Professional Documents

Culture Documents

APMS Troubleshooting

Uploaded by

Gullu Bhargava0 ratings0% found this document useful (0 votes)

2 views5 pagesL&T APMS

Original Title

APMS troubleshooting

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentL&T APMS

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views5 pagesAPMS Troubleshooting

Uploaded by

Gullu BhargavaL&T APMS

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

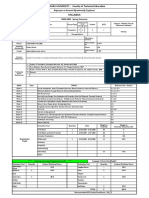

1 FAULT FINDING INSTRUCTIONS /

TROUBLESHOOTING

APMS is built with advance PLC which has BITE technology and provides

information’s for failure notification. BITE technology will guide the operator from

mimic pages and can find location of fault and reason for the same. PLC itself

has LED’s which will indicate the status of DI, DO etc. For system interface

details refer APMS architecture.

1.1 The following table gives brief description of troubleshooting:

Sr. Problem Possible Cause To be checked

No.

MSB Remote I/O PLC

1. Switching “ON” MCB’s but No Input Wiring of MCB and Check Wiring of MCB or

power Supply is delivered to Output Wiring of MCB are loose Check Wiring Connections

PLC or Fuse blown. fuse terminal and fuse

healthiness.

2. Switching “ON” all MCB’s and Input wiring to PLC Module Check wiring.

PLC is OFF. CPS3020 might not be proper. Check availability of 24VDC

supply.

3. Switching “ON” all MCB’s and Input Voltage is not within range Check Wiring and remove

PLC Power supply OK LED is (21-26vdc) or Power supply the PLC from tier slot & re-

OFF module is not properly installed install the PLC Power supply

on their PLC rack slot. module at their PLC slot and

fit properly.

4. PLC is ON and some alarms & PLC Connector wiring to Check wiring and also check

indications are not showing on Terminal Block or Field cables whether that alarm

HMI display. on Terminal Block might be corresponds to their

loose. respective channel number

which can be visualized on

Input Modules with a Green

LED Indication (Refer

Channel List).

5. PLC is ON and Output LED PLC Connector Wiring to Check Wiring.

corresponding to Buzzer ON, Interposing Relay or Looping of Check Whether Interposing

Digital Output from PLC is Power supply to Relay might not Relay functions properly or

generated but Interposing relay be proper. not.

does not switch ON.

6. DG Electrical parameters & Modbus Connection loose or Check the Polarity of Data+

Mechanical parameters are not wrong termination. and Data- termination as per

updating on HMI SWBD drawing scheme and

properly fix it.

7. P Load sharing & Q load sharing Relay of P Load sharing and Q Check relay and its

not coming to PPU when load sharing may not be connection between relay

switchboard is in remote mode. activated or cable termination contacts to PPU terminal.

will be loose from relay contact

to PPU. For details refer below PPU

documents:-

a) ML-2 operators

manual 4189340579

b) General guidelines for

commissioning

4189340703

c) ML-2 quick start guide

4189340603

8. Ethernet switch and PLC is off Power Supply cable might not be Check for the power supply

however 24vdc power supply connected or must be loose. cable and if loose connect it

available at SMPS & MCB is properly.

ON.

9. HMI display is not being power Power supply may not be Check Power supply at

up. available at MFCs display. MFCs power input terminals.

10. Ethernet Switch is ON, but CAT6 cable may not be Check for the CAT 6 cable if

Ethernet port’s LED does not connected or must be loose. connected and if loose,

glow. Ethernet port must also be connect it properly. Check

faulty. whether there is breakage in

the cable or any kind of

physical damage in cable.

Check for Ethernet port as

well.

11. HMI Display is ON but not Ethernet cable must be loose or Check for the Ethernet cable

showing field status. not connected properly. and if loose, connect it

properly. Check for cable

breakage if any.

12. Online Alarm is showing on Speaker/ amplifier terminals Check the connection at

HMI display, but Speaker is not connection may not be proper. terminal of amplifier /

sounding. speaker.

13. HSBY PLC changeover not Interlinking cable termination Check all Ethernet cable

happening not proper which are connected at PLC

CPU & NOC as per System

architecture.

Table 1 Troubleshooting Instruction

For all PLC LED indications meaning refer this table:-

LED ON Flashing ON OFF

RUN (green) PLC running normally, PLC in stop mode or blocked PLC not configured;

program executing by a software execution application missing,

invalid or

incompatible.

ERR (red) Processor or system error - PLC not configured. Normal state.

- PLC blocked by a No internal Error.

software error.

- PLC bus error

IO (red) Input / output errors coming PLC bus error Normal state.

from a module, a channel or No internal error.

a configuration error.

ETH ACT Communication Activity - No communication

(green) detected activity detected.

ETH LINK Ethernet Link detected - No Ethernet Link

(green) detected.

ETH STS (green) Communication OK 2 flashes : Invalid MAC -

Address.

3 flashes : Link not connected.

4 flashes : Duplicate IP

address.

5 flashes : Waiting for a served

IP addresses.

6 flashes : Safe Mode. Default

IP.

7 flashes : Configuration

conflict ( rotary switches /

internal configuration)

SER COM - Communication activity -

(yellow)

CARDERR (red) Card missing or not usable - Card is correct and

or card content inconsistent application is

with Internal Application consistent with CPU

RAM. Internal Application

RAM.

CARDAC Card Access enabled Card being accessed Card access disabled.

(green)

Memory card The CPU can access the SD The CPU does not recognize The CPU attempts to

status memory card the SD memory card access the SD memory

card

DL(Downloaded - Firmware upgrade in progress No Firmware upgrade

) in progress

BACKUP The memory card or CPU - The memory card or

flash memory is missing or CPU contents is valid,

inoperable the application in the

execution memory is

identical

MS Configured, Powering ON. Power off

Recoverable Not Configured

detected error

NS Configured, Valid IP address but no Power off

Recoverable Ethernet connection In-valid IP

detected error address

A The CPU set as “A” station Off indicates local

CPU A/B/Clear rotary

switch is not set to

“A”.

B The CPU set as “A” station Off indicates local

CPU A/B/Clear rotary

switch is not set to

“B”.

Remote RUN The remote PLC is in RUN The remote PLC is in STOP The local PLC cannot

state state read the status of

remote PLC. Both the

HSBY link and

Ethernet link are lost.

PREM The Local PLC is primary The local PLC is in wait state The Local PLC is not

primary

STBY The Local PLC is standby The local PLC is in wait state The Local PLC is not

standby

Table 2 Fault Finding Instructions

VISUAL INDICATORS AND MEANING FOR H57 24M

LED Continually lit Flashing Off

2,5s ON, 500ms OFF :

RUN PLC running in Primary PLC running in Standby PLC not configured :

(green) mode, full program mode, only first application missing,

execution section execution. invalid or

500ms ON, 2,5s OFF : incompatible

PLC running in Offline

mode, no program

execution.

500ms ON, 500ms OFF :

PLC in STOP mode or

blocked by a software

error

- PLC not configured

ERR Processor or system - PLC blocked by a Normal state,

(red) error software error no internal error

- memory card battery

error

- X bus error

Input/output errors

I/O Normal state,

coming from a module, X bus error

(red) no internal error

a channel or a

configuration error

TER Terminal port link

Link not active

(yellow) active

VISUAL INDICATORS AND MEANING FOR TSX ETY4103

RUN ERR STS COL TX RX Meaning

O O O ns ns ns No supply to module

O O P ns ns ns Module running self-test

P O O ns ns ns Module ready

O P O ns ns ns Module not operational

O P P ns ns ns Software operation error

O F P,F ns ns ns Module not configured or configuration in progress

P O P ns ns ns Module configured, operational

Module configured:

ns ns F ns ns ns - 2 flashes: module has no MAC address

- 3 flashes: ETHERNET cable not connected on the

module or Hub side

- 4 flashes: the module IP address is duplicated

by another IP address on the network

- 5 flashes: module configured as a BOOTP client

and is waiting for a BOOTP server response

P O P O F O Ethernet communication sending

P O P O O F Ethernet communication receving

P O P O F F Ethernet communication in sending/receving

P O P F F O Module has detected collision

P = Permanently on, F = Flashing, O = Off, ns = not significant

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- CAT - G3516H Throttle Actuator - Test PDFDocument5 pagesCAT - G3516H Throttle Actuator - Test PDFwagner_guimarães_1No ratings yet

- PLC ProgrammingDocument117 pagesPLC ProgrammingAhmedEEENo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- CAN Data Link - TestDocument7 pagesCAN Data Link - TestNay SoeNo ratings yet

- FB 20-35K - Alarm Code ListDocument24 pagesFB 20-35K - Alarm Code Listحسن الأمينNo ratings yet

- TMEIC PV Inverter Modbus ProtocolDocument57 pagesTMEIC PV Inverter Modbus ProtocolarunghandwalNo ratings yet

- PLC ProgrammingDocument116 pagesPLC ProgrammingVali Ene100% (4)

- PLC and Ladder Logic (20110303v004)Document28 pagesPLC and Ladder Logic (20110303v004)sreeyukthaNo ratings yet

- PLC Interview Questions and AnswersDocument6 pagesPLC Interview Questions and AnswersJêmš NavikNo ratings yet

- 05 - DC Motor Control Using PLCDocument49 pages05 - DC Motor Control Using PLCKoppoju PadmaNo ratings yet

- PLC & ScadaDocument43 pagesPLC & ScadaRama Kant Sahu90% (21)

- PLC Programming For Industrial Automation: Kevin CollinsDocument10 pagesPLC Programming For Industrial Automation: Kevin CollinsLuka Nikitovic100% (1)

- PLC Programming For Industrial AutomationDocument117 pagesPLC Programming For Industrial AutomationJohn Rey Avena100% (3)

- PSP-00024A6D 2023/09/12 09:32:28+08:00 RENR9324 © 2023 Caterpillar IncDocument8 pagesPSP-00024A6D 2023/09/12 09:32:28+08:00 RENR9324 © 2023 Caterpillar IncZiFiENo ratings yet

- Land Rover Esquema EletricoDocument209 pagesLand Rover Esquema EletricoMayla CristinaNo ratings yet

- BSC Alarm List and Its DescriptionDocument7 pagesBSC Alarm List and Its Descriptiontissonktom78% (9)

- Tadano AML M1 M2-TR (MkII Connection Instructions)Document5 pagesTadano AML M1 M2-TR (MkII Connection Instructions)Daniel AguirreNo ratings yet

- 5.2 - PLC Test Run, Monitor and MaintenanceDocument4 pages5.2 - PLC Test Run, Monitor and MaintenanceLawzy Elsadig SeddigNo ratings yet

- Substation Control Part 3Document7 pagesSubstation Control Part 3rachaide.saidNo ratings yet

- SWITCH BDCOM S2508B Hardware Installation ManualDocument20 pagesSWITCH BDCOM S2508B Hardware Installation ManualHarry Chan Putra. SP. MTCNA. MTCTCE. MTCRENo ratings yet

- Lesson 1 Hard Wiring Lesson 2 PLC Troubleshooting and Preventive MaintenanceDocument5 pagesLesson 1 Hard Wiring Lesson 2 PLC Troubleshooting and Preventive MaintenanceKurisuchan WolfNo ratings yet

- PLC Troubleshooting: Troubleshooting Inputs and OutputsDocument5 pagesPLC Troubleshooting: Troubleshooting Inputs and OutputsMd Omar FaruqueNo ratings yet

- Rhapsody Fault Finding IZ132-5Document11 pagesRhapsody Fault Finding IZ132-5Jibjab7No ratings yet

- Cautions, Warnings, and Regulatory Information: A010-9915 Bacpac Ethernet Installation InstructionsDocument20 pagesCautions, Warnings, and Regulatory Information: A010-9915 Bacpac Ethernet Installation InstructionsANo ratings yet

- Multiplex Communication PDFDocument17 pagesMultiplex Communication PDFgandhi permana adjieNo ratings yet

- The DIY Smart Saw - Desktop Version - Troubleshooting and AppendicesDocument21 pagesThe DIY Smart Saw - Desktop Version - Troubleshooting and AppendicesEduardo Hassin RodriguesNo ratings yet

- Electrical DistributionDocument52 pagesElectrical DistributionJuan JoseNo ratings yet

- MORE PLC APPLICATIONS in TRAFFIC SIGNAL OPERATIONSDocument9 pagesMORE PLC APPLICATIONS in TRAFFIC SIGNAL OPERATIONSapi-3770306100% (3)

- Checking Item3-8Document12 pagesChecking Item3-8Martinez AndryjNo ratings yet

- Solenoid driver card FIP and installation guideDocument3 pagesSolenoid driver card FIP and installation guideJose luis ConsuegraNo ratings yet

- A Power Line Communication On DC Bus With Photovoltaic StringsDocument6 pagesA Power Line Communication On DC Bus With Photovoltaic StringslaeeeqNo ratings yet

- E1 To Eth ConverterDocument12 pagesE1 To Eth ConverterawaazdevNo ratings yet

- Solidmation MA HPA 2300 - V3 Installation - Manual 00 ESDocument2 pagesSolidmation MA HPA 2300 - V3 Installation - Manual 00 ESOscarRiosNo ratings yet

- Truble Shooting L27-38 pdfDocument7 pagesTruble Shooting L27-38 pdfcarmaNo ratings yet

- Critical Power Quick Start GuideDocument8 pagesCritical Power Quick Start GuidejuanNo ratings yet

- Troubleshooting Reference - 7000Document16 pagesTroubleshooting Reference - 7000Marine JolieNo ratings yet

- Tadano Aml m1 m2 TR Mkii Connection InstructionsDocument5 pagesTadano Aml m1 m2 TR Mkii Connection Instructionsej ejaz0% (1)

- PLC Configuration and Programming FundamentalsDocument34 pagesPLC Configuration and Programming Fundamentalsmariam nkoyooyoNo ratings yet

- Technical Information: ThemeDocument8 pagesTechnical Information: ThemeessameldinNo ratings yet

- LDCS QBDocument47 pagesLDCS QBSimpleNo ratings yet

- InstallGuide FlatpackPRSB15kW PDFDocument20 pagesInstallGuide FlatpackPRSB15kW PDFСергей СалтыковNo ratings yet

- PLC Quick Working ExplainDocument8 pagesPLC Quick Working ExplainMalik SameeullahNo ratings yet

- OptiXaccess EA5801S-GP16Document10 pagesOptiXaccess EA5801S-GP16tang alexNo ratings yet

- ZB633KL EE Trouble Shooting GuideDocument18 pagesZB633KL EE Trouble Shooting GuidestandupikeNo ratings yet

- Techline Buslink Quick Guide Brochure EngDocument13 pagesTechline Buslink Quick Guide Brochure EngKlaus AllowsNo ratings yet

- L L L L L LDocument6 pagesL L L L L LQuốc Phú ĐinhNo ratings yet

- PLC ScadaDocument43 pagesPLC ScadaabhijeetNo ratings yet

- X-LINE Testing Device STB 01X.: ManualDocument19 pagesX-LINE Testing Device STB 01X.: ManualSerban NicolaeNo ratings yet

- Quadrax Manual 1.2.1 2021.03.09Document48 pagesQuadrax Manual 1.2.1 2021.03.09ilyaNo ratings yet

- Erickson1996 PLCDocument4 pagesErickson1996 PLCbobleeNo ratings yet

- CAN Data Link Circuit - Test (RENR5096)Document3 pagesCAN Data Link Circuit - Test (RENR5096)Josip MiškovićNo ratings yet

- Canon imageRUNNER ADVANCE C2030 C2025 C2020 Series Service Manual Digest PDFDocument448 pagesCanon imageRUNNER ADVANCE C2030 C2025 C2020 Series Service Manual Digest PDFKevon SmallNo ratings yet

- Ethernet Data Link - Test: TroubleshootingDocument8 pagesEthernet Data Link - Test: TroubleshootingMbahdiro KolenxNo ratings yet

- Chloride Chloride Chloride Chloride Chloride: IndexDocument16 pagesChloride Chloride Chloride Chloride Chloride: IndexQuangNguyenNo ratings yet

- WAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksFrom EverandWAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksNo ratings yet

- Tef Elc470 4bk BaharDocument1 pageTef Elc470 4bk Bahar1fenerbahceNo ratings yet

- Desktop NproDocument31 pagesDesktop NproJinsen Paul MartinNo ratings yet

- Isl9r3060g2 F085 DDocument7 pagesIsl9r3060g2 F085 DRemy MendozaNo ratings yet

- M02 - Configuring and Administering ServerDocument77 pagesM02 - Configuring and Administering ServerTerefe GezahegnNo ratings yet

- Cisco AS5300 Voice Gateway - Technical Data SheetDocument16 pagesCisco AS5300 Voice Gateway - Technical Data SheetsamsulNo ratings yet

- CMOS & BIOS Configurations GuideDocument16 pagesCMOS & BIOS Configurations GuideKartik GuptaNo ratings yet

- Java AWT GUI ComponentsDocument15 pagesJava AWT GUI Components19BMA111 GOKULNo ratings yet

- Touchscreen PDFDocument14 pagesTouchscreen PDFAntonio OliveiraNo ratings yet

- Course Slot and Faculty DetailsDocument26 pagesCourse Slot and Faculty DetailsPranjal RuhelaNo ratings yet

- SAP PP Interview QuestionDocument8 pagesSAP PP Interview QuestionAshishNo ratings yet

- ASP Virtual Implementation PDFDocument724 pagesASP Virtual Implementation PDFmulyadiNo ratings yet

- VG278 Series LCD Monitor User GuideDocument24 pagesVG278 Series LCD Monitor User GuideEdsel LoquillanoNo ratings yet

- Data Stage and DB Services SOPDocument6 pagesData Stage and DB Services SOPManish KanodiaNo ratings yet

- Riscv V Spec 1.0 Rc2Document112 pagesRiscv V Spec 1.0 Rc2best124612No ratings yet

- Cmosedu Com Jbaker Courses Ee421L f13 Students Wolvert9 LabDocument15 pagesCmosedu Com Jbaker Courses Ee421L f13 Students Wolvert9 LabPerumal NamasivayamNo ratings yet

- RC Circuits Fundamentals - 2Document6 pagesRC Circuits Fundamentals - 2chipulinoNo ratings yet

- CX9000 - Basic CPU Module: CX900x-xx0x CX900x-xx0x CX900x-xx0xDocument2 pagesCX9000 - Basic CPU Module: CX900x-xx0x CX900x-xx0x CX900x-xx0xMike moreNo ratings yet

- Design and Implementation of Alcohol Detector and Accident Detection System Using GSM ModemDocument5 pagesDesign and Implementation of Alcohol Detector and Accident Detection System Using GSM ModemEditor IJTSRDNo ratings yet

- Digital Electronics and OpticsDocument90 pagesDigital Electronics and OpticsSteve MachariaNo ratings yet

- 1Document5 pages1KarinaEvandraNo ratings yet

- Block Diagram: P8H61-M LX3 R2.1 Repair GuideDocument6 pagesBlock Diagram: P8H61-M LX3 R2.1 Repair GuideAdi copycenterNo ratings yet

- Data Communication and Networking 2 Prelim ExaminationDocument1 pageData Communication and Networking 2 Prelim ExaminationGian CarloNo ratings yet

- Electro-L Hrit Lrit Eng v1 0Document32 pagesElectro-L Hrit Lrit Eng v1 0usamafalakNo ratings yet

- Pfsense 1448Document15 pagesPfsense 1448Mahmoud AhmedNo ratings yet

- Networking Linux.Document636 pagesNetworking Linux.Dan DanielNo ratings yet

- LGMV Total ENGDocument47 pagesLGMV Total ENGMarcelo RamirezNo ratings yet

- Network and Storage Options for WorkstationsDocument15 pagesNetwork and Storage Options for WorkstationsArun SasidharanNo ratings yet

- Ni Visa Programmers ManualDocument381 pagesNi Visa Programmers Manualmacarong272No ratings yet

- Summary: Do You Ever Feel You Wish You Could Answer Some of Your Own Questions When YouDocument22 pagesSummary: Do You Ever Feel You Wish You Could Answer Some of Your Own Questions When YouDVRaoNo ratings yet

- FFFIScom Euroradio C UserGuide 2 0 0Document26 pagesFFFIScom Euroradio C UserGuide 2 0 0anon-967264100% (1)