Professional Documents

Culture Documents

Design Resistance of Pin Joints

Uploaded by

irmakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Resistance of Pin Joints

Uploaded by

irmakCopyright:

Available Formats

Design Resistance of Pin joints

Whenever there is a risk of pins becoming loose they should be secured.

Pin connections which involve not joint rotation may be designed as single bolted connections conditional that

the length of pin , in the joint is less than 3 times the diameter. For all other applications the method below

should be used.

In pin connected members the geometry of the unstiffened element that contains the hole for the pin should

satisfy the dimensional requirements identified below.

Pin connected members should be arranged to avoid eccentricity and should be of sufficient size to distribute

the load from the region of the pinned member into the main member

Failure Mode Design Requirements

Shear resistance of pin Fv,Rd = 0,6.A.fup / γM2 >= Fv,Ed

Bearing resistance of plate & pin Fb,Rd = 1,5.t.d.fy / γM0 >= Fb,Ed

If pin is to be replaceable this requirement is also to be satisfied Fb,Rd,ser = 0,6.t.d.fy / γM6,ser >= Fb,Ed,ser

Bending resistance of pin MRd = 1,5.Wel.fyp / γM0 >= MEd

If pin is to be replaceable this requirement is also to be satisfied Fb,Rd,ser = 0,8.Wel.fyp / γM6,ser >= MEd,ser

combined shear and bending resistance of pin

d = dia of pin

fy = lower yield strengths of pin and connected parts

fup = ultimate tensile strength of pin

fyp = yield strength of pin

t = thickness of connected part

A = cross-sectional area of pin.

You might also like

- Chapter 6-Connections PDFDocument12 pagesChapter 6-Connections PDFTemesgenAbiy100% (2)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Screw Thread CalculationsDocument4 pagesScrew Thread Calculationsyauction50% (2)

- BS EN 1993-1-8:2005 EN 1993-1-8:2005 (E) : 3.10.4 Lug AnglesDocument5 pagesBS EN 1993-1-8:2005 EN 1993-1-8:2005 (E) : 3.10.4 Lug Anglesmn4webNo ratings yet

- Screw Thread CalculationsDocument4 pagesScrew Thread CalculationsbagmassNo ratings yet

- Beam Column ConnectionDocument10 pagesBeam Column Connectionmaniram7No ratings yet

- Bolted Connection (Wk7-Wk10)Document20 pagesBolted Connection (Wk7-Wk10)Ma. Angelica TamayaoNo ratings yet

- Screw Thread Calculations - Roy MechDocument6 pagesScrew Thread Calculations - Roy Mechangelo collaNo ratings yet

- Free Estimating & Takeoff Software For Estimators, Gcs & PmsDocument4 pagesFree Estimating & Takeoff Software For Estimators, Gcs & PmsDhimas Surya NegaraNo ratings yet

- Chapter 2 Tension MembersDocument8 pagesChapter 2 Tension MembersGamtesa EjetaNo ratings yet

- Rosca Acme 3-2 MasmecánicaDocument6 pagesRosca Acme 3-2 MasmecánicaBachoNo ratings yet

- Bolt Effective AreaDocument5 pagesBolt Effective AreaMuraleedharan100% (1)

- 2.1 Bolts GeneralDocument54 pages2.1 Bolts GeneralIyrin JohnNo ratings yet

- Structural Steel ConnectionsDocument54 pagesStructural Steel ConnectionsnikNo ratings yet

- Tensioner Nuts & Bolts We Make Thread Gauges Cold Forgings From ChinaDocument4 pagesTensioner Nuts & Bolts We Make Thread Gauges Cold Forgings From ChinamohanjatinderNo ratings yet

- 171CE113-bolted ConnectionDocument9 pages171CE113-bolted ConnectionARJUN RNo ratings yet

- Lecture10 PDFDocument8 pagesLecture10 PDFnihithNo ratings yet

- Chapter 6 ConnectionDocument30 pagesChapter 6 ConnectionIvy SeahNo ratings yet

- Tension Members DesignDocument42 pagesTension Members DesignVermuch CasioNo ratings yet

- 4.2bearing Type ConnectionsDocument6 pages4.2bearing Type ConnectionsMani KumarNo ratings yet

- Bolted ConnectionsDocument49 pagesBolted Connectionsabhijithshettyk100% (2)

- Factored Load Factored StrengthDocument12 pagesFactored Load Factored Strengthhello whelloNo ratings yet

- Screw Thread CalculationsDocument4 pagesScrew Thread CalculationsKelvin TsoiNo ratings yet

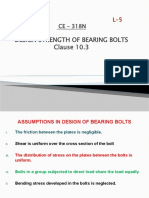

- Design Strength of Bearing Bolts Clause 10.3Document39 pagesDesign Strength of Bearing Bolts Clause 10.3michael mwaranguNo ratings yet

- 1 Screw Rivet WeldDocument26 pages1 Screw Rivet WeldWajih RaziUddin100% (1)

- Table 3.10: Design Criteria For Pin Connections: T D D D F EDocument2 pagesTable 3.10: Design Criteria For Pin Connections: T D D D F EDev lamichhaneNo ratings yet

- SDM Chapter E - 0708Document6 pagesSDM Chapter E - 0708Janice FernandezNo ratings yet

- Welded ConnectionsDocument9 pagesWelded ConnectionsAnonymous 1sJXK1DKZNo ratings yet

- ME-311 Machine Design - Lecture 5Document17 pagesME-311 Machine Design - Lecture 5Muhammad Zun Nooren BangashNo ratings yet

- Design of Tension MembersDocument11 pagesDesign of Tension MembersWilfharry billyNo ratings yet

- Flust-Extended End Plate ConnectionDocument8 pagesFlust-Extended End Plate ConnectionamachmouchiNo ratings yet

- Connection Design - Its Role in Steel DetailingDocument9 pagesConnection Design - Its Role in Steel DetailingEduardo De Castro Cruz Jr.No ratings yet

- LESSON 8. Tension MemberDocument8 pagesLESSON 8. Tension MemberAdarsh bhatNo ratings yet

- Design of Bolted ConnectionsDocument15 pagesDesign of Bolted ConnectionsAritroNo ratings yet

- Design and Analysis of Simple ConnectionsDocument88 pagesDesign and Analysis of Simple ConnectionsSabih Hashim Alzuhairy100% (1)

- Design OF Flush-Extended End Plate ConnectionsDocument3 pagesDesign OF Flush-Extended End Plate Connectionskapilnandwana100% (1)

- SteelDesign Fastener Fu 455Document40 pagesSteelDesign Fastener Fu 455Landel SmithNo ratings yet

- AISC 341 Section 9Document9 pagesAISC 341 Section 9Quốc KhánhNo ratings yet

- Haunched Joint - Capacity DesignDocument9 pagesHaunched Joint - Capacity Designd_i_z_zNo ratings yet

- Riveted Joint Design: Middle Technical University Technical Engineering Material DepartmentDocument12 pagesRiveted Joint Design: Middle Technical University Technical Engineering Material DepartmentTokki TokkiNo ratings yet

- Bolted ConnectionsDocument10 pagesBolted ConnectionsAbhi ANo ratings yet

- Tension MemberDocument30 pagesTension MemberLuke LdhNo ratings yet

- Ethics Team 26Document13 pagesEthics Team 26Kareem MagdyNo ratings yet

- Pages From Civil EngineeringDocument50 pagesPages From Civil EngineeringRagavanNo ratings yet

- ConnectionsDocument205 pagesConnectionsbsitler100% (1)

- Steel DesignDocument18 pagesSteel DesignJaninaRuzzleSilangNo ratings yet

- Structural ConnectionsDocument205 pagesStructural ConnectionsbsitlerNo ratings yet

- IPE 360 Hem 260Document23 pagesIPE 360 Hem 260benzarstefanNo ratings yet

- Chapter 4 - Design of Tension MembersDocument41 pagesChapter 4 - Design of Tension MembersKhaled KhafagyNo ratings yet

- Lecture - 5 - Tension MembersDocument67 pagesLecture - 5 - Tension Membersayoub aliousalahNo ratings yet

- Structural ConnectionsDocument26 pagesStructural ConnectionsAlemtsehay ShiferawNo ratings yet

- Mitec1 03 2005Document21 pagesMitec1 03 2005Sunilkumar ReddyNo ratings yet

- Fastener and Screw Torque DesignDocument6 pagesFastener and Screw Torque DesignjigneshNo ratings yet

- School of Engineering: J. Toby MottramDocument9 pagesSchool of Engineering: J. Toby MottramEdwardGuangcoNo ratings yet

- AWS ReferenceDocument2 pagesAWS ReferenceKent TanakNo ratings yet

- Machinedesign 3417 Specifying Fastener TorqueDocument5 pagesMachinedesign 3417 Specifying Fastener TorqueStarlord PlazaNo ratings yet

- Design of Steel BeamsDocument4 pagesDesign of Steel BeamsSankalp LamaNo ratings yet

- (Asce) SC 1943-5576 0000367 PDFDocument5 pages(Asce) SC 1943-5576 0000367 PDFirmakNo ratings yet

- Steel ConnectionsDocument157 pagesSteel ConnectionsAlem LoajnerNo ratings yet

- Ending Stress: 2 Is Such That The Curve of Deflection IsDocument6 pagesEnding Stress: 2 Is Such That The Curve of Deflection IsirmakNo ratings yet

- Steel ConnectionsDocument157 pagesSteel ConnectionsAlem LoajnerNo ratings yet

- CISC GUIDE FOR ARCHITECTURAL EXPOSED STEEL AESSGuide2EDocument52 pagesCISC GUIDE FOR ARCHITECTURAL EXPOSED STEEL AESSGuide2EmindwriterNo ratings yet

- Maheri 2008 Engineering-StructuresDocument11 pagesMaheri 2008 Engineering-StructuresteodorabogdanNo ratings yet

- 2.4 / Structural Components / CombinedDocument28 pages2.4 / Structural Components / CombinedirmakNo ratings yet

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDIonut SavaNo ratings yet

- Anchor Bolt For ShearDocument22 pagesAnchor Bolt For ShearAnonymous P73cUg73LNo ratings yet

- EN 1090 White Paper17 119019 PDFDocument24 pagesEN 1090 White Paper17 119019 PDFZaza PokumbaNo ratings yet

- Technical Lamination SDocument4 pagesTechnical Lamination SirmakNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- A Welder’s Handbook to Robotic ProgrammingFrom EverandA Welder’s Handbook to Robotic ProgrammingRating: 5 out of 5 stars5/5 (3)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- Evil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityFrom EverandEvil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (3)

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- Arduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!From EverandArduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Rating: 3 out of 5 stars3/5 (1)

- Practical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)From EverandPractical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)No ratings yet

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsFrom EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsRating: 5 out of 5 stars5/5 (3)

- How to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionFrom EverandHow to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionRating: 3.5 out of 5 stars3.5/5 (129)

- Artificial Intelligence: Machine Learning, Deep Learning, and Automation ProcessesFrom EverandArtificial Intelligence: Machine Learning, Deep Learning, and Automation ProcessesRating: 5 out of 5 stars5/5 (2)

- ChatGPT: The Future of Intelligent ConversationFrom EverandChatGPT: The Future of Intelligent ConversationRating: 3.5 out of 5 stars3.5/5 (8)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityFrom EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityRating: 3.5 out of 5 stars3.5/5 (22)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)