Professional Documents

Culture Documents

Watlow Mineral Insulated Thermocouple

Uploaded by

Tadau EnergyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Watlow Mineral Insulated Thermocouple

Uploaded by

Tadau EnergyCopyright:

Available Formats

SPECIFICATION SHEET

Mineral Insulated Thermocouple

Thermocouples,

Fast-Responding,

Durable and Capable;

Ideal for Handling Higher

Temperatures

Mineral insulated thermocouples from Watlow® are Outer sheath

fast-responding, durable and capable of handling higher • Protects wires from oxidation and hostile environments

temperatures. Wide range of sheath materials, diameters and calibrations

These thermocouples are manufactured with XACTPAK®, • Meets specific requirements

Watlow’s trademark for metal-sheathed, mineral insulated In-house manufacturing of XACTPAK material

(MI) thermocouple material. XACTPAK responds fast • Rigid quality control procedures

because the protective metal outer sheath allows the use of • Assures high standards are met

smaller diameter thermocouple conductors. The rock hard • Single source reliability

compacted MgO insulation further enhances the sensor’s

Custom capabilities

ability to “read” temperature by transferring heat quickly to

• Include options such as special lead lengths, lead wires and

the measuring junction.

terminations

The XACTPAK protecting sheath and compacted insulation

outperforms bare wire thermocouple in most applications. Typical Applications

• Heat treating

Performance Capabilities

• Furnaces/kilns

• Easily handles temperatures up to 2200°F (1200°C)

• Turbines

• Meets or exceeds initial calibration tolerances per

• Bearing temperature

ASTM E 230

• Power stations

Features and Benefits • Steam generators

Special mineral insulation • Diesel engines

• Protects thermocouple from moisture and thermal shock • Nuclear reactors

• Permits operation in high temperatures, high pressure • Atomic research

environments • Jet engines and test cells

Diameters as small as 0.020 in. (0.50 mm) • Rocket engines

• Ideal when physical space or extremely fast response are • Semiconductor manufacturing

critical

• Refineries/oil processing

Flexibility of the XACTPAK material

• Catalytic reformers

• Allows forming and bending of the thermocouple

• Food processing

without the risk of cracking to meet design requirements

Styles

Cut and Stripped - Style AB Metal Transitions - Style AF and AQ

The main feature of Watlow’s Style AB thermocouple is that Metal transitions are the distinguishing feature of Styles AF

it allows you to terminate the thermocouple yourself. Style and AQ thermocouples. The transition provides a durable,

AB is simply a section of XACTPAK material, junctioned and potted connection between the XACTPAK sheathed

stripped. It is the most basic of all the mineral insulated thermocouple material and the flexible SERV-RITE® insulated

thermocouple styles. wire.

Because it is constructed with XACTPAK mineral insulation, On Style AF the transition is crimped to the sheath 0.040

the thermocouple is protected from moisture, thermal shock, in.(1 mm) and larger. Crimping is a quick, reliable method of

high temperatures and high pressure. attachment.

Features The Style AQ miniature transition thermocouple is designed

• Cold end, stripped and sealed with epoxy inhibits moisture for limited space applications where size and/or response

penetration time are critical. It is designed to give instant readings in

• Dual element style allows two instruments to run off the various mediums. More accurate readings are possible

same element, reducing costs because of its small size and fast response.

Features

Plug or Jack Termination - Style AC • The transition body is filled with a potting compound,

Featuring plug or jack terminations, Style AC thermocouples which insulates and strengthens the splice

can be quickly connected or disconnected. Besides saving • Coiled spring strain relief on Style AF protects the wire

time, this thermocouple style offers the advantage of ease against sharp bends in the transition area

of use even by inexperienced personnel. In addition, the • Custom lead wire terminations include plug-in jacks, spade

thermocouples are color coded per ASTM E 230 specifications lugs, plugs with mating connectors and more

so you can easily determine the calibration.

• Many made-to-order options are available in lead wire

On all Style AC thermocouples except ASTM E 230 Type R construction, length and sheath material

and S, the pins and contacts are of the same alloy as the

• Stranded lead wire construction is an ideal choice for

thermocouple, resulting in higher accuracy. This technique

applications where the lead wire is subjected to continuous

eliminates errors due to temperature gradients across the

flexing

connector. Type R and S connectors have compensating

alloys. Connection Head - Style AR

Features Featuring connection heads, Style AR mineral insulated

• Plugs and jacks are easy to connect and disconnect, saving thermocouples are resistant to dust and moisture, ensuring

you time continuous long term reliability. This is possible because the

• ASTM color coded connectors allow quick identification of covers keep the connection to the extension wire clean.

the thermocouple calibration The connection heads are designed for mating to a conduit,

• Miniature connectors, available with thermocouple allowing permanent installation. A variety of head styles are

diameters up to 0.125 in. (3.0 mm), can be used in locations available, including plastic, cast iron, aluminum and explosion

where space is minimal. The miniature plug permits quick proof.

connection to portable instrumentation Features

• Matching thermocouple alloys provide higher accuracy • Connection head provides superior dust and moisture

resistance

• An adapter assures the connector is mounted rigidly to the

sheath, preventing the connector from turning or twisting • Eight different head styles are available to meet various

application requirements

• Lugs on covers allow tightening with either a screwdriver or

wrench

• Plastic heads are weather resistant and can be exposed

to weak acids, organic solvents, alkalies, sunlight and dust.

Bottom mounting is standard; side mounting is available on

request

• Cast iron heads are available in standard and miniature

sizes and are suitable for demanding high temperature

environments, such as heavy industrial and process

applications

• Optional head-mounted transmitter, 4-20mA, reduces

electrical noise. The transmitter is available on connection

head Styles A, B, C, D, E and H

Styles (con’t) Ordering Information

Wafer Head - Style AS Ordering information varies. Please contact your Watlow

The Style AS thermocouple features a “wafer” head, representative for details.

which allows quick access to terminal screws for wiring.

This thermocouple is an economical choice because the

termination is brazed directly to the XACTPAK sheath.

Features

• Termination directly to sheath allows quick hookup and

disassembly

• The terminal head is available in a wide range of materials

in both single and dual configurations

• Ceramic termination rating to 540°C (1000°F)

For Use with Thermowells - Style AT

Style AT thermocouple is an energy and process temperature

sensor that features XACTPAK metal-sheathed mineral

insulation, enhancing the sensor’s ability to “read”

temperature by transferring heat quickly to the measuring

junction.

This thermocouple style is ideal for process petrochemical

and power applications where a sensor-thermowell assembly

is typically used. Thermowells protect the thermocouple and

allow replacement of the sensor without shutting down the

process, saving valuable downtime.

Features

• Designed for use with thermowells, Style AT is ideal for

process industry applications

• Compliance with specifications such as ASTM assures high

quality sensor products

• Manufacturing capabilities include special tube cleaning

processes, insulation baking to 1095˚C (2000˚F) and much

more

• Connection heads come in four different styles

• Spring-loading option allows the thermocouple to

maintain contact against the bottom of the thermowell,

assuring rapid heat transfer to the sensor

Applications

• Petrochemical

• Refineries

• Power stations

• Blast furnaces

• Incinerators

Watlow®, XACTPAK® and SERV-RITE® are registered trademarks of Watlow Electric

Manufacturing Company.

Powered by Possibility

To be automatically connected to the nearest International Technical Sales Offices:

North American Technical Sales Office: Austria +43 6244 20129 0 India +91 40 6661 2700 Mexico +52 442 256 2200

China +86 21 3532 8532 Italy +39 02 458 8841 Singapore +65 6773 9488

1-800-WATLOW2 • www.watlow.com France +33 1 41 32 79 70 Japan +81 3 3518 6630 Spain +34 91 675 1292

inquiry@watlow.com Germany +49 7253 9400 0 Korea +82 2 2169 2600 Taiwan +886 7 288 5168

UK +44 115 964 0777

©2019 Watlow Electric Manufacturing Company all rights reserved. RIC-MIT-0116

You might also like

- HW2 SolutionDocument7 pagesHW2 SolutionAnson ChanNo ratings yet

- Interaction With MatterDocument13 pagesInteraction With MatterMark Gonzales100% (1)

- CAT NR3000 Service ManualDocument273 pagesCAT NR3000 Service ManualKelli BrownNo ratings yet

- Terminal de 52 y 72.5kVDocument6 pagesTerminal de 52 y 72.5kVkevin huamanNo ratings yet

- Ca Ohvt Bro 0217 Epp0413 - EngDocument4 pagesCa Ohvt Bro 0217 Epp0413 - EngchengkkNo ratings yet

- Tubular and Process Assemblies: W A T L O WDocument26 pagesTubular and Process Assemblies: W A T L O WEliasNo ratings yet

- Air 0423Document34 pagesAir 0423AdilsonNo ratings yet

- Tubular and Process Assemblies: W A T L O WDocument10 pagesTubular and Process Assemblies: W A T L O WEliasNo ratings yet

- Catalog Appleton WSR Interlocked Receptacle Cover en Us 178392Document3 pagesCatalog Appleton WSR Interlocked Receptacle Cover en Us 178392Eecol phone ParedesNo ratings yet

- Cable TrayDocument5 pagesCable Traykxalxo7637No ratings yet

- Cabillas Convencionales PDFDocument12 pagesCabillas Convencionales PDFgenesisNo ratings yet

- Publication - Painting, Coating & Corrosion Protection - Aremco Inc - High Temperature Materials - Coatings and AdhesivesDocument56 pagesPublication - Painting, Coating & Corrosion Protection - Aremco Inc - High Temperature Materials - Coatings and Adhesiveszinha_alNo ratings yet

- CABLE LUG AND HEATSHRINK SELECTION GUIDEDocument2 pagesCABLE LUG AND HEATSHRINK SELECTION GUIDEkwagga125No ratings yet

- Xuper 6804 XHD: WeldingDocument2 pagesXuper 6804 XHD: WeldingAravind rajNo ratings yet

- Select Arc Brochure On Ni Alloy Welding ProductsDocument6 pagesSelect Arc Brochure On Ni Alloy Welding Productsharan2000No ratings yet

- Leroy Somer Lsa 49,1 123Document28 pagesLeroy Somer Lsa 49,1 123Elinton De Jesus SarmientoNo ratings yet

- Power Series BrochureDocument12 pagesPower Series BrochureJuan BrasalNo ratings yet

- RTD BrochureDocument2 pagesRTD Brochureshadrick kasubaNo ratings yet

- Receptaculo Con Tapa y Caja Mod. ARE-6424Document7 pagesReceptaculo Con Tapa y Caja Mod. ARE-6424Rolando GilNo ratings yet

- TDS Siltherm-AluFlex 05-2022Document2 pagesTDS Siltherm-AluFlex 05-2022benjaminNo ratings yet

- Chromcarb N6006: WeldingDocument2 pagesChromcarb N6006: WeldingCasa de Adoración ConcepciónNo ratings yet

- Anema Induction MotorsDocument12 pagesAnema Induction MotorszdrahalNo ratings yet

- Cartridge Heaters FIREROD ImmersionDocument3 pagesCartridge Heaters FIREROD ImmersionEliasNo ratings yet

- Structural Materials: Metals and Metal AlloysDocument9 pagesStructural Materials: Metals and Metal AlloysAbhishek AroraNo ratings yet

- Surface Modification for Power PlantsDocument9 pagesSurface Modification for Power Plantsraj patelNo ratings yet

- Cartridge HeatersDocument48 pagesCartridge Heatersprsking187No ratings yet

- RO3035 Laminate Data Sheet PDFDocument2 pagesRO3035 Laminate Data Sheet PDFrahul05singhaNo ratings yet

- Cartridge Heaters FIRERODDocument34 pagesCartridge Heaters FIRERODEliasNo ratings yet

- Introduction To Strain GaugesDocument32 pagesIntroduction To Strain GaugesManjunatha Babu N.s100% (1)

- Acs-Climacs Rooftop Catalogue.Document28 pagesAcs-Climacs Rooftop Catalogue.Saber EntzNo ratings yet

- 1973 BACKER Shaped Heat 20111009Document50 pages1973 BACKER Shaped Heat 20111009Hank MarvinNo ratings yet

- Lugs & Ferrules NewDocument3 pagesLugs & Ferrules NewOhaneje UzomaNo ratings yet

- Rgzesd MSDocument2 pagesRgzesd MSmaliNo ratings yet

- Hollow Core BushingDocument4 pagesHollow Core BushingAkhileshkumar PandeyNo ratings yet

- Cartridge 0124Document48 pagesCartridge 0124estampados25032020No ratings yet

- Industrial Air Heater PDFDocument34 pagesIndustrial Air Heater PDFleoNo ratings yet

- Rooftop Package Unit Catalog 8 kW to 500 kWDocument25 pagesRooftop Package Unit Catalog 8 kW to 500 kWSaber EntzNo ratings yet

- RTD 171203114400Document32 pagesRTD 171203114400Eng-anwer kadhimNo ratings yet

- Premium Industrial Spark Plug for Jenbacher Gas Engines (FBM80WPNDocument2 pagesPremium Industrial Spark Plug for Jenbacher Gas Engines (FBM80WPNHelder Pinto0% (1)

- Resistance Temperature Detector (RTD)Document21 pagesResistance Temperature Detector (RTD)Soumik DasNo ratings yet

- Chapter 5 Application of Insulating MaterialDocument21 pagesChapter 5 Application of Insulating MaterialAmir nawazNo ratings yet

- Power Series - Electric MotorsDocument12 pagesPower Series - Electric MotorsTAIYONG GUONo ratings yet

- Cable Heaters K-RINGDocument2 pagesCable Heaters K-RINGEliasNo ratings yet

- Cartridge Heaters Metric FIRERODDocument10 pagesCartridge Heaters Metric FIRERODEliasNo ratings yet

- Portable MIG-Welders WorkhorseDocument2 pagesPortable MIG-Welders WorkhorseCristea IonelNo ratings yet

- "Lightning Arrester": Seminar Report ONDocument14 pages"Lightning Arrester": Seminar Report ONDev KumarNo ratings yet

- EnerSys Mseries SpecsDocument2 pagesEnerSys Mseries Specsibs434No ratings yet

- Low Heat Input SMAW Welding ElectrodesDocument62 pagesLow Heat Input SMAW Welding ElectrodesShukla SuyashNo ratings yet

- Battery Range Summary: Safe SafeDocument2 pagesBattery Range Summary: Safe SaferadikahendryNo ratings yet

- Product Catalog - Distribution TransformersDocument12 pagesProduct Catalog - Distribution Transformerspt epjNo ratings yet

- Nemalux MR Series Brochure A33Document3 pagesNemalux MR Series Brochure A33Chio ArosteguiNo ratings yet

- Sucker Rods Brochure 851 06Document12 pagesSucker Rods Brochure 851 06Ronald LlerenaNo ratings yet

- Colcfh 0311Document4 pagesColcfh 0311JYK STONENo ratings yet

- EutecTrode Manual Metal Arc Electrodes PDFDocument12 pagesEutecTrode Manual Metal Arc Electrodes PDFswapneel_kulkarniNo ratings yet

- Mineral Insulated Metal-Sheathed CableDocument13 pagesMineral Insulated Metal-Sheathed CablekmiqdNo ratings yet

- Fusion Bond Epoxt Coating BrochureDocument12 pagesFusion Bond Epoxt Coating Brochure4uengineerNo ratings yet

- Cavi RychemDocument4 pagesCavi RychemmammolloNo ratings yet

- Universal Boxes and CoversDocument2 pagesUniversal Boxes and CoversCharles YaoNo ratings yet

- E109 Control LinesDocument11 pagesE109 Control LinestongsabaiNo ratings yet

- Watlow AF Style ThermocoulpeDocument3 pagesWatlow AF Style ThermocoulpehamadaNo ratings yet

- Welding WireDocument20 pagesWelding WirefoxmancementNo ratings yet

- Immersion Heaters Square FlangeDocument4 pagesImmersion Heaters Square FlangeEliasNo ratings yet

- 2A Ultra Low Dropout Linear Regulator TJ4320Document20 pages2A Ultra Low Dropout Linear Regulator TJ4320Rizky GultomNo ratings yet

- Currentwatch Current Sensors 1: DescriptionDocument52 pagesCurrentwatch Current Sensors 1: DescriptionFlorin MNo ratings yet

- Scotia UpgradesDocument31 pagesScotia UpgradesForexliveNo ratings yet

- Digital Resistance Meter - Innova I63CDocument1 pageDigital Resistance Meter - Innova I63CSourabh ChoudharyNo ratings yet

- FUST NOVOMATIC 1268.3_051306Document27 pagesFUST NOVOMATIC 1268.3_051306Asemota OghoghoNo ratings yet

- Carbon Tax: Implementation Plan in IndonesiaDocument14 pagesCarbon Tax: Implementation Plan in IndonesiaMiftahul Huda100% (1)

- MRT - Belitung Oil TerminalDocument26 pagesMRT - Belitung Oil TerminalMohammadNo ratings yet

- Apl Iit DelhiDocument1,215 pagesApl Iit DelhiManral SaurabhNo ratings yet

- Modular FURNACE INSULATION THKNESS CALDocument2 pagesModular FURNACE INSULATION THKNESS CALRamachandra Bhat HireNo ratings yet

- CV (Rehan Mustafa)Document4 pagesCV (Rehan Mustafa)wasim92khanNo ratings yet

- Waste to Energy Status in IndonesiaDocument18 pagesWaste to Energy Status in IndonesiaRadian Ahmad MaulanaNo ratings yet

- Gölcük VET Scenario - Oil Tempereture HighDocument1 pageGölcük VET Scenario - Oil Tempereture HighCantekin CeNo ratings yet

- Man - Ge - Tables de FiliationDocument13 pagesMan - Ge - Tables de FiliationSaid HajjamiNo ratings yet

- X3E Series Servo Drive User Manual V5.1 (En)Document162 pagesX3E Series Servo Drive User Manual V5.1 (En)Salai Kyaw Naing Tun100% (1)

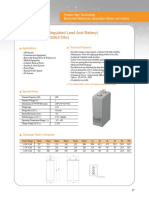

- (Valve Regulated Lead Acid Battery) ESG 200 (2V, 200AH/10hr)Document1 page(Valve Regulated Lead Acid Battery) ESG 200 (2V, 200AH/10hr)RosiinNo ratings yet

- Roland Rolled Over The Floor in Order To Put Off The Fire That Caught Her Clothes. Which Principle Explains This?Document3 pagesRoland Rolled Over The Floor in Order To Put Off The Fire That Caught Her Clothes. Which Principle Explains This?Rovz GC BinNo ratings yet

- Solarworld - Magazine 2016 - en - WebDocument18 pagesSolarworld - Magazine 2016 - en - WebSamuel Arévalo GNo ratings yet

- 69 Cooler Motor Fan Asa0367 Sandvic QJ341Document4 pages69 Cooler Motor Fan Asa0367 Sandvic QJ341FilipposNo ratings yet

- Lecture Notes Conductors, Insulators, and SemiconductorsDocument2 pagesLecture Notes Conductors, Insulators, and Semiconductorsoduleke davidNo ratings yet

- Jet Fans: Singapore T: +65-65660371 F: +65-65626736 Asia Distribution - Please Contact UsDocument2 pagesJet Fans: Singapore T: +65-65660371 F: +65-65626736 Asia Distribution - Please Contact Uspo truongNo ratings yet

- 1-1. Safety HintsDocument25 pages1-1. Safety Hintsmargotsilva96No ratings yet

- Unit 3 Problem With SvaDocument6 pagesUnit 3 Problem With SvaFatih DebenefitsNo ratings yet

- Keep fluids flowing with an electric ball valveDocument2 pagesKeep fluids flowing with an electric ball valveFranciscoBarichivichNo ratings yet

- TWX1 Flyer ENUDocument2 pagesTWX1 Flyer ENUJoão Márcio JorgeNo ratings yet

- Mga Sagot Ni Ashe Montage Gen Physics1Document4 pagesMga Sagot Ni Ashe Montage Gen Physics1Valencia AngieNo ratings yet

- Surge Protector and Filter Specifications: Technical DataDocument16 pagesSurge Protector and Filter Specifications: Technical DataJuan Esteban Benjumea BenjumeaNo ratings yet

- Char Lynn 104 2000 Series Motor Data SheetDocument28 pagesChar Lynn 104 2000 Series Motor Data Sheetsyahril boonieNo ratings yet