Professional Documents

Culture Documents

1495-Article Text-11046-2-10-20171027

Uploaded by

15041168Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1495-Article Text-11046-2-10-20171027

Uploaded by

15041168Copyright:

Available Formats

Article

Production of 1,3-Dihydroxyacetone by

Gluconobacter nephelii in Upflow Aerated Bioreactors

with Agro-industrial Wastes as External Nitrogen

Source

Thanaporn Wannachod1, Chutimon Satirapipatkul1,a, Wiboonluk Pungrasmi2,

and Kasidit Nootong1,b,*

1 Chemical Engineering Research Unit on Value-Adding of Bioresource, Department of Chemical

Engineering, Faculty of Engineering, Chulalongkorn University, Bangkok 10330, Thailand

2 Department of Environment Engineering, Faculty of Engineering, Chulalongkorn University, Bangkok

10330, Thailand

E-mail: achutimon.s@chula.ac.th, bkasidit.n@chula.ac.th (Corresponding author)

Abstract. Cultivation of recently identified Gluconobacter nephelii to produce 1,3-

dihydroxyacetone (DHA) was conducted using the growth medium containing the external

nitrogen source from agro-industrial wastes. Cell cultivation in 250 mL glass flasks using

80 g/L glycerol and corn steep liquor as nitrogen source yielded the highest biomass (1.75

± 0.23 g/L) and DHA (49.5 ± 3.14 g/L) concentrations as compared to other nitrogen

sources (i.e., glutamic mother liquor and soybean meal hydrolysate). Subsequent

cultivation in larger bioreactors (32 L) with corn steep liquor as the preferred nitrogen

source indicated that internal-loop airlift bioreactor yielded significantly higher biomass

and DHA concentrations than flat-panel airlift and bubble column bioreactors. Further

optimization of internal-loop airlift photobioreactor revealed that DHA production in G.

nephelii depended on the aeration rates, with the maximum DHA concentrations (46.09 ±

1.01 g/L) obtained when maintaining the aeration rates at 0.64 vvm.

Keywords: DHA, Gluconobacter, agro-industrial waste, airlift, glycerol, corn steep liquor.

ENGINEERING JOURNAL Volume 21 Issue 5

Received 17 January 2017

Accepted 28 March 2017

Published 29 September 2017

Online at http://www.engj.org/

DOI:10.4186/ej.2017.21.5.81

DOI:10.4186/ej.year.vol.issue.pp

1. Introduction

1,3-Dihydroxyacetone (C3H6O3) is a high valued chemical, which is used extensively in cosmetic industry

especially for the making of sunless tanning [1-3]. It was also served as the building block for the

production of fine chemicals such as 1,2-propylene glycerol or lactic acid [2,4]. Due to wide range of

applications, the demand for DHA was predicted to increase significantly, thereby requiring the production

process to be both technically and economically feasible [5]. It has been suggested that the biological

production of DHA is more efficient than the chemical pathways due to lesser expense required for process

safety and easier product separation, and importantly DHA compounds produced biologically are more

acceptable by pharmaceutical and cosmetic industries than those produced via chemical synthesis [6].

Various microorganisms are able to produce DHA from different substrates, for examples Komagataeibacter

(Acetobacter) xylinum, Ogataea (Hansenula) polymorpha, Klebsiella aerogenes, Escherichia coli, Pichia membranifaciens,

Saccharomyces cerevisiae, Gluconobacter frateurii and Gluconobacter oxydans [3,6-12]. Among reported species, G.

oxydans has received the most attention due to relatively high DHA yield and fewer byproducts [13].

Recently, new strain of acetic acid bacteria in genus Gluconobacter was isolated from tropical fruits rambutan

and identified as Gluconobacter nephelii, yet limited information on growth and DHA production by G. nephelii

was available [14,15].

Oxygen availability was one of the factors that influenced growth and DHA production in

Gluconobacter so that providing well-mixed condition and adequate oxygenation in cultivating systems have

become necessary for the success of biological DHA production [16-18]. Aerated stirred tank bioreactors

have been generally employed in the cultivation of Gluconobacter at various scales. In spite of the advantages

such as low construction cost and ease of operation, aerated stirred tank bioreactors often experience mass

and heat transfer limitation when attempting to scale up or culture at high cell density [5]. Airlift

bioreactors were suggested as the possible alternatives to stirred tank bioreactors because they exhibited

relative high gas-liquid mass transfer, good liquid mixing, low liquid shear force as a result of no mechanical

moving parts and low operating cost [19-22]. Airlift bioreactors are available in different configurations

such as internal-loop column, external-loop column, cone-shape, cone-shape with baffle inside, and flat-

panel, with the selection criteria depending on types of bioprocess, microorganisms, growth media,

sterilization options, scaling up, ease of construction and operation, space limitation and budget [3,19,23-

25]. Unfortunately, only one report on DHA production in airlift bioreactor is available. In that work, a

laboratory scale (2 L) internal-loop airlift bioreactor subjected to increasing aeration rates from 0.9 to 2.1

vvm was employed to grow G. oxydans, resulting in DHA concentrations approximately 35 g/L and

subsequently 153 g/L after optimizing glycerol feeding method [3].

On the separated note, growth medium is the major expense in biological processes, in some cases

accounting for as high as 60% of the total operating cost [26,27]. The growth medium for Gluconobacter

usually contains expensive ingredients such as peptone and yeast extract, which are external source of

nitrogen [28]. Out calculation of growth medium cost for G. oxydans revealed that peptone and yeast

extract accounted for approximately 55% of medium total cost. One of the possible options for reducing

medium cost is using external nitrogen source from agro-industrial byproducts or wastes [26,28]. Corn

steep liquor, glutamic mother liquor and soybean meal are common agro-industrial wastes in Thailand. The

costs of these materials per kg in Thailand are approximately 5 to 196 times cheaper than those of yeast

extract and peptone [29].

Therefore, the objectives of this works aimed to evaluate the feasibility of using G. nephelii to produce

DHA by using the growth medium that contained external nitrogen source from agro-industrial wastes (i.e.,

corn steep liquor, glutamic mother liquor and soybean meal hydrolysate). Moreover, the study intended to

compare the performance of different bioreactors in the cultivation of G. nephelii to produce DHA, and

finally to determine the effects of aeration rates on DHA production.

2. Materials and Methods

2.1. Preparation of Culturing Strain

Gluconobacter nephelii, previously isolated from rambutan, was obtained from the Department of

Biochemistry and Microbiology, Faculty of Pharmaceutical Science, Chulalongkorn University [30]. Inocula

(3 mL) were transferred into 125-mL glass flasks, which already contained sterile growth medium (27 mL)

82 ENGINEERING JOURNAL Volume # Issue #, ISSN 0125-8281 (http://www.engj.org/)

DOI:10.4186/ej.year.vol.issue.pp

with the composition described as follows: 20 g/L glycerol, 10 g/L yeast extract, 10 g/L peptone, 5 g/L

glucose and 100 mL/L potato extract [30]. Glass flasks and growth medium were autoclaved at 121 °C for

20 mins before use. Initial pH of culture suspension was adjusted to 5.0 by adding 2.0 M NaOH. Flasks

containing microbial seeding were maintained in a temperature controlled shaker at 115 rpm and 30 °C for

24 h.

2.2. Preparation of Agro-industrial Wastes

Corn steep liquor from Friendship Corn Starch Limited (Thailand) and glutamic mother liquor from

Ajinomoto (Thailand) were centrifuged at 10,000g for 10 min to obtain clear supernatant. Soybean meal

samples, purchased from local market, were grinded and submerged in 1 M HCl at the weight ratio of solids

to acid solution at 1:6 at 50 °C for about 20 h, then solids were separated from liquid by filtration and the

pH of clear supernatant was adjusted to neutral by adding 2 M NaOH [31]. Prepared liquid samples from

agro-industrial wastes were stored in the refrigerator at 3 °C to preseved quality. Liquid samples (100 mL)

from each agro-industrial waste were analyzed for CHN contents, which revealed the nitrogen mass

fractions of 4.28%, 5.87% and 2.3% for corn steep liquor, glutamic mother liquor and soybean meal

hydrolysate, respectively.

2.3. Optimal Glycerol Concentrations

Microbial inocula (3 mL) from section 2.1 were mixed in 125 mL glass flask, which contained the growth

medium (27 mL) having the composition as described earlier [30]. Glycerol concentrations in the growth

medium, chosen as experimental variable, were varied from 20 to 120 g/L. Glass flasks were kept in the

temperature controlled shaker at 115 rpm and 30 °C. The initial pH of cell suspension in flasks was

adjusted to 5.0 by the addition of 2 M NaOH. Liquid samples (1 mL) from glass flasks were collected every

6 h interval and analyzed for the concentrations of DHA, glycerol and biomass.

2.4. Selection of Nitrogen Source from Agro-industrial Wastes

Agro-industrial wastes (i.e., corn steep liquor, glutamic mother liquod and soybean meal hydrolysate) were

evaluated as the external nitrogen source to substitute peptone and yeast extract in the growth medium for

G. nephelii. Initial nitrogen concentrations in control and treatment flasks were prepared at 2.1 mg N/L,

which were equal to nitrogen concentrations in the growth medium for G. nephelii as describe in section 2.1

[30]. For control flasks (i.e., C), microbial inocula (3 mL) from section 2.1 were cultured in 125 mL glass

flasks containing 27 mL sterile growth medium [30]. Corn steep liquor (1.48 mL), glutamic mother liquor

(1.44 mL) and soybean meal hydrolysate (1.92 mL) were mixed with microbial inocula (3 mL) and sterile

growth medium (27 mL) in the absence of peptone and yeast extract in 125 mL flasks, which were referred

to as T1, T2 and T3, respectively. For the remaining treatment flasks (i.e., T4, T5 and T6), the same

amounts of corn steep liquor (1.48 mL), glutamic mother liquor (1.44 mL) and soybean meal hydrolysate

(1.92 mL) were also mixed in 125 mL glass flasks containing microbial inocula (3 mL) and growth medium

(27 mL) excluding glycerol. Table 1 summarizes the details of control and treatment flasks in this section.

Initial glycerol concentrations were prepared according to the results from section 2.3. All flasks were

maintained in the temperature controlled shaker at 115 pm and 30 °C while the initial pH of cell suspension

was adjusted to 5.0. Liquid samples (1 mL) from each flask were collected every 6 h interval and analyzed

for biomass and DHA concentrations.

ENGINEERING JOURNAL Volume # Issue #, ISSN 0125-8281 (http://www.engj.org/) 83

DOI:10.4186/ej.year.vol.issue.pp

Table 1. Details of control and treatment flasks in the experiment to select agro-industrial wastes as

external nitrogen source in the growth medium of G. nephelii.

Contents of growth medium

Experiment

Glycerol Nitrogen source Other compositions

C Section 2.3 Peptone and yeast extract [29]

T1 Section 2.3 Corn steep liquor [29]

T2 Section 2.3 Glutamic mother liquor [29]

T3 Section 2.3 Soybean meal hydrolysate [29]

T4 - Corn steep liquor [29]

T5 - Glutamic mother liquor [29]

T6 - Soybean meal hydrolysate [29]

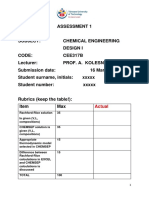

2.5. Bioreactor Description

Internal-loop airlift bioreactor was constructed from two co-axial transparent acrylic cylinders (i.e., outer

cylinder: diameter 20 cm, thickness 0.5 cm, height 135 cm; inner diameter: diameter 10 cm, thickness 0.5

cm, height 90 cm), resulting in total working volume of 32 L (Fig. 1(a)). Sterile air, obtained by passing

compressed air through Gelman Acrodisc filtered paper with average pored size of 0.45 µm, was

introduced into the internal-loop airlift bioreactor through an aquarium air diffuser located at the center

bottom of inner cylinder (i.e., draft tube). Bubble column bioreactor was also built from transparent acrylic

cylinder (i.e., inner diameter 20 cm, thickness 0.5 cm, height 135 cm), resulting in total working volume of

32 L (Fig. 1(b)). Aquarium air diffuser was installed at the bottom of cylinder. Sterile air for bubble

column bioreactor was obtained by filtering compressed air through Gelman Acrodisc paper (average pored

size 0.45 µm). For flat-panel airlift bioreactor as shown in Fig. 1(c), it was assembled from two rectangular

transparent acrylic slabs (i.e., height 50 cm, length 55 cm and thickness 0.5 cm) to create a parallel walls

with distance 20 cm apart. Rectangular baffle (i.e., height 30 cm, length 55 cm and thickness 0.5 cm),

located at the middle between two parallel slabs, was mounted to bioreactor walls about 5 cm above the

curve bottom. The total working volume of flat-panel airlift bioreactor was 32 L. Aquarium air diffusers

were placed at the bottom along the length of riser section to induce liquid circulation within bioreactor.

Sterilized air was obtained by passing compressed air through Gelman Acrodisc filtered paper (average

pored size 0.45 µm).

2.6. Cultivation of G. nephelii in Bioreactors

Cell suspension of G. nephelii (300 mL), prepared according to the procedure described in section 2.1, was

transferred to a 5 L stirred tank bioreactor to combine with the growth medium (2.7 L) containing the same

compositions as indicated in section 2.1 [30]. Initial glycerol concentrations and external nitrogen source

from agro-industrial wastes were prepared according to the results of section 2.3 and 2.4, respectively.

Stirred tank bioreactors were operated in batch mode under room temperature (30 to 32 °C) and constant

aeration to maintain aerobic condition. Cell cultures in stirred tank bioreactor were maintained at pH 5.0

by an automatic additon of 2 M NaOH. Cell cultivation in stirred tank bioreactors was conducted until

obtaining biomass concentration about 10 g/L, then the entire cell suspension (3 L) was transferred and

mixed with sterile growth medium (29 L) containing glycerol and agro-industrial wastes in larger bioreactors

previously described in section 2.5. In this section, three bioreactor designs (i.e., internal-loop airlift,

bubble column and flat-panel airlift) and aeration rates ranged from 0.12 to 0.84 vvm (i.e., vvm = volumes

of air per min/effective volume of bioreactor) were chosen as experimental variables. All bioreactors were

placed under room temperature (30 to 32 °C) while the pH of cell suspension was maintained at 5.0 by an

automatic addition of 2 M NaOH. The batch cultivation of G. nephelii was conducted for 72 h for all

bioreactors. Liquid samples (10 mL) were obtained from each bioreactor at 6 h interval and analyzed for

biomass and DHA concentrations.

84 ENGINEERING JOURNAL Volume # Issue #, ISSN 0125-8281 (http://www.engj.org/)

DOI:10.4186/ej.year.vol.issue.pp

Fig. 1. Schematic drawing (not to scale) of bioreactors for the cultivation of G. nephelii to produce DHA:

(A) internal-loop airlift bioreactor (B) bubble column bioreactor and (C) flat-panel airlift bioreactor.

2.7. Analytical Methods

Liquid samples were centrifuged at 10,000g for 10 min to obtain clear supernatant, which was

subsequently used to determine DHA concentrations according to diphynylamin assay [32,33]. Glycerol

concentrations were determined using HPLC according to the precedure described elsewhere [34].

Biomass concentrations was measured gravimetrically given the linear relationship to the optical density at

660 nm [33]. Experimental data were statistically compared by using one-way ANOVA and performing

Tukey HSD post-hoc test with the significance level of 0.05 [35]. Yield of glycerol conversion to cellular

ENGINEERING JOURNAL Volume # Issue #, ISSN 0125-8281 (http://www.engj.org/) 85

DOI:10.4186/ej.year.vol.issue.pp

biomass (i.e., YX/S) was calculated according to YX/S = -X/S where ΔS and ΔX are the amounts of

glycerol consumption and biomass production during the cultivation, respectively. Yield of glycerol

conversion to DHA (YDHA/S) was calculated according to YDHA/S = -DHA/S where ΔDHA is the

amount of DHA production during the cultivation.

3. Results and Discussion

3.1. Optimal Glycerol Concentrations

G. nephelii fed with the growth medium containing different initial glycerol concentrations from 20 to 120

g/L exhibited similar growth patterns by displaying the lag period for about 6 h, following by the period of

rapid cell growth in the next 18 to 24 h that led to the increase of cell biomass from neligible levels to about

1 to 2 g/L, and finally reaching the stationary period. Similar concentration profiles were observed for

DHA that is the significant DHA production occurred during the period of rapid cell growth before

reaching relatively constant levels. The concurrent increase of cell biomass and DHA concentrations

suggested that DHA is the growth associated product [28]. As shown in Fig. 2, average biomass and DHA

concentrations depended on the initial glycerol concentrations in the growth medium with the highest

biomass (1.96 ± 0.01 g/L) and DHA (55.1 ± 1.89 g/L) concentrations observed when using 80 g/L initial

glycerol. Increasing glycerol concentrations from 20 to 80 g/L resulted in the increase of biomass

concentrations to the maximum before biomass concentrations decreased when applying higher glycerol

concentrations than 80 g/L. The similarity was noticed for DHA concentrations, which initially increased

with increasing glycerol concentrations and followed by the decreasing trend after glycerol concentrations

exceeded 80 g/L. The increase of biomass and DHA concentrations was likely the results of providing

sufficient amounts of essential substrates to support growth and DHA metabolic pathways. Despite the

limited data for G. nephelii, results of previous works on other related bacterial species in genus Gluconobacter

seemed to indicate the declining growth and lower DHA production when maintaining excessive glycerol

concentrations in the growth medium. For examples, adverse effects on growth of DHA production of G.

oxydans were demonstrated when increasing glycerol concentrations over 100 g/L while subsequent work

reported the rapid reduction of both biomass and DHA concentrations in G. frateruii after applying

biodiesel-derived glycerol exceeding 100 g/L [6,36-38]. Product inhibition by DHA was also unlikely in

this experiment since the obtained DHA concentrations were significantly lower than inhibitory thresholds

repored between 65 and 85 g/L for G. oxydans [36,37]. Finally, biomass yields (YX/S) and DHA product

yields (YDHA/S) were determined in the range from 1.7% to 6.3% and 92% to 98%, respectively, which are

comparable to the findings from previous works [6,37].

Fig. 2. Effects of applying different initial glycerol concentrations in the growth medium on cell biomass

and DHA concentrations during the batch cultures of G. nephelii.

86 ENGINEERING JOURNAL Volume # Issue #, ISSN 0125-8281 (http://www.engj.org/)

DOI:10.4186/ej.year.vol.issue.pp

3.2. Selection of Nitrogen Source from Agro-industrial Wastes

Three agro-industrial wastes including corn steep liquor, glutamic mother liquor, soybean meal hydrolysate

were evaluated as the nitrogen source to substitute peptone and yeast extract in the growth medium of G.

nephelii with the results displayed in Fig. 3. The highest biomass (1.96 ± 0.01 g/L) and DHA (55.1 ± 1.89

g/L) concentrations were associated with control flasks, which contained the growth medium comprising

of peptone and yeast extract. Among agro-industrail wastes evaluated, corn steep liquor (i.e., T1) yielded

the highest biomass (1.75 ± 0.23 g/L) and DHA (49.5 ± 3.14 g/L) concentrations as compared to glutamic

mother liquor (i.e. T2) and soybean meal hydrolysate (i.e., T3). Biomass and DHA concentrations

associated with glutamic mother liquor were determined at 1.25 ± 0.02 and 13.2 ± 0.36 g/L, respectively,

while the use of soybean meal hydrolysate produced biomass and DHA concentrations at 1.11 ± 0.05 and

16.5 ± 1.39 g/L, respectively. According to the results presented, the use of corn steep liquor produced

comparable biomass and DHA concentrations to those from control flasks, suggesting that it could be

employed to substitute peptone and yeast extract in the original growth medium for G. nephelii. Previous

works also reported the use of corn steep liquor as the nitrogen source for Gluconobacter. For examples, Hu

et al. concluded that corn steep liquor was equally preferable to peptone and yeast extract as external

nitrogen source in the growth medium for G. oxydans after obtaining insignificant differences in DHA

concentrations (i.e. ≈ 35 g/L) while Lui et al. demonstrated that G. frateruii produced the highest DHA

concentrations (72.6 ± 2.2 g/L) when corn steep liquor was employed as compared to other nitrogen

sources [3,40]. The effectiveness of corn steep liquor in promoting growth and DHA production might be

linked to its compositions and the method of processing raw materials (i.e., corn). Valuable organic

ingredients in raw materials such as reducing sugars, essential minerals and vitamins that were required to

support growth and DHA synthesis might leach into liquid phase during the wet milling process of corn

starch production. Another previous work also demonstrated that corn steep liquor could provide the

complete source of nitrogen, phosphorus, vitamins and other trace elements in microbial growth medium

[39]. Lower effectiveness of glutamic mother liquor was perhaps related to its composition, which

contained mostly lysine and insignificant amount of carbon source [29]. Despite achieving lower

effectiveness in promoting cell growth and DHA production as compared to corn steep liquor, there have

been no reports on the use of glutamic mother liquor or soybean meal hydrolysate as substituted nitrogen

source in the growth medium for Gluconobacter. Moreover, the absence of glycerol in growth media for T4,

T5 and T6 led to ineffective production of biomass and DHA. The obtained results clearly suggested that

the presence of other carbon sources in agro-industrial wastes was unable to influence growth and DHA

production in G. nephelii. This finding agreed with previous results that identified glycerol as the main

substrate for growth and DHA metabolic pathways in the related strain G. oxydans [13].

ENGINEERING JOURNAL Volume # Issue #, ISSN 0125-8281 (http://www.engj.org/) 87

DOI:10.4186/ej.year.vol.issue.pp

Fig. 3. Biomass and DHA concentrations during the batch cultivation of G. nephelii with different nitrogen

sources in the growth medium: control flasks (C) were supplied with nitrogen sources from peptone and

yeast extract; treatment flasks T1, T2 and T3 were supplied with nitrogen sources from corn steep liquor,

glutamic mother liquor and soybean meal hydrolysate, respectively; and T4, T5 and T6 were supplied with

corn steep liquor, glutamic mother liquor and soybean meal hydrolysate, respectively, but without glycerol.

3.3. Cultivation of G. nephelii in Bioreactors

Three bioreactor designs including internal-loop airlift, flat-panel airlift and bubble column were employed

to culture G. nephelii to produce DHA under different aeration rates. In this section, the initial glycerol

concentrations in growth medium were prepared at 80 g/L and corn steep liquor were selected as the

external nitrogen source according to the results of section 3.1 and 3.2, respectively. During the cultivation,

significant amount of foam formation was observed in internal-loop airlift and bubble column bioreactors

when maintaining aeration rates exceeded 0.32 vvm. Due to this operational difficulty, simple mechanical

foam breakers (i.e., plastic paddles mounted to small motor) were placed on top of cylindrical columns of

both bioreactors, leading to significant reduction of foam on water surface up to the aeration rates of 0.84

vvm. Nonetheless, the range of aeration rates (i.e., 0.12 to 0.84 vvm) used in this experiment was still lower

than the values reported in earlier publications, which indicated the range of aeration rates from 0.5 to 2.5

vvm during the batch cultures of G. oxydans [3,40]

Batch cultivation of G. nephelii in different bioreactor designs was carried out for 72 h for a given

aeration rate with the results illustrated in Fig. 4. For the range of aeration rates considered, biomass and

DHA concentrations varied from 2.23 ± 0.04 to 4.58 ± 0.32 g/L and 19.66 ± 0.19 to 46.09 ± 1.01 g/L,

respectively, for cell cultivation in internal-loop airlift bioreactors. Biomass concentrations from flat-panel

airlift and bubble column bioreactors were determined in the range from 1.88 ± 0.12 to 4.37 ± 0.52 g/L

and 1.91 ± 0.05 to 4.3 ± 0.37 g/L, respectively, which were slightly lower than the results from internal-

loop airlift system over the range of aeration rates applied. In contrast, DHA concentrations from internal-

loop airlift bioreactor were significantly higher (p < 0.05) than the results from remaining bioreactors,

which yielded DHA concentrations in the range from 11.83 ± 0.76 to 35 ± 0.89 g/L for flat-panel airlift

bioreactor and 14.51 ± 0.51 to 39.1 ± 1.89 g/L for bubble column. Better performance of internal-loop

airlift bioreactor as compared to other bioreactor configurations might be linked to better distribution of air

bubbles and well-definded liquid flow patterns in bioreactor. Based on our observation, air bubbles

dispersed fully in the riser section of internal-loop airlift bioreactor while they were unable to diffuse into

the section near edges and corners of the flat-panel system so that cells residing in the stagnant zone of flat-

panel airlift bioreactor were likely to receive lesser oxygen, hence resulting in lower DHA production. G.

nephelii cultured in internal-loop airlift bioreactor probably experienced relatively unchanged hydrodynamic

condition due to well-established liquid flow patterns. This is in contrast to cells in bubble column

bioreactor in which their movement in bulk liquid was random as a result of constantly changing liquid

88 ENGINEERING JOURNAL Volume # Issue #, ISSN 0125-8281 (http://www.engj.org/)

DOI:10.4186/ej.year.vol.issue.pp

motion. The established liquid circulation in internal-loop airlift bioreactor was cited as one of the reasons

for higher growth and astaxanthin production by H. pluvialis as compared to the cultivation in bubble

column bioreactor [20].

Fig. 4. Biomass and DHA concentrations during the batch cultivation of G. nephelii in internal-loop airlift

bioreactor (i.e., IAB), flat-panel airlift bioreactor (i.e., FAB) and bubble column bioreactor (i.e., BC)

subjected to increasing aeration rates.

It should also be pointed out that the range of DHA concentrations (i.e., 11.83 ± 0.76 to 19.66 ± 0.19

g/L) when maintaining the aeration rates at 0.12 vvm in bioreactors were lower than the results of flask

cultivation, which yielded DHA concentrations as high as 49.5 ± 3.14 g/L. Since Gluconobacter is the

oblique aerobic species, it was possible that at this aeration rates (i.e., 0.12 vvm) oxygen availability in

bioreactors might become the limiting factor on DHA production after performing cell cultivation in larger

bioreactor (i.e., 32 L). By increasing aeration rates from 0.12 to 0.84 vvm, the effects of oxygen limitation

on DHA production could be reduced as can be seen by the significant rise of DHA concentrations in all

bioreactor designs. For internal-loop airlift bioreactor, DHA concentrations increased from 19.66 ± 0.19

to 46.09 ± 1.01 g/L when the aeration rates were increased from 0.16 to 0.64 vvm. Further increase of

aeration rates to 0.84 vvm resulted in lower DHA concentrations measured at 37.28 ± 1.90 g/L. Similar

DHA concentration profiles were observed for the remaining bioreactors, where the maximum DHA

concentrations were determined at 35 ± 0.89 and 39.1 ± 1.89 g/L for flat-panel airlift and bubble column

bioreactors, respectively, when maintaining aeration rates at 0.64 vvm. Despite the requirement for aerobic

condition during DHA production, limited data were available on the influence of aeration rates on DHA

ENGINEERING JOURNAL Volume # Issue #, ISSN 0125-8281 (http://www.engj.org/) 89

DOI:10.4186/ej.year.vol.issue.pp

production in Gluconobacter [3]. Along with the results presented in current work, only few publications

demonstrated the dependency of DHA concentrations on aeration rates in the upflow oxygenated

bioreactor systems. In those works, DHA concentrations increased significantly after increasing aeration

rates in bubble column and airlift bioreactors up to 1.5 vvm, resulting in DHA concentrations

approximately 35 to 39 g/L [3,40]. Finally, DHA yield (YDHA/S) associated with the optimal operating

condition (i.e., 0.64 vvm) were determined at 91% for this work.

4. Conclusions

Series of batch cultivation were conducted to culture G. nephelii to produce DHA. Initial glycerol

concentrations in growth medium should be prepared at 80 g/L while corn steep liquor was identified as

the preferred nitrogen source as compared to glutamic mother liquor and soybean meal hydrolysate.

Subsequent cultivation of G. nephelii in larger bioreactors revealed that internal-loop airlift bioreactor yielded

higher DHA concentrations as compared to flat-panel airlift and bubble column bioreactors. Increasing

aeration rates up to 0.84 vvm were able to decrease oxygen-limitation on DHA production. The maximum

DHA concentrations measured at 46.09 ± 1.01 g/L were associated with internal-loop airlift bioreactor

when maintaining the aeration rates at 0.64 vvm.

Acknowledgement

This work was supported by the Ratchadapiseksompot Endowment Fund of the Chulalongkorn University

(CU-58-008-FW), the National University Project, Office of Higher Education Commission (WCU-58-007-

FW), and the Thailand Research Fund (IRG5780014).

References

[1] Z. Wang, J. Zhuge, H. Fang, and B. A. Prior, “Glycerol production by microbial fermentation: A

review,” Biotechnol. Adv., vol. 19, pp. 201-223, 2001.

[2] D. Hekmat, R. Bauer, and J. Fricke, “Optimization of the microbial synthesis of dihydroxyacetone

from glycerol with Gluconobacter oxydans,” Bioproc. Biosyst. Eng., vol. 26, pp. 109-116, 2003.

[3] Z. C. Hu, Y. G. Zheng, and Y. C. Shen, “Use of glycerol for producing 1,3-dihydroxyacetone by

Gluconobacter oxydans in airlift bioreactor,” Bioresour. Technol., vol. 102, pp. 7177-7182, 2011.

[4] M. Bicker, S. Endres, L. Ott, and H. Vogel, “Catalytical conversion of carbohydrate in subcritical

water: a new chemical process for lactic acid production,” J. Mol. Catal. A Chem., vol. 239, pp. 151-157,

2005.

[5] L. Ma, W. Lu, Z. Xia, and J. Wen, “Enhancement of dihydroxyacetone production by mutant of

Gluconobacter oxydans,” Biochem. Eng. J., vol. 49, pp. 61-67, 2010.

[6] Y. P. Liu, Y. Sun, C. Tan, H. Li, X. J. Zheng, K. Q. Jin, and G. Wang, Efficient product of

dihydroxyacetone from biodiesel-derived crude glycerol by newly isolated Gluconobacter frateurii,”

Bioresour. Technol., vol. 142, pp. 382-389, 2013.

[7] H. T. T. Nguyen and E. Nevoigt, “Engineering of Saccharomyces cerevisiae for the production of

dihydroxyacetone (DHA) from sugars: A proof of concept,” Metab. Eng., vol. 11, no. 6, pp. 335-346,

2009.

[8] Z. Liu, Z. Hu, H. Zheng, and Y. Shen, “Optimization of cultivation conditions for the production of

1,3-dihydroxyacetone by Pichia membranifaciens using response surface methodology,” Biochem. Eng. J.,

vol. 38, pp. 285-291, 2007.

[9] R. E. Asnis and A. F. Brodie, “A glycerol dehydrogenase from Escherichia coli,” Biol. Chem., vol. 203, pp.

153-159, 1953.

[10] O. M. Neijssel, S. Hueting, K. L. Crabbendam, and D. W. Tempest, “Dual pathways of glycerol

assimilation in Klebsiella aerogenes NCIB 418,” Arch. Microbiol., vol. 104, pp. 83-87, 1975.

[11] N. Kato, H. K. M. Shimao, and C. Sakazawa, “Dihydroxyacetone production from methanol by a

dihydroxyacetone kinase deficient mutant of Hansenula polymorpha,” Appl. Microbiol. Biotechnol., vol. 23,

pp. 180-186, 1986.

[12] K. Nabe, N. Izuo, S. Yamada, and I. Chibata, “Conversion of glycerol to dihydroxyacetone by

immobilized whole cells of Acetobacter xylinum,” Appl. Microbiol. Biotechnol., vol. 39, pp. 1056-1060, 1979.

90 ENGINEERING JOURNAL Volume # Issue #, ISSN 0125-8281 (http://www.engj.org/)

DOI:10.4186/ej.year.vol.issue.pp

[13] J. Svitel and E. S. Senkal, “Product yield and by-product formation in glycerol conversion to

dihydroxyacetone by Gluconobacter oxydans,” J. Ferment. Bioeng., vol. 78, no. 5, pp. 351-355, 1994.

[14] J. Kommanee, S. Tanasupawat, P. Yukphan, T. Malimas, Y. Muramatsu, Y. Nakagawa, and Y.

Yamada, “Gluconobacter nephelii sp. nov., an acetic acid bacterium in the class Alphaproteobacteria,” Int. J.

Evol. Microbiol., vol. 61, pp. 2117-2122, 2011.

[15] P. Semjonovs, L. Shakirova, R. Treimane, K. Shvirksts, L. Auzina, I. Cleenwerck, and P. Zikmanis,

“Production of extracellular fructans by Gluconobacter nephelii P1464,” Letts. Appl. Microbiol., vol. 62, pp.

145-152, 2015.

[16] U. Deppenmeier, M. Hoffmeister, and C. Prust, “Biochemistry and biotechnological applications of

Gluconobacter strains,” Appl. Microbiol. Biotechnol., vol. 60, pp. 233-242, 2002.

[17] C. Prust, M. Hoffmeister, H. Liesegang, A. Wiezer, and W. F. Fricke. “Complete genome sequence of

the acetic acid bacterium Gluconobacter oxydans,” Nat. Biotechnol., vol. 23, pp. 195-200, 2005.

[18] M. Li, J. Wu, and J. Lin, “Expression of Vitreoscilla hemoglobin enhances cell growth and

dihydroxyacetone production in Gluconobacter oxydans,” Curr. Microbiol., vol. 61, pp. 370-375, 2010.

[19] S. Krichnavaruk, W. Loataweesup, S. Powtongsook, and P. Pavasant, “Optimal growth conditions and

the cultivation of Chaetoceros calcitrans in airlift photobioreactor,” Chem Eng. J., vol. 105, pp. 91-98,

2005.

[20] K. Kaewpintong, A. Shotipruk, S. Powtongsook, and P. Pavasant, “Photoautotrophic high-density

cultivation of vegetative cells of Haematococcus pluvialis in airlift bioreactor,” Bioresour. Technol., vol. 98,

pp. 288-295, 2007.

[21] I. Sikula, M. Jurascik, and J. Markos, “Modeling of fermentation in an internal loop airlift bioreactor,”

Chem. Eng. Sci., vol. 62, pp. 5216-5221, 2007.

[22] Y. G. Zheng, X. L. Chen, and Z. Wang, “Microbial biomass production from rice straw hydrolysate in

airlift bioreactors,” J. Biotechnol., vol. 118, pp. 413-420, 2005.

[23] K. Issarapayup, S. Powtongsook, and P. Pavasant, “Economical review of Haematococcus pluvialis

culture in flat-panel airlift photobioreactor,” Aqua. Eng., vol. 44, pp. 65-71, 2011.

[24] W. Ritcharoen, S. Powtongsook, K. Kangvansaichol, and P. Pavasant, “Effect of daytime CO2

supplement on productivity and biochemical composition of Scenedesmus armatus under outdoor

cultivation,” Prep. Biochem. Biotechnol., vol. 46, no. 3, pp. 267-273, 2016.

[25] S. Silapakul, S. Powtongsook, and P. Pavasant, “Nitrogen compounds removal in a packed bed

external loop airlift bioreactor,” Korean J. Chem. Eng., vol. 22, no. 2, pp. 393-398, 2005.

[26] C. P. M. L. Fontes, M. S. Silveira, A. A. Guilhermme, F. A. N. Fernandes, and S. Rodrigues,

“Substitution of yeast extract by ammonium sulfate for mannitol production in cashew apple juice,”

Biocatal. Agri. Biotechnol., vol. 2, pp. 69-75, 2013.

[27] C. Kaewrat, “Production of 1,3-propanediol from biodiesel-based glycerol by Clostridium butyricum

DSM 5431 and reduction of production expense by modifying the composition of culture medium,”

Master of Engineering thesis, Department of Chemical Engineering, Chulalongkorn University,

Bangkok, Thailand, 2011.

[28] S. Wei, Q. Song, and D. Wei, “Production of Gluconobacter oxydans cells from low-cost culture medium

for conversion of glycerol to dihydroxyacetone,” Prep. Biochem. Biotechnol., vol. 37, pp. 113-121, 2007.

[29] P. Thongkhaw, “Effects of Clostridium strains and nitrogen sources on butanol fermentation,” Master

of Engineering thesis, Department of Chemical Engineering, Chulalongkorn University, Bangkok,

Thailand, 2012.

[30] J. Kommanee, “Taxonomy of acetic acid bacteria and oxidative products of Acetobacter and

Gluconobacter strains,” Doctor of Philosophy thesis in Pharmaceutical Science, Chulalongkorn

University, 2010.

[31] M. B. A. G. Al-Bahri, S. A. AL-Naimi, and S. H. Ahammed, “The optimum conditions for production

of soya peptone by acidic hydrolysis of soya proteins,” Al-Khwarizmi Eng., vol. 5, no. 1, pp. 1-19, 2009.

[32] V. A. Karklinya, A. J. Vereris, and D. R. Zhigure, “Dihydroxyacetone measurement in liquids of

Acetobacter suboxydans,” Prikl. Biokhim. Microbiol., vol. 18, pp. 262-265, 1985.

[33] Z. C. Hu and Y. G. Zheng, “Enhancement of 1,3-dihydroxyacetone production by a UV-induced

mutant Gluconobacter oxydans with DO control strategy,” Appl. Biochem. Biotechnol., vol. 165, pp. 1152-

1160, 2011.

[34] T. Suratago and K. Nootong, “Production of 1,3-propanediol by Clostridium butyricum DSM 5431 in an

anaerobic moving-bed bioreactor,” Macedonian J. Chem. Chem. Eng., vol. 31, no. 2, pp. 245-253, 2012.

ENGINEERING JOURNAL Volume # Issue #, ISSN 0125-8281 (http://www.engj.org/) 91

DOI:10.4186/ej.year.vol.issue.pp

[35] D. C. Montgomery and C. R. George, Applied Statistics and Probability for Engineers, 6th ed. New York:

John Wiley & Sons, 2013; p. 605.

[36] R. Bauer, N. Katsikis, S. Varga, and D. Hekmat, “Study of the inhibitory effect of the product

dihydroxyacetone on Gluconobacter oxydans in semi-continuous two-stage repeated-fed-batch process,”

Bioproc. Biosyst. Eng., vol. 28, pp. 37-43, 2005.

[37] C. Claret, J. M. Salmon, C. Romieu, and A. Bories, “Physiology of Gluconobacter oxydans during

dihydroxyacetone production from glycerol,” Appl. Microbiol Biotechnol., vol. 41, pp. 359-365, 1994.

[38] S. Yamada, K. Nabe, N. Izuo, M. Wada, and I. Chibata, “Fermentative production of

dihydroxyacetone by Acetobacter suboxydans ATCC621,” J. Ferment. Technol., vol. 57, pp. 215-220, 1979.

[39] R. P. Kona, N. Qureshi, and N. J. S. Pai, “Production of glucose oxidase using Aspergillus niger and

corn steep liquor,” Bioresour. Technol., vol. 78, pp. 123-126, 2001.

[40] Z. C. Hu, Z. Q. Liu, Y. G. Zheng, and Y. C. Shen, “Production of 1,3-dihydroxyacetone from glycerol

by Gluconobacter oxydans ZJB09112,” J. Microbiol. Biotechnol., vol. 20, no. 2, pp. 340-345, 2010.

92 ENGINEERING JOURNAL Volume # Issue #, ISSN 0125-8281 (http://www.engj.org/)

You might also like

- Journal of Advanced Scientific ResearchDocument5 pagesJournal of Advanced Scientific Researchzulaika22No ratings yet

- Yee Sang 2014Document14 pagesYee Sang 2014Taxman HarrisonNo ratings yet

- tmp4E2F TMPDocument13 pagestmp4E2F TMPFrontiersNo ratings yet

- Cultivation of Oscillatoria SP in Dairy Waste Water in Two Stage Photo Bioreactors For Biodiesel ProductionDocument10 pagesCultivation of Oscillatoria SP in Dairy Waste Water in Two Stage Photo Bioreactors For Biodiesel ProductionMatthew JohnsonNo ratings yet

- Bajaj, Singhal. 2011. Flocculation Properties of Poly (γ-Glutamic Acid) Produced from Bacillus subtilis IsolateDocument8 pagesBajaj, Singhal. 2011. Flocculation Properties of Poly (γ-Glutamic Acid) Produced from Bacillus subtilis IsolateAzb 711No ratings yet

- Energies: Improving Production of Bioethanol From Duckweed (Landoltia Punctata) by Pectinase PretreatmentDocument14 pagesEnergies: Improving Production of Bioethanol From Duckweed (Landoltia Punctata) by Pectinase PretreatmentDeboraNainggolanNo ratings yet

- Pretreatment Conditions of Rice Straw For Simultaneous Hydrogen and Ethanol Fermentation by Mixed CultureDocument8 pagesPretreatment Conditions of Rice Straw For Simultaneous Hydrogen and Ethanol Fermentation by Mixed CultureAldrienNo ratings yet

- Optimization of Biogas Production From Co-Digestion of Whey andDocument10 pagesOptimization of Biogas Production From Co-Digestion of Whey andRahman çalhanNo ratings yet

- Production of Fermentable Sugars by Combined Chemo-Enzymatic Hydrolysis of Cellulosic Material For Bioethanol ProductionDocument9 pagesProduction of Fermentable Sugars by Combined Chemo-Enzymatic Hydrolysis of Cellulosic Material For Bioethanol ProductionJerome JavierNo ratings yet

- chuyên đề nhựa cần dịch - lấy hìnhDocument10 pageschuyên đề nhựa cần dịch - lấy hìnhDao YenNo ratings yet

- Pilot-Scale Lactic Acid Production Via Batch Culturing of Lactobacillus Sp. RKY2 Using Corn Steep Liquor As A Nitrogen SourceDocument6 pagesPilot-Scale Lactic Acid Production Via Batch Culturing of Lactobacillus Sp. RKY2 Using Corn Steep Liquor As A Nitrogen SourcekopisusumantapNo ratings yet

- Accepted Manuscript: Bioresource TechnologyDocument18 pagesAccepted Manuscript: Bioresource TechnologyRuxandra BadiuNo ratings yet

- Shafkat Rahman PDFDocument7 pagesShafkat Rahman PDFAbu BakkarNo ratings yet

- Production of Acetone-Butanol-ethanol From Spoilage Date PalmDocument7 pagesProduction of Acetone-Butanol-ethanol From Spoilage Date PalmI-Twins RgnNo ratings yet

- Fermentation and Recovery of L-Glutamic - Acid - FromDocument8 pagesFermentation and Recovery of L-Glutamic - Acid - FromPrachi BhoirNo ratings yet

- ViewFreeArticle PDFDocument5 pagesViewFreeArticle PDFMaria Alyssa EdañoNo ratings yet

- Preparation and Physical Characterization of Alginate Microparticles Using Air Atomization MethodDocument12 pagesPreparation and Physical Characterization of Alginate Microparticles Using Air Atomization MethodfacarofNo ratings yet

- Shahzad 2019 IOP Conf. Ser. Earth Environ. Sci. 257 012025Document10 pagesShahzad 2019 IOP Conf. Ser. Earth Environ. Sci. 257 012025Dr-Muhammad Asim UmerNo ratings yet

- Research 6Document7 pagesResearch 6UgoStanNo ratings yet

- Polymeric Cellulose Derivative Carboxymethyl Cellulose As Useful Organic Flocculant Against Industrial Waste WatersDocument7 pagesPolymeric Cellulose Derivative Carboxymethyl Cellulose As Useful Organic Flocculant Against Industrial Waste WatersJR NilNo ratings yet

- Analisa KuantitatifDocument5 pagesAnalisa KuantitatifAswina NadiaNo ratings yet

- Enhanced Penicillin Production by Oligosaccharides From Batch Cultures of Penicillium Chrysogenum in Stirred-Tank ReactorsDocument6 pagesEnhanced Penicillin Production by Oligosaccharides From Batch Cultures of Penicillium Chrysogenum in Stirred-Tank Reactorsazzahra ghina fadillahNo ratings yet

- Jurnal 4Document7 pagesJurnal 4SalmaNo ratings yet

- Supercritical Fluid Extraction of Byproduct From PECAN (Caryaillinoinensis (Wangenh.) K. Koch) OIL INDUSTRYDocument7 pagesSupercritical Fluid Extraction of Byproduct From PECAN (Caryaillinoinensis (Wangenh.) K. Koch) OIL INDUSTRYGuillermo Serralde PaezNo ratings yet

- GSJ7016 (Aryan - Ramteke)Document20 pagesGSJ7016 (Aryan - Ramteke)CH24Aryan.RamtekeNo ratings yet

- Research Article Bacillus SubtilisDocument10 pagesResearch Article Bacillus SubtilisDương Nguyễn Thùy DungNo ratings yet

- Biotechnology Reports: Suvra Sadhukhan, Raffaella Villa, Ujjaini SarkarDocument10 pagesBiotechnology Reports: Suvra Sadhukhan, Raffaella Villa, Ujjaini SarkarAndres MarinNo ratings yet

- Use of CowDung As A Source of Bio Culturing For ETPDocument7 pagesUse of CowDung As A Source of Bio Culturing For ETPRG SegaranNo ratings yet

- Energies: Second Generation Ethanol Production From Brewers' Spent GrainDocument12 pagesEnergies: Second Generation Ethanol Production From Brewers' Spent GrainmulerNo ratings yet

- CNSL Process For BDDocument27 pagesCNSL Process For BDshyam murariNo ratings yet

- ArticuloDocument16 pagesArticuloErick NestaresNo ratings yet

- Microbial Production of Polyhydroxybutyrate, A Biodegradable Plastic Using Agro-Industrial Waste ProductsDocument11 pagesMicrobial Production of Polyhydroxybutyrate, A Biodegradable Plastic Using Agro-Industrial Waste Productsashuna249396No ratings yet

- Bio-Hydrogen Generation From Mixed Fruit Peel Waste Using Anaerobic Contact FilterDocument7 pagesBio-Hydrogen Generation From Mixed Fruit Peel Waste Using Anaerobic Contact FilterLiviaBFNo ratings yet

- Microalgal Lipid Extraction and Evaluation of Single-Step Biodiesel ProductionDocument10 pagesMicroalgal Lipid Extraction and Evaluation of Single-Step Biodiesel ProductionMuhammad AminNo ratings yet

- 2021-Bioethanol Production From Azolla FiliculoidesDocument13 pages2021-Bioethanol Production From Azolla FiliculoidesLili MarleneNo ratings yet

- Yi-Huang Chang, Ku-Shang Chang, Cheng-Wei Huang, Chuan-Liang Hsu, Hung-Der JangDocument8 pagesYi-Huang Chang, Ku-Shang Chang, Cheng-Wei Huang, Chuan-Liang Hsu, Hung-Der JangNoor SalamNo ratings yet

- Fermentation and Crystallization of Succinic Acid From Actinobacillus Succinogenes ATCC55618 Using Fresh Cassava Root As The Main SubstrateDocument11 pagesFermentation and Crystallization of Succinic Acid From Actinobacillus Succinogenes ATCC55618 Using Fresh Cassava Root As The Main SubstrateYudid Anaya CaroNo ratings yet

- Xylinus From Agricultural Waste: Biotechnological Production of Cellulose by GluconacetobacterDocument8 pagesXylinus From Agricultural Waste: Biotechnological Production of Cellulose by GluconacetobacterpaolealNo ratings yet

- Integrated Production of Biofuels and Succinic Acid From Biomass After Thermochemical PretreatmentsDocument16 pagesIntegrated Production of Biofuels and Succinic Acid From Biomass After Thermochemical PretreatmentsJames TomosoriNo ratings yet

- ScribdDocument9 pagesScribdSrinivas ReddyNo ratings yet

- Optimization of Cellulase Enzyme From Vegetable Waste by Using Trichoderma Atroviride in Solid State FermentationDocument6 pagesOptimization of Cellulase Enzyme From Vegetable Waste by Using Trichoderma Atroviride in Solid State FermentationIOSRjournalNo ratings yet

- 1 s2.0 S2214785316303583 MainDocument6 pages1 s2.0 S2214785316303583 MainMaría Camila GonzalezNo ratings yet

- 13 67 Lipase DOtensionDocument7 pages13 67 Lipase DOtensionNena Och Exha Part IINo ratings yet

- Biohydrogen Production From Palm Oil Mill Effluent Pretreated by Chemical Methods Using Thermoanaerobacterium-Rich SludgeDocument8 pagesBiohydrogen Production From Palm Oil Mill Effluent Pretreated by Chemical Methods Using Thermoanaerobacterium-Rich SludgefransiscaNo ratings yet

- Value-Added Utilization of Crude Glycerol From BiodieselDocument16 pagesValue-Added Utilization of Crude Glycerol From BiodieselKaweepoj SiwanartnusornNo ratings yet

- Inmovilizacion de MicroorganismosDocument18 pagesInmovilizacion de MicroorganismosArmando Yuseth CatalanNo ratings yet

- Solvent Extraction of PullulanDocument7 pagesSolvent Extraction of PullulananirbanNo ratings yet

- C. Cohnii Fed-BatchDocument7 pagesC. Cohnii Fed-BatchLucilaFernandezNo ratings yet

- Bioproduction of Hydrogen by Simultaneous SaccharificationDocument8 pagesBioproduction of Hydrogen by Simultaneous SaccharificationProfessor Douglas TorresNo ratings yet

- Physiological and Microbiological Studies On Production of Alkaline Protease From Locally Isolated Bacillus SubtilisDocument11 pagesPhysiological and Microbiological Studies On Production of Alkaline Protease From Locally Isolated Bacillus SubtilisLaorenciaNo ratings yet

- 2 PBDocument9 pages2 PBAMELIA ULMNo ratings yet

- Bioetanol Por TrichodermaDocument7 pagesBioetanol Por TrichodermaJeah Gogh GoahhNo ratings yet

- Enzymatic Saccharification and Fermentation of CelDocument10 pagesEnzymatic Saccharification and Fermentation of CelSharmaNo ratings yet

- Biosurfactant Production by Bacillus Strains Isolated From Sugar Cane Mill WastewatersDocument12 pagesBiosurfactant Production by Bacillus Strains Isolated From Sugar Cane Mill WastewatersyutefupNo ratings yet

- Oonkhanond 2017Document37 pagesOonkhanond 2017Gebby FebriliaNo ratings yet

- Precise Pretreatment of Lignocellulose Relating Substrate Modification With Subsequent Hydrolysis and Fermentation To Products and by ProductsDocument15 pagesPrecise Pretreatment of Lignocellulose Relating Substrate Modification With Subsequent Hydrolysis and Fermentation To Products and by Productsjadofo6No ratings yet

- Optimization For The Production of Cellulase Enzyme From Municipal Solid Waste Residue by Two Novel Cellulolytic FungiDocument9 pagesOptimization For The Production of Cellulase Enzyme From Municipal Solid Waste Residue by Two Novel Cellulolytic FungiThao ChaungocNo ratings yet

- Fungi and Lignocellulosic BiomassFrom EverandFungi and Lignocellulosic BiomassChristian P KubicekNo ratings yet

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationFrom EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationRating: 3 out of 5 stars3/5 (1)

- Black Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.From EverandBlack Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.Rating: 4 out of 5 stars4/5 (1)

- Vitaminas With Cover Page v2Document69 pagesVitaminas With Cover Page v215041168No ratings yet

- Encapsulation of Lactobacillus Window Drying: Fermentum K73 by RefractanceDocument15 pagesEncapsulation of Lactobacillus Window Drying: Fermentum K73 by Refractance15041168No ratings yet

- Aplicaciones Potenciales Del SueroDocument13 pagesAplicaciones Potenciales Del SueroErica marcela PinedaNo ratings yet

- Probiotics Media: Significance, Challenges, and Future Perspective - A Mini ReviewDocument13 pagesProbiotics Media: Significance, Challenges, and Future Perspective - A Mini Review15041168No ratings yet

- A Narrative Review On MicroencapsulationDocument31 pagesA Narrative Review On Microencapsulation15041168No ratings yet

- Aerobic BalDocument23 pagesAerobic Bal15041168No ratings yet

- Brodkorb (2019)Document73 pagesBrodkorb (2019)15041168No ratings yet

- Microencapsulación de Carotenoide de Boniato de Pulpa Naranja y Concentrado de Proteína de SueroDocument8 pagesMicroencapsulación de Carotenoide de Boniato de Pulpa Naranja y Concentrado de Proteína de Suero15041168No ratings yet

- Huang 2004Document8 pagesHuang 200415041168No ratings yet

- Limosilactobacillus Fermentum ATCC-14931Document14 pagesLimosilactobacillus Fermentum ATCC-1493115041168No ratings yet

- Ardestani Et Al., 2015Document8 pagesArdestani Et Al., 201515041168No ratings yet

- Gastric Digestion in VivoDocument25 pagesGastric Digestion in Vivo15041168No ratings yet

- Lactic Acid BacteriaDocument43 pagesLactic Acid Bacteriaravi_seth_9No ratings yet

- Low-Cost Culture Medium For Biomass Production of Lactic Acid BacteriaDocument9 pagesLow-Cost Culture Medium For Biomass Production of Lactic Acid Bacteria15041168No ratings yet

- Development of Food Grade MediaDocument8 pagesDevelopment of Food Grade Media15041168No ratings yet

- Fernández de Palencia, 2008Document31 pagesFernández de Palencia, 200815041168No ratings yet

- Shoji 2013Document6 pagesShoji 201315041168No ratings yet

- Avila Reyes2014Document8 pagesAvila Reyes201415041168No ratings yet

- Heenan 2002Document6 pagesHeenan 2002Jorge SaenzNo ratings yet

- Marteau, 1997Document7 pagesMarteau, 199715041168No ratings yet

- Omay 2012Document8 pagesOmay 201215041168No ratings yet

- 2014 Chemistry Cbse Sample PaperDocument26 pages2014 Chemistry Cbse Sample PaperVijaykumar Shukla100% (1)

- Indian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionDocument7 pagesIndian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionAlok DoshiNo ratings yet

- Gasket Brochure Complete MDS EngDocument20 pagesGasket Brochure Complete MDS EngAditya JainNo ratings yet

- As1 Cee317b 2022Document4 pagesAs1 Cee317b 2022Pheletso Andrias MoloantoaNo ratings yet

- Sedimentation and Sedimentation TanksDocument43 pagesSedimentation and Sedimentation TanksDevendra Sharma80% (10)

- Lasers For Industrial Applications - 56850 - 12Document15 pagesLasers For Industrial Applications - 56850 - 12ΈλσαΟγκρένιNo ratings yet

- BL4S Results 2021Document2 pagesBL4S Results 2021Sadika AkhterNo ratings yet

- Abg Analysis-1Document22 pagesAbg Analysis-1PAMNo ratings yet

- PPIIDocument1,106 pagesPPIIVineeta SharmaNo ratings yet

- Smaw 12 Module 1 Grade 12Document39 pagesSmaw 12 Module 1 Grade 12Francis Rico Mutia Rufon100% (14)

- Ship PreCargo MatrixDocument4 pagesShip PreCargo MatrixRigel NathNo ratings yet

- Aromatic Substi-Wps OfficeDocument54 pagesAromatic Substi-Wps OfficeTariq ZiaNo ratings yet

- Improvement of Biocomposite Properties Based Tapioca Starch and Sugarcane Bagasse Cellulose NanofibersDocument7 pagesImprovement of Biocomposite Properties Based Tapioca Starch and Sugarcane Bagasse Cellulose Nanofibersyasin AhmedNo ratings yet

- Assay of Chloroquine Phosphate Experiment No.: Date: Aim: To Perform The Assay of Chloroquine Phosphate. Reference: RequirementsDocument3 pagesAssay of Chloroquine Phosphate Experiment No.: Date: Aim: To Perform The Assay of Chloroquine Phosphate. Reference: RequirementsDinesh ThakkarNo ratings yet

- Calculating The True Cost of SteamDocument2 pagesCalculating The True Cost of Steamisquare77No ratings yet

- Yunus 2014Document10 pagesYunus 2014La Ode Muhamad RusliNo ratings yet

- Biotech Math Problems Part1 AnswersDocument5 pagesBiotech Math Problems Part1 AnswersAmanpreet ManderNo ratings yet

- Biochemistry Notes - Nucleotide MetabolismDocument5 pagesBiochemistry Notes - Nucleotide MetabolismneedthisforepiNo ratings yet

- KBR - Ammonia Specific ExamplesDocument16 pagesKBR - Ammonia Specific Examplesqwerty9123460% (5)

- Fundamentals of Machine Design 2, Orlov (OCR, BM) PDFDocument207 pagesFundamentals of Machine Design 2, Orlov (OCR, BM) PDFarcelitas75% (4)

- LVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateDocument1 pageLVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateEMTC EMTCNo ratings yet

- Kluber PresentationDocument79 pagesKluber PresentationZegera MgendiNo ratings yet

- Dutch Pollutant StandardsDocument5 pagesDutch Pollutant Standardsumair2kplus492No ratings yet

- Chemical Industry ReleasesDocument152 pagesChemical Industry ReleasesKiran KrishnanNo ratings yet

- Copper Sheet, Strip, Plate, and Rolled Bar: Standard Specification ForDocument7 pagesCopper Sheet, Strip, Plate, and Rolled Bar: Standard Specification ForgoggerNo ratings yet

- Manufacture of RadiopharmaceuticalsDocument9 pagesManufacture of RadiopharmaceuticalsRainMan75No ratings yet

- Basic Molecules of LifeDocument78 pagesBasic Molecules of LifeRavi ParkheNo ratings yet

- GR 12 Biology Moddel ExamDocument8 pagesGR 12 Biology Moddel ExamDawit MarkosNo ratings yet

- HT Solved NumericalsDocument56 pagesHT Solved NumericalsKiran AkkoliNo ratings yet

- Summer Training ProgramDocument21 pagesSummer Training ProgramAyan BorgohainNo ratings yet