Professional Documents

Culture Documents

Te Sensor Solutions Applicationnote Understanding RTDs

Uploaded by

Thura AungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Te Sensor Solutions Applicationnote Understanding RTDs

Uploaded by

Thura AungCopyright:

Available Formats

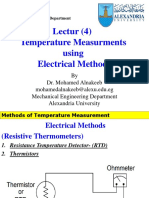

UNDERSTANDING RTDs

APPLICATION NOTE

Understanding RTDs

An RTD is a sensor whose resistance changes as its temperature changes. The resistance increases as the temperature of the

sensor increases. The resistance vs temperature relationship is well known and is repeatable over time.

An RTD is a passive device. It does not produce an output on its own. External electronic devices are used to measure the

resistance of the sensor by passing a small electrical current through the sensor to generate a voltage. Typically 1 mA or less

measuring current, 5 mA maximum without the risk of self-heating.

Standard Tolerances

RTDs are built to several standardized curves and tolerances. The most common standardized curve Degrees 0°C

is the ‘DIN’ curve. The curve describes the resistance vs temperature characteristics of a Platinum, 0 100.00

100 ohm sensor, the standardized tolerances, and the measurable temperature range. 10 103.90

20 107.79

The DIN standard specifies a base resistance of 100 ohms at 0°C, and a temperature coefficient 30 111.67

of .00385 Ohm/Ohm/°C. The nominal output of a DIN RTD sensor is shown below: 40 115.54

50 119.40

There are three standard tolerance classes for DIN RTDs. 60 123.24

These tolerances are defined as follows: 70 127.07

80 130.89

90 134.70

DIN Class A: ±(0.15 + .002 |T|°C)

100 138.50

DIN Class B: ±(0.3 + .005 |T|°C)

DIN Class C: ±(1.2 + .005 |T|°C)

RTD Element Types

When deciding the RTD element type, first consider what instrument you will be reading the sensor with. Choose an element type

that is compatible with the instrument’s sensor input. By far the most common RTDs are 100 Ohm Platinum with .00385

temperature coefficient.

Element Type Base Resistance in Ohms TCR (Ohm/Ohm/°C)

Platinum 100 Ohms at 0°C .00385

Platinum 100 Ohms at 0°C .00392

Platinum 100 Ohms at 0°C .00375

Nickel 120 Ohms at 0°C .00672

Copper 10 Ohms at 25°C .00427

TE CONNECTIVITY SENSORS /// UNDERSTANDING RTDS 07/2016 Page 1

UNDERSTANDING RTDS

APPLICATION NOTE

RTD Accuracy

Secondly, decide what accuracy is needed in your measurement. Accuracy is a combination of both base resistance tolerance

(resistance tolerance at the calibration temperature) and temperature coefficient of resistance tolerance (tolerance in the

characteristic slope). Any temperature above or below this temperature will have a wider tolerance band or less accuracy (see

graph below). The most common calibration temperature is 0°C.

TE CONNECTIVITY SENSORS /// UNDERSTANDING RTDS 07/2016 Page 2

UNDERSTANDING RTDS

APPLICATION NOTE

Sensor Connections

RTD Sensors are available in a number of different lead wire configurations. The most common configuration is the single element,

three lead configuration. Schematics of the available lead wire configurations are shown below:

Two wire sensors are typically used in applications where accuracy is not critical. The two wire configuration allows for the simplest

measurement technique, but suffers from an inherent inaccuracy due to the resistance of the sensor leads. In the two wire

configuration, there is no way to directly compensate for the resistance of the lead wires which will cause an offset increase in the

resistance measurement.

Three wire sensors are built with a compensation loop to allow the measurement to factor out the resistance of the leads. With this

configuration, the controller/measurement device makes two measurements. The first measurement measures the total resistance

of the sensor and the connecting lead wires. The second measurement is the resistance of the compensation loop resistance. By

subtracting the compensation loop resistance from the total resistance, an account net resistance is determined. Three wire

sensors are the most common and give a good combination of accuracy and convenience.

The four wire sensor configuration and measurement techniques allow measurement of the sensor resistance without the influence

of the lead wires. While this technique gives the best accuracy, many industrial controllers/measurement devices cannot make a

true four wire measurement.

The transition from the sensor lead wires to the field wiring is typically done in a connection head attached to the sensor. Terminal

blocks are used to facilitate the connection.

TE CONNECTIVITY SENSORS /// UNDERSTANDING RTDS 07/2016 Page 3

UNDERSTANDING RTDS

APPLICATION NOTE

Lead Wire Effects

Measurement of temperature with a resistance temperature detector is a matter of measuring resistance. Unbalanced Wheatstone

bridges are invariably used to measure the resistance. When measuring the resistance of the sensing element, all external factors

must be minimized or compensated for, in order to obtain an accurate reading.

A major cause of error can be the resistance of the lead wires, especially in two lead configurations.

The resistance is in series with the sensing element, so the readout is the sum of the resistances of the sensing element and the

lead wires. Two-lead RTDs are possible when the sensing element has a high resistance and the lead wires have a low resistance.

When the lead wire resistance is comparably high, however, it must be compensated. Compensation can be achieved with a

three-lead configuration. As shown in the three-lead diagram, one side of the power supply is taken to one side of the RTD via L3.

This puts L1 and L2 in opposite arms of the bridge so they cancel each other out and have no effect on the bridge output voltage.

Three-lead connections are recommended for RTDs, especially with low sensing element resistance, where a small lead wire

resistance can have a large effect on readout accuracy.

te.com/sensorsolutions

Measurement Specialties, Inc., a TE Connectivity company.

Measurement Specialties, MEAS, TE Connectivity, and the TE connectivity (logo) are trademarks. All other logos, products

Measurement Specialties, Inc.,

and/or company names referred to herein might be trademarks of their respective owners. a TE Connectivity Company

1711 139th Lane NW

The information given herein, including drawings, illustrations and schematics which are intended for illustration purposes Andover, MN 55304

only, is believed to be reliable. However, TE Connectivity makes no warranties as to its accuracy or completeness and

Tel +1 763 689 4870

disclaims any liability in connection with its use. TE Connectivity‘s obligations shall only be as set forth in TE Connectivity‘s

Standard Terms and Conditions of Sale for this product and in no case will TE Connectivity be liable for any incidental,

Fax +1 763 689 5033

indirect or consequential damages arising out of the sale, resale, use or misuse of the product. Users of TE Connectivity customercare.ando@te.com

products should make their own evaluation to determine the suitability of each such product for the specific application.

© 2016 TE Connectivity Ltd. family of companies All Rights Reserved.

TE CONNECTIVITY SENSORS /// UNDERSTANDING RTDS 07/2016 Page 4

You might also like

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- Resistance Temperature DetectorDocument3 pagesResistance Temperature Detectordark*nightNo ratings yet

- Taking Temperature Measurements With RTDS: How-To Guide: 1. RTD OverviewDocument3 pagesTaking Temperature Measurements With RTDS: How-To Guide: 1. RTD OverviewRandy SihombingNo ratings yet

- Stem: Science, Technology, Engineering and Maths Principles V11From EverandStem: Science, Technology, Engineering and Maths Principles V11No ratings yet

- Resistance Temperature Detector (RTD) - Principle of Operation, Materials, Configuration and BenefitsDocument5 pagesResistance Temperature Detector (RTD) - Principle of Operation, Materials, Configuration and BenefitsSaad NasirNo ratings yet

- A Practical Guide To Improving Temperature Measurement Accuracy White Paper Moore IndustriesDocument5 pagesA Practical Guide To Improving Temperature Measurement Accuracy White Paper Moore IndustriesNXSkeeperNo ratings yet

- CEPs Course Work 1 (1) IsDocument6 pagesCEPs Course Work 1 (1) Iszayyanraajpoot456No ratings yet

- RTD Temperature Measurement 917ADocument16 pagesRTD Temperature Measurement 917Amitha07No ratings yet

- RTD Questions and AnswersDocument19 pagesRTD Questions and AnswersJêmš NavikNo ratings yet

- RTD Standards: AccuracyDocument11 pagesRTD Standards: AccuracyAhmad Adel El TantawyNo ratings yet

- RTD Temperture Measurement 917ADocument15 pagesRTD Temperture Measurement 917AJohn Rey AranoNo ratings yet

- Rtds - or Resistance Temperature Detectors - Are Temperature Sensors That Contain A Resistor ThatDocument6 pagesRtds - or Resistance Temperature Detectors - Are Temperature Sensors That Contain A Resistor Thatmuhammad aliNo ratings yet

- AN687 Precision Temperature-Sensing With RTD CircuitsDocument8 pagesAN687 Precision Temperature-Sensing With RTD CircuitsdekisterNo ratings yet

- RTD Temperature MeasurementDocument22 pagesRTD Temperature MeasurementverneNo ratings yet

- RTD Microchip AN687A - Pt100Document8 pagesRTD Microchip AN687A - Pt100ge_bdNo ratings yet

- A Basic Guide To RTD Measurements: Application ReportDocument42 pagesA Basic Guide To RTD Measurements: Application ReportSyfNo ratings yet

- Sbaa 275Document42 pagesSbaa 275Salman AlparisiNo ratings yet

- PT 100 OhmDocument2 pagesPT 100 OhmRaj ChavanNo ratings yet

- MSL Technical Guide 18 Resistance Measurement For ThermometryDocument5 pagesMSL Technical Guide 18 Resistance Measurement For ThermometrydlonguinhoNo ratings yet

- Temperature Sensing Technologies: So Many Temperature SensorsDocument12 pagesTemperature Sensing Technologies: So Many Temperature SensorsMaria ClaytonNo ratings yet

- Table 1. Common Temperature Sensor TypesDocument7 pagesTable 1. Common Temperature Sensor TypesEligiusz PawłowskiNo ratings yet

- General Purpose PT100 Temperature Sensors: AccessoriesDocument7 pagesGeneral Purpose PT100 Temperature Sensors: AccessoriesierasterNo ratings yet

- TExas InstrumentsDocument29 pagesTExas InstrumentsPandhari SanapNo ratings yet

- Beamex White Paper - Pt100 Temperature Sensor ENGDocument8 pagesBeamex White Paper - Pt100 Temperature Sensor ENGJGlobexNo ratings yet

- SEN-30201: MAX31865 RTD-to-Digital Breakout Board, Multiple Cal OptionsDocument8 pagesSEN-30201: MAX31865 RTD-to-Digital Breakout Board, Multiple Cal OptionsAchref NajjarNo ratings yet

- A Practical Guide To Improving Temperature Measurement Accuracy White Paper Moore IndustriesDocument5 pagesA Practical Guide To Improving Temperature Measurement Accuracy White Paper Moore IndustriesralexmlNo ratings yet

- Temperature Sensing Technologies: So Many Temperature SensorsDocument13 pagesTemperature Sensing Technologies: So Many Temperature Sensorsikaro181083No ratings yet

- Microchip Application NoteDocument12 pagesMicrochip Application NoteAttila IllésNo ratings yet

- Sensor Basics Types Function and ApplicationsDocument16 pagesSensor Basics Types Function and ApplicationsMohit SinghNo ratings yet

- Sensor Basics Types Function and ApplicationsDocument16 pagesSensor Basics Types Function and ApplicationsSURYADITYA005No ratings yet

- RTD Tolerance Classes TBRTDTOL-0614Document4 pagesRTD Tolerance Classes TBRTDTOL-0614Anonymous zdCUbW8HfNo ratings yet

- Lecture (4) RTD and ThermistorDocument24 pagesLecture (4) RTD and ThermistorHassan El SayedNo ratings yet

- 3 and 4 Wire PRT MeasurementsDocument3 pages3 and 4 Wire PRT MeasurementsnewthebNo ratings yet

- RTD Theory: So What Exactly Is An RTD?Document6 pagesRTD Theory: So What Exactly Is An RTD?ouhamidNo ratings yet

- Comparison of Thermocouples, RTDS, and ThermistorsDocument2 pagesComparison of Thermocouples, RTDS, and ThermistorsAlwyzz Happie RaamzzNo ratings yet

- Temperature MesurementDocument2 pagesTemperature Mesurementujwol_phaijuNo ratings yet

- Temperature Mesurement Resistance Temperature Detectors or Rtds Are Sensors Which MeasureDocument2 pagesTemperature Mesurement Resistance Temperature Detectors or Rtds Are Sensors Which Measureujwol_phaijuNo ratings yet

- Introduction of TransducerDocument6 pagesIntroduction of TransducerFairus AffiniNo ratings yet

- Precise Measurement FaqsDocument9 pagesPrecise Measurement FaqsOmar SaadiqNo ratings yet

- Pt100 Transmitter MicrochipDocument8 pagesPt100 Transmitter Microchipem01803257No ratings yet

- RTDDocument4 pagesRTDCss GaneshNo ratings yet

- RTD Gen Specs RefDocument4 pagesRTD Gen Specs RefRamesh SubramanianNo ratings yet

- 5 Temperature Measurement Mistakes With RtdsDocument17 pages5 Temperature Measurement Mistakes With RtdsrahulNo ratings yet

- Industrial VariablesDocument59 pagesIndustrial VariablesMuhamad RidzwanNo ratings yet

- Some Guide Lines For Obtaining The Best Performance From RTD'S and Pt100'S ParticularlyDocument12 pagesSome Guide Lines For Obtaining The Best Performance From RTD'S and Pt100'S ParticularlyghrairiNo ratings yet

- ThermistorsDocument4 pagesThermistorss_geethanathan9290No ratings yet

- Catalog VikorDocument16 pagesCatalog VikorBinhvvNo ratings yet

- Sensor Compare ChartDocument3 pagesSensor Compare ChartPopescu QescuNo ratings yet

- RTDs BullDocument8 pagesRTDs BullYsidro MundarainNo ratings yet

- ApNote711 RTDHook UpsDocument2 pagesApNote711 RTDHook UpsasyyasNo ratings yet

- SUBJECT: To Study and Verify Characteristic OF Resistor Temp. DetectorDocument30 pagesSUBJECT: To Study and Verify Characteristic OF Resistor Temp. DetectorvishalsanziraNo ratings yet

- RTD BasicsDocument5 pagesRTD BasicsMourougapragash SubramanianNo ratings yet

- The Temperature Tango: Temperature Instrumentation Problems and Solutions in Industrial ProcessesDocument6 pagesThe Temperature Tango: Temperature Instrumentation Problems and Solutions in Industrial ProcessesEdison_SiqueiraNo ratings yet

- Resistive Temperature Measuring DevicesDocument7 pagesResistive Temperature Measuring DevicesBatuhan KalyoncuNo ratings yet

- 1117 RTD (Datasheet)Document4 pages1117 RTD (Datasheet)Mohammad Randy SetiawanNo ratings yet

- Thermosensitive Sensors Part - 1Document15 pagesThermosensitive Sensors Part - 1jayNo ratings yet

- Omnigrad T TST310: Technical InformationDocument12 pagesOmnigrad T TST310: Technical InformationArief SetyawanNo ratings yet

- B.E. (Instrumentation & Control) Subject: Building Automation-Ii Experiment Number: 2 Title: To Study Fas Loops and ClassificationsDocument11 pagesB.E. (Instrumentation & Control) Subject: Building Automation-Ii Experiment Number: 2 Title: To Study Fas Loops and ClassificationsNɩĸʜɩɭ AɱɓʀɘNo ratings yet

- Manual Atlas CopcoDocument52 pagesManual Atlas CopcoRobertoSoaresNo ratings yet

- Microstrip DesignDocument426 pagesMicrostrip DesignesesesNo ratings yet

- Product Overview: Data Sheet - H665GR GPON Gigabit ONT With Video ServiceDocument7 pagesProduct Overview: Data Sheet - H665GR GPON Gigabit ONT With Video ServiceTuấn minh DuongNo ratings yet

- Details Make The Difference: Xlpe Insulated Heavy Duty Cables 650/1100VDocument25 pagesDetails Make The Difference: Xlpe Insulated Heavy Duty Cables 650/1100VlogixNo ratings yet

- User Manual 22mt44dp-pzDocument36 pagesUser Manual 22mt44dp-pzVideoHi VizanteaNo ratings yet

- A Bridgeless Single-Stage Half-Bridge AC DC ConverterDocument12 pagesA Bridgeless Single-Stage Half-Bridge AC DC ConverterSaravana Prakash PNo ratings yet

- 710AA90L7BV-EMD26CLT 59w (LBP) - DatasheetDocument5 pages710AA90L7BV-EMD26CLT 59w (LBP) - Datasheetmohamad tajvidiNo ratings yet

- DC Machines1.1 1Document19 pagesDC Machines1.1 1Janaka Chathuranga AbeywardenaNo ratings yet

- Timer0 Code ATmega328pDocument3 pagesTimer0 Code ATmega328pmladen divacNo ratings yet

- Acer Aspire 5551 Newx5 Pew56Document45 pagesAcer Aspire 5551 Newx5 Pew56nikola1660No ratings yet

- Passenger Bus Alert System For Easy Navigation of BlindDocument5 pagesPassenger Bus Alert System For Easy Navigation of BlindArshad Mohammed0% (1)

- Grove - Ultrasonic Ranger: Product Ve Rs Ion Change S Released DateDocument5 pagesGrove - Ultrasonic Ranger: Product Ve Rs Ion Change S Released DateErwinsyah SatriaNo ratings yet

- 05 - Arco 400Document17 pages05 - Arco 400NgigiDanielNo ratings yet

- URIT-660 Service Manual PDFDocument15 pagesURIT-660 Service Manual PDFCharlys RajaobelinaNo ratings yet

- August Inventory 2018Document75 pagesAugust Inventory 2018Cleyton Archbold BarkerNo ratings yet

- Manual Te 805 EnuDocument11 pagesManual Te 805 EnuMutu Daniel100% (2)

- Frequency MeterDocument5 pagesFrequency MeterNh Chuminda YapaNo ratings yet

- Optimal Capacitor Configuration For Enhancement of System Reliability Using Genetic Algorithm: A Case Study of IEEE 30 Bus SystemDocument5 pagesOptimal Capacitor Configuration For Enhancement of System Reliability Using Genetic Algorithm: A Case Study of IEEE 30 Bus SystemIDESNo ratings yet

- dl150 Rev2Document450 pagesdl150 Rev2Eleonor CamargoNo ratings yet

- DepikDocument8 pagesDepikCharak Ram SNo ratings yet

- Home Theater Onkyo HT-SR750Document68 pagesHome Theater Onkyo HT-SR750Vinicius MarcosNo ratings yet

- Digital-to-Analog Analog-to-Digital Conversions: Microprocessor InterfaceDocument34 pagesDigital-to-Analog Analog-to-Digital Conversions: Microprocessor Interfaceeugen lupuNo ratings yet

- Ac17 AisDocument2 pagesAc17 AisParul MehtaNo ratings yet

- Omni Lifenet SpecsDocument2 pagesOmni Lifenet SpecsAngel JuarezNo ratings yet

- Hengxin HF Jumper CableDocument9 pagesHengxin HF Jumper Cableculeros1No ratings yet

- PLX 7200Document3 pagesPLX 7200ismailNo ratings yet

- Fusibles HH de ETIDocument9 pagesFusibles HH de ETIYben ZutaNo ratings yet

- Ultrasonic Flaw Detector NOVOTEST UD2301Document3 pagesUltrasonic Flaw Detector NOVOTEST UD2301Ashish SrivastavaNo ratings yet

- BNP c3040 (Eng) eDocument280 pagesBNP c3040 (Eng) eVladNo ratings yet