0 ratings0% found this document useful (0 votes) 179 views13 pagesReach Tuck Error Codes

Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content,

claim it here.

Available Formats

Download as PDF or read online on Scribd

If the intelligent instrument can not receive information from the CAN chain, the

following can be done:

~~ I'the fault occurs with other faults, itis probably the freblem of the CAN

interface of the display. That means the display ean not receive any information from

CAN. It is suggested to check CAN Lines or other circuits to the display.

sil it do not occur other faults, the problem may exists in the CAN

interface of other modules, 7

“SEVICE REQUIRED’

‘The routine maintenance falls due, it needs a thoroughly check and maintain.

“COIL SHORTED”

A short circuit occurs in a toad which connects to the power output (AT9 and,

20). So the relative drivers generate big current the following can be done:

-~.check whether the load is broken or shot circuit or not.

--- check the relative circuit

IF the fault stilt exists when the load connective ire

it is open, it is probably

the broken of the big current protective circuit of the display. Change the instrument

“HYDRAULIC O1

The input of the hydraulie oil lever is effective when starting. The following can

be done #0 resolve the problem

Check whether the relative digital input (A9) of the display is effective. (To

TESER menu). And check the effective (ype of the electric lever of the input point

B or GND) (a SET OPTIONS menut)

f the input point is effective, check the condition of the relative switch,

circuit and oil lever.

~if the input point is ineffective check the input circuit of the intelligent

instrument...

“PUMP MOTOR TEMPERATURE”�9 LOGIC FAILURE#I 70 | HIGH CURRENT

FORW VMN LOW 7 POWER FAILUREAS

FORW VMN HIGH 2 POWER FATLTURER2

[ [ 73. | POWER FAILURE#I

BACK VMN HIGH m4 ‘CURRENT SENS. KO

LEFT VMN LOW 5 CONNECTER DRIVER

5 LEFT VMN HIGH 76 COIL SHORTED

26 RIGHT VMN LOW 7 COIL INTERRUPTED,

2 RIGHT VMN HIGH 78 VACC NOT OK

8 PUMP VMN LOW 1 INCORRECT START

[29 PUMP VMN HIGH 80 FORW*BACK

30 VMNLOW 81 BAD STEER 0-SET

(a VMN HIGH 2 ENCODER ERROR

2 VMN NOTOK 3 BAD ENCODER SIGN

3B NO FULL COND 7 STEER SENSOR KO

M4 _RGTNO FULL COND 35 STEER HAZARO

35__|_LFTNO FULL COND 86 PEDAL WIRE KO

36 PUNO FULL COND 87 PEDAL FAILURE

37 CONNECTOR CLOSED 88 TRACYION BRUSHES

38 “CONNECTOR OPEN 89 PUMP BRUSHE ‘|

39 BRAKE CON. CLOSED _ 90 DRIVER | KO

40 BRAKE CONT. OPEN 31 DRIVER 2 KO

a DIR CONT. OPEN 2 DRIVER 1 SIC. KO

42 | _DIRCONT. CLOSED 3 DRIVER2SIC. KO

[Loa 4 INPUTERROR#6

a 95 INPUT ERRORS

[as | _LeFreonr.cLoseD | 96 INVERTION |

46 | LEFT CONT. OPEN o7_ | POSITIONHANDLE

a7 MAIN CONT. CLOSED | _ 98 INPUT ERROR#2 |

8 MAIN CONT. OPEN %9 INPUTERRORN |

49 __FOLEVER [-

50 LEFT I-0 EVER -

Fault analysis,

EEPROM KO”

Itmeans a fault of parameter storing and adjustment in memory. “EEPROM KO”

means the truck can work on under the set value before selling, If the fault still exists

after restarting the electric lock, replace the instruments: If it disappears, the value set

betiore will be replaced by the one set before selling,

“CAUSE KO’

60�The error oceurs when

5 ous DATA adjusting the parameter of the | Turn the key switch

ACQUISITION | current amplifier of obtaining again

the motor impedance. -

: 85 STEER ‘A warning of the exceeding oF

HAZARD, steering angle

‘A waming that these ofthe

warriyg | CAN BUS is PRESENT; The

2 | a7 data ofthe steering cooler

| DATs is transferred through traction

controller by CAN BUS.

Steering controler works on

ne condition that traction wari

wairinG For |S : me

3 | 239 hone controler sends out the order

of shutting off the safety

switeh,

‘There isa disparity between

the data from the processor's

EPS NOT

4 iagnosis and the set one. Cut

238 | aignen | sismosis and the set one. Cu |

the steering and traction ater 6

seconds |

4.6.3.4 Fault code on the intelligent instrument

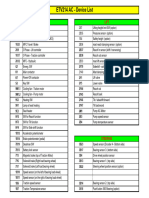

Code Fault name code | Fault name

wo | NODE SI RIGHT I=0 EVER

oO CHOPPER RUNNING 32 PUMP I=0 EVER

2 NO COMMUNICATION 3 STBY THIGH

@ UNKONWN CHOPPER Sa LEFT STBY 1 HIGH

o4 CONSOLE EEPROM 7 RCG STBY | HIGH _|

05 | SEARIAL ERROR? | PUMP STBY I HIGH

06 RIAL ERRORS HIGH FIELD CUR,

07 | __ CHOPPER NOT CONF 58 NO FIELD CUR,

08 WATCHDOG 39 HIGH BRAKING |

09 FIELD FF FAILURE oo CAPACITOR CHARGE

10 EEPROMDATAKO | 6l HIGH TEMPERATURE

EEPROMPAR.KO | 62 HIGH TEMPERATURE

2 EEPROM CONF. KO 8 THERMIC LEVER

13 EEPROM KO ot PUMPTEMPEATURE |

4 EFPROM OFFLINE 65 MOTOR TEMPERAT.

15 LOGIC FAILURE#S 66 BATTERY LOW

16 LOGIC FAILURE# 67 | _ BATTERY LEVER#2

| 17 | Loci FAILURE#3 | 68 BATTERY LEVER#]

18

LOGIC FAILURE? o | CURRENT SES. KO�SENSOR KO. feedback potential( the truck did not apply to it)

JERKING FB | The output voltage of the | Change feedback digital

7 23

por igital resistor is incorrect, resistor

Check whether the

feedback digital resistor

lose or not; check

whether the steering |

Wheel seizures oF not.

“The output voltage of the check whether the

digital resistor is invariable. | feedback digital resistor

LOCKED exceeds the limit ofthe

electricity when the

steering wheel moving;

‘check the rotation of the

steering motor.

A disparity between the

9 | a1 | STEPER jana compe of | Change hope

va | exconen | Aap ten | ange sod

- ERROR sencoder Irequeney andthe channel of the encoder,

| order frequency

t 13_| EEPROM KO | A failure of EPROM writing | Change the chopper.

7 T iis necessary to adjust eurrent

2a | GAIN | Iris necessary to aut Connect with ZAPI

EEPROM KO | _ ofthe controler |

| CURRENT eis necessary to aust current | a apy

GAIN of the controle.

HIGH The temperature ofthe | Change the way of heat

61 | TEMPERATUR | controller board is higher than | transferring or change

E 155. the controller

‘Check the temperature

TOR |The temperature sensor ofthe

2 os |, Moro he kemperatare sensor or change the

TEMPERATE. | motors higher than 150°

way of heat transferring

‘The current of the current

’ 53. STBYIHIGH ‘Change the chopper

amplifier is high.

‘The voltage of the voltage ]

2 | 32 | VMNNoTOK < Change the chopper

LY OK | amplifiers high,

The voltage amplifier of

ci Vu-Vw exceeds the range of

3 fav) toate es Change the chopper

FAILURES | -0.25V-+0.25V under the

| "|The voltage amplifier of — | -

Locic | vw-Wv exceeds the range of

hange the chopper

4 7 16 | eamrurees | -0.25V-+0.25V under the | hanes the chore

alternate condition,

8�controlier’s positive

POWER ‘The current of the phase V is

“ [7 | ramurees | ov when thematorwors. | Changethe shopper. |

s | | tO | avvotncsenene' | chagetecmper |

r Locie The voltae ofthe phases W ]

+ ag | MAINCONT, eens making the main

OPEN - contactor open circuit in

8 | 2487 | CANBUSKO No communication "ne AN BUS

9 jaan | MOO na |i wtre

oo ‘Check the connection of |

| _ = - 3ohms more o ess) |

| 5 op QLINE The voltage of A,B phases of | especially the resistance

~ SENSOR KO the walking motor is null. between the CAN#9 and

| — 300hms more or less)

3 [zag | SPONTOF | therange ofthe digital resistor fre oie st

4 | nag | PR OUTOF | the range ofthe digital resistor ee

Cheek whether the |

POEITION The feedback digital resistor digital resistor input or

6 sa | STEER AA disparity between the order digital resistor and the |

3�load.

‘No communication between

1 | aan | SECON. | Ae totendcboune | Change cprer

10 251 | KMOPEN hecho by saben Change the chopper

The safe switch inside the -

11 | 254 | KSCLOSED | before receiving the order Choneechoper

- "The safe switch inside the

[an | ksorew | sities 00 | une tgp

| The analogue signal sent by

CLOCK PAL. rinciple processor is error,

28) “Norox | shih ischeckesty | Comet shonre

- sabosinate processor |

‘Check whether the

The current exceeds the motor and the controller

wy | Mot | tscedcurme ae | Moore soot

‘motor starts or works. aster or change the |

a — | cen fi chopper __

Check the fuse; check

5 POWER | The current of the phase W is cooler spose

- Change the chopper.

3 n POWER ‘The current of the phase U is ‘Check the fuse; check

“| FAILURE#2 | _ OV when the motor works. the input of the

56�WARN controller will | and the alarm will

ING send ater signal | disappear

ifthe titing

ro controller

| checks the fault

of iting

chopper.

PUMP Error starting | Exclude the fault)

243 | INC x |x) x corder of the | and the alarm will

START lifting controller | disappear

~f The voltage of

wn | eta

24 | Nor x |x | x higher than the | *™4 he alarm wit

OK set min. voltage | “#PPOH

WV.

4.6.3.3 The fault cade of EPS-ACO inverter

| Glimmer ] Fault | Description in - description The condition |

ing times | code_| the hand manual of excluding the faults

MICRO SLAVE | disparity between the

1) 246 KO controller and the walking and | Change the chopper

| steering motors

A disparity of rotation direction

MICRO | between the steering motor and

2 | 21 | sLaves | the watking motor checked by | Cranes te chopper

controller

The frozen of OXF field data

3 | 250 | MICRO SLAVE of the prineiple and Change the chopper

subordinate miero processor

«Jan | MER | tent penopcand | chert tmp:

SLAVE#S

subordinate processor

| Before the turning off of

the safe switch, the

| voltage ofthe CAN#4 |

‘The vohage of the CAN#A | “lOSE (0 OV whether the

: oo INPUT | higher than 12V before the safe soothes

| ERROR# | switch ise the contotter | eee ech |

| beingoth connected to the

positive point, the

CAN#4 will connect the

negative point through a�LOW disappear

CPOT voltage

higher than the

vec set, number } Exclude the fut |

7s | Nor x 1 volt when | andthe alarm will

OK switches of the disappear

allowance point

INCOR cir macign | EU the al

79 | Rect x an the alarm will

START require order disappear

FORW Both exe | ge an

80 ARD= x ofthe backwand and the alarm will

BACK and forward disappear

WARD input signal

cnc The traction or

ms ling controller | Exclude the fault

ae | x temperature | andthe alarm will

on sensor exceeds | disappear

No Exclude the fault

ast | FOR x Ale ted the alarm wil

NODE Sepiyed in| dapper

4s

contol

want The traction

NG prowess 0" | exclude theft

2st | FoR x tS andthe lar wll

NODE lifting micro disappear

8

rooms

ration

No como 85 | gain a

247 CaN x the connection and the alarm will

Mess withthe ‘en

AGE#S iting

controle,

x contri | Bade he ut

247 CAN x the connection | and the alarm will

MESS

mss withthe iting | disappear

contol

PUMP x _The traction | Exclude the fault�lifting

‘micro-processor

or a disparity

between the

input order and

the main order

A disparity

between the

input state

checked by

INPUT lifting

5 Reclose the

250 | MISM x |x mmicro-processor

ATCH input sae from | eee took

traction

nmiero-processor

through

CANBUS

Exclude the Fault

and the alarm will

The short circuit | disappear ifin the

AUX orbroken way | initializing tate;

253 | ouTP x | x of iFin other states,

UTKO electromagnetic | exclude the Faults

brake coil | and make the

traction require in

farce

The fault oF the

EEPRR Eprom as the | Exclude the fault |

13) OM x |x controller using | and the alarm wil

Ko ating disappear

_ parameter |

Temperature of |

HIGH |

oe x | x retin mtr str ll

ERATU orth met ee pew

RE higher than

75°C

- High

temperature of | Exclude the fault

65 x x either traction or | and the alam will

lifting motor or | disappear

both

66 x lx Battery capacity | Exclude the fault

lower than 20%

and the alarm will�‘main connector

and

electromagnetic

brake; alert state

or working

state: short

circuit of coils,

connector and

electromagnetic

‘and make the

traction require in

force

brake

- Exclude the faults

CONT The

when working;

AcTO un-returning of

a7 | touch point of | Tlose te

electric lock

CLOSE the main vin

D contactor omerting

Exclude the faults

when working:

coNr Poor connect of omnes

ag | ACTO ‘oe reclose the |

Blok a electric lock

oven contactor he

oft-working,

ENco Abnormal ofthe

DER . Reclose the

82 X | motor speed

ERRO electric lock

t sensor (encoder)

PEDAL — Exclude the falls

ac | wine | Thefault of the | and make the

NPOT circuit | traction require in

Ko "

force

WRON disparity | Exclude the faults

ays | OSET between the and make the

OS | Barre battery voltage | traction require in

RY and battery set force

‘A fault of lifting

mmiero-processor

PUMP Reclose the

246 | ko. | checked By | tect lock

traction

_ mmicro-processor

‘A fault of

action Reclose the

nag | MAST x srnctio c

ERKO miero-processor | electric lock

checked by

2�Taso eT

foree

“| ] Exclude the fault

and the alarm will

retuanor | tori the

STBY! feedback circuit inisalizing states

33 HIGH x voltage of the if'in other states,

essa he ate

cients] ue

icon ee

| force

Newest

thovalngs of

tepowsr

cape

thee

CAP being off; the | Exclude the fault

60 | CHAR faults ofthe | and the alarm will

GE power disappear

Ph pnt oft

logic er orth

diving PCB

| Beckie fa

andthe sa

Soper te

DRIVE ‘The short circuit | initializing state:

Pan x Sicmsn | noha

wor cometor cot | exclu ts

and make the

wan ee

force

cont Te akan of hem

| acto thedvng | Excite

as |r x crete

one Be tiie

ore

R connector’s coil -

“I Initializing | Exclude the fault

con se: he woken | and ie al wi

16. | sHoRT x ofthe driving | disappear if in the

ros postion | ian ste

L cle he�4.6.3.2 Fault code of the COMBIA AC2 inverter

The states ofthe

controller

coa | eau | = = The condition

aul Traci © | the | TM | description | of excluding the

e | name | on ina work

alert faults

S| sate | "8

state state

| Exclude the ful

andthe alarm wil

disappear iin the

ware | intalizing sate

are The failure of| we ses

8 | HDOG | x Xx fx | Tee | tin other sates,

we watch JOB | sctude the faults

and make the

traction require in

forve

elude the faults

Fait Oren atc

iy | TAU x protection ofthe | Smt meke the

RERS tration requie in

hardware ciruit

| force

The fault ofthe | Exclude the faults

ws lout | x x feedback circuit | and make the

oF U.V,W phase | tration require in

UREW

voltage force |

Loaie

wer voltage or | Reclose the

19 | FAW | x x |x |x oe vole ; el ‘

bac short of voltge | electric loc

Exclude the fault

‘The fault ofthe | and the alarm will

output of motor | disappear iin the |

| wer the fault | inializing stat:

vMN | powes ©

30 x X | x | xX | ofpower | ifinotherstates.

Low

assessment, oF | exclude the faults

MOS driving | and make the

cireuit or motor | traction require in |

force

The fault ofthe | Exelude the fault

output of motor | andthe alarm will

power; the faut | disappear iin the |

vn power the fut | sppea iin ihe |

a x x | x of power | initializing state:

HIGH :

assessment, ot | ifn other stats,

MOS driving | exclude the faults

LL circuit or motor |_and make the�2) Use notice:

© Auto liquid replenishment shall be carried out at the end of charging, and it is

strictly prohibited to be done before charging,

@The auto liquid replenishment device shall ensure the correct liquid pressure.

@ Liquid storage devices and pipelines shall be kept clean and there shall be no dirt.

@ only special liquid for batteries shall be used.

its strictly forbidden to flush the injection plug with tap water,

@ Pay attention to the temperature to prevent the auto liquid replenishment system

from freezing

4.6.2.6 Panel switch

Switches on the panel can be on or off according to the customer's choose.

If the button is pressed, the speed of the whole truck will slow down.

©) © = irihe two buttons are pressed at the same time, the steering wheel

will center automatically.

4.6.3 Diagnosis

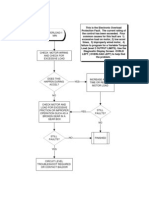

4.6.3.| General instruction

The traction control system, loading control system, steering control system and

clligent instrument system assembled in the truck are continually monitoring

micro-processor controller. They all have a diagnosis program to a main function, The

program includes the following point:

(1) diagnosis when the eleetrie lock being off: the circuit of the watching dog,

current censor, charging of the capacity, phase voltage, driving of the connector,

can-bus connector, the order of the switch operation, the output of the acceleration,

the synchronism of the two micro-processor, the input of the hardware that having

something to do with the safety.

(2) The alternate check; The circuit of the watch dog, phase voltage, current

censor, driving of the connector, can-bus connector

(3) Check when working: the circuit of the watch dog, the driving of the

connector, the current sensor, can-bus connector

(4) Continuously check: inverter temperature, motor temperature

Ways of diagnosis: the digital hand manual which can supply detailed diagnosis

information; the can-bus which will send fault code and the code and module node

will display in the meter

”