Professional Documents

Culture Documents

10inch 24.03.2023

Uploaded by

B rgOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10inch 24.03.2023

Uploaded by

B rgCopyright:

Available Formats

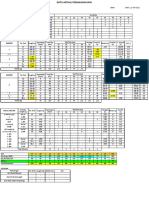

NAIMA 3E Plus v5.1.

0

Generated by Kam Mar

24.03.2023

Project: desf

Scenario: checj

(1 calculations)

Parameters and Assumptions

Process Temp: 392 (°F) Ambient Temp: 46.2 (°F)

Wind Speed: 8.72 (mph) Hours / Year: 8320

Pipe Insulation Price: 5 ($/ft) Board Insulation Price: 2 ($/ft^2)

Fuel Cost: 8.963 ($/Mcf) Heat Content: 927 (BTU/ft^3)

Efficiency: 93 (%) Labor Rate By Hour: 60

Labor Productivity Factor: 100 Fuel Type: Natural Gas

Base Metal: Steel Jacket Material: Aluminum, oxidized, in service

Surface Geometry: Tube - Horizontal Dimensional Standard: ASTM C 585 Rigid

Even Increment: 0 Pipe Size: 10

Results: Economic (Simple)

Insulation Insulation Cost Fuel Cost ($) Fuel Savings ($) Payback (yrs) Heat Flow

Thickness (in) ($/ft/yr) (kBTU/hr/ft)

Bare — 102.31 — — 9841

1.0 11.45 8.82 93.49 0.1 848

1.5 12.4 6.15 96.16 0.1 592

2.0 13.37 4.72 97.59 0.1 454

2.5 14.44 3.83 98.48 0.1 368

3.0 15.53 3.22 99.09 0.2 310

Double Layer — — — — —

4.0 17.27 2.45 99.86 0.2 235

3.0 19.63 3.22 99.09 0.2 310

4.0 21.18 2.45 99.86 0.2 235

5.0 23.24 1.97 100.34 0.2 189

Triple Layer — — — — —

6.0 25.13 1.65 100.66 0.2 159

1/2

NAIMA 3E Plus v5.1.0

Generated by Kam Mar

24.03.2023

Insulation Insulation Cost Fuel Cost ($) Fuel Savings ($) Payback (yrs) Heat Flow

Thickness (in) ($/ft/yr) (kBTU/hr/ft)

6.0 28.62 1.65 100.66 0.3 159

7.0 30.2 1.42 100.89 0.3 136

8.0 31.93 1.24 101.06 0.3 120

9.0 33.72 1.11 101.2 0.3 107

10.0 35.4 1 101.31 0.3 96

2/2

You might also like

- Deep7 - Electrically Traced Pipes PDFDocument16 pagesDeep7 - Electrically Traced Pipes PDFNicolasNo ratings yet

- Book - Steel TableDocument120 pagesBook - Steel Tablevisarut100% (1)

- Mast DesignDocument18 pagesMast DesignPoulomi BiswasNo ratings yet

- Accropode™ Design Guide Table: F F F FDocument4 pagesAccropode™ Design Guide Table: F F F FJoeNo ratings yet

- Ball Charge Design - VDocument11 pagesBall Charge Design - VKaran_Agarwal_4807100% (2)

- Floor Deck Profile TS 47/180: Product Data SheetDocument3 pagesFloor Deck Profile TS 47/180: Product Data SheetMohamed KareemNo ratings yet

- Loading Metering Skids LPG 050/080: Certified and Standardized Solutions For Custody Transfer ApplicationsDocument4 pagesLoading Metering Skids LPG 050/080: Certified and Standardized Solutions For Custody Transfer ApplicationsB rgNo ratings yet

- FM-900 HpA Loading TableDocument20 pagesFM-900 HpA Loading TablekzoneasdfNo ratings yet

- Description Layers Dia Length Spacing GF PT SLAB 280 MM Thick Sl. NoDocument103 pagesDescription Layers Dia Length Spacing GF PT SLAB 280 MM Thick Sl. Noepe civil1No ratings yet

- LNG Tank Cool Down Calculation 1. InputDocument4 pagesLNG Tank Cool Down Calculation 1. InputThinh ViproNo ratings yet

- ETICS BrochureDocument8 pagesETICS Brochureterec_mariusNo ratings yet

- Bare and Lagged Pipe - Expt 9Document10 pagesBare and Lagged Pipe - Expt 9Shalimar SolatreNo ratings yet

- Failure - Mechanisms - of - C-Steels - API - 571 - .Xls - Filename UTF-8''Failure Mechanisms of C-Steels (API 571)Document100 pagesFailure - Mechanisms - of - C-Steels - API - 571 - .Xls - Filename UTF-8''Failure Mechanisms of C-Steels (API 571)أحمد صبحى100% (2)

- Measurement - 345mm Thk. BrickwallDocument2 pagesMeasurement - 345mm Thk. BrickwallFaiz Ahmad100% (1)

- Application of UG-140 For Overpressure Protection: FeaturesDocument4 pagesApplication of UG-140 For Overpressure Protection: FeaturesB rg100% (1)

- Tunnel KilnDocument4 pagesTunnel KilnSatria PurwantoNo ratings yet

- Understanding Heat Flux Limitations CCTI 2010Document8 pagesUnderstanding Heat Flux Limitations CCTI 2010B rgNo ratings yet

- Pump MAWP CalculationDocument6 pagesPump MAWP CalculationSantosh0% (1)

- ACSR Conductor Data SheetsDocument4 pagesACSR Conductor Data SheetsPrasad Yeluripati100% (2)

- Stas 6400-84-EngDocument12 pagesStas 6400-84-EnglucicotoiNo ratings yet

- Tempcon "TCSQ" Insulated Steel Panel (Nominal Thickness T 100 MM)Document1 pageTempcon "TCSQ" Insulated Steel Panel (Nominal Thickness T 100 MM)Ashuu MohammedNo ratings yet

- JIS G3466: Carbon Steel Square Tubes For General StructureDocument1 pageJIS G3466: Carbon Steel Square Tubes For General StructureDio Rian PrambudiNo ratings yet

- Weight of Reinforcement Steel Bars With Their Standard Cross Sectional AreasDocument2 pagesWeight of Reinforcement Steel Bars With Their Standard Cross Sectional AreasAbhinay SoniNo ratings yet

- ตารางเหล็กDocument41 pagesตารางเหล็กสิทธิชัย หอมจรรย์No ratings yet

- TR 60Document3 pagesTR 60Narayanan MoorthyNo ratings yet

- Axis: H Storey: 1: Bending (Top Edge) ..Document2 pagesAxis: H Storey: 1: Bending (Top Edge) ..amadi4bizNo ratings yet

- Final F.M.Document12 pagesFinal F.M.avismlNo ratings yet

- 45-150 Floor Deck Data SheetDocument1 page45-150 Floor Deck Data SheetAkhil VNNo ratings yet

- Lap. Cutting 1C-223 (BS07-KJ29-9%)Document2 pagesLap. Cutting 1C-223 (BS07-KJ29-9%)Rengga KharismaNo ratings yet

- TS 60-300 Floor Deck Profile Data Sheet - 2013Document5 pagesTS 60-300 Floor Deck Profile Data Sheet - 2013maheshbandhamNo ratings yet

- Steel Quantity For Hexane Storage TankDocument2 pagesSteel Quantity For Hexane Storage TankTom JosephNo ratings yet

- Period Start Time PLMN Name: Call - Setup - Success - Rate - TGC Immediate Assignment Success RateDocument59 pagesPeriod Start Time PLMN Name: Call - Setup - Success - Rate - TGC Immediate Assignment Success Ratedenoo williamNo ratings yet

- DN Pipe PDFDocument6 pagesDN Pipe PDFnassimNo ratings yet

- International Steel Limited SectionsDocument4 pagesInternational Steel Limited SectionsNabeel SheikhNo ratings yet

- Simulador de Hidrociclon D - 10Document2 pagesSimulador de Hidrociclon D - 10César Jacobo0% (1)

- RoofDek D153 Load TableDocument1 pageRoofDek D153 Load TableЙордан ЛиляновNo ratings yet

- VSL Data Sheets USDocument22 pagesVSL Data Sheets USLydia WangNo ratings yet

- VSL Data Sheets MultistrandDocument13 pagesVSL Data Sheets MultistrandJoão SousaNo ratings yet

- Table - 8 Conductor PropertiesDocument1 pageTable - 8 Conductor PropertiesMichael DarmstaedterNo ratings yet

- Parallel Flanges Channels - Steel DimensionsDocument1 pageParallel Flanges Channels - Steel DimensionsAxiv The GreatNo ratings yet

- Jis g3466-3Document1 pageJis g3466-3Nhuận PhạmNo ratings yet

- Taller Modelos de ViscosidadDocument12 pagesTaller Modelos de ViscosidadAlejandraMNo ratings yet

- Stud Bolts DIN 976-1: 2002-12: 1. ScopeDocument6 pagesStud Bolts DIN 976-1: 2002-12: 1. ScopejayNo ratings yet

- Carbon Steel PipeDocument3 pagesCarbon Steel Pipesaravoot_jNo ratings yet

- cp3 Wind Load CalculationsDocument1 pagecp3 Wind Load CalculationsSumedha MayadunnaNo ratings yet

- Moment at Each SectionDocument9 pagesMoment at Each SectionSanket BhaleraoNo ratings yet

- Book 11111Document2 pagesBook 11111Nailul MasniyahNo ratings yet

- Boiler Output Chart PDFDocument4 pagesBoiler Output Chart PDFUsaid KhanNo ratings yet

- Specification For Philippine Steel Bars For Concrete Reinforcement Product Standard Agency, Department of Trade and Industry (D.T.I.)Document18 pagesSpecification For Philippine Steel Bars For Concrete Reinforcement Product Standard Agency, Department of Trade and Industry (D.T.I.)Azel GarciaNo ratings yet

- Sand Blasting Clac.Document23 pagesSand Blasting Clac.koraina2015No ratings yet

- ACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis ReportDocument7 pagesACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis Reportdwi sutiknoNo ratings yet

- UJI TANAH 1 - 2A TBR Kel3Document15 pagesUJI TANAH 1 - 2A TBR Kel3Nur IkhlasNo ratings yet

- Client:ITD Consultant:NKDM Contractor: Abdul Monem LTD Diabari, Uttara, DhakaDocument1 pageClient:ITD Consultant:NKDM Contractor: Abdul Monem LTD Diabari, Uttara, DhakaZam ZamNo ratings yet

- RoofDek D159-Acoustic Load TableDocument1 pageRoofDek D159-Acoustic Load TableЙордан ЛиляновNo ratings yet

- Ethyl Acetate ExtractDocument4 pagesEthyl Acetate ExtractL edrineNo ratings yet

- DC DC: Table 5.13: Overhead Line Conductor - Hard Drawn CopperDocument8 pagesDC DC: Table 5.13: Overhead Line Conductor - Hard Drawn CopperVino VinoNo ratings yet

- Sibanye Stillwater Q32020 Historical StatsDocument14 pagesSibanye Stillwater Q32020 Historical StatsMashudu MbulayeniNo ratings yet

- GC Turpentine Lot 69Document2 pagesGC Turpentine Lot 69sidharthsud28No ratings yet

- Firecon FCSQ 100Document1 pageFirecon FCSQ 100chandra shekarNo ratings yet

- Ade Rifky IlhamsyahDocument39 pagesAde Rifky IlhamsyahMr. DreamNo ratings yet

- TechDocument1 pageTechB rgNo ratings yet

- C 680 - 03 Qzy4mc0wm0uxDocument16 pagesC 680 - 03 Qzy4mc0wm0uxB rgNo ratings yet

- Measuring Maximum Spontaneous Heating Temperature of Art MaterialsDocument4 pagesMeasuring Maximum Spontaneous Heating Temperature of Art MaterialsB rgNo ratings yet

- C 680 - 03 Qzy4mc0wmwDocument16 pagesC 680 - 03 Qzy4mc0wmwB rgNo ratings yet

- Controllers - Direct - Vs - Reverse-Acting ControlDocument4 pagesControllers - Direct - Vs - Reverse-Acting ControlB rgNo ratings yet

- Stack Max Velocity LinerDocument5 pagesStack Max Velocity LinerB rgNo ratings yet

- High Performance Trays For A Fractionator - in - A - AromaticsDocument5 pagesHigh Performance Trays For A Fractionator - in - A - AromaticsB rgNo ratings yet

- Operating Vacuum Distillation Ejector SystemsDocument10 pagesOperating Vacuum Distillation Ejector SystemsB rgNo ratings yet

- Handball Scout Admin (HSA) Manual August 2017 SportsData Edition UDDocument40 pagesHandball Scout Admin (HSA) Manual August 2017 SportsData Edition UDB rgNo ratings yet

- Fuel HC VaporizationDocument61 pagesFuel HC VaporizationB rgNo ratings yet

- Atmospheric Attenuation - Radiation: TransmissivityDocument2 pagesAtmospheric Attenuation - Radiation: TransmissivityB rgNo ratings yet

- EHF European League Men 2020 21Document105 pagesEHF European League Men 2020 21B rgNo ratings yet

- Ehf 134879 3Document8 pagesEhf 134879 3B rgNo ratings yet

- Sportsdata Shouting Guideline For HandballDocument7 pagesSportsdata Shouting Guideline For HandballB rgNo ratings yet

- Hubble Fact Hubble Space Telescope Servicing Mission 3A A New Thermal Blanket LayerDocument2 pagesHubble Fact Hubble Space Telescope Servicing Mission 3A A New Thermal Blanket LayerBob Andrepont100% (1)

- Hot Insulation ProcedureDocument8 pagesHot Insulation Procedurered patriotNo ratings yet

- Measurement of Soil Potential (Suction) Using Filter Paper: Standard Test Method ForDocument8 pagesMeasurement of Soil Potential (Suction) Using Filter Paper: Standard Test Method ForDiego Lizana OlarteNo ratings yet

- Unit 1Document108 pagesUnit 1amarparimiNo ratings yet

- Differential Equations ProblemsDocument6 pagesDifferential Equations ProblemsNygen Keith Louise TurlaNo ratings yet

- Nitrile Vs SMART PIR (Energy and Other Advantages) - VER 1Document3 pagesNitrile Vs SMART PIR (Energy and Other Advantages) - VER 1Mahesh KhadeNo ratings yet

- Mineral Wool Pipe InsulationDocument4 pagesMineral Wool Pipe InsulationMiguel Martinez GuerreroNo ratings yet

- ESA Steel CheckDocument64 pagesESA Steel CheckKostas AnastasiadesNo ratings yet

- 20ME111, Heat Transfer-Unit I II-Question BankDocument7 pages20ME111, Heat Transfer-Unit I II-Question BankR.MANIKANTHANo ratings yet

- Hvac Duct Insulation SpecificationDocument2 pagesHvac Duct Insulation SpecificationPrabhat DhekaleNo ratings yet

- Extruded Polystyrene Insulation DatasheetDocument2 pagesExtruded Polystyrene Insulation DatasheetFadi HNo ratings yet

- 9 Specification For Mechanical Pipework Insulation PDFDocument4 pages9 Specification For Mechanical Pipework Insulation PDFAgung Pramu AjiNo ratings yet

- Heat T CH 2-1Document67 pagesHeat T CH 2-1Fira tubeNo ratings yet

- Ieee 99-1980Document11 pagesIeee 99-1980juaninjaNo ratings yet

- K - W/ (M.K) Temperature - 25 125 225: Thermal ConductivityDocument16 pagesK - W/ (M.K) Temperature - 25 125 225: Thermal ConductivityJosNo ratings yet

- Ozo ProtectDocument6 pagesOzo ProtectMax NovaxNo ratings yet

- Pt. Global Power Services: Section 12 - InsulationDocument5 pagesPt. Global Power Services: Section 12 - InsulationDangolNo ratings yet

- 2.3 Transfer of Thermal EnergyDocument7 pages2.3 Transfer of Thermal EnergyDhanBahadurNo ratings yet

- Cables CalefactorescatalogoDocument56 pagesCables CalefactorescatalogoGerardoDemarcoNo ratings yet

- Glass Block TechnicalDocument18 pagesGlass Block TechnicalPrunici IonNo ratings yet

- Lab H1: IMPORTANT NOTE To Respective GroupsDocument70 pagesLab H1: IMPORTANT NOTE To Respective GroupsHritik LalNo ratings yet

- Technical Data of 800KW Syngas-Biomass Generator Set-Ettes Power160107Document8 pagesTechnical Data of 800KW Syngas-Biomass Generator Set-Ettes Power160107周庆卓No ratings yet

- Starts Per HourDocument1 pageStarts Per HourPreetham BharadwajNo ratings yet