Professional Documents

Culture Documents

Cougar 1967l

Cougar 1967l

Uploaded by

d dOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cougar 1967l

Cougar 1967l

Uploaded by

d dCopyright:

Available Formats

Downloaded from www.Manualslib.

com manuals search engine

Copyright © 2006, Forel Publishing Company, LLC, Woodbridge, Virginia

All Rights Reserved. No part of this book may be used or reproduced in any manner

whatsoever without written permission of Forel Publishing Company, LLC. For

information write to Forel Publishing Company, LLC, 3999 Peregrine Ridge Ct.,

Woodbridge, VA 22192

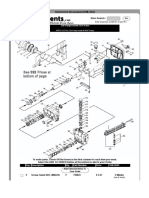

1967 Cougar, Fairlane, Falcon, Mercury and Mustang Shop Manual

(Form 7760-67, First printing – March 1967)

ISBN: 0-9673211-4-X

EAN: 978-0-9673211-4-1

Forel Publishing Company, LLC

3999 Peregrine Ridge Ct.

Woodbridge, VA 22192

Email address: webmaster@ForelPublishing.com

Website: http://www.ForelPublishing.com

This publication contains material that is reproduced and distributed under a

license from Ford Motor Company. No further reproduction or distribution of the

Ford Motor Company material is allowed without the express written permission

of Ford Motor Company.

Disclaimer

Although every effort was made to ensure the accuracy of this book, no representations or warranties of

any kind are made concerning the accuracy, completeness or suitability of the information, either expressed

or implied. As a result, the information contained within this book should be used as general information

only. The author and Forel Publishing Company, LLC shall have neither liability nor responsibility to any

person or entity with respect to any loss or damage caused, or alleged to be caused, directly or indirectly by

the information contained in this book. Further, the publisher and author are not engaged in rendering legal

or other professional services. If legal, mechanical, electrical, or other expert assistance is required, the

services of a competent professional should be sought.

Downloaded from www.Manualslib.com manuals search engine

GROUP INDEX

VEHICLE IDEMIIRCATION 1

BRAKES 2

SUMMON, STEERING, INNERS AND TIRES 3

REAR AXLE 4

NW- DRIVE SHAFT AND CLUTCH 5

MANUAL SHIFT TRANSMISSION 6

. AUTOMATIC TRANSMISSION 7

ENGINE

FALCON :. 1GNRION SYSTEM

FUEL SYSTEM

9

10

MERCURY- COOLING SYSTEM

EXHAUST SYSTEM

11

12

imam SYSTEM 13

Mir ' VARTIHG SYSTEM 14

MUSTANG SMOG SYSTEM, HORNS AND INSTRUMENTS

MPIMI.ATING, HEATING AND ACCESSORIES

15

16

nt. BODY, DOORS AND WINDCNV5

TM % SEATS AND CONVERTIBLE TOP 1$

5O

$ A 5 19

SERVICE PUBLICATIONS

SPECIFICATIONS AND SPECIAL SERVICE TOOLS

IPSTPF FIT NG-0ARCH_ 1907 AT END OF EACH GROUP

19 19+7 FORD 1111OYpM CO PAPAW, DEAR yQR11 . 1NIC.H14AN

Downloaded from www.Manualslib.com manuals search engine

FOREWORD

This shop manual provides the Service Technician with information

for the proper servicing of the 1967 Cougar, Fairlane, Falcon,

Mercury Intermediate, Comet and Mustang cars.

The maintenance schedule and procedures for maintenance oper-

ations are published in the 1967 h s e n g e r Car Maintenance and

Lubrication Manual.

The information in this manua! is grouped according to the type

of work being performed, such as diagnosis and testing, frequent-

ly performed adjustments and repairs, in-vehicle adjustments, over-

hau!, etc. Specifications and recommended special tools areincluded.

Refer to the opposite page for important vehicle identification data.

The descriptions and specifications in this manual were in effect at

the time this manual was approved for printing. The Ford Motor

Company reserves the right to discontinue models at any time, or

change specifications or design, without notice and without incur-

ring obligation.

Downloaded from www.Manualslib.com manuals search engine

Downloaded from www.Manualslib.com manuals search engine

1-2 GROUP 1-Vehicle Identification

BODY SERIAL AND STYLE CODES BODY SERIAL AND STYLE CODES-4continu.d)

FAIRLANE

The two-digit numeral which follows the assembly plant, code identifies

the body series. This two-di it number i s used in coniunct~onwith the Body B+Y B*

Style Code, in the Vehicle bate, which consists of a two-d~gitnumber with Serlal - Style

a letter suffix. The following chart lists the Body Serial Codes, Body Style Code Code Body Type . Model

Codes and the model.

31 54A 4.Door Sedan @ Fairlane

30 62A 2-Door Sedan s

MERCURY4OMET (INTERMEDIATE-SIZE)

34 548 &Door Sedan 2) Fair lane 500

33 628 2-Door Sedan 8

w

Serial

Body 35

36

638

76 B

2-Door Hardtops

2-Door Convertible a

Sbk

Code Code Body TYpe Model

40 63C 2-Door Hardtop ~s Fairlane 500XL

02 54A 4-Door Sedan 3 Comet 202 41 76C 2-Door Convertible 2

01 62A 2.Door Sedan 61

42 63D 2-Door Hardtop Fairlane 500GT

08 54 B &Door Sedan Comet Capri 43 76D 2-Door Convertible 3

07 :63B 2-Door Hardtop 8

32 71D &Door Station Wagon

10 540 4-Door Sedan 3 Caliente 37 718 4-Door

11 630 2-Door Hardtop O 38 71E &Door

12 76 D 2-Door Convertible

47 66A 2-Door @ Ranchero

15 63E 2-Door Hardtop @ Cyclone 48 668 2.Door 3

16 76C 2.Door Convertible @ 49 66 D 2-Door m

17 63H 2-Door Hardtop 3 GT @ Bench Seat

18 76H 2-Door Convertible @) @ Bucket Seat

03 7 1A 4-Door 6 Passenger Comet Voyager

FALCON

08 71C 4-Door 6 Passenger Villager

Bench Seat Body

Serial

. !$

Bucket Seat

Code Code Body Type Model

10 62A 2-Door Club Coupe I!. Standard

COUGAR 11 54A Sedan 3

-. 20 628 2-Door Club Coupe s Futura

MY Body Body TYpe 21 548 4-Door Sedan

Serial Style

22 62C 2-Door @ Sport Coupe

Code Code

91 65A 2-door Hardtop (Bucket Seat) 12 71A &Door Wagon (Std.)

91 658 2-Door Hardtop (Bucket Seat) 8

91 65D 2-Door Hardtop (Bench Seat) 2; 23 718 &Do01 Wagon (Deluxe)

91 65C 2-Door Hardtop (Bench Seat)

o Bench Seat

@ Luxury Model o Bucket Seat

CONSECUTIVE UNIT NUMBER

MUSTANG Each model year, each assembly plant begins production with number

500001 (Mercury, Comet or Cougar) or 100001 (Fairlane, Falcon, Mustang)

and continues on for each unit built.

B e Body

Serial Sgle

Code Code Body TYpe

ENGINE CODES

02 63A 2-Door Fastback Q'

01 65A 2-Door Hardtop C'i Code TYP

03 76A 2-Door Convertible g!

02 638 2-Door Fastback -'I :z U ........................................................... 6 Cyl. 170 Cu. In. ( l V )

01 658 2.Door Hardtop .fi :3) T ......................................................... 6 Cyl. 200 Cu. In. (1V)

03 768 2-Door Convertible :D @ 2 ......................................................... 6 Cyl. .ti 200 Cu. In. ( l V )

01 65C 2-Door Hardtop B) C ........................................:..................8 Cyl. 289 Cu. In. (2V)

03 76C 2.Door Convertible (8 3 ...........................................................8 Cy I. 1: 289 Cu. In. (2V)

A ..........................:..............................8 Cyl. 289 Cu. In. (4V) Prem. Fuel

Bucket Seat K ........................................................8 Cyl. 289 Cu. In. (4V) Hi-Perf.

@ Bench Seat Y ...........................................................8 Cyl. 390 Cu. In. (2V)

o Luxury Model H ........................................................... 8 Cy I. 390 Cu. In. (2V)

S ...........................................................8 Cyl. 390 Cu. In. (4V)

W ........................................................... 8 Cyl. 427 Cu. In. (4V) HLPerf.

R ........................................................... 8 Cyl. 427 Cu. In. (8V) Hi-Perf.

;!I Low Compression

Downloaded from www.Manualslib.com manuals search engine

GROUP I-Vehicle Identification

T R A N S M I S S I O N CODES

DISTRICT CODES ( D S O )

Code TYP

1 .............................................................................................S p e e d Manual Units built on a Domestic Special Order, Foreign Special Order, or other spe-

2 ............................................................................................ Overdrive cial orders will have the complete order number in this space. Also to appear

3 .............................................................................................S p e d Manual in this space is the twedigit code number of the District which ordered the

5 .............................................................................................S p e d Manual unit. If the unit is a regular production unit, only the District code number

W ........................................................................................... Automatic (C4) will appear.

U......................................................................................... Automatic (C6)

FORD

REAR A X L E R A T I O CODES Code District

A number designates a conventional axle, while a letter designates a locking 11.................................................................................. Boston

differential 13.................................................................................. New York

15.................................................................................. Newark

16.................................................................................. Philadelphia

17.................................................................................. Washington

21.................................................................................Atlanta

22 ..................................................................................Charlotte

24 ................................................................................. Jacksomille

25 .................................................................................. Richmond

27 .................................................................................. Cincinnati

28.................................................................................Louisville

32 .................................................................................. Cleveland

33 ................................................................................. Detroit

34 .................................................................................. Indianapolis

35 ..................................................................................Lansing

37 ..................................................................................Buffalo

DATE CODES 38 .................................................................................. Pittsburgh

41 ..................................................................................Chicago

A number signifying the date precedes the month code letter. A second.year 42 .................................................................................. Fargo

code letter will be used if the model exceeds 12 months. 43 ..................................................................................Milwaukee

44 .................................................................................Twin Cities

45 ..................................................................................Davenport

51..................................................................................Denver

Code Code 52 ..................................................................................D e Moines

Month First Year Second Year 53 ..................................................................................Kansas City

54 ................................................................................ Omaha

January ............................................... A ............................................... N 55 ..................................................................................S t Louis

February ............................................ B ............................................... P 61................................................................................. Dallas

March ................................................C ............................................... Q 62 ................................................................................. Houston

April ..............................................D ............................................... R 63 .................................................................................. Memphis

May ................................................. E ............................................... S 64 ................................................................................ New Orleans

June ................................................... F ............................................... T 65 ..................................................................................Oklahoma City

July ..................................................... G ............................................... U 71..................................................................................L o Angeles

August ................................................ ti ............................................... V 72 .................................................................................. a n Jose

September ......................................... J ................................................ W 73 ..................................................................................I Lake City

October ............................................... K ...............................................X 74 ................................................................................ Seattle

November ......................................... L ............................................... Y 75 ..................................................................................Phoenix

December ...........................................M............................................... Z 81.................................................................................. Ford of Canada

83 .................................................................................. Government

84 ................................................................................. Home Office Reserve

85 ................................................................................. American Red Cross

89 .................................................................................. Transportation Services

ASSEMBLY P L A N T CODES 90-99 .............................................................................Export

Code Code

Letta Letta

A ........................................... Atlanta L ................................... Michigan Truck MERCURY

B ........................... Oakville (Canada) N ............................................... Norfolk

C .................................Ontario Truck P .......................................... Twin Cities 1

D ......................................... Dallas R ............................................. a n Jose Code District Code District

E .......................................... M a w S........................................... P o Plant

F ......................................... e a r n T ............................................ Metuchen 11 ................... Boston 34 ...................Detroit

G...........................................Chicago U ............................................ Louisville 16 ...................Philadelphia 41 ...................Chicago

H ............................................ L o r n W ................................................ Wayne 15 ................... New York 42 ...................St. Louis

J .....................................Los Angeles Y ................................................. Wixom 17 ...................Washington 46 ...................Twin Cities

K .....................................Kansas City Z .........................................S t Louis 21 .................. Atbnta 51 ...................Denver

22 ...................Dallas 52 ...................Los Angeles

23 ...................Jacksonville 53 ...................Oakland

26 ................... Memphis 54 ...................Seattle

31 ...................Buffalo 84 ...................Home Office Reserve

32 ................... Cincinnati

33 ................... Cleveland 90 ...................Export

Downloaded from www.Manualslib.com manuals search engine

GROUP 1-Vehicle Identification

EXTERIOR PAINT COLOR CODES INTERIOR TRIM CODES-(continued)

M30-J

Code M32-J Color Code Trim Schemes

A ........................................... 1724-A ...................................... Bbc k 8G ....................................... I Gold Vinyl

B...........................................A ...................................... L t Aqua 8K ...................................... Aqua Vinyl

E ........................................... 2 0 4 5 ...................................... M e . Beige Met. 8U ....................................... Parchment Vinyl W/Black

I...........................................2 1 ...................................... Lime Met. 9A ....................................... Black Cloth and Black Vinyl

K ........................................... 1 - A ...................................... Dk. Blue Met. 90 ....................................... Dk. Blue Cloth and Dk. Blue Vinyl

M ..........................................1 6 1 9 ......................................White 90 ...................................... Dk. Red Cloth and Dk. Red Vinyl

Q ........................................... 16244 ......................................Med. Blue. Met. 9K ......................................Aqua Cloth and Aqua Vinyl

T ..........................................A ...................................... Red 9U .......................................Parchment Cloth and Parchment Vinyl WIBlack

V ..........................................2 0 6 6 ...................................... Bronze Met. FA ....................................... Parchment Vinyl WIBlack

W ..........................................A ......................................M e . Aqua Met. FB ................!......................Parchment Vinyl WIBlue

X ...........................................1 6 3 2 - ...................................... Maroon Met. FD .......................................Parchment Vinyl WiRed

Y ........................................... 2 0 3 ...................................... D k Green Met. FG .......................................P Vinyl Wllvy Gold

Z ........................................... 1 1 - ...................................... M e . Gold Met. FK ....................................... Parchment Vinyl WIAqua

2 ........................................... A ...................................... Yellow GA ....................................... Back Vinyl WParchment

4 ...........................................A ......................................M e . Gray Met. GB ....................................... B e Vinyl WParchment

6 ........................................... 163-A ...................................... L t Beige GD ....................................... Red Vinyl WParchment

8 ........................................... 1 9 5 5 - ...................................... Yellow GG ....................................... I Gold Vinyl WIParchment

GF ....................................... S a d Vinyl WParchment

GK ......................................A Vinyl WParchment

LB ....................................... Red Vinyl

LD ....................................... B e Vinyl

LU....................................... Parchment Cloth and Parchment Vinyl WIBlack

OU....................................... Parchment Vinyl

UA ....................................... P a r c h m e Vinyl WIBbck

INTERIOR T R I M CODES UB....................................... Parchment Vinyl WBlue

UD.......................................Parchment Vinyl WIRed

UF ....................................... Parchment Vinyl W/Saddle

Code Trim Schema UG .......................................Parchment Vinyl Wllvy Gold

UK ....................................... Parchment Vinyl WIAqua

10 ....................................... B e Cloth and Blue Vinyl

1D ....................................... Red Cloth and Red Vinyl

1K ....................................... Aqua Cloth and Aqua Vinyl

1U ....................................... Parchment Cloth and Parchment Vinyl WBlack

2A .......................................Black Vinyl

28 .......................................B e Vinyl

2 0 ....................................... Red Vinyl

2F ....................................... S a d Vinyl

2G ....................................... I Gold Vinyl

2K ......................................Aqua Vlnyl

2U .......................................Parchment Vinyl WIBbck

38 ....................................... B e Cloth and Blue Vinyl

36 .......................................I Gold Cloth and Ivy Gold Vinyl

3K .......................................Aqua Cloth and Aqua Vtnyl

3U .......................................Parchment Cloth and Parchment Vinyl WBlack

4A .......................................Black Vinyl

4 8 .......................................B e Vinyl

4D ....................................... R V i 1

4G ........................................ ~oly~in~l

4K ...................................... Aqua Vlnyl

4U ....................................... Parchment Vinyl

SA ....................................... Black Cloth and Black Viny!

SB ....................................... Dark Blue Cloth and BlueVtnyl

SK ...................................... Aqua Cloth and Aqua Vinyl

SU ....................................... P a r c h m e Cloth and Parchment Vinyl W/Saddle

6A ....................................... Black Vinyl

6 0 ....................................... Dark Bluevinyl

6 0 ....................................... Red Vinyl

6F .......................................S a d Vinyl

6G ....................................... D k Ivy Gold Vinyl

6K ......................................Aqua Vinyl

6U ....................................... Parchment Vinyl

7A ....................................... Black Vinyl

I B ......:................................ B e Vinyl

7U ....................................... Parchment Cloth and Parchment Vinyl

8A ....................................... B c k Vinyl

88 ....................................... B e Vinyl

8 0 .......................................R Vinyl

8F ....................................... S a d Vinyl

Downloaded from www.Manualslib.com manuals search engine

Downloaded from www.Manualslib.com manuals search engine

2-2 GROUP 2-Brakes

STEERING WHEEL RIM pedal measurement under a 50

pound load should be within the speci-

fied maximum pedal travel service

specification B in Fig. 1.

5. If the pedal travel is more than

the specified maximum shown in Fig.

I, dimemion B, make several sharp

reverse stops (equivalent to 50 pounds

pedal pressure) with a forward stop

before each. Move the, car in reverse

and forward for a distance of ap-

proximately ten feet; then apply the

brakes sharply and hold the brake

pedal down until the car is completely

stopped. This will actuate the brake

self-adjusters. If these stops do not

bring the brake pedal travel with-

in specification, make several addi-

tional forward and reverse stops as

outlined above.

6. If the second series of stops do

not bring the brake pedal travel

within specification, remove the brake

drums and check the brake adjusters

to make sure they are functioning.

Check the brake linings for wear or

damage. Repair or replace all worn

or damaged parts and non-function-

N O T E : A DIMENSION T O i3E MEASURED T O SHEET M E T A L

ing adjusters. Adjust the brake lin-

B DIMENSION T O B E MEASURED P A R A L L E L 70 THE V E R T I C A L C E N T E R L I N E OF T H E

STEERING COLUMN WlTH A 50 POUND L O A D A P P L I E D TO T H E C E N T E R L I N E OF THE

ing outside diameter to The approxi-

B R A K E P E D A L PAD. (CHECKS ON POWER B R A K E V E H I C L E S M A D E WlTH ENGINE RUNNIP4C-l H1551-~ mate inside diameter of the brake

drlrm wi!h Rotunda Too! HRE 8650

FIG. I-Brake Pedal Height and Travel Measurements (Figs. I I and 12, Part 2-2).

7. If all the brake adjusters.

brake drums and linings are func-

tional and the brake pedal travel is

not within specifications, check the

pedal linkage for missing bushings.

or loose attachments. Bleed the brake

and centralize the differential valve.

POWER BRAKE

F U N C T I O N A L TEST

I . With the transmission in neutral.

stop the engine and apply the parking

brake. Depress the brake pedal sev-

eral times to exhaust all vacuum in

the system.

2. With the engine shut off. de-

press the brake pedal and hold it in

the applied position. I f the pedal

gradually falls away under this

pressure, the hydraulic system is

leaking. Check all tubing, hoses.

FIG. 2-Brake Pedal Effort Gauge Installed - Typical calipers (if so equipped), wheel cyl-

inders and connections for leaks.

Brake Pedal Travel 3. With the steel tape still hooked I f the brake pedal movement f&ls

Measurement to the brake pedal depress the brake spongy, bleed the hydfaulic system

by pressing downward on the brake to remove air from the system. Refer

1. Install a Brake Pedal Pressure pedal effort gauge. Apply a 50 to Hydraulic Systern Bleeding, Part

Gauge on the brake pedal pad (Fig. pound load to the center of the pedal 1, Section 2. Also, check for leaks or

2). by observing the pressure gauge, insufficient fluid.

2. Hook a steel measuring tape agd measure the distance ffom the 3. With the engine shut off and

to the brake pedal as shown in Fig. brake pedal to the fixed reference all vacuum in the system exhausted,

I. Measure and record the distance point on the steering wheel rim, depress the pedal arid hold it in the ap-

from the brake pedal free height po- parallel to the ccnterline of the steer-. plied position. Start the engine. If the

sition to the reference point, which is ing column. vacuum system is operating, the

at the six o'clock position on the steer- 4. The difference between the brake pedal will tend to fall .away under

ing wheel rim. pedal free height and the depressed foot pressure and less pressure will

Downloaded from www.Manualslib.com manuals search engine

PART 2-1-General Brake Service 2-3

be required to hold the pedal in the applied position. Then, check the opera- tion of those resolved in the Brake Sys-

applied position. I f no action is felt, tion of the brake linkage when the tem Tests and brake chatter. To check

the vacuum booster system is not parking brake controls are moved to for brake chatter or surge, apply the

functioning. the released position. These checks brakes lightly at 50 mph. For each

should indicate whether the manual of the symptoms encountered, check

LOCKED WHEEL BRAKE parking brake control linkage is op- and eliminate the causes which are

erating properly or requires repair listed in Figs. l l and 12.

Should one of the wheel brakes be or adjustment due to inability of the

locked and the car must be moved, parking brake to hold against mod- If the road test reveals one or more

open the bleeder screw long enough erate vehicle movement. problem conditions listed in Figs. 1 1

to let out a few drops of brake fluid. and 12, correct all malfunctions of

This bleeding operation will release R O A D TEST the vacuum system, brake booster

the brakes but will not correct the and hydraulic system prior to re-

cause of trouble. A road test should only be con- moving brake drums, brake calipers

ducted when the operator is sure the (if so equipped), brake shoes and

PARKING BRAKE brakes w i l l stop the vehicle. linings or backing plates.

During a road test, apply the ve-

Visually check the operation of the hicles brakes at a road speed of 20

parking brake linkage as the park- mph for all problem conditions listed

ing brake controls are moved to the in Figs. I I and I2 with the excep-

C O M M O N ADJUSTMENTS AND REPAIRS

P A R K I N G BRAKE

LINKAGE ADJUSTMENT

MUSTANG- COUGAR

Check the parking brake cables

when the parking brakes are fully

released. If the cables are loose, ad-

just them as follows:

I. Fully release the parking

brake by turning the handle coun-

terclockwise and pushing it inward.

2. Pull the parking brake handle

outward to the third notch from its

normal released position.

3. Raise the vehicle. Remove the

wheel cover. Install Tool T66L-

4204-L on the rear wheel (Fig. 3).

4. Turn the locking adjustment

nut forward against the cable guide

on the equalizer (Fig. 4) until there FIG. 3-Checking Parking Brake Break-Away Torque

is 100 ft-lbs break-away torque at

the rear wheel when turning the rear I f the cables are loose, adjust them ADJUSTMENT NUT-37993062

wheels in the direction of forward ro- as follows:

tation with a torque wrench (Fig. 3). 1. Fully release the parking brake

The torque measurement must be pedal. EQUALIZER-2A602

made relative to the centerline of the

wheel. 2. Raise the vehicle. Loosen the

5. Release the parking brake and equalizer lock nut (Fig. 5) and turn

make sure the brake shoes return to the nut forward against the cable EQUALIZER ROD-2628

the fully released position and no guide on the equalizer until there is

drag is felt when turning the rear 22 to 27 pounds tension on the left

wheels. rear cable or there is 100 ft-lbs

6. Remove Tool T66L-4204-L. In- break-away torque when turning the

stall the wheel attaching bolts and rear wheels in the direction of forward

torque them to specification. Install rotation with a toraue wrench and H1552-A

the wheel cover. Lower the vehicle. Tool T66L-4204-L as shown in FIG. 4-Parking Brake Linkage

Fig. 3. The torque measurement

Adjustment - Mustang and Cougar

must be made relative to the center-

COMET-FALCON- line of the wheel. Tighten the lock nut.

FAIRLANE torque wrench and Tool T66L-4204-L,

3. M a k e sure there is no drag if required, Install the wheel attach-

Check the parking brake cables when turning the rear wheels. inn nuts and torque them to specifi-

when the brakes are fully released. 4. Lower the vehicle. Remove the cation. Install the wheel cover.

Downloaded from www.Manualslib.com manuals search engine

GROUP 2-Brakes

\ CONVERTIBLE NU'L

PARKING

eERAKE

RAKE CA: Y RETAINER-74277.5

AND CONDUIT ,

ASSEMBLY-2853 \

, SPRING-2A651

,

A /

CAaLE ASSEMSLY

2A604

7-10 LB.FT.

CONVERTIBLE ONLY

\LR~'~AINER-~A~I~

H1553-A

FIG. 5-Parking Brake Linkage

Adjustment -

Comet, Fairlane a n d

Falcon FIG. 7-Push Rod Adjustment -

Midland-Ross

-

r #16 G A U G E

SHEET STEEL

T o check the adjustment of the

screw, fabricate a gauge of the

dimension shown in Fig. 6. Then place

the gauge against the master cyl-

inder mounting surface of the booster

FIG. 8-Push-Rod

Bendix

Adjustment

heavy duty brake fluid is colored

blue for identification purposes. Do

body as shown in Figs. 7 or 8. The not mix low temperature brake fluids

push rod screw should be adjusted with the specified fluid during the

s o that the end of the screw just touch- bleeding operations. Never re-use

es the inner edge of the slot in the brake fluid which has been drained

gauge. Do not set up side forces on from the hydraulic system.

the push rod. Side forces may break I. Loosen the bleed screw located

the valve plunger. on the side of the master cylinder.

This is an approximate adjust-

Do not use the secondary piston stop

screw, located on the bottom of the

ment only. The push rod should not

master cylinder to bleed the brake

move more than 0.015 inch as it

system. Loosening or removing this

contacts the master cylinder piston.

screw could result i n damage to the

N o movement (exact contact) is ideal.

secondary piston or stop screw.

2. T o bleed the secondary (rear)

HYDRAULIC SYSTEM BLEEDING brake system, position a suitable

A N D CENTRALIZING O F THE 318 inch box wrench (Fig. 9) on

DIFFERENTIAL VALVE the bleeder fitting on the brake wheel

cylinder. Attach a rubber drain

When any part of the hydraulic tube to the bleeder fitting. The end of

system has been disconnected for re- the tube should fit snugly around

pair or replacement, air may enter the bleeder fitting.

the system and cause spongy pedal 3. Submerge the free end of the

action. Bleed the hydraulic system tube in a container, partially filled

HIX)8-0

after it has been properly connected, with clean brake fluid, and loosen

FIG. 6-Push Rod G a u g e Dimensions to be sure that all air is expelled. the bleeder fitting approximately

314 turn.

POWER BRAKE MASTER MAN U A L BLEEDING 4. Push the brake pedal down

CYLINDER PUSH R O D slowly through its full travel. Close

ADJUSTMENT The primary and secondary (front the bleeder fitting, then return the

and rear) hydraulic brake systems pedal to the fully-released position.

The push rod is provided with an are individual systems and are bled Repeat this operation until air bub-

adjustment screw to maintain the cor- separately. Bleed the longest line bles cease to appear at the sub-

rect relationship between the booster. first on :he individual system being merged end of the bleeder tube.

control valve plunger and the master serviced. During the complete bleeding 5. When the fluid is completely

cylinder pistons. Failure to maintain operation, D O N O T allow the reser- free of air bubbles, close the bleeder

this relationship will prevent the master voir to run dry. Keep the master cyl- fitting and remove the bleeder tube.

cylinder piston from completely re- inder reservoirs filled with Rotunda 6. Repeat this procedure at the

leasing hydraulic pressure and can Fluid - Extra Heavy Duty - Part brake wheel cylinder on the opposite

cause the brakes to drag, or cause Number C6AZ- 19542-A (ESA- side. Ref ill the master cylinder reser-

excessive brake pedal travel. M6C25-A). The disc brake extra voir after each wheel cylinder is bled

Downloaded from www.Manualslib.com manuals search engine

PART 2-1-General Brake Service 2-5

APPROXIMATELY 45" pressure. Never exceed 50 pounds 11. When the bleeding operation

pressure. is completed, close the bleeder tank

1. Clean all dirt from the master valve and remove the tank hose from

cylinder reservoir cover. the adapter fitting.

2. Remove the master cylinder res- 12. On disc brake equipped ve-

ervoir cover and rubber gasket, and hicles, be sure that the front brake

fill the master cylinder reservoir with pistons are returned to their normal

the specified brake fluid. Install the positions and that the shoe and lining

H1300-A

pressure bleeder adapter tool to the assemblies are properly seated by

master cylinder, and attach the depressing the brake pedal several

FIG. 9- Wrench for Bleeding Brake times until normal pedal height is

bleeder tank hose to the fitting on the

Hydraulic System adapter. obtained. Install the front wheel and

tire assemblies on the front wheels, and

and install the master cylinder cover Master cylinder pressure bleeder torque the mounting bolts to specifi-

and gasket. Be sure the diaphragm adapter tools can be obtained from cation. 1 nstall the wheel covers.

type gasket is properly positioned in the various manufacturers of pres-

sure bleeding equipment. Follow the 13. Remove the Pressure Bleeder

the master cylinder cover. When the Adapter Tool. Fill the master cylinder

bleeding operation is completed, the instructions of the manufacturer

when installing the adapter. reservoirs to within 114 to 112 inch

fluid level should be filled to within from the top. lnstall the master cyl-

114 to 112 inch from the top of 3. Loosen the primary and sec- inder cover and gasket. Be sure the

the reservoirs. ondary tube nuts at the master cyl- diaphragm-type gasket is properly

7. If the primary (front brake) inder and bleed the master cylinder positioned in the master cylinder cover.

system is to be bled, remove the front until the fluid flow is free of air

wheel covers, and the front wheel and 14. Centralize the pressure dif-

bubbles, then tighten the tube nuts

tire assemblies to gain access to the to the specified torque. Refer to Figs. ferential valve as follows:

bleeder fittings on the disc brake cal- 20 and 21, Part 2-2. Do not over-

ipers. Repeat steps 2 through 6 at tighten the nuts. CENTRALlZlNG T H E

the right front disc brake caliper and PRESSURE DIFFERENTIAL

ending at the left front disc brake 4. If the rear wheel cylinders and VALVE

caliper. the secondary brake system is to be

bled, position a 318 inch box After a failure of the primary

8. Be sure that the front brake wrench (Fig. 9) on the bleeder fitting (front brake) or secondary (rear

pistons are returned to their normal on the right rear brake wheel cylinder. brake) system has been repaired

positions and that the shoe and lining Attach a bleeder tube to the bleeder and bled, the dual-brake warning

assemblies are properly seated by fitting. The end of the tube should light will usually continue to be il-

depressing the brake pedal several fit snugly around the bleeder fitting. luminated due to the pressure dif-

times until normal pedal height exists. ferential valve remaining in an off-

Install the front wheel and tire assem- 5. Open the valve on the bleeder center position.

blies on the front wheels, and torque tank to admit pressurized brake fluid To centralize the pressure differ-

the mounting bolts to specification. to the master cylinder reservoir. ential valve and turn off the warning

Install the wheel covers. 6. Submerge the free end of the light after a repair operation, a pres-

9. Centralize the pressure dif- tube in a container partially filled sure differential or unbalance con-

ferential valve. Refer to the Centraliz- with clean brake fluid, and -loosen dition must be created in the opposite

ing the Pressure Differential Valve the bleeder fitting. brake system from the one that was

Procedures which follow. repaired and bled last.

7. When air bubbles cease to ap- 1. Turn the ignition switch to the

PRESSURE BLEEDlNG pear in the fluid at the submerged ACC or O N position. Loosen the dif-

end of the bleeder tube, close the ferential valve assembly brake tube

Bleed the longest lines first. The bleeder fitting and remove the tube. nut at the outlet port on the opposite

bleeder tank should contain enough side of the brake system that was

new Rotunda Brake Fluid to complete 8. Repeat steps 3 through 7 a t the

left wheel cylinder of the secondary sys- repaired and/or bled last. Depress

the bleeding operation. Use Rotunda the brake pedal slowly to build line

Brake Fluid - Extra Heavy Duty - tem being bled.

pressure until the pressure differential

Part Number C6AZ- 19542-A 9. If the primary (front brake) valve is moved to a centralized posi-

(ESA-M6C25-A) or equivalent for all system is to be bled, remove the front tion and the brake warning light

disc brake applications and Rotunda wheel covers, and the front wheel and goes out; then, immediately tighten

Brake Fluid - Heavy Duty - Part tire assemblies to gain access t o the the outlet port tube nut to the speci-

Number B7AZ- 19542-A, R103-A bleeder fittings on the disc brake fied torque. Refer to Fig. 20 and 2 I .

or equivalent for power drum or calipers. Repeat steps 4 through 7, 2. Check the fluid level in the

standard drum applications. The starting at the right front disc cali- master cylinder reservoirs and fill

brake fluid is colored blue for identi- per and ending at the left front disc them to within 114 to 112 inch of

fication purposes. Do not mix low caliper. the top with the specified brake fluid,

temperature brake fluid with the

10. If the vehicle contains drum- if necessary.

specified disc brake fluid during the 3. Turn the ignition switch t o the

bleeding operations. Never re-use type front brakes and the primary

(front) brake system is to be bled, O F F position.

brake fluid that has been drained

from the hydraulic system. The tank repeat steps 4 through 7, starting 4. Before driving the vehicle, check

should be charged with approxi- at the right front wheel cylinder and the operation of the brakes and be

mately 10 to 30 pounds of air ending at the left wheel cylinder. sure that a firm pedal is obtained.

Downloaded from www.Manualslib.com manuals search engine

GROUP 2-Bra kes

CLEANING AND INSPECTION

LATERIAL RUNOUT

D I S C ( F R O N T ) BRAKES mension B) must be observed when 0.002 MAXIMUM TOTAL

removing material from the rotor INDICATOR READING

1. Remove the wheel and tire, cali- braking surfaces.

per splash shield, and the shoe and lin- When the runout check is finished,

ing assemblies as outlined in Part be sure to adjust the bearings as

2-2, Section 2. outlined in Group 3, in order to pre-

2. Make three thickness measure- vent bearing failure.

ments with a micrometer across the 6. Check the rotor for scoring.

middle section of the shoe and lining. BEARING CUP

Minor scores can be removed with a

Take one reading at each side and fine emery cloth. If the rotor is exces-

one in the center. If the assembly has sively scored, refinish it as outlined DIMENSION "B"

1 . 1 1 7 MINIMUM

worn to 'a thickness of 0.231 inch in step 5 or replace the rotor, if re-

(shoe and lining together) or 0.066 quired. DIMENSION "A"

inch (lining material only) at any 7. Visually check the caliper. If 0.402 MAXIMUM

one of the three measuring locations excess leakage is evident, it should

or if the brake lining shows evidence be replaced. Slight leakage around

of brake fluid contamination, re- SURFACE FINISH-

the pistons or seized pistons indicate /IS MICRO INCHES

place all four shoe and lining as- removal and disassembly: .

semblies on both front wheels. H1%3-A

8. If upon disassembly the cali-

3. Check the caliper to spindle per is found to be distorted or dam-

attaching bolt and caliper bridge aged, or if the cylinder bores are FIG. 10-Disc Brake Rotor Service

bolt torque. Tighten them to the scored or excessively worn, replace Limits - Typical

specified torque, if required. the assembly .

4. To check rotor runout, first The two halves of the caliper as-

eliminate the wheel bearing end play sembly should never be separated. replacement of the retracting and

by tightening the adjusting nut. Damage or failure of one requires hold down springs and the parking

After tightening the nut check to see replacement of both as a unit. brake cable is necessary. Overheated

that the rotor can still be rotated. springs lose their pull and could

5. Clamp a dial indicator to the cause the new lining to wear pre-

caliper housing so that the stylus REAR BRAKES maturely if they are not replaced.

contacts the rotor at a point approxi- 5. If the car has 30,000 or more

mately I inch from the outer edge. 1. Remove the wheel from the drum, miles of operation, or signs of ex-

Rotate the rotor and take an indica- then remove the drum as outlined in treme overheating are present when

tor reading. If the reading exceeds Part 2-2, Section 2. Wash all the relining brakes, the wheel cylinders

0.002 inch total lateral runout on parts except the brake shoes in a should be disassembled and inspected

the indicator, replace or resurface cleaning solvent and dry with com- for wear and dirt in the cylinder. The

the disc brake rotor. The following pressed air. cylinder cups and other parts con-

requirements must be met when re- 2. Brush all dust from the back- tained in the overhaul kit should be

surfacing disc brake rotors: ing plates and interior of the brake replaced thus avoiding future prob-

Rotunda Disc Brake Attachment drums. lems.

FRE-2249-2 is the only approved 3. Inspect the brake shoes for ex-

tool to be used to refinish the disc cessive lining :wear or shoe damage. 6. Inspect all other brake parts

brake rotors. The step-by-step resur- I f the lining is worn to within 1/32 and replace any that are worn or

facing procedure provided with the inch of the rivet heads or if the shoes damaged.

tool must be adhered to. are damaged, they must be re- 7. Inspect the brake drums and,

The finished braking surfaces of placed. Replace any lining that has if necessary, refinish. Refer to Part

the rotor must be flat and parallel been contaminated with oil, grease 2-2, Section 4 for refinishing.

within 0.0007 inch; lateral runout or brake fluid. Replace lining, in

must not e x u e d 0.002 inch total axle sets. Prior to replacement of BOOSTER U N I T

indicator reading, and the surface lining, the drum diameter should be

finish o f the braking surfaces are checked to determine if oversize linings Check the booster operation as

to be 85/15 micro inches. The min- must be installed. noted in Part 2-1, Section 1, Power

imum limiting dimensions (Fig. 10) 4. Check the condition of the brake Brake Functional Test. If the brake

from the inboard bearing cup to shoes, retracting springs, and drum booster is damaged or defective, re-

the outboard rotor face (dimension for signs of overheating. If the springs place it with a new booster. The

A ) and from the inboard bearing show any loss of load or change in booster is serviced only as an assem-

cup to the inboard rotor face (di- free length indicating overheating, bly.

Downloaded from www.Manualslib.com manuals search engine

-

PART 2-1-General Brake Service

Trouble Symptoms

m 3 C

t

.-

c

.->

C

- =0

C

ii

+ m

L O

II),m

r

Possible Causes Of Trouble

Shoe and Lining Knock-back after Violent Cornering or

Rough Road Travel X

Shoe and Lining Assembly not Properly Seated or Positioned X X X

Leak or Insufficient Fluid in System or Caliper X X X X

Loose Wheel Bearing Adjustment X X

Damaged or Worn Caliper Piston Seal X X X

Improper Master Cylinder Push Rod Adjustment X

Excessive Rotor Runout or Out of Parallel X

.- -- --

Incorrect Tire Pressure X X

-

Frozen or Seized Pistons X X X X

Brake Fluid, Oil o r Grease on Linings X X ?( X

Shoe and Lining Worn Below Specifications X

Proportioning Valve Malfunction X X

-

Booster Inoperative X

-

Caliper Out of Alignment with Rotor X X'

Loose Caliper Attachment X X X X .Y

Metering Valve Seal Leaks >i

Excessive Clearance Between Shoe and Caliper or Between

Shoe and Splash Shield X

Shoe Hold Down Clips Missing or Improperly Positioned X

Operator Riding Brake Pedal ?(

Scores in the Cylinder Bore X

Corrosion Build-Up in the Cylinder Bore or on the Piston

Differential Pressure Valve Is Not Centered

Wiring T o Warning Lamp or Switch Is Grounded .Y

Warning Lamp Switch Is Grounded S

Warning Lamp Is Burned Out X

Warning Lamp or Switch Has An Open Circuit X

Warning Lamp Switch Is Inoperative

Wiring T o Warning Lamp Has Open Circuit

FIG. I I-Front Wheel Disc Brake Trouble Symptoms and Possible Causes

Downloaded from www.Manualslib.com manuals search engine

2-8 GROUP 2-Bra kes

Trouble Symptoms

-t

C

z

0

Y 4)

.-

4

P

al

2

- r

r -

'Possible Causes Of Trouble

Mechanical Resistance at Pedal or Shoes X X

I

I

1 I I I I I 1 1 1 1 1 1

I I I I I I I

Warning Lamp Switch Is Inoperative X

FIG. 12-Drum Brake and General System Trouble Symptoms and Possible Causes

Downloaded from www.Manualslib.com manuals search engine

Section Page Section Page

I 1 Description and Operation ..........................2-9

Dual-Master Cylinder Brake System ...........2-9

Brake Tube Replacement ......................2-20

Brake Hose Replacement ......................2-20

Disc Brakes ...........................................

2-1 1 3 Removal and Installation ............................ 2-23

Hydraulic Self-Adjusting Brake System ........2-13 Dual Master Cylinder - Standard Brakes......2-23

Booster System ......................................2-13 Dual-Master Cylinder-Power Brakes .........2-24

Parking Brakes ......................................2-14 Pressure Differential Valve Assembly ..........2-24

2 In-Vehicle Adjustments and Repairs ..............2-14 Brake Booster ........................................2-25

Front (Disc) Brake Shoe and Lining Brake Pedal ........................................... 2-25

Replacement .......................................2-17 Parking Brake Control Assembly ...............2-26

Disc Brake Caliper Assembly ....................2-18 Parking Brake Equalizer to Control

Front Wheel H u b and Rotor Assembly .......2-18 Cable .....................................................2-26

Disc Brake Rotor Splash Shield .................2-19 Parking Brake Equalizer to Rear Wheel

Proportioning Valve.. ..............................2-19 Cable ................................................2-27

Brake Shoe Adjustments-Rear Wheels ........2-16 4 Major Repair Operations ............................2-28

Rear Brake Drum. ..................................2-20 Brake Drum Refinishing ..........................2-28

Rear Brake Shoe Replacement ..................2-20 Rotor Refinishing ................................... 2-28

Rear Wheel Cylinder Repair .....................2-19 Brake Shoe Relining ............................... 2-29

Rear Wheel Cylinder Replacement .............2-19 Dual-Master Cylinder ..............................2-29

Rear Brake Backing Plate Replacement .......2-20 Disc Brake Caliper ................................ .2-30

Hydraulic Lines .................................... 2-20

DESCRIPTION AND OPERATION

Disc brakes are available as op- The dual-master cylinder used on

tional equipment for the front wheels Fairlane, Falcon and Comet vehicles (front brake) and smaller secondary

on the various vehicle models listed equipped with power brakes have the (rear brake) cover domes.

in (Fig. I). master cylinder outlet ports for the A code letter is stamped on the

The dual-master cylinder equipped rear brake system located on the bot- side or outer end of each master cyl-

hydraulic brake system employes sin- tom of the master cylinder body. inder body casting for easy service

gle-anchor, internal expanding and Master cylinder hydraulic system identification. The vehicle application,

self-adjusting drum brake assemblies bleed screws are located in the out- type of brakes and the identification

on the rear wheels of vehicles with board side of those master cylinders code are shown in Fig. 3.

disc brakes, and on the front and rear having secondary (rear brake) system A brake pressure differential valve

wheels of all others (Fig. 1). outlet ports in the bottom of the mas- assembly (Fig. 4) incorporating an hy-

ter cylinder castings (Fig. 29). draulically operated mechanical

DUAL-MASTER CYLINDER switch is utilized to operate a dual-

BRAKE SYSTEM All Fairlane, Falcon and Comet ve- brake warning light, located on the

The dual-master cylinder brake sys- hicles equipped with standard drum instrument panel.

tem has been incorporated in all car brakes and all Mustang and Cougar Hydraulic pressure for both front

models to provide increased vehicle vehicles equipped with power disc, wheel brakes is provided from the pri-

safety. The system consists of a dual- power drum and standard drum mary system (front) brake outlet port

master cylinder, pressure differential brakes have both the primary (front) and line, located opposite the primary

valve assembly and a switch. The and secondary (rear) brake system system inlet port of the differential

switch on the differential valve acti- outlet ports located on the outboard valve.

vates a dual-brake system warning side of the dual-master cylinder body Hydraulic pressure for both rear

light, located on the instrument panel. castings. These master cylinders d o wheel brakes is provided from the sin-

The dual-master cylinder brake sys- not require master cylinder bleed gle secondary (rear brake) outlet

tem is similar to a conventional screws (Figs. 27, 28 and 30). line, located opposite the secondary

(single) brake master cylinder sys- system inlet port of the differential

tem. In the dual-system, two master The external appearance of the dual valve. On disc brake equipped ve-

cylinders are combined in a single master cylinders for the various ve- hicles, a proportioning valve is located

cast iron casting (Fig. 2). One por- hicles also differ in configuration in the secondary (rear brake) system

tion actuates the front brake system of the covers. All vehicles having line that leads to the brake hose

and the other actuates the rear brake standard drum brake systems and bracket on the rear axle housing. The

system (Figs. 20 and 21). Hydraulic Mustang, Cougar vehicles equipped brake hose bracket serves as a junc-

fluid leakage or failure of one of with power drum brakes have primary tion point for the individual brake

the systems does not impair the oper- and secondary master cylinder cover lines that lead to the wheel cylinders

ation of the other portion of the dual- domes of equal size. Dual master cyl- of right and left rear brake com-

brake system. A dual-brake warning inders for all other vehicles equipped ponents.

light signals a failure of either the with power disc and power drum When the brake pedal is depressed,

front or rear brake system. brake systems have large primary both the primary (front brake) and

Downloaded from www.Manualslib.com manuals search engine

GROUP 2-Bra kes

secondary (rear brake) master cylin-

der pistons are moved simultaneously Car Model Power Drum Power Disc

to exert hydraulic fluid pressure on

their respective independent hydraulic Falcon RPO Not Available

system. The fluid displacement of the

duallmaster cylinders is proportioned Fairlane RPO RPO 3 B

to fulfill the requirements of, each of Mustang Zi RPO . RPO @

the two independent hydraulic brake

systems (Fig. 2). Comet RPO RPO 3 .o

If a failure of the rear (secondary)

brake system should occur, initial Cougar RPO RPO

brake pedal movement causes the un- 3 Standard with Mustang G T equipment group option, Fairlane G T model.

restricted secondary piston to bottom Mustang brake options available only on eight-cylinder models.

in the master cylinder bore. Primary 3 Standard for Acc. Fairlane and Comet 427 V-8 Engine,

piston movement displaces hydraulic

fluid in the primary section of the

dual-master cylinder to actuate the FIG. I-Power Disc Brake and Power Drum Brake Options

front brake system.

Should the front (primary) brake vides a visual indication the warning switch is located on the side of the

system fail, initial brake pedal move- lamp is functional. When the ignition pressure differential valve assembly

ment causes the unrestricted primary switch is turned to the ON or ACC between the front and rear brake sys-

piston to bottom out against the sec- position, a dual-brake warning light tem inlet ports. The inner-end of the

ondary piston. Continued downward on the instrument panel also provides spring loaded switch-plunger contacts

movement of the brake pedal moves a visual indication if one portion of the bottom of a tapered shoulder

the secondary piston to displace hy- the dual-brake system has become groove in the center of the valve (Fig.

draulic fluid in the rear brake sys- inoperative. 4). O-ring seals are retained in seal

tem, actuating the rear brakes. Should a failure of either the front ring lands near each end of the

The increased pedal travel and the or rear brake hydraulic system occur, valve.

increased pedal effort required to com- the hydraulic fluid pressure differen- Should a failure of the rear brake

pensate for the loss of the failed tial resulting from the pressure loss system occur, hydraulic fluid pressure

portion of the brake system provides of the failed brake system forces the in the rear brake system would drop.

a warning that a partial brake system valve toward the low pressure area to During brake pedal operation the fluid

failure has occured. When the ignition illuminate the brake warning light pressure build-up of the front brake

switch is turned to the START posi- (Fig: 4). system forces the valve to move to-

tion, a dual-brake warning light pro- A mechanically operated electrical ward the low pressure area, or toward

FIG. 2- Dual-Master Cylinder

Downloaded from www.Manualslib.com manuals search engine

PART 2-2-Brake System 2-1 1

the rear brake system outlet port (Fig.

4). Movement of the differential valve Car Model Type Of Brake Identifiation Code

forces the switch plunger upward over

the tapered shoulder of the valve to Power Disc B

close the switch electrical contacts and Fairlane and Falcon Power Drum S

light the dual brake warning lamp,

signalling a brake system failure. Standard Drum T

In the event a front brake system

failure should occur, greater pressure Power Disc M

from the rear brake system during Mustang Power Drum X

brake pedal operation forces the valve

forward, moving the switch plunger Standard Drum T

upward onto the valve ramp to light

the brake system warning lamp. How- Comet Power Disc B

ever, failure of either the front or Power Drum S

rear system does not impair operation

of the other brake system. Standard Drum T

DISC BRAKE ASSEMBLIES Cougar Power Disc M

Power Drum X

Disc brakes are available as op-

tional equipment for the front wheels. Standard Drum T

The hydraulic brake system employs

single -anchor, internal expanding and FIG. 3-Dual Master Cylinder Identification

self-adjusting drum brake assemblies

on the rear wheels of vehicles with cylinders (drum brakes). The pistons lated disc type, actuated by a hy-

disc brakes, and on the front and rear in turn convert hydraulic pressure draulic system (Fig. 5). There is no

wheels of all others. back into physical force at the brake lateral movement of either the disc

A vacuum booster is available as shoes. (rotor) or the caliper. The caliper

optional equipment. assembly consists of two caliper

The master cylinder converts phys- RELATION AND FUNCTION housings bolted together with each

ical force from the brake pedal (and OF COMPONENT PARTS half containing two cylinder bores

booster if so equipped) into hydraulic of 1 15/16 inch diameter. Each cyl-

pressure against the pistons in the The disc brake is a fixed caliper, inder bore contains a piston with an

I

I

calipers (disc brakes) or in the wheel

BRAKE WARNIFIS LAMP SWITCH

opposed piston, non-energized, venti- attached molded rubber dust boot

BRAKE WARNING LAMP SWITCH

I

VALVE PISTON HAS MOVED TO LOW PRESSURE AREA. VALVE PISTON S; CENTRALIZED.

WARNING LAMP SWITCH PLUNGER IS DEPRESSED, BRAKE FLUID PRIMARY AND SECONDARY SYSTEM

LIGHTING THE BRAKE WARNING LAMP PRESSURES ARE EQUALIZED H1471-A

FIG. 4-Pressure Differential Valve and Brake Warning Lamp Switch Operation

Downloaded from www.Manualslib.com manuals search engine

CALIPER TO ROTOR CLEARANCE

I WTRAN TUBE

FIG. 6-Typical Caliper Assembly-Sectional View

PISTON

1

FIG. 5-Typical Disc Brake Assembly

t o seal the cylinder bore from con-

tamination (Fig. 6). Square-section

rubber piston seals are positioned in

grooves in the cylinder bores.

The piston seals perform three im-

portant tasks:

1. They provide hydraulic sealing

between the cylinders and pistons.

2. They return the pistons t o re-

leased position, when hydraulic pres-

sure is released. BRAKES A P P L I E D BRAKES RELEASED til3m~

3. They maintain the shoes in cor- FIG. 7-Function of Piston Seal

rect adjustment at all times (com-

parable to the automatic adjusters in shoe and lining assemblies. The cali- of the revolving rotor to effect brak-

drum-type brakes). per assembly is mounted to a bracket ing action.

The cylinders are connected hy- located between the spindle and rotor During brake application, the rub-

draulically by means of internal pas- splash shield, to the front of the ber seal on each piston stretches as

sages in the caliper housing and an wheel vertical centerline. the piston moves against the shoe

external transfer tube between the The cast iron disc is of the venti- (Fig. 7). When the hydraulic pres-

two halves of the caliper assembly. lated rotor type. incorporating forty sure against the piston is released,

One bleeder screw and fluid inlet fins and is attached to, and rotates the seal relaxes or rolls back. This

fitting is provided on each caliper with, the wheel hub. The outside roll-back action pulls the piston away

assembly. ' diameter of the rotor is 11.290 in- from the shoe just enough to relieve

The shoe and lining assemblies are ches and the inside diameter is 7.170, the force of the lining against the

located between parallel machined inches. This type of design increases rotor and, thereby, provide the re-

abutments within the caliper, and cooling area and permits circulation - quired running clearance. Also, inher-

are supported radially by tabs on the of air through the rotor resulting in ent rotor runout contributes to the

outer ends of the shoe assemblies more rapid cooling of the brake. A maintenance of running clearance.

(Fig. 25). The shoes slide axially in splash shield bolted to the spindle is Automatic adjustment is achieved by

the caliper abutments by means of used primarily to prevent road con- the pistons sliding in the seals out-

the tabs which ride on machined taminants from contacting the inboard ward from the cylinder bores. The pis-

ledges (bridges) when hydraulic pres- rotor and lining surfaces (Fig. 17). ton gradually changes its position rela-

sure is applied to the piston (Fig. The wheel provides protection for the tive to the seal as the lining wears

6). A shoe and lining assembly con- outboard surfaces of the rotor. and, thus, maintains the correct ad-

sists of friction material bonded to a As the brake pedal is depressed, justment location at all times. -

metal platc called the shoe. It is re- hydraulic pressure from the master When the brakes- are in the un-

placed as a unit. Brake torque is ab- cylinder forces the pistons out of the applied position, there is no hydrau-

sorbed by the mating of the shoe end caliper bores against their respective lic pressure t o the calipers because

against the caliper abutments (Fig. shoe and lining assemblies. The the fluid source at the master cylin-

25). Two spring clips are attached to force of the pistons against the shoes der by-passes the residual check

the top of the caliper to retain the moves the linings against both sides valve.

Downloaded from www.Manualslib.com manuals search engine

PART 2-2-Brake System 2-1 3

CLIP MUST NOT TOUCH OR COVER TUBE-2265

RUBBER RING AROUND OUTSIDE DlSC BRAKE CONTROL

TORQUE TO 6.15 LB. F T .

OF VALVE ASS,EMBLY

A

TUBE-2265

PROPORTIONING VALVE

I

ASSEMBLY-26272 TUBE-2B113

FLAT SlDE 0F"D" SHAPED HOLE

MUST BE LOCATED ON INBOARD

SlDE OF HOSE BRACKET

DlSC BRAKE PRESSURE HOSE-2A448

CONTROL VALVE

ASSEMBLY-ZBOPI B0LT-376459-S2 BOLT-376459.52

INSTALLATION-DISC BRAKES SAME AS

INSTALLATION-DISC BRAKES ONLY INSTALLATION-DISC i3RAKE ALTERNATE ONLY MAIN VIEW EXCEPT AS SHOWN H1561-A

NG. 8-Disc Brake Pressure Control Valve

REAR BRAKE FRONT BRAKE

NG. 9-Self-Adjusting Brake Assemblies-9 Inch Drum

A disc brake pressure control valve cable guide. The adjuster spring is pulls the lever downward causing the

located between the pressure differen- hooked to the primary brake shoe star-wheel to turn and expand the

tial valve and the rear brake wheel and to the lever. The automatic ad- shoes. The star-wheel is turned one

cylinders provides balanced braking juster operates only when the brakes tooth at a time as the linings pro-

action between the front and the rear are applied while the car is moving gressively wear.

brakes under a wide range of braking rearward and only when the second- With the vehicle moving forward

conditions (Fig. 8). By regulating the ary shoe is free to move toward the and the brakes applied, the secondary

hydraulic pressure applied to the rear drum beyond a predetermined point. shoe is against the anchor pin and

wheel cylinders, the valve limits rear With the vehicle moving rearward the primary shoe is moved toward

braking action when high pressures and the brakes applied, the wrap- the drum. Therefore, the adjuster

are required at the front brakes. In around action of the shoes follow- does not operate.

this manner. Dremature rear wheel ing the drum forces the upper end The rear brake assembly is basic-

skid is prevdnied. The proportioning of the primary shoe against the ally the same as the front brake.

valve is serviced as an assemblv and anchor pin. The action of the wheel The conventional parking brake lever,

is never adjusted o r overhauled. cylinder moves the upper end of the link, and spring are used in the rear

secondary shoe away from the an- brake.

HYDRAULIC SELF-ADJUSTING chor pin. The movement of the sec- The anchor pins on all brakes are

BRAKE SYSTEM ondary shoe causes the cable to pull fixed and are non-adjustable.

the adjusting lever upward and

The self-adjusting brake mecha- against the end of a tooth on the BRAKE BOOSTER SYSTEM

nism consists of a cable, cable guide, adjusting screw star-wheel. The up-

adjusting lever, and adjuster spring ward travel of the lever increases as The diaphragm-type brake booster

(Figs. 9 and 10). The cable is hooked lining wear increases. When the lever is a self-contained vacuum-hvdraulic

over the anchor pin at the top and is can move upward far enough, it braking unit mounted on thd engine

connected to the lever at the bottom. passes over the end of the tooth and side of the dash panel. The brake

The cable is connected to the sec- engages the tooth. When the brakes booster is of the vacuum suspended

ondary brake shoe by means of the are released, the adjusting spring type which utilizes engine intake

Downloaded from www.Manualslib.com manuals search engine

2-1 4 GROUP 2-Bra kes

FIG. 10-Self Adiusting Brake Assemblies- 10 Inch Drum

manifold vacuum and atmospheric pres- forced against the rear brake drums. drums. The pedal is held in the ap-

sure for its power. The handle is held in the applied plied position by the engagement of

Adjllstment of the push rod is the position by the engagement of a a spring-loaded pawl with a ratchet

only service permitted on a brake spring loaded pawl with a ratche!. in the control assembly (Fig. 32).

booster. The booster unit is to be Turning the handle counterclockwise

exchanged when i t is inspected, check-

The. parking brake control assem-

disengages the pawl from the ratchet

ed and found to be defective. bly is mounted to the cowl inner side

to release the brakes.

panel. The cedal ~ i v o t son a station-

ary pedal 'mouni. A spring-loaded

PARKING BRAKES-MUSTANG PARKING BRAKES- pawl and a release lever are assem-

A N D COUGAR COMET, FAIRLANE A N D bled to the pedal. A ratchet is as-

FALCON sembled to the upper end of the

An independent hand-operated park- pedal. The pawl contacts the ratchet

ing brake control actuates the rear at such an angle that the ratchet

wheel brake shoes through a cable An independent foot-operated park- teeth will slide over the pawl as the

linkage. The operating cable is routed ing brake control actuates the rear pedal is depressed; however, when

from the parking brake control as- wheel brake shoes through a cable the applying motion stops and the

sembly t o the equalizer pivot lever linkage. The operating cable is routed pedal starts to release, the pawl en-

which is attached to the equalizer from the parking brake control as- gages the ratchet and thus locks the

assembly to the floor pan. The rear sembly to the equalizer. The rear brakes in the applied position.

brake cables connect the equalizer brake cables connect the equalizer as-

assembly to the parking brake lever sembly to the parking brake lever at When the manual release lever is

at each rear secondary shoe as shown each rear secondary shoe (Fig. 9). . pulled back (Fig. 32), the cam ac-

in Figs. 9, 10 and 3 1. When the pedal is depressed the tion of the lever on the pawl cam

When the handle is pulled the pri- primary and secondary brake shoes pin will disengage the pawl from the

mary and secondary brake shoes are are forced against the rear brake ratchet to release the brakes.

IN-VEHICLE ADJUSTMENTS A N D REPAIRS

Alter any brake service work, ob- BRAKE SHOE ADJUSTMENTS shoes have been relined, replaced, or

tain a firm brake pedal before moving -DRUM BRAKE when the length of the adjusting

the vehicle. Riding the brake pedal screw has been changed while per-

(common on left foot applications) The hydraulic service brakes are forming some other service opera-

should be avoided when driving the self-adjusting and require a manual tion. The manual adjustment is per-

vehicle. adjustment only after the brake formed with the drums removed, us-

Downloaded from www.Manualslib.com manuals search engine

PART 2-2-Bra ke System

Tool - HRE8650

FIG. 1 ]-Measuring Drum FIG. 12-Measu ring Shoes

ing the tool and the procedure de- wheel and tire clear the floor. Remove

tailed below. the wheel cover o r hub cap, and re- FIG. 13- Backing Off Brake

When adjusting the rear brake move the wheel and tire from the

Adiustment

shoes, check the parking brake ca- drum.

bles for proper adjustment. Refer to

Parking Brake Linkage Adjustment, 2. Remove the grease cap from 3. Install the outer wheel bearing,

Part 2-1, Section 2. Make sure that the hub. Remove the cotter pin, nut washer and adjusting nut.

the equalizer operates freely. lock, adjusting nut, and flat washer 4. Adjust the wheel bearing as out-

To adjust the brake shoes: from the spindle. Remove the outer lined in Part 3-5, Section 2, then in-

1. Using Rotunda Tool H R E bearing cone and roller assembly. stall the grease cap. Install the wheel

8650, (Fig. I I) determine the inside and hub cap or cover.

diameter of the drum braking sur- 3. Pull the hub and drum assem-

bly off the wheel spindle. REAR BRAKE DRUM

face.

2. Reverse the tool as shown in REMOVAL

Fig. 12 and adjust the brake shoe 4. If the drum will not come off,

diameter to fit the gauge. Hold the remove the rubber cover from the 1. Raise the vehicle so that the

automatic adjusting lever out of en- brake backing plate. Insert a narrow wheel is clear of the floor.

gagement while rotating the adjust- screwdriver through the slot and 2. Remove the hub cap and wheel.

ing screw, to prevent burring the disengage the adjusting lever from Remove the three Tinnerman nuts

screw slots. Make sure the adjust- the adjusting screw. While holding and remove the brake drum. If the

ing screw rotates freely. If neces- the adjusting lever away from the drum will not come off, remove the

sary, lubricate the adjusting screw screw, back off the adjusting screw rubber cover from the backing plate.

threads with a thin, uniform coating with the brake adjusting tool (Fig. Insert a narrow screwdriver through

of CIAZ- 19590-B Grease. 13). Be very careful not to burr, the hole in the backing plate, and

3.Rotate Tool HRE 8650 chip, or damage the notches in the disengage the adjusting lever from

around the brake shoes to be sure adjusting screws; otherwise the self- the adjusting screws. While holding

of the setting. adjusting mechanism will not func- the adjusting lever away from

4. Apply a small quantity of high tion properly. the adjusting screw, back off the ad-

temperature grease to the points justing screw with the brake ad-

where the shoes contact the carrier INSTALLATION justing tool (Fig. 13). Be very care-

plate and anchor pin, being careful I. If the drum is being replaced, ful not to burr, chip or damage the

not t o get the lubricant on the linings. remove the protective coating from notches in the adjusting screw; other-

5. Install the drums. Install the the new drum with carburetor de- wise, the self-adjusting mechanism

Tinnerman nuts and tighten securely. greaser; then, sand lightly and wipe will not function properly.

Install the wheel on the drum and with a cloth soaked with denatured

tighten the mounting nuts to specifi- alcohol. Install new bearings and INSTALLATION

cation. grease retainer. Soak the new ser-

6. Complete the adjustment by ap- vice-type grease retainer in light 1. Remove the protective coating

ply ing the brakes several times with engine oil for at least 30 minutes from a new drum with carburetor

a minimum of 50 Ibs pressure on the before installation if retainer is degreaser; then, sand lightly and

pedal while backing the car. After of a leather composition. Pack the wipe with a cloth soaked in denatured

each stop, the vehicle must be moved wheel bearings, install the inner alcohol.

forward. bearing cone and roller assembly in

7. After the brake shoes have the inner cup, and install the new 2. Adjust the brakes as outlined

been properly adjusted, check the grease retainer. See Part 3-5, Sec- under Brake Shoe Adjustments in this

operation of the brakes by making tion 4 for procedure. section.

several stops while operating in a If the original drum is being in- 3. Place the drum over the brake

forward direction. stalled, make sure that the grease assembly and into position. Install

in the hub is clean and adequate. the three Tinnerman nuts and tighten

FRONT BRAKE DRUM them securely. Install the wheel on

2. Adjust the brakes and install the

REMOVAL drum assembly as outlined under the axle shaft flange studs against

Brake Shoe Adjustments in this sec- the drum, and tighten the attaching

1. Raise the vehicle untiI the tion. nuts to specifications.

Downloaded from www.Manualslib.com manuals search engine

GROUP 2-Bra kes

BRAKE SHOES A N D temperature grease (Part Number

ADJUSTING SCREW CIAZ-19580-B) t o the threads and

the socket end of the adjusting screw.

REMOVAL Turn the adjusting screw into the ad-

justing pivot nut t o the limit of

1. With the wheel and drum re- the threads and then back off 112

moved, install a clamp over the ends turn.

of the wheel cylinder as shown in Interchanging the brake shoe ad-

Fig. 14. justing screw assemblies from one