Professional Documents

Culture Documents

Resource Power Manager (RPM - BF) : User Guide

Uploaded by

burdun777Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Resource Power Manager (RPM - BF) : User Guide

Uploaded by

burdun777Copyright:

Available Formats

Resource Power Manager (RPM.

BF)

User Guide

80-NA157-15 E

April 17, 2014

Submit technical questions at:

https://support.cdmatech.com/

Confidential and Proprietary – Qualcomm Technologies, Inc.

NO PUBLIC DISCLOSURE PERMITTED: Please report postings of this document on public servers or websites

to: DocCtrlAgent@qualcomm.com.

Restricted Distribution: Not to be distributed to anyone who is not an employee of either Qualcomm or its

subsidiaries without the express approval of Qualcomm’s Configuration Management.

Not to be used, copied, reproduced, or modified in whole or in part, nor its contents revealed in any manner to others

without the express written permission of Qualcomm Technologies, Inc.

Qualcomm reserves the right to make changes to the product(s) or information contained herein without notice. No

liability is assumed for any damages arising directly or indirectly by their use or application. The information

provided in this document is provided on an “as is” basis.

This document contains confidential and proprietary information and must be shredded when discarded.

Qualcomm is a trademark of QUALCOMM Incorporated, registered in the United States and other countries. All

QUALCOMM Incorporated trademarks are used with permission. Other product and brand names may be

trademarks or registered trademarks of their respective owners.

This technical data may be subject to U.S. and international export, re-export, or transfer (“export”) laws. Diversion

contrary to U.S. and international law is strictly prohibited.

Qualcomm Technologies, Inc.

5775 Morehouse Drive

San Diego, CA 92121

U.S.A.

© 2012-2014 Qualcomm Technologies, Inc.

All rights reserved.

Contents

1 Introduction...................................................................................................... 7

1.1 Purpose.......................................................................................................................... 7

1.2 Scope............................................................................................................................. 7

1.3 Conventions .................................................................................................................. 7

1.4 References..................................................................................................................... 7

1.5 Technical assistance ...................................................................................................... 7

1.6 Acronyms ...................................................................................................................... 7

2 RPM Overview .................................................................................................. 8

2.1 Hardware overview ....................................................................................................... 8

2.1.1 RPM processor................................................................................................... 8

2.1.2 AHB ................................................................................................................... 9

2.1.3 Boot ROM ......................................................................................................... 9

2.1.4 Code RAM ......................................................................................................... 9

2.1.5 Data/log RAM ................................................................................................... 9

2.1.6 Message RAM ................................................................................................. 10

2.1.7 Interrupt controller ........................................................................................... 10

2.1.8 Timers .............................................................................................................. 10

2.1.9 CSR.................................................................................................................. 10

2.2 RPM software overview ............................................................................................. 11

2.2.1 Kernel .............................................................................................................. 11

2.2.2 RPM handler .................................................................................................... 12

2.2.3 Drivers ............................................................................................................. 12

3 RPM Build Instructions ................................................................................. 14

4 RPM Scheduling ............................................................................................ 15

4.1 Task............................................................................................................................. 15

4.2 Dispatcher ................................................................................................................... 16

4.3 Scheduler .................................................................................................................... 17

4.4 Schedule collision – Stack up example ....................................................................... 18

4.5 Concurrency – Next awake set ................................................................................... 20

4.6 Schedule code layout .................................................................................................. 22

4.7 Example of scheduling with preemption .................................................................... 23

80-NA157-15 E 2 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

Contents

5 RPM Messaging ............................................................................................. 24

5.1 RPM message infrastructure ....................................................................................... 24

5.2 RPM message RAM ................................................................................................... 25

5.3 Transport layer – SMD Lite ........................................................................................ 25

5.3.1 SMD Lite data structures ................................................................................. 25

5.3.2 SMD Lite functions ......................................................................................... 26

5.4 Message format – Key Value Pairs (KVPs)................................................................ 26

5.4.1 Example of request to change LDO3 voltage and current ............................... 27

5.4.2 KVP usage ....................................................................................................... 27

6 RPM Railway .................................................................................................. 28

6.1 Railway-related components....................................................................................... 28

6.1.1 RPM server ...................................................................................................... 28

6.1.2 PMIC driver ..................................................................................................... 28

6.1.3 Railway ............................................................................................................ 28

6.1.4 SVS .................................................................................................................. 28

6.1.5 Clock driver ..................................................................................................... 29

6.1.6 CPR driver ....................................................................................................... 29

6.1.7 DDR driver ...................................................................................................... 29

6.1.8 Sleep ................................................................................................................ 29

6.2 Interfaces and dependencies ....................................................................................... 30

7 RPM RBCPR ................................................................................................... 31

7.1 RPM CPR ................................................................................................................... 31

7.2 CPR initialization ........................................................................................................ 32

7.3 CPR measurement and adjustment ............................................................................. 34

7.4 CPR voltage switching................................................................................................ 35

7.5 CPR driver source code .............................................................................................. 35

7.6 CPR debug .................................................................................................................. 36

7.6.1 Enable/disable CPR at runtime ........................................................................ 36

7.6.2 Retrieve the RBCPR log .................................................................................. 36

8 RPM Debugging ............................................................................................. 38

8.1 Trace32 scripts ............................................................................................................ 38

8.1.1 Save RAM dump – rpm_dump.cmm ............................................................... 38

8.1.2 Load RAM dump – rpm_load_dump.cmm...................................................... 38

8.1.3 Restore a crash – rpm_restore_core.cmm ........................................................ 38

8.1.4 Parse log – rpm_parse_faults.cmm .................................................................. 38

8.1.5 Examine the preempted process – rpm_m3_unstack.cmm .............................. 39

8.2 Getting the RPM log ................................................................................................... 39

8.2.1 Using T32 ........................................................................................................ 39

80-NA157-15 E 3 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

Contents

9 Software Events ............................................................................................. 40

9.1 RPM SWEvent range table ......................................................................................... 40

9.2 Adding RPM SWEvents ............................................................................................. 41

9.2.1 Add new SWEvent to tech area SConscript .................................................... 41

9.2.2 Add SWEVENT calls for new SConscript ...................................................... 41

9.2.3 Add SWEVENT RAM post-parsing................................................................ 42

10 RPM Master User Guide .............................................................................. 43

10.1 Active mode usage .................................................................................................... 43

10.2 Sleep mode usage...................................................................................................... 44

10.2.1 RPM.AF→RPM.BF RPM sleep interaction differences ............................... 44

80-NA157-15 E 4 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

Contents

Figures

Figure 2-1 RPM example block diagram ..................................................................................................... 8

Figure 2-2 RPM software topology ........................................................................................................... 11

Figure 4-1 Scheduling with preemption..................................................................................................... 23

Figure 5-1 RPM message RAM partition .................................................................................................. 25

Figure 6-1 Interfaces and dependencies ..................................................................................................... 30

Figure 7-1 RBCPR core with master and sensors ...................................................................................... 31

Figure 7-2 Two-point STEP_QUOT calculation during boot.................................................................... 32

Figure 7-3 STEP_QUOT is the number of QUOT units per PMIC step ................................................... 33

Figure 7-4 CPR measurement/adjustment ................................................................................................. 34

Figure 7-5 CPR voltage switching flow..................................................................................................... 35

Tables

Table 1-1 Reference documents and standards ............................................................................................ 7

Table 2-1 Example RPM messaging masters ............................................................................................ 10

Table 9-1 Software event entry .................................................................................................................. 40

80-NA157-15 E 5 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

Revision history

Revision Date Description

A Jul 2012 Initial release

B Oct 2012 Numerous changes were made to this document; it should be

read in its entirety

C Nov 2013 Added MDM9x35

D Apr 2014 Numerous changes were made to this document; it should be

read in its entirety.

E Apr 2014 Updated Sections 1.1 and 1.2

80-NA157-15 E 6 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

1 1 Introduction

2 1.1 Purpose

3 This document describes the Resource Power Manager (RPM) for chipsets that use the RPM.BF

4 subsystem.

5 1.2 Scope

6 This document is intended for customers who must understand details about RPM.BF.

7 1.3 Conventions

8 Function declarations, function names, type declarations, and code samples appear in a different

9 font, e.g., #include.

10 Code variables appear in angle brackets, e.g., <number>.

11 Shading indicates content that has been added or changed in this revision of the document.

12 1.4 References

13 Reference documents are listed in Table 1-1. Reference documents that are no longer applicable

14 are deleted from this table; therefore, reference numbers may not be sequential.

15 Table 1-1 Reference documents and standards

Ref. Document

Qualcomm Technologies

Q1 Application Note: Software Glossary for Customers CL93-V3077-1

16

17 1.5 Technical assistance

18 For assistance or clarification on information in this document, submit a case to Qualcomm

19 Technologies, Inc. (QTI) at https://support.cdmatech.com/.

20 If you do not have access to the CDMATech Support Service website, register for access or send

21 email to support.cdmatech@qti.qualcomm.com.

22 1.6 Acronyms

23 For definitions of terms and abbreviations, see [Q1].

80-NA157-15 E 7 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

1 2 RPM Overview

2 2.1 Hardware overview

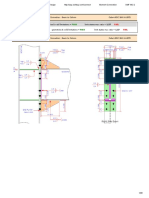

3 Figure 2-1 shows the top-level example block diagram of the RPM.

5 Figure 2-1 RPM example block diagram

6 2.1.1 RPM processor

7 The RPM core consists of:

8 Cortex-M3 processor with integrated NVIC

9 128 KB multibank code RAM

10 64 KB multibank data/log RAM

11 16 KB message RAM

80-NA157-15 E 8 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Overview

1 The RPM processor has a native Advanced High-performance Bus (AHB) Lite interface and

2 built-in ETM/ITM and DAP support. The processor target frequency is 100 MHz. The Cortex-M3

3 supports a native SWFI instruction, which allows the processor to turn off its own clock when the

4 clock is not needed.

5 The Cortex-M3 processor uses a Harvard architecture, enabling simultaneous instruction fetch

6 with data load/store. It supports thumb2, single-cycle 32-bit multiply, and hardware divide.

7 2.1.2 AHB

8 The RPM AHB is synchronous to the RPM processor. It instantiates an aPU, which is configured

9 to protect the code RAM and mPU. The code RAM and mPU are configured to protect different

10 predecoded address space within the RPM. The RPM AHB has Cortex-M3 as the default master

11 for the bus. The RPM AHB allows byte, half-word, and word accesses for the code and data/log

12 RAM. The RPM AHB allows only word accesses for CSR registers.

13 2.1.3 Boot ROM

14 The RPM boot ROM block houses the actual ROM that the RPM processor uses to boot out of on

15 system reset, along with the AHB logic to access it through the RPM AHB bus. The main

16 purpose of the boot ROM is to store the Primary Boot Loader (PBL). The PBL is the first piece of

17 code that the chip executes and is responsible for initial hardware setup to a point where further

18 bootup can proceed from the Flash. The PBL must reside in an internal boot ROM to guarantee

19 that the chip always boots from a known trusted code.

20 2.1.4 Code RAM

21 The RPM instantiates a 128-KB code RAM. It is a single-port compiler memory. The RPM code

22 RAM operates at a clock frequency that is synchronous to the RPM AHB. The RPM code RAM

23 allows single-cycle read access and is 32 bits wide. The Cortex-M3 core data accesses can spill

24 into code RAM space if the software chooses, though this is at the loss of optimal performance.

25 2.1.5 Data/log RAM

26 The RPM instantiates a 64-KB data/log RAM. This RAM is a single-port compiler memory. The

27 RPM data RAM operates at a clock frequency that is synchronous to the RPM AHB. The RPM

28 data RAM allows single-cycle read access and is 32 bits wide. The Cortex-M3 core instruction

29 accesses can spill into data RAM space if the software chooses, though this is at the loss of

30 optimal performance.

80-NA157-15 E 9 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Overview

1 2.1.6 Message RAM

2 The RPM message RAM provides memory for sending messages to and from the RPM core. The

3 messaging masters use this memory to communicate with the RPM. See Table 2-1 for examples.

4 Table 2-1 Example RPM messaging masters

Chipset MSM8974 MDM9x25 MDM9x35

Messaging masters APSS (Krait) APSS (A5) APSS

Modem Modem Modem

LPASS LPASS LPASS

WCNSS Pronto

TZ

5 2.1.7 Interrupt controller

6 The Cortex-M3 has a built-in Nested Vectored Interrupt Controller (NVIC), with a configurable

7 number of interrupts. The RPM is configured to use 64 interrupts. Sources external to the RPM

8 include MPM, SPM, messaging, and nonmessaging masters. Sources internal to the RPM include

9 general-purpose timers, WDOG timer bark, and CTI interrupts. The RPM interrupt controller

10 provides priority queuing of interrupts and supports both edge-sensitive and level-sensitive

11 interrupts.

12 The NVIC can only be fully accessed from Privileged mode, but interrupts can pend in User

13 mode if they are enabled via the Configuration Control Register (CCR). Any other user mode

14 access causes a bus fault. All NVIC registers are accessible using byte, half-word, and word,

15 unless otherwise stated. All NVIC registers and system debug registers are little-endian,

16 regardless of the endianess state of the processor.

17 2.1.8 Timers

18 The RPM instantiates the QTimer with two frames, one for the kernel and one for the user. The

19 QTimer keeps track of real time in every power mode.

20 The RPM also has a WDOG timer running on the SLEEP clock, with a configurable bark and bite

21 expiration.

22 2.1.9 CSR

23 The RPM Control/Status Register (CSR) provides IPC and GPO registers to generate IPC

24 interrupts and general-purpose pulses respectively. The RPM CSR provides a WFI_CONFIG

25 register to generate requests to turn off the RPM bus clocks and CHIP_SLEEP_EN, also known

26 as SW_DONE, to signal the MSM™ Power Manager (MPM) that the MSM is ready for sleep.

27 WDOG timer software interface registers, test bus configuration registers, and other

28 miscellaneous use registers are supported.

80-NA157-15 E 10 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Overview

1 2.2 RPM software overview

2 The RPM software topology is shown in Figure 2-2.

Master 1 Master 2 Master 3 Master N

RPM

RPM HANDLER

NPA

SLEEP

CLK DDR PMIC BUS MPM

WDOG SPMI

DRIVERS

KERNAL (DALSYS Native)

Master 1 Master 1 Master N Master N

Master 2

Core 0 Core 1 Core 0 Core N

SPM

SPM SPM SPM SPM

3

4 Figure 2-2 RPM software topology

5 2.2.1 Kernel

6 The kernel for the RPM supports:

7 Interrupts

8 Intlock, priorities, and configuration

9 Busy waits

10 Timers

11 SWFI

12 Reduced code size

13 The kernel is implemented using DALSYS to the metal, providing the RPM with a lightweight

14 kernel and allowing for easier driver porting.

80-NA157-15 E 11 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Overview

1 2.2.2 RPM handler

2 The RPM handler abstracts the RPM message protocol away from other software. The driver

3 handles the RPM-side client and server portions of the RPM messaging and hands data to the rest

4 of the drivers via callbacks.

5 2.2.3 Drivers

6 Drivers for each resource supported by the RPM register with the RPM handler to request

7 notification when requests are received for the resource that the driver controls. Upon receiving

8 this notification, the drivers perform arbitration that must be performed between the new request

9 and previous requests from other masters. Based on the arbitration results, the driver determines

10 how to modify the hardware resource.

11 2.2.3.1 NPA

12 A driver may use the Node Power Architecture (NPA) to represent resources controlled by the

13 driver. NPA is a generic framework that allows nodes to represent resources. Each node has

14 clients and is responsible for aggregating workload requirements on their resources while

15 optimizing power usage. The nodes make up a distributed graph, allowing one node to be a client

16 of another node.

17 2.2.3.2 Clock driver

18 The clock driver consists of two parts. One part resides on each master and the other part resides

19 on the RPM.

20 The RPM clock driver directly handles aggregating requests from each master for the system-

21 wide clock resources controlled by the RPM. The driver also handles RPM-specific clocks.

22 2.2.3.3 Bus arbitration driver

23 The bus arbiter driver consists of multiple parts. One part resides on each master and one part

24 resides on the RPM.

25 The RPM bus arbiter driver takes bus arbiter settings as requests from the different masters in the

26 system and aggregates them to represent the frequency-independent system settings. From these

27 settings, the frequency required to meet the settings is calculated.

28 Using the calculated value, the bus arbiter driver makes a request of the RPM clock driver. The

29 clock driver request sets a floor for the frequency at which the buses/FABRICs can operate. The

30 system settings are then converted into frequency-dependent settings, and the driver configures

31 the bus arbiter hardware with those settings.

32 2.2.3.4 PMIC driver

33 The PMIC driver consists of multiple parts. One part resides on each master and the other part

34 resides on the RPM.

35 The RPM PMIC driver directly aggregates requests from each master for the system-wide PMIC

36 resources controlled by the RPM.

80-NA157-15 E 12 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Overview

1 2.2.3.5 WDOG driver

2 The WDOG is a fail-safe for incorrect or stuck code. If a register is not written within a specific

3 time period, an interrupt occurs that allows the software to attempt to recover. If the register is

4 still not written within a specific time period, the system resets.

5 For the RPM subsystem, only the scheduler has the capability to pet the WDOG and reset the

6 WDOG counter. There is no software task monitoring other software tasks for stuck conditions.

7 Dealing with the WDOG during scheduler operations should meet the fail-safe needs. The

8 software does not have to explicitly deal with the WDOG in most scenarios.

9 The WDOG also supports a freeze, stopping the countdown, for scenarios where the scheduler

10 does not run within a given timeframe. Examples of scenarios requiring freeze support include

11 long memory or hardware accesses. Such scenarios should be avoided in most cases by the

12 software design. Freeze is supported when the RPM enters Sleep mode.

13 The RPM watchdog driver cannot reset the system.

14 2.2.3.6 MPM driver

15 The MPM driver is used to program the MPM hardware block during systemwide sleep. This

16 driver resides on the RPM and is responsible for programming the MPM to do the following:

17 Vdd_Dig retention – Puts the system-wide power rail in the Retention state

18 Vdd_Dig collapse – Puts the system-wide power rail in the Collapse state

19 Vdd_Mem retention – Puts the system-wide power rail in the Retention state

20 Vdd_Mem collapse – Puts the system-wide power rail in the Collapse state

21 CXO shutdown – Turns off CXO

22 The driver must support programming of the MPM timer hardware and the MPM interrupt

23 controller.

24 The MPM driver must also initialize several configuration registers to properly handle the

25 hardware combination and configuration needs of the system.

80-NA157-15 E 13 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

1 3 RPM Build Instructions

2 See the appropriate software user manual or build and integration documentation for detailed

3 instructions of building the RPM subsystem. Additional information may also be found in the

4 software release notes.

5 NOTE: To build the RPM, install ARMCT 5.01 build 94 on your machine.

80-NA157-15 E 14 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

1 4 RPM Scheduling

2 4.1 Task

3 An RPM task is an instance of the class Task. The class Task is defined in rpm_task.h and

4 rpm_task.cpp and has the following interface:

5 Get task name:

6

7 const char *get_name() const;

8

9 Get task priority:

10

11 uint8_t get_priority() const;

12

13 Set the deadline by which the execution should complete:

14

15 void set_deadline(uint64_t deadline);

16

17 Get the deadline by which the execution should complete:

18

19 bool get_deadline(uint64_t& deadline) const;

20

21 Get the estimate of how long this task takes to execute:

22

23 virtual uint64_t get_length() const = 0;

24

25 Get the time the task should start by in order to finish on time:

26

27 uint64_t get_start() const;

28

29 Set the time the task should start by in order to finish on time:

30

31 void set_start(uint64_t start_time);

32

33 Check if the task has immediate work to do:

34

35 virtual bool hasImmediateWork() const = 0;

80-NA157-15 E 15 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Scheduling

1 Check if the task has scheduled work to do:

2

3 virtual bool hasScheduledWork() const;

4

5 Run this task until it completes, stops, or is preempted:

6

7 void execute(volatile bool &preempt, uint64_t stop_time);

8

9 There are two tasks created for each master: one of RPMFWRequestHandler which handles

10 resource requests from the master; and one of RPMFWSetChanger which handles set transitions

11 when the master enters or exits sleep.

12 The task priority is inherited from its master: MPSS has the highest priority, APPS has the

13 intermediate, and LPASS has the lowest priority.

14 4.2 Dispatcher

15 A dispatcher is an object embedded in a task. The dispatcher executes the batches of work

16 associated with the task. The class RPMFWDispatcher is defined in DalRPMFWDispatcher.h and

17 DalRPMFWDispatcher.cpp, which has the following interface:

18 Set up a new batch of work to be executed:

19

20 void set_work(const DAL_rpm_ResourceIndType &changed_resources,

21 DAL_rpm_ConfigSetType changed_set);

22

23 Get the estimate worst-case execution time:

24

25 uint64_t get_length() const;

26

27 Perform the dispatching until all tasks are done, run out of time, or be preempted:

28

29 bool dispatch(volatile bool &preempt,

30 uint64_t stop_time,

31 bool &rejected,

32 RPMResourceDataLayout &new_req,

33 bool save_req,

34 RPMResourceDataLayout *acknowledgement);

80-NA157-15 E 16 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Scheduling

1 4.3 Scheduler

2 The scheduler is the static instance of the class Sched which implements cooperative multiple

3 tasking. The class Sched is defined in rpm_sched.h and rpm_sched.cpp.

4 The scheduler has three private members:

5 Immediate task list – Tasks with immediate work is kept in this binary heap.

6

7 TaskHeap immediateQ_;

8

9 Scheduled task list – Tasks with scheduled work is added into this sorted list.

10

11 TaskList scheduledQ_;

12

13 Preemption flag – The dispatcher checks this flag periodically to see if it should stop current

14 work prematurely and yield the processor for higher priority task.

15

16 volatile bool preempt_;

17

18 The scheduler provides the following interfaces:

19 Retrieve the single scheduler instance:

20

21 friend Sched &theSchedule();

22

23 Add a new task to be scheduled, causing the task be added to the immediate or scheduled list

24 and the preemption flag be updated as needed:

25

26 void schedule_task(Task &new_task,

27 ScheduleType schedule_type = DEFAULT);

28

29 Run the next outstanding task, returning only when there is no immediate work to do:

30

31 void run();

32

33 Return the time by which the scheduler should run next:

34

35 uint64_t get_next_start() const;

36

37 Return the estimated duration of the scheduler’s next run:

38

39 uint64_t get_next_duration() const;

80-NA157-15 E 17 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Scheduling

1 4.4 Schedule collision – Stack up example

2 Every scheduled conflict has either been explored or is just another permutation of what has been

3 covered. What about immediate work? How should it interact with the scheduled timeline? An

4 example follows.

5 1. Task A, task B, and task D are on the schedule, each with their own deadline – deadline A,

6 deadline B, and deadline D.

A’s

estimated

work B’s estimated work D’s estimated work

time

deadline ‘A’ deadline ‘B’ deadline ‘D’

7

8 2. A new task, task C, comes in with a new deadline, deadline C.

A’s

estimated

work B’s estimated work D’s estimated work

time

deadline ‘A’ deadline ‘B’ deadline ‘D’

C’s estimated work

deadline ‘C’

9

80-NA157-15 E 18 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Scheduling

1 3. Task C is inserted; based on the deadline, task C now conflicts with task D in the queue, so

2 the execution time for task C is pushed out.

C’s estimated work

A’s

estimated

work B’s estimated work D’s estimated work

deadline ‘A’ deadline ‘B’ deadline ‘C’ deadline ‘D’

3

4 Now, task A conflicts with task B, so the execution time for task B is pushed out.

C’s estimated work

A’s

estimated

work

B’s estimated

work

D’s estimated work

deadline ‘A’ deadline ‘B’ deadline ‘C’ deadline ‘D’

5

80-NA157-15 E 19 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Scheduling

1 4. Task D’s original schedule remains unchanged. The rest of the schedule needed

2 modifications. This is called stack up when the problem occurs, and the resolution is called

3 schedule fix up.

C’s estimated work

A’s

estimated

work

B’s estimated

work

D’s estimated work

5 4.5 Concurrency – Next awake set

6 Wake-up information from the modem goes from time to deadline; missing the deadline is

7 considered a failure. Allow the modem to avoid a resource double state change by storing a next

8 awake set into memory before sleep to save the handshake time cost as described in the following

9 steps.

10 1. When going to sleep, a new sleep set is written and sent to the RPM. The settings for the next

11 wake-up are then left as an unsent request in message RAM.

WCDMA

GPS

Active set Sleep set Message RAM

12

80-NA157-15 E 20 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Scheduling

1 2. Once the RPM detects a sleep transition on a master, it checks to see if there is an unsent

2 message in message RAM.

WCDMA

GPS

Active set Sleep set Message RAM

5 3. If there is an unsent message, it schedules the application of that request just before the

6 wake-up of that master.

WCDMA

GPS

Active set Sleep set Message RAM

80-NA157-15 E 21 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Scheduling

1 4. At wake-up, the active set is updated. This allows the active set to be changed ahead of time

2 and to skip double-state changes upon wake-ups.

WCDMA

GPS

Active set Sleep set Message RAM

4 4.6 Schedule code layout

5 Request handling algorithms:

6 DalRPMFWHandler.cpp

7 DalRPMFWHandler.h

8 Set transition algorithms:

9 DalRPMFWSetChanger.cpp

10 DalRPMFWSetChanger.h

11 Common code between request handling and set transitions – Iterating over a list of resource

12 requests and sending them off to drivers:

13 DalRPMFWDispatcher.cpp

14 DalRPMFWDispatcher.h

15 Schedule code – Code that is responsible for keeping track of how long each resource will

16 take to transition:

17 DalRPMFWEstimator.cpp

18 DalRPMFWEstimator.h

19 Schedule framework:

20 rpm_sched.cpp

21 rpm_task.cpp

22 rpm_timeservice.cpp

23 task_heap.cpp

24 task_list.cpp

80-NA157-15 E 22 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Scheduling

1 4.7 Example of scheduling with preemption

2 Figure 4-1 shows an example of scheduling with preemption.

5 Figure 4-1 Scheduling with preemption

80-NA157-15 E 23 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

1 5 RPM Messaging

2 5.1 RPM message infrastructure

3 RPM messaging is built around three core concepts:

4 Masters – These are the subsystems that make requests to the RPM. The messaging masters

5 for different targets are given in Table 2-1.

6 Resources – These are the physical components that the RPM is responsible for controlling:

7 Clocks

8 Bus arbitration

9 PMIC

10 DDR (DMM)

11 Chip sleep wakeup interrupts

12 Processor wakeup deadlines

13 Configuration sets – These are a collection of settings, one for each resource, that fits a

14 logical use case. Three sets are currently provided for each master:

15 Active set – This set contains the settings used when the subsystem is awake.

16 Sleep set – This set contains the settings used when the subsystem is sleeping (when an

17 SPM handshake occurs).

18 Next active set – This set contains the settings used when the subsystem is awake and

19 before the active set.

80-NA157-15 E 24 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Messaging

1 5.2 RPM message RAM

2 Messaging is the main method for each system master to communicate with the RPM. The

3 message RAM is partitioned into several regions, using an RPU with 512-byte granularity. A

4 majority of the partitions are dedicated for master/RPM pairs. These partitions are only accessible

5 by that master and the RPM. See Figure 5-1.

7 Figure 5-1 RPM message RAM partition

8 5.3 Transport layer – SMD Lite

9 SMD Lite is a message-oriented FIFO transport layer selected to replace the previous register

10 emulation.

11 SMD Lite is a lightweight interprocessor communication layer available on the most recent chips.

12 It is focused on the mechanism of moving data between processors and tries to remain entirely

13 ignorant of the policy of what that data means and of higher-level constructs, e.g., queuing.

14 The SMD Lite API is documented in the smd_lite.h header file that is available with the build.

15 Since the API has evolved over time, the header file that ships with the build is considered to be

16 the canonical documentation. It defines the structures and functions in Sections 5.3.1 and 5.3.2.

17 5.3.1 SMD Lite data structures

18 The SMD Lite data structures are:

19 smdl_handle_type

20 smdl_iovec_type

21 smdl_event_type

22 smdl_sig_type

23 smdl_callback_t

80-NA157-15 E 25 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Messaging

1 5.3.2 SMD Lite functions

2 The SMD Lite functions are:

3 smdl_init()

4 smdl_open()

5 smdl_close()

6 smdl_rx_peek()

7 smdl_tx_peek()

8 smdl_read()

9 smdl_write()

10 smdl_readv()

11 smdl_writev()

12 5.4 Message format – Key Value Pairs (KVPs)

13 The messages are formatted as KVP. The KVP format was selected for better compatibility and

14 expandability, low overhead, and because it can be incrementally parsed easily.

15 At a high level, a KVP structure is simply:

16 What you are talking about

17 Blob of data that you are saying

18 At a lower level, this is just 2+n words of data.

19 One word for key – Generally used as a 4-byte string (uv\0\0, clk\0, etc.)

20 One word for length – Describes how many bytes follow

21 Blob of data

22 This structuring is repeated recursively to build full messages.

23 Internally, a request to an RPM is a concatenated array of KVP objects. KVP objects are simple

24 in their layout in memory:

25

26 <4 bytes of key> <4 bytes of length> <0..* bytes of value>

27

28 Therefore, a request to the microvolts key (“uv”) of a regulator might be laid out in memory, e.g.,

29 shown byte-by-byte:

30

31 75 76 00 00 | 04 00 00 00 | e0 c8 10 00

32

33 The pipe symbol (|) separates the fields for visual effect. The first field is the little-endian

34 rendering of 0x7675, which is the transliteration of “uv” as explained above. The second field

35 indicates that the request is a 4-byte data buffer. The final field is the 4-byte data buffer

36 containing a little-endian rendering of the value 1,100,000 µV (or 1.1 V).

80-NA157-15 E 26 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Messaging

1 5.4.1 Example of request to change LDO3 voltage and current

2 {

3 “req\0” : {

4 {“rsrc” : “ldo\0”}

5 {“id” : 3}

6 {“set” : 0}

7 {“data” : {

8 {“uv\0\0” : 1100000}

9 {“mA\0\0” : 130}

10 }

11 }

12 }

13 }

14 5.4.2 KVP usage

15 In practice, there is a kvp module which is used to build these buffers of KVP objects. A brief

16 overview of the API follows.

17 First, a kvp instance is created. KVP instances contain an internally managed, dynamically

18 expanding buffer that holds the requests and their data.

19

20 kvp_t *cxo_request = kvp_create(12);

21

22 The magic number 12 above is a hint about how much data will be placed in the stream. This

23 example case uses 12; if you know in advance what your requests will look like, use the

24 following rules to pick a guideline number:

25 8 bytes of overhead per call to kvp_put(), plus however many bytes of data you are “putting,”

26 rounded up to a 4-byte boundary on each put()

27 0 is always an acceptable hint; the kvp object always reallocates a larger buffer as required

28 Next, put the KVP into the buffer:

29

30 unsigned nCXORequirement = 1;

31 unsigned units_Enab = 0x62616e45; // = "Enab" -- the units for CXO

32 kvp_put(cxo_request, units_Enab, sizeof(nCXORequirement),

33 &nCXORequirement);

34

35 Every time you pass a kvp object to an RPM function call, its contents are “consumed.” To reuse

36 the kvp object later on, make sure to take the following cleanup actions:

37 To reuse the buffer to resend the exact same data, call kvp_reset(<your object>).

38 To reuse the buffer to send /different/ data, call kvp_clear(<your object>). Do not forget to

39 use kvp_put() to add new data before sending.

40 Of course, if there is no further required use of the buffer, kvp_destroy(<your object>) can be

41 used to clean it up entirely.

80-NA157-15 E 27 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

1 6 RPM Railway

2 6.1 Railway-related components

3 6.1.1 RPM server

4 The RPM server routes requests from masters and internal clients to the correct resource in the

5 RPM.

6 6.1.2 PMIC driver

7 The PMIC driver processes voltage transition requests from masters and internal clients on the

8 RPM. All knowledge of the power grid for the specific target is contained within the PMIC

9 driver.

10 6.1.3 Railway

11 Manages the Vdd_Mx, Vdd_Cx, and Vdd_Gfx rails and their dependencies

12 Vdd_Mx must be greater than or equal to Vdd_Cx and Vdd_Gfx at all times

13 Vdd_Mx must never be more than 370 mV higher than any logical rail

14 Provides notifications to registered clients when one of the ‘managed’ rails changes voltage

15 Provides notification to the sleep module regarding whether it is possible to go into Vdd

16 minimization based on the aggregated votes on Vdd_Cx and Vdd_Mx

17 Allows the Core Power Reduction (CPR) driver to override the default corner values with the

18 dynamic values that are recommended by the CPR (Vdd_Cx and Vdd_Gfx)

19 Provides NPA nodes to allow the clock driver to vote on voltages for Vdd_Cx and Vdd_Gfx

20 Allows internal RPM clients to make nonsuppressible requests for voltages on any of the

21 managed rails; these nonsuppressible requests influence whether Vdd minimization can occur

22 6.1.4 SVS

23 Tracks the Vdd_Cx voltage and votes on the RPM CPU clock to be maximum speed that is

24 available at the current Vdd_Cx voltage

25 Can also vote to raise Vdd_Cx in order to boost the CPU frequency should the current

26 scheduler workload make that the sensible thing to do

80-NA157-15 E 28 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Railway

1 6.1.5 Clock driver

2 The clock driver manages all of the shared clocks on the system; it votes via NPA to raise

3 voltages as required to scale clock frequencies.

4 6.1.6 CPR driver

5 The CRP driver manages the CPR hardware for the Vdd_Cx and Vdd_Gfx rails, provides a table

6 of dynamic corner voltages to the railway, and updates this table (per rail) as the CPR hardware

7 notifies it that the voltage should be raised/lowered to maintain timing.

8 6.1.7 DDR driver

9 The DDR driver manages the DDR settings and updates the DDR controller hardware as Vdd_Cx

10 and Vdd_Mx change.

11 6.1.8 Sleep

12 Sleep code is executed whenever the RPM is idle. The sleep code will put the RPM into halt/Vdd

13 minimization/XO shutdown depending on a number of factors:

14 How long it expects the RPM to be idle

15 The state of the masters; any master being active prevents XO shutdown and Vdd

16 minimization

17 Depending on what railway votes for the sleep target of various rails, Vdd minimization may

18 or may not be possible

80-NA157-15 E 29 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Railway

1 6.2 Interfaces and dependencies

2 Figure 6-1 illustrates the interfaces and dependencies of the RPM railway.

4 Figure 6-1 Interfaces and dependencies

5 The following numbered steps correspond to Figure 6-1:

6 1. The PMIC driver registers with the RPM server to receive all PMIC requests

7 (RPM_SMPS_A_REQ, RPM_LDO_A_REQ, etc.).

8 2. Railway registers with the RPM server to receive PMIC requests for specific resources, i.e.,

9 Vdd_Cx, Vdd_Mx, Vdd_Gfx. These override the registration done by the PMIC driver; the

10 PMIC driver receives no notification for votes on these resources. For these resources, the

11 RPM server routes both the xlate and apply functions to the overrider, i.e., railway.

12 3. Railway makes requests for voltages on the rails it manages directly to the PMIC driver. The

13 PMIC driver is responsible for understanding the power grid of the specific target being run

14 on and adjusting the parent regulators as required.

15 4. SVS registers with railway for notifications on when Vdd_Cx changes. It also uses the

16 railway API for voting for Vdd_Cx up when it wants to boost the CPU speed.

17 5. Clock driver registers with railway for notifications on when Vdd_Cx or Vdd_Gfx changes. It

18 also votes on /pmic/client/clk_regime_dig and /pmic/client/gfxnodes for when it wants to

19 change voltages on Vdd_Cx and Vdd_Gfx respectively; these nodes are implemented by the

20 railway component.

21 6. CPR registers with railway for notifications when either Vdd_Cx or Vdd_Gfx change (so that

22 it can reinitialize the CPR hardware to the new corner). It also uses an API on railway to

23 initiate a voltage change when the dynamic CPR-derived voltage for the current corner has

24 been updated.

25 7. DDR driver registers with railway for notifications on when Vdd_Cx and Vdd_Mx change.

26 8. Railway is responsible for updating the /sleep/uber node depending on whether there are any

27 nonsuppressible votes for Vdd_Cx, which would prevent Vdd minimization.

80-NA157-15 E 30 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

1 7 RPM RBCPR

2 7.1 RPM CPR

3 CPR is a system that embeds into the SoC and is used to control the VDD level of a chip. CPR

4 consists of a CPR master core and satellite sensors that are integrated into blocks on the SoC. It

5 utilizes sensors to estimate whether the chip is relatively fast or slow, then produces a result that

6 can be interpreted and used to send a VDD modification command to the PMIC. The CPR driver

7 was added in the RPM to control the Vdd DIG, Vdd GPU, etc.

8 The RapidBridge Core Power Reduction (RBCPR) core consists of one master and a number of

9 sensors, shown in green in Figure 7-1. There is additional QTI wrapper logic called rbif, shown in

10 blue in Figure 7-1. The software can program registers in the rbif_csr block, in the QTI rbif.

11 There are no programmable registers in the RapidBridge logic.

rbcpr_wrapper

rbif rbif_csr

msm bus msm bus

xo IF irq_ctl

hispeed_clk

clk mux

CSRs

action

cgc rbif_decision

(up/down decision pmic request

logic)

timer

bsr_chn_in rbif_bsr bsr_chn_out

cont_ack

loop_en

step_up

step_dn

rbif_clk

target

busy

gcnt

refclk cpr_sense_chain

cpr_master_v2

sys_cpr_sense

snext

sprev snext

sprev

snext

sprev

sys_cpr_sense

sys_cpr_sense sys_cpr_sense

snext sprev snext sprev

cpr_sense_chain

cpr_master_sense_chain

12

13 Figure 7-1 RBCPR core with master and sensors

80-NA157-15 E 31 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM RBCPR

1 7.2 CPR initialization

2 The software must configure some registers prior to using RBCPR. One of the register values,

3 STEP_QUOT, determines how many PMIC voltage steps should be taken to compensate for

4 changes in the quotient (QUOT). The QUOT is basically the raw count of the slowest sensor and

5 is taken while the cpr_master is counting GCNT cycles of the reference clock. If the silicon is on

6 the slow side, the QUOT value is lower; if the silicon is on the fast side, the QUOT is higher.

7 During RBCPR operation, the QUOT is subtracted from the target value (TARG) to determine an

8 error value. This error value is converted to some number of PMIC steps by factoring in the

9 STEP_QUOT. See Figure 7-2.

Power ON Boot ROM

2-point

STEP_QUOT

calculation

Adjust VDD

Secondary Boot

Loader

SBL1

Continue

Boot Sequence

10

11 Figure 7-2 Two-point STEP_QUOT calculation during boot

80-NA157-15 E 32 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM RBCPR

1 RPM performs an arithmetic calculation in the software to derive STEP_QUOT as shown in

2 Figure 7-3.

STEP_QUOT

is the slope

1.05 V

@ 12.5 mV each

8 PMIC steps

Vdd

0.95 V

quot1 quot2

Quot

4 Figure 7-3 STEP_QUOT is the number of QUOT units per PMIC step

5 Division by 8 is used because the two quotients were measured at Vdd points that are eight PMIC

6 steps apart. Each PMIC step is 12.5 mV; quot_1 was measured at 1.05 V and quot_2 at 0.95 V.

7 The STEP_QUOT shows how many QUOT units correspond to one PMIC step.

8 quot1 – quot2 = delta_quot

9 delta_quot / 8 = STEP_QUOT

80-NA157-15 E 33 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM RBCPR

1 7.3 CPR measurement and adjustment

2 This section describes how the CPR takes measurements and makes adjustments.

3 1. Configure the CPR interrupts.

4 2. Receive the CPR interrupt, look at RBCPR_STATUS, and make the PMIC adjustment.

5 a. If step_up is 1, increase the PMIC Vdd by one step.

6 b. If step_down is 1, decrease the PMIC Vdd by one step.

7 3. Tell the CPR to take another RBCPR measurement.

8 See Figure 7-4.

Configure RBCPR interrupts

Begin first RBCPR

measurement

Receive IRQ

Run Interrupt Service Routine

Clear interrupt

Make Vdd adjustment

Tell cpr_master to take

another measurement

10 Figure 7-4 CPR measurement/adjustment

80-NA157-15 E 34 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM RBCPR

1 7.4 CPR voltage switching

2 The RPM runs in one of three modes:

3 Nominal

4 Turbo

5 SVS

6 Figure 7-5 shows the CPR voltage switching modes.

Turbo

Mode

Nominal

Power ON Boot Flow

Mode

SVS

Mode

8 Figure 7-5 CPR voltage switching flow

9 When there is a requirement to switch the core voltage for a mode change, RBCPR callbacks are

10 called before and after the voltage to:

11 Disable the RBCPR block and interrupts

12 Set new Vdd through the software (not RBCPR)

13 Perform two-point STEP_QUOT calculation

14 Configure RBCPR with the new GCNT/TARG pairs

15 Re-enable the block and interrupts

16 7.5 CPR driver source code

17 The CPR driver source code resides in the folder rpm_proc\core\power\rbcpr\ and has the

18 following properties:

19 The read-only data is present in HAL_rbcpr_bsp.c and rbcpr_bsp.c, depending on whether the

20 data applies to the hardware register settings or the software algorithm respectively.

21 The driver code is in rbcpr.c.

22 Cx rail voltage is adjusted by the CPR driver. Mx voltage is always set to a static, or safe,

23 voltage for the operating corner.

24 The recommendation provided by CPR is in terms of PMIC steps:

25 One step = 12.5 mV

80-NA157-15 E 35 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM RBCPR

1 7.6 CPR debug

2 7.6.1 Enable/disable CPR at runtime

3 RBCPR is enabled by default during rpm_init() and can be disabled/enabled at runtime in

4 rpm_ctl.c by using the DISABLE bit in RPM_CTL.

5 7.6.1.1 Enable/disable CPR with the DISABLE bit in RPM_CTL

6 To enable/disable CPR with the DISABLE bit in RPM_CTL:

7 Set the bit − Disable CPR

8 Clear the bit − Enable CPR

9 7.6.1.2 Enable/disable CPR in the Linux kernel

10 To enable/disable CPR in the Linux kernel:

11 Disable CPR

12

13 adb shell “echo 8 > /sys/module/rpm_resources/mode/rpm_ctl”

14

15 Enable CPR

16

17 adb shell “echo 0 > /sys/module/rpm_resources/mode/rpm_ctl”

18 7.6.2 Retrieve the RBCPR log

19 RBCPR statistics are used to collect information about the voltage scaling recommendations from

20 the RBCPR hardware:

21 Fuse voltage (CPR starting point)

22 For each mode (SVS/Nominal/Turbo):

23 Number of mode interrupts

24 Latest recommendations with timestamps

25 Programmed voltage to railway

26 Exception events – Recommended voltage hitting Min or Max

27 Mode and voltage of the last interrupt

28 Ability to turn on/off statistics

29 RBCPR statistics are placed in a dedicated location of the RPM MSG RAM to make it always

30 available for the HLOS to read and send out through a diagnostic mechanism.

31 On the Android™ side, the debugfs can be mounted to read the RBCPR information.

32

33 mount -t debugfs none /sys/kernel/debug

34 cat /sys/kernel/debug/rpm_rbcpr

80-NA157-15 E 36 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM RBCPR

1 Example

2

3 :RBCPR Platform Data (upside_steps: 1)(downside_steps:2)(svs_voltage:

4 1050000)(nominal_voltage: 1162500)(turbo_voltage: 1287500)

5 :RBCPR Stats (status_counter: 8) (current_corner:

6 RBCPR_CORNER_TURBO)(current_timestamp: 0x2646943) (railway_voltage:1100000)

7 : RBCPR Corner Data (name: RBCPR_CORNER_SVS) (efuse_adjustment: -

8 37500)(programmed_voltage: 912500(isr_counter:1)(min_counter: 0)(max_counter:0)

9 : Voltage History[0] (voltage: 0) (timestamp: 0x0)

10 : Voltage History[1] (voltage: 0) (timestamp: 0x0)

11 : Voltage History[2] (voltage: 912500) (timestamp: 0x12b209)

12 : RBCPR Corner Data (name: RBCPR_CORNER_NOMINAL) (efuse_adjustment: -

13 37500)(programmed_voltage: 1112500)(isr_counter: 4)(min_counter:

14 0)(max_counter:0)

15 : Voltage History[0] (voltage: 1062500) (timestamp: 0x10ca11)

16 : Voltage History[1] (voltage: 1087500) (timestamp: 0x10ca1c)

17 : Voltage History[2] (voltage: 1112500) (timestamp: 0x10ca26)

18 : RBCPR Corner Data (name: RBCPR_CORNER_TURBO) (efuse_adjustment: -

19 37500)(programmed_voltage: 1100000)(isr_counter: 3)(min_counter:

20 1)(max_counter:0)

21 : Voltage History[0] (voltage: 1162500) (timestamp: 0x1d5ac)

22 : Voltage History[1] (voltage: 1125000) (timestamp: 0x13fd6a)

23 : Voltage History[2] (voltage: 1087500) (timestamp: 0x14170e

80-NA157-15 E 37 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

1 8 RPM Debugging

2 8.1 Trace32 scripts

3 8.1.1 Save RAM dump – rpm_dump.cmm

4 If the RPM crashes and there is no expert available, use the following script to capture the state of

5 the session for later analysis:

6

7 do rpm_dump.cmm \\location\to\put\logs

8 8.1.2 Load RAM dump – rpm_load_dump.cmm

9 If rpm_dump.cmm was used to capture the state of an RPM session, it can be tedious to manually

10 restore the many dumps. Use the following script to accelerate this process:

11

12 do rpm_load_dump.cmm \\location\of\logs

13 8.1.3 Restore a crash – rpm_restore_core.cmm

14 If the RPM crashes, it is likely that it dumped its core and then moved on to some other crash

15 management code. To restore the RPM to a point that is as close as possible to the point of the

16 crash, use the following script to load the core dump:

17

18 do rpm_restore_core.cmm

19 NOTE: This script requires that memory dumps and symbols are loaded before it can be used.

20 8.1.4 Parse log – rpm_parse_faults.cmm

21 An RPM crash may be due to a software fault. If so, the core dump may include useful

22 information about the fault that occurred. Use the following script to analyze this information:

23

24 do rpm_parse_faults.cmm

25 NOTE: This script requires that memory dumps and symbols are loaded before it can be used.

80-NA157-15 E 38 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Debugging

1 8.1.5 Examine the preempted process – rpm_m3_unstack.cmm

2 A dead RPM may indicate that an executing process was preempted by a software fault handler or

3 interrupt. To examine the interrupted process, navigate to the top of the fault handler and run the

4 following script:

5

6 do rpm_m3_unstack.cmms

7

8 Since the core dump generally occurs at the top of the fault handler, running this script

9 immediately after rpm_restore_core.cmm will usually place you at the faulting instruction.

10 8.2 Getting the RPM log

11 The RPM has a log that is very useful for determining what has occurred on the RPM. This is the

12 primary source of debugging reset and hang problems and can also be useful for looking at

13 performance issues.

14 8.2.1 Using T32

15 While attached to the RPM in the Break state, run the following commands in T32:

16

17 do rpm_proc\core\power\ulog\scripts\ULogDump.cmm <path to your directory>

18 do rpm_proc\core\power\npa\scripts\NPADump.cmm <path to your directory>

19

20 This places the RPM external log and the NPA log, which only contains dump information, into

21 the log directory. The RPM external log requires use of a parsing tool to interpret. To run the

22 ROM external log, run the following command from the log directory:

23

24 python rpm_proc\core\power\rpm\debug\scripts\rpm_log_bfam.py -f “RPM

25 External Log.ulog” -n “NPA Log.ulog” > rpm_parsed.txt

26

27 Additional switches are –r, which print raw (hex sclk value) timestamps.

80-NA157-15 E 39 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

1 9 Software Events

2 Software events are used to replace RPM log events in RPM.AF. Table 9-1 lists how to add the

3 software event entry.

4 9.1 RPM SWEvent range table

5 Table 9-1 reflects the enumeration in core/api/debugtrace/tracer_event_ids.h.

6 Table 9-1 Software event entry

ID range Tech area

0 RESERVED

1 to 63 DDR

64 to 191 BUS

192 to 319 RPM

320 to 383 SLEEP

384 to 511 CLOCK

512 to 639 PMIC

640 to 649 OCMEM

650 to 669 RAILWAY

670 to 1023 RESERVED

80-NA157-15 E 40 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

Software Events

1 9.2 Adding RPM SWEvents

2 9.2.1 Add new SWEvent to tech area SConscript

3 Add the new SWEvent to the bottom of the list of SWEvents in the SConscript, but before the last

4 event. The format is ['NEW_SWEVENT', 'description of new software event: param1 %d'].

5 An example of adding RPM_MASTER_SET_TRANSITION_COMPLETE to

6 core/power/rpm/build/Sconscript is:

7

8 if 'USES_QDSS_SWE' in env:

9 QDSS_IMG = ['QDSS_EN_IMG']

10 events = [['RPM_BOOT_STARTED=192','rpm boot started'],

11 ['RPM_BOOT_FINISHED','rpm boot finished'],

12 ['RPM_BRINGUP_REQ','rpm_bringup_req: (master %d) (core %d)'],

13 ['RPM_BRINGUP_ACK','rpm_bringup_ack: (master %d) (core %d)'],

14 ['RPM_SHUTDOWN_REQ','rpm_shutdown_req: (master %d) (core %d)'],

15 ['RPM_SHUTDOWN_ACK','rpm_shutdown_ack: (master %d) (core %d)'],

16 ['RPM_TRANSITION_QUEUED','rpm_transition_queued: (master %d) (status

17 %d) (deadline: %d)'],

18 ['RPM_MASTER_SET_TRANSITION','rpm_master_set_transition: (master %d)

19 (fromSet %d) (toSet: %d)'],

20 ['RPM_MASTER_SET_TRANSITION_COMPLETE','rpm_set_transition_complete:

21 (master %d)'],

22 ['RPM_LAST=319','rpm last placeholder'],

23 ]

24 env.AddSWEInfo(QDSS_IMG, events)

25

26 9.2.2 Add SWEVENT calls for new SConscript

27 Include swevent.h and make calls of the form SWEVENT(<enum>, params...).

28 For example:

29

30 #include "swevent.h"

31 ...

32 SWEVENT(RPM_MASTER_SET_TRANSITION_COMPLETE, master_id);

80-NA157-15 E 41 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

Software Events

1 9.2.3 Add SWEVENT RAM post-parsing

2 1. Add parsing details to core/power/rpm/debug/scripts/<tech area>_parser.py.

3 2. ID is a hex value which matches the swevent ID.

4 RPM_MASTER_SET_TRANSITION_COMPLETE = 200 = 0xc8.

5 3. The class should return a string describing the SWEvent.

6 4. Data is parseable with various functions, described in core/power/rpm/debug/scripts/

7 target_data.py.

8 An example of adding a parsing class for RPM_MASTER_SET_TRANSITION_COMPLETE is:

9

10 class RPMTransitionComplete:

11 __metaclass__ = Parser

12 id = 0xC8

13 def parse(self, data):

14 return 'rpm_master_set_transition_complete (master: %s)' %

15 get_master_name(data[0])

16

80-NA157-15 E 42 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

1 10 RPM Master User Guide

2 10.1 Active mode usage

3 Assuming CXO = (clock, 0), to turn it on right now, submit the following Active mode RPM

4 driver request:

5

6 rpm_sync_request(RPM_ACTIVE_SET, RPM_CLOCK_REQ, 0, cxo_request);

7

8 RPM_CLOCK_REQ is a clk string. cxo_request is the KVP buffer constructed as described in

9 Section 5.4.2.

10 The function call above sends a request in Blocking mode. To asynchronously post a message,

11 e.g., because you have multiple messages to send and only want to wait on the last one, exchange

12 the call for a call to rpm_post_request.

13 rpm_post_request returns a message ID. Message IDs uniquely identify the changes that your

14 post request generated to the RPM. Sometimes the message ID can be 0. This may happen when

15 the request was redundant, e.g., the RPM already has that request, or deferred, i.e., some sets, like

16 the sleep set, are not generally synchronized until idle time.

17 To send asynchronously for just a while, and later “join” with your message, call the API

18 rpm_barrier(<message ID>) with the ID returned by rpm_post_request; this API can be used to

19 subsequently wait for the completion of that message (and all preceding messages).

20 To chain multiple messages and wait for them all to complete, use the following idiom:

21

22 unsigned last_id = 0, id;

23 id = rpm_post_request(...);

24 last_id = id ? id : last_id;

25 id = rpm_post_request(...);

26 last_id = id ? id : last_id;

27 id = rpm_post_request(...);

28 last_id = id ? id : last_id;

29 rpm_barrier(last_id);

30

31 This sequence invokes three RPM requests and then waits for all three to complete. It is robust to

32 the 0 return cases and guarantees that all of the requests have completed, regardless of set request

33 or redundance.

80-NA157-15 E 43 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Master User Guide

1 10.2 Sleep mode usage

2 10.2.1 RPM.AF→RPM.BF RPM sleep interaction differences

3 A very important difference in the RPM protocol between RPM.AF and RPM.BF families that

4 significantly affects the optimal usage of the RPM messaging channel is that the RPM now

5 allows multiple messages in flight at a time. It might be able to do some synchronization of the

6 sleep set in advance. The strategy for doing this is not obvious and may vary by processor, but

7 this could include (and is certainly not limited to):

8 Detecting a use case change and presynchronizing new sleep set resources

9 Speculatively preupdating the sleep set based on sleep set usage patterns or other activity

10 occurring on the processor

11 Doing absolutely nothing different than on RPM.AF when standard sleep set caching already

12 results in 0 RPM traffic for nearly all sleep set needs

13 Further, the biggest, largest, and most salient point in all of these discussions is that the limitation

14 on RPM.AF where we strictly enforced that masters must wait until the entire sleep set has been

15 acknowledged before entering into an SPM-RPM handshake has been lifted. This should allow

16 masters to “blast” sleep sets into the RPM and go directly to sleep, minimizing the amount of

17 energy spent in the idle task doing no useful work, i.e., we are trying to achieve RPM processing

18 of any changes to the sleep set in parallel with other expensive power-collapse work, e.g.,

19 flushing caches, etc. We already achieved many gains in this category by enabling sleep set

20 caching on RPM.AF, but this change should further those advances, continuing to make the

21 latency of the RPM handshake LPR smaller and (perhaps more importantly) less variable.

22 At a high level, the normal flow for master processor sleep with RPM has changed from

23 RPM.AF:

24 1. Send sleep set

25 2. Poll for response

26 3. Send next active set and poll for response

27 4. Wi-Fi/handshake

28 5. Force send next active set and wait for response

29 To the faster and more efficient:

30 1. Send sleep set

31 2. Send next active set

32 3. Disable ack interrupt

33 4. Wi-Fi/handshake

34 5. Enable ack interrupt

35 6. If <last next active set msg_id> is nonzero:

36 a. Set the SMDLite signal SMDL_SIG_RI

37 b. rpm_churn_queue(<last next active set msg_id>)

38 c. Clear the SMDLite signal SMDL_SIG_RI

80-NA157-15 E 44 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

RPM Master User Guide

1 This covers all four interesting combinations of sleep success and next active set usage:

2 1. If there was no next active set request, the last ID is 0; regardless of whether the WFI was

3 successful, we return immediately.

4 If the WFI was not successful, the RPM continues acknowledging the sleep set requests.

5 These acks are processed concurrently with the reason for wakeup so that when sleep

6 does occur next, we should have already reset the RPM status (and, with luck, the sleep

7 set will already be in sync for the next sleep).

8 If the WFI was successful, the acks for all sleep messages will already have been

9 received; the SMD ISR runs once after wakeup to clear out the SMD FIFO. These acks

10 could potentially be processed from sleep context if you save the last sleep msg_id and

11 call churn_queue with the most recent (sleep OR next_active_set) ID. However, if it

12 blocks in sleep context to do this, it can delay processing on whatever wakeup interrupt

13 was received and pass up possible (or, on the Hexagon™, likely) parallelism in

14 processing the wakeup interrupt/sleep acks at the same time.

15 2. If there was a next active set message and the WFI failed:

16 Setting SIG_RI instructs the RPM to process the next active set requests now, rather than

17 waiting for a processor sleep event. (Normally, NAS requests are not touched by the

18 RPM until the master processor goes to sleep.)

19 rpm_churn_queue runs a polling loop waiting for RPM acknowledgement of all next

20 active set requests.

21 3. If there was a next active set message and the WFI succeeded:

22 Setting SIG_RI has no effect on the RPM (all of the outstanding NAS requests will have

23 been handled at the time of the sleep handshake).

24 rpm_churn_queue clears the SMD FIFO of all the existing next active set messages.

80-NA157-15 E 45 Confidential and Proprietary – Qualcomm Technologies, Inc.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION

You might also like

- CNC Machining Handbook: Building, Programming, and ImplementationFrom EverandCNC Machining Handbook: Building, Programming, and ImplementationNo ratings yet

- MSM8916.LA.1.0 Linux Android™ Release 1.0.25 For MSM8916 DevicesDocument42 pagesMSM8916.LA.1.0 Linux Android™ Release 1.0.25 For MSM8916 Devicesburdun777No ratings yet

- Cyclone V Device Handbook Volume 3 Hard Processor System Technical Reference Manual PDFDocument670 pagesCyclone V Device Handbook Volume 3 Hard Processor System Technical Reference Manual PDFMaximiliano NietoNo ratings yet

- MSM8916.LA.1.1 Linux Android™ Release 1.1.32 For MSM8916 DevicesDocument44 pagesMSM8916.LA.1.1 Linux Android™ Release 1.1.32 For MSM8916 Devicesburdun777No ratings yet

- eMBMS Middleware Configuration Parameters: Profile Specification Release 3.2Document42 pageseMBMS Middleware Configuration Parameters: Profile Specification Release 3.2burdun777No ratings yet

- Coreriver Semiconductor Gc49c501g1 Sj20ig 7cd22b693fDocument86 pagesCoreriver Semiconductor Gc49c501g1 Sj20ig 7cd22b693fSpart GorancNo ratings yet

- Netserver e 800Document103 pagesNetserver e 800shyamNo ratings yet

- eMBMS Middleware Provisioning Parameters: Profile Specification Release 3.2Document40 pageseMBMS Middleware Provisioning Parameters: Profile Specification Release 3.2burdun777No ratings yet

- TU0308 Tutorial ARM Cortex-M1 Embedded ProcessorDocument57 pagesTU0308 Tutorial ARM Cortex-M1 Embedded ProcessorJack GoodNo ratings yet

- MPC5676RRMDocument1,581 pagesMPC5676RRMBalraj ParabNo ratings yet

- Oms 1000 K Operator GuideDocument284 pagesOms 1000 K Operator GuideRobertPivacNo ratings yet

- RAID Array 230/plus Subsystem RAID Configuration Utility: User's GuideDocument99 pagesRAID Array 230/plus Subsystem RAID Configuration Utility: User's GuideChristopher AiyapiNo ratings yet

- 3 Phase Ac Induction Motor Control With PFCDocument50 pages3 Phase Ac Induction Motor Control With PFChieuhuech1No ratings yet

- Oracle Database Backup and Recovery Advanced User GuideDocument586 pagesOracle Database Backup and Recovery Advanced User Guideapi-25919427100% (1)

- MOD-15-1825 - V10.14-022 Software Release Note - Issue 1.0Document22 pagesMOD-15-1825 - V10.14-022 Software Release Note - Issue 1.01012268087No ratings yet

- 2012 Qlogic Storage Area Networking Interoperability GuideDocument748 pages2012 Qlogic Storage Area Networking Interoperability GuideRaul RodriguezNo ratings yet

- Performance and Tuning For Oracle WebLogic ServerDocument162 pagesPerformance and Tuning For Oracle WebLogic Serverhelmy_mis1594No ratings yet

- ManualDocument153 pagesManualvicente puentesNo ratings yet

- UniSP AUG3Document268 pagesUniSP AUG3Andrei DanaiataNo ratings yet

- CD E23943 01 Web.1111 E13814 PDFDocument162 pagesCD E23943 01 Web.1111 E13814 PDFErivelto OliveiraNo ratings yet

- Powerflex Drives With Totalforce Control: Programming ManualDocument130 pagesPowerflex Drives With Totalforce Control: Programming Manualabner kaiberNo ratings yet

- Sas3flash quickRefGuide Rev1-0Document28 pagesSas3flash quickRefGuide Rev1-0alexiavgNo ratings yet

- HP Storageworks Msa San Switch 2/8: Installation GuideDocument72 pagesHP Storageworks Msa San Switch 2/8: Installation GuidenetfinityfrNo ratings yet

- Firmware Update User ManualDocument53 pagesFirmware Update User ManualSamdan NamhaisurenNo ratings yet

- Proliant Ml330 Generation 2 Server: Setup and Installation GuideDocument160 pagesProliant Ml330 Generation 2 Server: Setup and Installation Guidejfreddy026864No ratings yet

- LAN - Mellanox OFED Linux User Manual 1 - 5 - 3-1 - 0 - 0Document224 pagesLAN - Mellanox OFED Linux User Manual 1 - 5 - 3-1 - 0 - 0Nanard78No ratings yet

- Secure Web Management (SWM) User Guide: Magnum 6K Family of SwitchesDocument296 pagesSecure Web Management (SWM) User Guide: Magnum 6K Family of SwitchesnaceurmaNo ratings yet

- Planning and Designing Your DeltaV™ Digital Automation Systems and DeltaV™ SIS Process Safety Systems 2015 PDFDocument214 pagesPlanning and Designing Your DeltaV™ Digital Automation Systems and DeltaV™ SIS Process Safety Systems 2015 PDFquocthaimt97No ratings yet

- Fan ModuleDocument414 pagesFan Modulefouad boutatNo ratings yet

- IPS Tempo: User ManualDocument262 pagesIPS Tempo: User ManualdevaseelanNo ratings yet

- Jace8000Startup GuideDocument48 pagesJace8000Startup GuideChris MeinNo ratings yet

- PRM User Manual - enDocument212 pagesPRM User Manual - ensofianigniteNo ratings yet

- VSC7424-02, VSC7425-02, VSC7426-02, and VSC7427-02Document772 pagesVSC7424-02, VSC7425-02, VSC7426-02, and VSC7427-02Hosein movahedian attarNo ratings yet