Professional Documents

Culture Documents

V2-0 SIVACON S4 at IEC 61439 - en - 1703

Uploaded by

David LimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V2-0 SIVACON S4 at IEC 61439 - en - 1703

Uploaded by

David LimCopyright:

Available Formats

SIVACON S4

IEC 61439 design verification

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten. siemens.com/lowvoltage

SIVACON S4

IEC 61439 design verification

• Overview

• IEC 61439 @SIVACON S4

• Additional tests

• Summary

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

SIVACON S4

IEC 61439 design verification

• Overview

• IEC 61439 @SIVACON S4

• Additional tests

• Summary

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439 History

Milestones of Switchboard Standards

1896 First publication of standards, rules and guidelines of the VDE with first security rules for switching and distribution boards.

1941 VDE 0100 "Regulations on the installation of power circuits with nominal voltages below 1000V"

1958 VDE 0100 §29 N Requirements for insulation, short-circuit strength and protection against contact with live parts

1967 VDE 0660 Teil 5 factory assembled switchgear assemblies

(1973) (EN (IEC) 60439)

VDE 0100 §30 b: Construction requirements for not factory

1973 assembled switching and distribution boards

1984 VDE 0660 Teil 500 (TTA) type-tested switchgear and VDE 0660 Teil 500: (PTTA) Partially type-tested switchgear and

controlgear assemblies controlgear assemblies

(1985)

(EN (IEC) 60439-1) (EN (IEC) 60439-1)

joint construction requirements

IEC 61439-1/2 New standard for power switchgear and controlgear assemblies

2009 VDE 0660-600-1/2

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 60439 problems

Reasons for the new standard series IEC 61439

With the new IEC 61439 the series of standards for low-voltage switchgear and controlgear assemblies was radically

revised and restructured. The main reasons for this were the following key points of criticism about the previous

IEC 60 439 standard.

Difficult to understand IEC60439 part 1 with Some manufacturers

TTA / PTTA dilemma

and execute double function and specific market

segments are ignoring

• Grey areas leading • Wrongly interpreted • Product standard the IEC 60439.

to subjective categories and

interpretations • Limited applicability • General

• Poorly structured requirements for all

• classification useless

content other standards of

for end customers

this series

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 60439 problems

Reasons for the new standard series IEC 61439

With the new IEC 61439 the series of standards for low-voltage switchgear and controlgear assemblies was radically

revised and restructured. The main reasons for this were the following key points of criticism about the previous

IEC 60 439 standard.

Difficult to understand IEC60439 part 1 with Some manufacturers

TTA / PTTA dilemma

and execute double function and specific market

segments are ignoring

• Grey areas leading • Wrongly interpreted • Product standard the IEC 60439.

to subjective categories and

interpretations • Limited applicability • General

• Poorly structured requirements for all

• classification useless

content other standards of

for end customers

this series

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 60439 problems

Reasons for the new standard series IEC 61439

With the new IEC 61439 the series of standards for low-voltage switchgear and controlgear assemblies was radically

revised and restructured. The main reasons for this were the following key points of criticism about the previous

IEC 60 439 standard.

Difficult to understand IEC60439 part 1 with Some manufacturers

TTA / PTTA dilemma

and execute double function and specific market

segments are ignoring

• Grey areas leading • Wrongly interpreted • Product standard the IEC 60439.

to subjective categories and

interpretations • Limited applicability • General

• Poorly structured requirements for all

• classification useless

content other standards of

for end customers

this series

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

Significant Modification IEC 60439

• From empty enclosure standards IEC 62208 additional criteria added in IEC 61439-1

classification 08.x

• Distribution of IEC 61439-1 in general section and product standards -2, -3, ...

• Elimination of the categories TTA and PTTA

• Introduction of design verification

• Shared proof responsibility (panel builder, equipment manufacturer)

• Implementation of „Black Box“ concept for interface definition

• Modified building and conduct requirements

• Verification of switching devices through alternative but equivalent methods

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439 architecture

Replaced Standards

IEC 61439-1

General rules

Replaces IEC 60 439-1

IEC 61439-2 IEC 61439-3 IEC 61439-4 IEC 61439-5 IEC 61439-6

Power switchgear

Distribution Assemblies for Assemblies for Busbar trunking

and controlgear

boards construction sites power distribution systems

assemblies

replaces IEC 60439-1 replaces EC 60439-3 replaces IEC 60439-4 replaces EC 60439-5 replaces IEC 60439-2

SIVACON

SIVACON

ALPHA

SIKUS

ALPHA

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439 Responsibility of manufacturer

IEC 60439 IEC 61439 valid as of Nov. 2014

LV switchgear and controlgear ASSEMBLY LV switchgear and controlgear ASSEMBLY

Original manufacturer

Type tests to verify the conformity Design Verification from original manufacturer

TSK type-tested Type-tested Not type-tested

SK device device

Test Derivation Assessment

System manufacture

System manufacture

PTTA

Partially type- new ASSEMBLY (original system)

tested switchgear

Manufacturer of assembly can:

Assembly manufacturer

Assembly manufacturer

• perform the installation according to the rules

of the original manufacturer

• In case of modification, the manufacturer of

the assembly will become original

manufacturer for the customized system

Routine verification

Routine verification

Ready-to-use ASSEMBLY

Ready-to-use ASSEMBLY

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

Overview

Allowed Test methods

Design Verification

Comparison with

Test Assessment

reference design

„Worst case“ scenario

will be tested and

covers the rest of the

system.

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

Responsibility of the original manufacturer

IEC 61439@SIVACON S4

LV switchgear and controlgear ASSEMBLY

Design Verification from original manufacturer

Original manufacturer

Test Derivation Assessment

System manufacture

ASSEMBLY (original system)

Manufacturer of assembly can:

• perform the installation according to the rules of the

Assembly manufacturer

original manufacturer

• In case of modification, the manufacturer of the assembly

will become original manufacturer for the customized

system

Routine Verification

Ready-to-use ASSEMBLY

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

Overview

Tests

10.1 General introduction

10.2 Strength of materials and parts

10.3 Degrees of protection of enclosures

10.4 Clearances and creepage distances

10.5 Protection against electric shock and continuity of PE circuits

10.6 Incorporation of switching devices and components

10.7 Internal electrical circuits and connections

10.8 Terminal connections for external conductors

10.9 Dielectric properties

10.10 Verification of temperature rise

10.11 Short-circuit resistance

10.12 Electromagnetic compatibility (EMC)

10.13 Mechanical function

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Verification of materials and parts

10.2 Verification of materials and parts

Resistance to corrosion

• Test of the corrosion resistance according to IEC 61439-1

(Resistance to corrosion, security level A (clause A 10.2.2.2))

• Visual evaluation

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Verification of materials and parts

10.2 Verification of materials and parts

Resistance to corrosion In case of door cut-outs

• Corrosion protection at cutting edges

needs to be recovered

• Suitable systems are available at

specialist shops e.g.: BRILLUX painting

systems

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Verification of materials and parts

10.2 Verification of materials and parts

• Resistance of insulating materials to • Made of steel metal sheets

exceeding heat and fire due to internal • S4 is designed for indoor

electric effects applications

• UV test required by outdoor plastic parts • not relevant for SIVACON S4

Not

required

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Verification of materials and parts

10.2 Verification of materials and parts

Lifting MLFB Width (mm) Weight (kg)

8PQ3 000-1BA03 1200 1300

8PQ3 000-1BA02 1000 1350

8PQ3 000-1BA01 800 1400

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Verification of materials and parts

10.2 Verification of materials and parts

Mechanical impact

5 kg

200mm

IK 10 IK 09 IK 08 Done by

W k = 20 J W k = 10 J Wk = 5 J Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Verification of materials and parts

10.2 Verification of materials and parts

Marking

Delivered with every rack

Supported by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Degree of protection

10.3 Degree of protection

Code Solid particles Code Liquid protection

1 50 mm 1 Dripping water

Dripping water

2 12 mm 2 up to 15°angle

3 2,5 mm 3 Spraying water

4 1,0 mm 4 Splashing of water

Dust, no dangerous

5 amount inside housing 5 Water jets

6 No dust inside 6 Strong water jets

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Degree of protection

10.3 Degree of protection

IP 40 IP x1 IP 55 IP 40

ventilated extension cable entry

If standard parts are not modified,

no further actions are required!

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Degree of protection

10.3 Degree of protection

When using devices with tested IP degree of protection under

assembled conditions

IP degree is higher or equal to SIVACON S4

Follow up instructions given by device supplier

IP degree of protection is lower than SIVACON S4

IP degree of the system in total is reduced to device level

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Clearances and creepage distances

10.4 Clearances and creepage distances

Clearances: shortest distance between two conductors

Conductor

Channel Partition

Clearances

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Clearances and creepage distances

Table 1 – Minimum clearances in air1 (8.3.2)

Rated impulse withstand voltage

Minimum clearance

U imp

kV mm

≤ 2,5 1,5

4,0 3,0

6,0 5,5

8,0 8,0 SIVACON S4

12,0 14,0

1) Based on inhomogeneous field conditions and pollution degree 3

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Clearances and creepage distances

10.4 Clearances and creepage distances

Creepage distance: shortest distance along surface between two conductors

Conductor

Channel Partition

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Clearances and creepage distances

10.4 Clearances and creepage distances

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Clearances and creepage distances

10.4 Clearances and creepage distances

Assembly kits are already designed For mounting plate installations, these

according to this design rule design rules need to be respected

For Siemens

assembly kits

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Effective earth continuity between the exposed

conductive parts of the assembly & the protective circuit

10.5 Effective earth continuity between the exposed conductive parts of the

assembly and the protective circuit (1/3)

Protection class I

• measuring current:

10 A Done by

• not > 0,1 Ω Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Effective earth continuity between the exposed

conductive parts of the assembly & the protective circuit

10.5 Effective earth continuity between the exposed conductive parts of the

assembly and the protective circuit (2/3)

For door assemblies

8PQ9400-0BA15

6mm²

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Effective earth continuity between the exposed

conductive parts of the assembly & the protective circuit

10.5 Effective earth continuity between the exposed conductive parts of the

assembly and the protective circuit (3/3)

For connection to split PE busbars

Screw connection Connection clamp

With spring washer according to DIN 6796

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Incorporation of switching devices and components

10.6 Incorporation of switching devices and components

For SIVACON assembly kits For mounting plate installations

• Already prepared for the installation of Follow installation and mounting

specific devices instructions given by the device

manufacturer

• Using device accessories

(e. g. clamping covers) defined within

device manual

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Internal electric circuits and connections

10.7 Internal electric circuits and connections

1. Follow up fixed construction rules

2. Conductor material

• Copper, aluminium

• Cross section

• Marking

• Mechanical strength

3. Cable entrance

• IP degree of protection

4. Connection points

Supported by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Internal electric circuits and connections

10.7 Internal electric circuits and connections

Copper drawings

available through

Industry mall

Using type tested

materials according to

IEC 61439

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Terminals for external conductors

10.8 Terminals for external conductors

Device

accessories

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Dielectric properties

10.9 Dielectric properties 10.9.1 power frequency voltage

10.9.2 impulse voltage

12 kV for main busbars

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Verification of temperature rise

10.10 Verification of temperature rise

• Proof of temperature rise is provided by Siemens via testing

• Based on our test results different variants can be generated via the

power loss calculation from SIMARIS configuration

• For exact power loss calculation it is mandatory that the exact

environment parameters are entered (outside temperature, inner

temperature, etc.)

• The temperature rise verification is done field by field

RDF = 80%

Simultanous factor = 1

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Short-circuit strength

10.11 Short-circuit strength

Main busbar systems

• Tested by Siemens

Follow up instruction rules

• Number of reinforcements are contained in the catalogue

• SIMARIS configuration gives you the right quantity as well

• In addition, they are published in the mounting instructions

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Short-circuit strength

10.11 Short-circuit strength

Device installation

• Tested for SIVACON assembly kits

Follow up instruction rules

• Follow up mounting instructions and manual

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Electromagnetic compatibilty

10.12 Electromagnetic compatibility

Installed devices must be designed

according to environmental conditions.

Not

required

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Mechanical operation

10.13 Mechanical operation

Test requirement

• All movable parts need to be checked 200 times

• Approved by Siemens

Done by

Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

Assembly manufacturer responsibility

IEC 61439@SIVACON S4

LV switchgear and controlgear ASSEMBLY

Design Verification from original manufacturer

Original manufacturer

Test Derivation Assessment

System manufacture

ASSEMBLY (original system)

Manufacturer of assembly can:

• perform the installation according to the rules of the

Assembly manufacturer

original manufacturer

• In case of modification, the manufacturer of the assembly

will become original manufacturer of the customized

system

Routine Verification

Ready-to-use ASSEMBLY

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Customizing

LV switchgear and controlgear ASSEMBLY

Original manufacturer

Design Verification from original manufacture

Test Derivation Assessment • when modification affects

System manufacture

one of these 12 tests

ASSEMBLY (original system)

• Assembly manufacturer is

original manufacturer for

Manufacturer of assembly can:

• perform the installation according to the rules of the customized area

Assembly manufacturer

original manufacturer

• In case of modification, the manufacturer of the

assembly will become original manufacturer of the

customized system

Routine Verification

Ready to use ASSEMBLY

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

IEC 61439@SIVACON S4

Routine verification

Checking constructional requirements Follow up our step by step

• Degree of protection check list

• Clearances and creepage distance

• Protection against electric shock and

integrity of protective circuits

• internal circuits and connections

• terminals for external conductors

• mechanical function

Checking performance

• Electric properties

• Wiring, operating performance and Supported by

function Siemens

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

SIVACON S4

IEC 61439 design verification

• Overview

• IEC 61439 @SIVACON S4

• Additional tests

• Summary

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

Additional tests

IEC61641 – arc fault

Arc fault protection

In order to increase personal safety

Controlled pressure relief through:

• flapping roof

• spring lock

http://www.youtube.com/watch?v=KHyh3nyTgK4

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

Additional tests

ISO 9001

Quality standards fulfilled by our

production site

ALPHA

Verteilertechnik GmbH

Ringstr. 60

93413 Cham-Altenmarkt

Germany

ISO 9001

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

SIVACON S4

IEC 61439 design verification

• Overview

• IEC 61439 @SIVACON S4

• Additional tests

• Summary

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

Summary

Industry mall

Industry Mall

www.siemens.com/industrymall

Information and Copper

Catalogue Software Certifications Manuals

Training drawings

LV 56 IEC 61439 • SIMARIS • IEC 61439

design • ISO 9001

• SIMARIS • etc.

project

• SIMARIS

configuration

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

Summary

Certificate

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

Summary

Customer benefits

The “make it easy” solution to fulfill IEC 61439

SIVACON S4 offers more than standard requirements

• Arc fault protection

• Quality certification

One partner for housing and devices

We have the best knowledge on our own devices

Deep integration level of devices and accessories

Frei verwendbar © Siemens AG 2015. Alle Rechte vorbehalten.

You might also like

- Sivacon S4Document50 pagesSivacon S4ulasNo ratings yet

- Siemens SIVACON S8, IEC 61439 Switchgear and Control PanelDocument43 pagesSiemens SIVACON S8, IEC 61439 Switchgear and Control PanelGyanesh Bhujade100% (2)

- Siemens EN - (IEC) - 61439-1 - 2 - Newsletter - en PDFDocument27 pagesSiemens EN - (IEC) - 61439-1 - 2 - Newsletter - en PDFLuis Fernando CuaspudNo ratings yet

- EN (IEC) 61439 1 - 2 - en PDFDocument27 pagesEN (IEC) 61439 1 - 2 - en PDFasimjkhanNo ratings yet

- 2017 May Webinar Hal Penting SNI IEC 61439-2Document24 pages2017 May Webinar Hal Penting SNI IEC 61439-2Muhammad Fadhil BudimanNo ratings yet

- The New Standard IEC 61439: Low Voltage Switchgear and Controlgear AssembliesDocument20 pagesThe New Standard IEC 61439: Low Voltage Switchgear and Controlgear AssembliesAdnen BOUAZIZINo ratings yet

- Intertek IEC 61439 Edition 3 0 Low Voltage Switchgear Controlgear Assemblies PDFDocument8 pagesIntertek IEC 61439 Edition 3 0 Low Voltage Switchgear Controlgear Assemblies PDFjigar100% (1)

- The Change From Iec 60439 To Iec 61439 James Hunt Voltimum S Managing Editor Introduces This TopicDocument3 pagesThe Change From Iec 60439 To Iec 61439 James Hunt Voltimum S Managing Editor Introduces This TopicThanis SribovornmongkolNo ratings yet

- Presentation - New IEC 61439 and PNB 2013 v1 (ENG Version)Document25 pagesPresentation - New IEC 61439 and PNB 2013 v1 (ENG Version)Tinhtam8236No ratings yet

- IEC 6142 2 Low Voltage Switchgear and Controlgear AssembliesDocument66 pagesIEC 6142 2 Low Voltage Switchgear and Controlgear Assemblieshoangdungd12100% (1)

- LV SWG Verification IEC 61439 - 2009 (Siemens)Document42 pagesLV SWG Verification IEC 61439 - 2009 (Siemens)RudanekNo ratings yet

- 4OverviewofSEMIF47 0706Document38 pages4OverviewofSEMIF47 0706Bùi Quang ThịnhNo ratings yet

- Sinamics V50 Catalog V2.12Document45 pagesSinamics V50 Catalog V2.12Thamizhselvan KNo ratings yet

- Catalogue 8bt2 enDocument20 pagesCatalogue 8bt2 enPablo MarajNo ratings yet

- Catalogue-Simoprime en PDFDocument16 pagesCatalogue-Simoprime en PDFhizbi7No ratings yet

- IEC 61439 Sunlight - Technical - HandBook PDFDocument26 pagesIEC 61439 Sunlight - Technical - HandBook PDFJaggu JrzNo ratings yet

- Iec 61439Document17 pagesIec 61439Romario DiazNo ratings yet

- LS-VINA - MV - CatalogueDocument12 pagesLS-VINA - MV - CatalogueVietAnh NguyenNo ratings yet

- Sinamics v50 Drive CatalogDocument56 pagesSinamics v50 Drive Catalogsunil sahooNo ratings yet

- Iec-61439 Se6461Document32 pagesIec-61439 Se6461carlosmandopintoNo ratings yet

- Catálogo SM6 2017Document156 pagesCatálogo SM6 2017Jose OlivaresNo ratings yet

- UniGear ZS2 Catalogue V1 MEDDocument26 pagesUniGear ZS2 Catalogue V1 MEDkjkljkljlkjljlkNo ratings yet

- Unigear Type ZS2 Catalogue - enDocument26 pagesUnigear Type ZS2 Catalogue - ensyedfahadraza627100% (1)

- General Technical Information ENDocument6 pagesGeneral Technical Information ENjaelNo ratings yet

- 2.presentation StandardsDocument118 pages2.presentation Standardssumit kumarNo ratings yet

- Wel6 Air Cooler: API 682 4th Edition Product Range - Seal Supply Systems - CoolersDocument3 pagesWel6 Air Cooler: API 682 4th Edition Product Range - Seal Supply Systems - CoolersNet WalkerNo ratings yet

- Guide To Low Voltage Busbar Trunking Systems-BeamaDocument20 pagesGuide To Low Voltage Busbar Trunking Systems-BeamaGhayath Omer100% (1)

- Guide Busbar Issue2 Apr04Document20 pagesGuide Busbar Issue2 Apr04A.K.A. Haji100% (1)

- Improving Safety and Performance in Electrical Assemblies. A Guide To lEC 61439-2Document32 pagesImproving Safety and Performance in Electrical Assemblies. A Guide To lEC 61439-2abes1234100% (1)

- Rittal - Standard-Compliant Switchgear (Production)Document88 pagesRittal - Standard-Compliant Switchgear (Production)Ruben PauwelsNo ratings yet

- Perfect For Outdoor/indoor Flood Illumination: The Champ Pro PFMA LED FamilyDocument4 pagesPerfect For Outdoor/indoor Flood Illumination: The Champ Pro PFMA LED Familybeimarerodrigue1291No ratings yet

- MV Switchgear Alfa12Document36 pagesMV Switchgear Alfa12ABDUL HASEEBNo ratings yet

- Enerswit 40 5kV CatalogDocument20 pagesEnerswit 40 5kV CatalogJackie StlNo ratings yet

- SM6 Amted398078en 0918 PDFDocument164 pagesSM6 Amted398078en 0918 PDFManh Dat BuiNo ratings yet

- Western MotorDocument28 pagesWestern MotordinduntobzNo ratings yet

- Sharp Solar NA E120G5 NA E125G5 NA E130G5 NA E135G5glass Glass EU Vico E...Document4 pagesSharp Solar NA E120G5 NA E125G5 NA E130G5 NA E135G5glass Glass EU Vico E...I-Simion GNo ratings yet

- 1.5.3 Capacitor Modules 2016Document8 pages1.5.3 Capacitor Modules 2016HoTGreeKNo ratings yet

- MV Switchgear Alfa12 PDFDocument36 pagesMV Switchgear Alfa12 PDFYassine AlloucheNo ratings yet

- PVAC-E CatalogueDocument19 pagesPVAC-E CatalogueUmer FarNo ratings yet

- ABB - 7TKK000114 - Elastimold Cable Accessories - Catalogue - US - LoDocument113 pagesABB - 7TKK000114 - Elastimold Cable Accessories - Catalogue - US - LoRaulNo ratings yet

- 1) Technical Specification - 63MVA, 132kVDocument98 pages1) Technical Specification - 63MVA, 132kVGuru Mishra100% (1)

- Abb Pricelist 2016 16.03.2016 PDFDocument216 pagesAbb Pricelist 2016 16.03.2016 PDFhiralalnhpcNo ratings yet

- REM615 PG 756890 ENpDocument65 pagesREM615 PG 756890 ENpenmity283No ratings yet

- LanTEK IV Technical Specifications Feb 2021Document11 pagesLanTEK IV Technical Specifications Feb 2021WiteyElCaballeroOscuroNo ratings yet

- Experiences With The New Standards For LV Assemblies IEC 61439-1&2Document6 pagesExperiences With The New Standards For LV Assemblies IEC 61439-1&2cauvongkhongmauNo ratings yet

- Falcon Series WebDocument24 pagesFalcon Series WebGratifying SoulNo ratings yet

- DU DY MCCB Catalogue 1.1Document24 pagesDU DY MCCB Catalogue 1.14usangeetNo ratings yet

- a8cd09f2ef69793dff843b1397494446 (1)Document24 pagesa8cd09f2ef69793dff843b1397494446 (1)vishal.nithamNo ratings yet

- Belden MachFlex Industrial CablesDocument24 pagesBelden MachFlex Industrial CablesKleberNo ratings yet

- Operating Instructions I510 Cabinet Frequency Inverter ENDocument42 pagesOperating Instructions I510 Cabinet Frequency Inverter ENeletroandrade1980No ratings yet

- Champ Pro Pfma Led FloodlightsDocument4 pagesChamp Pro Pfma Led FloodlightsOreste HernandezNo ratings yet

- SFH 6156Document8 pagesSFH 6156elcomandanteNo ratings yet

- Power Electronics Design Handbook: Low-Power Components and ApplicationsFrom EverandPower Electronics Design Handbook: Low-Power Components and ApplicationsRating: 4 out of 5 stars4/5 (2)

- Practical Industrial Data Networks: Design, Installation and TroubleshootingFrom EverandPractical Industrial Data Networks: Design, Installation and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- TokaiDocument9 pagesTokaiDavid LimNo ratings yet

- Panasonic Multi Split Ac ManualDocument22 pagesPanasonic Multi Split Ac ManualDavid LimNo ratings yet

- 87 170417 1517361736 Preview Proposed Amendments Ubbl 2013Document124 pages87 170417 1517361736 Preview Proposed Amendments Ubbl 2013David LimNo ratings yet

- LT Line I Catalog 202311 CompressedDocument40 pagesLT Line I Catalog 202311 CompressedDavid LimNo ratings yet

- MXZ-3B MXZ-4B Installation Manual (JG79A237H01)Document9 pagesMXZ-3B MXZ-4B Installation Manual (JG79A237H01)David LimNo ratings yet

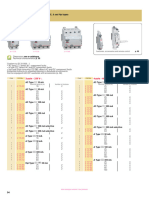

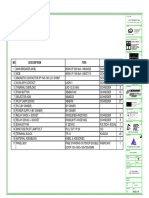

- Legrand RCDDocument1 pageLegrand RCDDavid LimNo ratings yet

- IEM Presentation On MS IEC 62305 V1.3 20032014Document128 pagesIEM Presentation On MS IEC 62305 V1.3 20032014David LimNo ratings yet

- DIG SIG 01082019 TrustSight Emergency System Gen2 A02Document35 pagesDIG SIG 01082019 TrustSight Emergency System Gen2 A02David LimNo ratings yet

- Basics of Lighting Control ApplicationsDocument35 pagesBasics of Lighting Control ApplicationsDavid LimNo ratings yet

- BSEEP Active Design GuidebookDocument218 pagesBSEEP Active Design GuidebookDavid LimNo ratings yet

- Ubbl by Law 38a 2012 Part 1Document76 pagesUbbl by Law 38a 2012 Part 1David LimNo ratings yet

- Registration of Engineers Regulations 1990: Lembaga Jurutera MalaysiaDocument21 pagesRegistration of Engineers Regulations 1990: Lembaga Jurutera MalaysiaDavid LimNo ratings yet

- ZX2 eDocument15 pagesZX2 eDavid LimNo ratings yet

- IEC TC64overview TisonDocument58 pagesIEC TC64overview TisonDavid LimNo ratings yet

- User Manual: Off Grid Solar Inverter SPF 5000 ESDocument42 pagesUser Manual: Off Grid Solar Inverter SPF 5000 ESGustavo CoppiniNo ratings yet

- Databases Designed ConceptDocument14 pagesDatabases Designed ConceptMUHAMMAD YAZIBNo ratings yet

- 1.5 Systems Software End of Topic QuizDocument12 pages1.5 Systems Software End of Topic QuizA popopNo ratings yet

- Cambridge O Level: Pakistan Studies 2059/02Document4 pagesCambridge O Level: Pakistan Studies 2059/02Aiman SanobarNo ratings yet

- JPSP 2022 504Document7 pagesJPSP 2022 504Befekadu BerhanuNo ratings yet

- Trigen Húmero + ShureshotDocument56 pagesTrigen Húmero + Shureshotgpe nola jpNo ratings yet

- HJ125 8 Manual de RepuestosDocument72 pagesHJ125 8 Manual de RepuestosFelix Rivera100% (1)

- DQ 2Document2 pagesDQ 2Salim KhanNo ratings yet

- A5 Brochure - Revise - Centre Pinning - With IndoscopeDocument32 pagesA5 Brochure - Revise - Centre Pinning - With IndoscopeGerman DrumsNo ratings yet

- ATP Network AdministratorDocument63 pagesATP Network AdministratorMukalele RogersNo ratings yet

- DM Screen 1 PDFDocument4 pagesDM Screen 1 PDFmaszerkNo ratings yet

- WWW Scribd Com Document 294196410 Investigatoy Project On Application of BiotechnologyDocument12 pagesWWW Scribd Com Document 294196410 Investigatoy Project On Application of BiotechnologyONLINE COMPUTER INSTITUTENo ratings yet

- CertyIQ AZ-204 UpdatedExam Dumps - Part 5Document51 pagesCertyIQ AZ-204 UpdatedExam Dumps - Part 5yobihNo ratings yet

- Flipkart - Graplling With Product ReturnsDocument13 pagesFlipkart - Graplling With Product ReturnsAbhilash C VNo ratings yet

- SEMICON-LAB SyllabusDocument6 pagesSEMICON-LAB Syllabusnandithanarayanan349No ratings yet

- CLB Toán - Hệ thống trường Quốc tế Châu Á Thái Bình Dương (APC)Document4 pagesCLB Toán - Hệ thống trường Quốc tế Châu Á Thái Bình Dương (APC)Linh Phan PhươngNo ratings yet

- Course: General Methods of Teaching (8601) Semester: Autumn, 2022Document18 pagesCourse: General Methods of Teaching (8601) Semester: Autumn, 2022bilal nazirNo ratings yet

- Form A1 PDFDocument10 pagesForm A1 PDF祝福No ratings yet

- Referat Plagiat 1Document4 pagesReferat Plagiat 1Raul Stefan CosteaNo ratings yet

- Complete English As A Second Language For Cambridge IGCSE® Writing & Grammar Practice Book Mark SchemeDocument46 pagesComplete English As A Second Language For Cambridge IGCSE® Writing & Grammar Practice Book Mark SchemePrince Yug67% (6)

- Karmachari Biniyawali 2078Document160 pagesKarmachari Biniyawali 2078sital chandNo ratings yet

- LinearblockcodingDocument19 pagesLinearblockcodingPavuluri SairamNo ratings yet

- ABD OL 108 A3.pdf.9Document1 pageABD OL 108 A3.pdf.9Berkah Jaya PanelNo ratings yet

- NTE Electronics NTE4049 DatasheetDocument2 pagesNTE Electronics NTE4049 DatasheetalejandrosaumethNo ratings yet

- Veeam Iq: Propartner Training GuideDocument6 pagesVeeam Iq: Propartner Training GuideSakthi Murugan SNo ratings yet

- Unit 1 NotesDocument3 pagesUnit 1 NotesswezinminhtutNo ratings yet

- TCF Bank Burr Ridge Village EmailsDocument3 pagesTCF Bank Burr Ridge Village EmailsDavid GiulianiNo ratings yet

- Promis eDocument2 pagesPromis eAppleNo ratings yet

- Menh deDocument5 pagesMenh deNguyễn HươngNo ratings yet

- (M5-TECHNICAL2) Software (MS Excel)Document4 pages(M5-TECHNICAL2) Software (MS Excel)Artus ArtigasNo ratings yet