condition (Seconds) with medical implants. Keep the magnet away from

Green Normal supervisory operation. 10 magnetic media such as credit cards and memory disks/

chips.

Detector is in trouble and needs

Yellow 5

replacement. CAUTION: UNDER NO CIRCUMSTANCES IS THE

Red Alarm 2½

DETECTOR HEAD TO BE DISASSEMBLED. NO REPAIRS

SHOULD BE ATTEMPTED.

No Detector is not powered or

-

Flashes replacement is needed. DO NOT PAINT

The detector/base plastic is marked DO NOT PAINT. This

is intended to prohibit painting during routine maintenance

TESTING AND MAINTENANCE of the occupancy which can affect proper operation of the

detector.

TEST

Testing requires no test equipment. A green flash of the

COMPAT IBLE CONT ROL EQUIPMENT

detector LED about every 10 seconds indicates that the

HI121 is operating properly. The minimum test schedule Equipment Installation/Wiring

may be found in the current edition of NFPA 72, inspection, Compatibility Identifier Instructions

testing and maintenance chapter for installations in the U.S. SZM (FS-250C System) P/N 315-034850C-4

and CAN/ULC-S537, The Verification of Fire Alarm SXL-EX P/N 315-095997-8

Systems, for installations in Canada.

The detector model number is the compatibility identifier.

Siemens Industry, Inc. Siemens Canada Limited A6V10281365_a_en_--

Building Technologies Division Building Technologies Division

Florham Park, NJ 2 Kenview Boulevard

Brampton, Ontario L6T 5E4 Canada

You might also like

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- DT11 - Installation InstructionsDocument2 pagesDT11 - Installation InstructionsFabrizzio IschaberNo ratings yet

- Installation Instructions Models OP121/OH121: Photoelectric Smoke Detector and Photo Smoke/Thermal DetectorDocument2 pagesInstallation Instructions Models OP121/OH121: Photoelectric Smoke Detector and Photo Smoke/Thermal DetectorPrabu KhayanganNo ratings yet

- FSP951 I56-6519Document2 pagesFSP951 I56-6519Marcelo Fabián OrtizNo ratings yet

- Honeywell 4219 Install GuideDocument2 pagesHoneywell 4219 Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- FSP-951T ManualDocument2 pagesFSP-951T Manualjohn hidalgoNo ratings yet

- Pre-Commissioning Check List (SAMSUNG DVMS)Document3 pagesPre-Commissioning Check List (SAMSUNG DVMS)Uzair JavedNo ratings yet

- FSP-951 Detector de FumaçaDocument2 pagesFSP-951 Detector de FumaçaRicardo Alves da SilvaNo ratings yet

- FST-951, FST-951-IV, FST-951R, FST-951R-IV, FST-951H, and FST-951H-IV Intelligent Programmable Temperature SensorsDocument2 pagesFST-951, FST-951-IV, FST-951R, FST-951R-IV, FST-951H, and FST-951H-IV Intelligent Programmable Temperature SensorsNguyễn Kim HùngNo ratings yet

- A0libr00d0046 Lie Laa1Document20 pagesA0libr00d0046 Lie Laa1cjroanNo ratings yet

- tk-8100 pdf0Document56 pagestk-8100 pdf0Jozo ĆurčićNo ratings yet

- Viewsat Ultra Manual V01Document21 pagesViewsat Ultra Manual V01Frank BarrettoNo ratings yet

- TK 7100 HDocument44 pagesTK 7100 HGiovany Toigo CollingNo ratings yet

- 4100-0304, - 1291 Remote Unit Interface Installation InstructionsDocument22 pages4100-0304, - 1291 Remote Unit Interface Installation Instructionswilliam jovelNo ratings yet

- Manual Serv tk7102h Version 1Document41 pagesManual Serv tk7102h Version 1Jesus GonzalezNo ratings yet

- Service Manual: Microphone (T91-0624-05) : KDocument43 pagesService Manual: Microphone (T91-0624-05) : KRichieNo ratings yet

- TK-7102 Revised II - B51-8584-20Document56 pagesTK-7102 Revised II - B51-8584-20Marcelo O' Kunz LU1FKNo ratings yet

- Dla-Nx9 Dla-Nx7 Dla-Nx5: InstructionsDocument99 pagesDla-Nx9 Dla-Nx7 Dla-Nx5: InstructionsDaltonist OggyNo ratings yet

- TK 7102H (Sup)Document25 pagesTK 7102H (Sup)Julio Cesar QuintelaNo ratings yet

- Satchwell Unifact Pro Terminal Unit Controller For Sigma Systems Wiring & Commissioning Guide PDFDocument34 pagesSatchwell Unifact Pro Terminal Unit Controller For Sigma Systems Wiring & Commissioning Guide PDFGabor KomuvesNo ratings yet

- Service Manual: © 2004-7 Printed in Japan B51-8691-00 (N) 1007Document85 pagesService Manual: © 2004-7 Printed in Japan B51-8691-00 (N) 1007Tecnica ACNNo ratings yet

- B501aus Installation ManualDocument2 pagesB501aus Installation ManualNurdin MubarokNo ratings yet

- Speaker Instalacion A6V11422379 - enDocument3 pagesSpeaker Instalacion A6V11422379 - enWERMER MORANo ratings yet

- Scorpio Fire Control PanelDocument16 pagesScorpio Fire Control PanelJORGE ENRIQUE ARANGONo ratings yet

- NX700 (H)Document109 pagesNX700 (H)FABIANNo ratings yet

- Manual Instalacion 900CRDocument16 pagesManual Instalacion 900CRgeovanyhazellopezsixtosNo ratings yet

- TK-7360 Service ManualDocument65 pagesTK-7360 Service ManualJason SloneNo ratings yet

- WEG Cfw11 Guia de Instalacion 10001803811 Manual EspanolDocument162 pagesWEG Cfw11 Guia de Instalacion 10001803811 Manual Espanoljerson camposNo ratings yet

- Service Manual: 2007-12 Printed in Japan B51-8803-00 (S) 343Document110 pagesService Manual: 2007-12 Printed in Japan B51-8803-00 (S) 343Wathek HassanNo ratings yet

- NX 700 Service.MDocument110 pagesNX 700 Service.MA&A LABORATORIONo ratings yet

- Operating Instructions DVD Recorder Model No. DMR-EZ17Document72 pagesOperating Instructions DVD Recorder Model No. DMR-EZ17fmick576847No ratings yet

- DVD Home Theatre SystemDocument84 pagesDVD Home Theatre SystemGeorgio HabibNo ratings yet

- Ad 28 XMVDocument20 pagesAd 28 XMVcorsini999No ratings yet

- 7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsDocument2 pages7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsAakash JunejaNo ratings yet

- Response House Alarm SA3 ManualDocument32 pagesResponse House Alarm SA3 ManualCarlos VieitesNo ratings yet

- Sylvania Sylvania Manual de UsuarioDocument96 pagesSylvania Sylvania Manual de Usuarioxthian goNo ratings yet

- HA502320U001Document138 pagesHA502320U001Diana Amaya NatividadNo ratings yet

- Projector Manual 10626Document92 pagesProjector Manual 10626Arun P KrishnanNo ratings yet

- Installsheet 4235 Htrc2liDocument4 pagesInstallsheet 4235 Htrc2litheka1627No ratings yet

- Series: Safety, Operation, and Procedure Instructions For The PTS Series of DC Hipot/MegohmmetersDocument37 pagesSeries: Safety, Operation, and Procedure Instructions For The PTS Series of DC Hipot/MegohmmetersBarajiux100% (1)

- rzcs4 00c Is Kp4cenasDocument2 pagesrzcs4 00c Is Kp4cenasHomevolutionNo ratings yet

- Manual TK 7160Document53 pagesManual TK 7160pepebeto79No ratings yet

- DB2 HRDocument4 pagesDB2 HRAhmedNo ratings yet

- Installation Instructions For Flm-325-2I4 Dual Input Monitor ModuleDocument1 pageInstallation Instructions For Flm-325-2I4 Dual Input Monitor ModuleLuiyi Lazcano MontalvoNo ratings yet

- LMV27Document17 pagesLMV27tespakNo ratings yet

- LG DR175, DR165, DR676XDocument108 pagesLG DR175, DR165, DR676XRICARDO ConteNo ratings yet

- EKRUMADocument12 pagesEKRUMAALEKSANDARNo ratings yet

- Ipela SNC-RZ25NDocument81 pagesIpela SNC-RZ25Nmax51sNo ratings yet

- Installation Manual: Remote User InterfaceDocument12 pagesInstallation Manual: Remote User InterfaceALEKSANDARNo ratings yet

- 05di-Hiecbxx-19 (1) (2016 - 09 - 14 20 - 59 - 34 Utc)Document14 pages05di-Hiecbxx-19 (1) (2016 - 09 - 14 20 - 59 - 34 Utc)Dhanushka RathnasooriyaNo ratings yet

- 7160 8160servicemanualDocument52 pages7160 8160servicemanualhectorieNo ratings yet

- Numark DM1125Document16 pagesNumark DM1125Henry PalNo ratings yet

- DSP Sine Wave Inv Manual Colossal SeriesDocument28 pagesDSP Sine Wave Inv Manual Colossal SeriesMonir HossainNo ratings yet

- NX-820H (G) /820H: Service ManualDocument89 pagesNX-820H (G) /820H: Service Manualp25digital2No ratings yet

- Rca Rled5543-Uhd Enfr OkDocument49 pagesRca Rled5543-Uhd Enfr OkCesar PinedoNo ratings yet

- BAC-5900 Series Controller: Installation GuideDocument9 pagesBAC-5900 Series Controller: Installation GuidePaul RyanNo ratings yet

- BlueLine Gen 2 W12 Installation Manual enUS 2603159435Document2 pagesBlueLine Gen 2 W12 Installation Manual enUS 2603159435thesowhatNo ratings yet

- VSM - Plus - IOM 9-14Document45 pagesVSM - Plus - IOM 9-14Sebastian Ojeda RiveraNo ratings yet

- DB HRDocument2 pagesDB HRGió Bốn MùaNo ratings yet

- Um 3200 enDocument11 pagesUm 3200 enFerreira MandaNo ratings yet

- SpaceLogic RP-C 24 V Controller Models Installation SheetDocument4 pagesSpaceLogic RP-C 24 V Controller Models Installation SheetFabrizzio IschaberNo ratings yet

- Cerberus Modular IOM A6V11231627 FDocument138 pagesCerberus Modular IOM A6V11231627 FFabrizzio IschaberNo ratings yet

- CDC4 - Data SheetDocument2 pagesCDC4 - Data SheetFabrizzio IschaberNo ratings yet

- A6V10283892 enDocument8 pagesA6V10283892 enAngel TumialanNo ratings yet

- XDLC - Installation InstructionsDocument18 pagesXDLC - Installation InstructionsFabrizzio IschaberNo ratings yet

- HI121 - DataSheetDocument2 pagesHI121 - DataSheetFabrizzio IschaberNo ratings yet

- Focused Ion BeamDocument9 pagesFocused Ion BeamnitheshsharmaNo ratings yet

- Low Voltage Alternators - 4 Pole: TAL046 - TAL047 - TAL049Document8 pagesLow Voltage Alternators - 4 Pole: TAL046 - TAL047 - TAL049zainahmedscribdNo ratings yet

- HartDocument10 pagesHartSandhya RaghunathNo ratings yet

- Ref PDFDocument37 pagesRef PDFSidhant JaiswalNo ratings yet

- 10KW Solor Tender Doucments Tener No.22-2022-23Document27 pages10KW Solor Tender Doucments Tener No.22-2022-23Hammad UllahNo ratings yet

- CCTV Ajay DubeyDocument2 pagesCCTV Ajay DubeyAjay DubeyNo ratings yet

- Classic PLC 5 Hardware Installation ManualDocument128 pagesClassic PLC 5 Hardware Installation ManualJuan EscutiaNo ratings yet

- M & I Exam Eee 207 - 201819Document4 pagesM & I Exam Eee 207 - 201819Naija RonaldoNo ratings yet

- Panasonic DVD Dmr-Es15Document70 pagesPanasonic DVD Dmr-Es15cristian ianosNo ratings yet

- Multiple Choice Questions For Chapter 14: All Questions Have Only One Correct AnswerDocument5 pagesMultiple Choice Questions For Chapter 14: All Questions Have Only One Correct AnswerJoshua GyetuahNo ratings yet

- Only-VLSI - VLSI Interview Questions With Answers - 1Document2 pagesOnly-VLSI - VLSI Interview Questions With Answers - 1Anupam DubeyNo ratings yet

- Ug Qps Timing AnalyzerDocument91 pagesUg Qps Timing AnalyzerNGNo ratings yet

- Elite Wireless Microphones Revolabs Executive: The Gold Standard in Next Generation Wireless MicrophonesDocument2 pagesElite Wireless Microphones Revolabs Executive: The Gold Standard in Next Generation Wireless MicrophonesMuhammad Naveed AshrafNo ratings yet

- LT 1866Document38 pagesLT 1866cherraj ahmedNo ratings yet

- EC-415A MidsemDocument2 pagesEC-415A MidsemV Prakash SinghNo ratings yet

- Technical Data: Air-Cooled EUWY 5-24KAZWDocument43 pagesTechnical Data: Air-Cooled EUWY 5-24KAZWDanijelSeđakNo ratings yet

- Description: Princeton Technology CorpDocument6 pagesDescription: Princeton Technology CorpThế giới điện tửNo ratings yet

- Lab 2Document3 pagesLab 2Vu LeNo ratings yet

- Ac Current / Voltage Configurable Indicator - Alarm Units: Main FeaturesDocument4 pagesAc Current / Voltage Configurable Indicator - Alarm Units: Main FeaturesSami KhalifaNo ratings yet

- TC-L47E50L: 47 Inch Class 1080p LCD HDTVDocument5 pagesTC-L47E50L: 47 Inch Class 1080p LCD HDTVсчавит счавитNo ratings yet

- BA Fieldbus Module Type 2133 Profibus-DP enDocument79 pagesBA Fieldbus Module Type 2133 Profibus-DP enArif RahmanNo ratings yet

- Activity-Lab-2-The DC Shunt Generator and MotorDocument14 pagesActivity-Lab-2-The DC Shunt Generator and MotorDiether PaderoNo ratings yet

- HY Hanyoung Series CatalogueDocument2 pagesHY Hanyoung Series CatalogueTrần NguyênNo ratings yet

- M Britt Profiles - Colonial PackDocument3 pagesM Britt Profiles - Colonial PackpavelscribdNo ratings yet

- Implementation of Smart Restaurant With E-Menu Card: Mayur D. Jakhete Piyush C. MankarDocument5 pagesImplementation of Smart Restaurant With E-Menu Card: Mayur D. Jakhete Piyush C. Mankarفاضل محمد مجبلNo ratings yet

- PI 95 TEM PicoIndenter User ManualDocument82 pagesPI 95 TEM PicoIndenter User ManualNight TenNo ratings yet

- Ec8453 Linear Integrated Circuits Year/Sem: Ii/Iv Dept: R&A Part-BDocument1 pageEc8453 Linear Integrated Circuits Year/Sem: Ii/Iv Dept: R&A Part-BARUNKUMARNo ratings yet

- Sirona DAC Autoclave - User ManualDocument74 pagesSirona DAC Autoclave - User Manualehab emamNo ratings yet

- PVIV Test Solution: Typical I-V Test Configuration With Optional Equipment Shown. Solar Simulator Is Sold SeparatelyDocument4 pagesPVIV Test Solution: Typical I-V Test Configuration With Optional Equipment Shown. Solar Simulator Is Sold Separatelyluciano_gularteNo ratings yet

- Dept. of Information Technology Class - SE: Programming Skill Development LabDocument8 pagesDept. of Information Technology Class - SE: Programming Skill Development LabMadhukar NimbalkarNo ratings yet