Professional Documents

Culture Documents

Fairstone Sawn Versuro Paving Installation Details

Uploaded by

nextomegagenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fairstone Sawn Versuro Paving Installation Details

Uploaded by

nextomegagenCopyright:

Available Formats

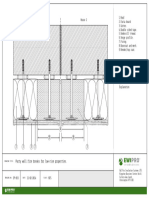

INSTALLATION DETAILS FOR FAIRSTONE SAWN VERSURO

PAVING

Health and Safety Information

Safe working practices should be employed at all times during the construction

process and all necessary Personal Protective Equipment (PPE) should be worn.

Pavement Design

For most domestic applications a sub-base of 100mm should prove to be sufficient.

However the paving design must be based upon the prevalent ground conditions,

type and frequency of anticipated loads.

Excavation

To allow the new paving to be installed correctly, a certain amount of excavation may

be required. The depth of this excavation will depend upon the thickness of the

required sub-base plus the sand and/or mortar, and the paving flag thickness. An

extremely important factor to consider when working out the depth of excavation is

that the finished surface level of the paving, when being laid up to an existing

structure, must be a minimum of 150mm below the DPC to prevent problems with

rising damp in the structure.

Edge Restraints

Edge restraints should be sufficiently robust to resist the lateral displacement from

imposed loadings placed upon the pavement and are installed prior to the installation

of the sub-base. The restraint must provide a consistent vertical face to a level below

the laying course material.

Domestic Application Only Page 1 of 3

01/2015/Issue 1

Sub-base

Material Selection

Granular sub-base material should be well graded (40mm to dust) Type 1 quality

material. Inferior quality material may be liable to failure under loading and be

susceptible to frost or moisture movement. Recycled materials such as crushed

masonry or concrete can be considered, provided it is well graded and compacts to

give a close textured finish. Materials containing organic matter should not be used.

Construction

Sub-base material should be placed in layers not exceeding 75mm in thickness or

twice the nominal maximum aggregate size. Each layer should be fully compacted

before the next layer is placed. Sub-base tolerance to be +5 -10mm from specified

levels. The surface should be clean and suitably close textured to prevent migration

of finer material through the construction.

A minimum longitudinal fall of 1.25% (1 in 80) and crossfall of 2.5% (1 in 40) should

be incorporated in the sub-layer construction to provide adequate surface water

runoff from the wearing course.

Rigidly Laid Paving

Material Selection

Paving units should be cleaned by washing the units with a sponge and clean water.

This is to remove any dust, loose material, packaging or production aids. To avoid

damaging the units, stack the units on timber battens with spacers between them

The backs of the units should be primed using a proprietary priming product or fine

mortar slurry prior to placement upon the bedding mortar.

Flags should be supported on a full ‘wet’ workable mix mortar bed of 1 part cement to

3 or 4 parts building sand. The mortar bedding should be laid to give a thickness

between 15mm and 30mm; however some adjustment may be necessary to ensure

that the units are fully supported and do not rock or move. A PVA, SBR or equivalent

bonding agent can be added to the mortar to assist bonding. An appropriate

plasticiser can also be considered to be added to the mix.

Keep checking levels and gradient across the units. String lines can be helpful to

define levels and lines within the laying pattern. Maintain the correct joint width by

gently shuffling with a trowel. Small pieces of timber are useful as temporary

spacers.

For most paving units Marshalls’ Weatherpoint 365 Jointing Compound can be used

where a minimum of 10mm joint and minimum 22mm thick paving units are being

utilised. Alternatively use a damp mortar mix of 1 part cement to 4 parts building

sand. If mortar gets onto the surface of the units, clean off immediately using a damp

sponge frequently rinsed in clean water.

Under no circumstances should dry or semi dry sand/cement mixes be

brushed into the joints. This practice leads to staining of the paving and does

not constitute a true rigid joint.

If a narrow 5mm joint is desired then a gun applied mortar compound may be used to

fill the joints or a good quality external grout should be considered.

Butt jointing is not recommended for any of these paving products.

Domestic Application Only Page 2 of 3

01/2015/Issue 1

Cutting

Cutting may be carried out using a diamond tipped power saw, or hammer and

bolster. It must however be noted that the aesthetic finish achieved will depend

greatly upon the choice of cutting mechanism and level of skill. Specific equipment

or blade types should be used when cutting natural stone units as those designed for

cutting concrete only may blunt easily. If more than 25% of a flag or slab requires

cutting then the remaining piece should be cut from the internal corner of the cut to

the external corner of the flag or slab, at an angle of preferably 45o.

Inclement Weather

Laying operations should be discontinued (and any open work face covered) if

weather conditions are such that the performance of the paving may be jeopardised.

Laying operations should not be undertaken when the temperature is below 3oC on a

falling thermometer and below 1oC on a rising thermometer. All unfinished areas and

stockpiles of materials should be covered in the advent of inclement weather to

prevent saturation.

Further Information

For technical advice on commercial installations, or when confronted by unusual

problems or circumstances, please contact Marshalls Technical Advisory Services on

0370 411 2233, or by email on advisory.services@marshalls.co.uk

Contacts

Parex Streetscape eg: Easipoint 01257 224900

Norcross Adhesives eg: Norcross Prime Bond 01782 524140

Lithofin eg: MN Stain Stop 01962 732126

Ultrascape eg: Pro-Prime 01827 872244

Landscape House, Premier Way, Lowfields Business Park, Elland, HX5 9HT

Domestic Application Only Page 3 of 3

01/2015/Issue 1

You might also like

- Installation Details For Cropped Granite SettsDocument3 pagesInstallation Details For Cropped Granite SettsRadu BuzamurgaNo ratings yet

- SMARTPAVE Permeable Paving System by Littlehampton BrickDocument7 pagesSMARTPAVE Permeable Paving System by Littlehampton Brickmihai968No ratings yet

- TDS - Mastertop 300Document3 pagesTDS - Mastertop 300Venkata RaoNo ratings yet

- High-Strength Concrete Screed Data SheetDocument6 pagesHigh-Strength Concrete Screed Data Sheetiask5275No ratings yet

- Constructing an All-Weather Outdoor Riding ArenaDocument6 pagesConstructing an All-Weather Outdoor Riding ArenaJNo ratings yet

- Substrate Preparation and System Guide 08.08.2019Document10 pagesSubstrate Preparation and System Guide 08.08.2019Volkmar LullNo ratings yet

- Flexible Expansion Joint MembraneDocument4 pagesFlexible Expansion Joint MembranemilanbrasinaNo ratings yet

- Installation GuideDocument3 pagesInstallation GuideVinka PrintNo ratings yet

- Product Info GuideDocument11 pagesProduct Info GuideniroNo ratings yet

- FloArm Screed Eco Ver7Document4 pagesFloArm Screed Eco Ver7imsNo ratings yet

- Mastertile 30Document3 pagesMastertile 30Vajira KumaraNo ratings yet

- 7GS 5000Document5 pages7GS 5000subhaschandraNo ratings yet

- Gallery 0768498605 Sika Level 100TDocument5 pagesGallery 0768498605 Sika Level 100TRobert EshwerNo ratings yet

- VersaBond DS 5 - 08Document3 pagesVersaBond DS 5 - 08cdubos1No ratings yet

- Preprufe 300R & 160RDocument6 pagesPreprufe 300R & 160RvelarajanNo ratings yet

- p8132 Your Guide To Concrete Brick and Block Making R PDFDocument2 pagesp8132 Your Guide To Concrete Brick and Block Making R PDFengkjNo ratings yet

- Uzin NC 152Document2 pagesUzin NC 152FloorkitNo ratings yet

- "Screedcrete" Exposed Aggregate: Insitu Coloured Flooring: Using A Screed System, For External FloorsDocument2 pages"Screedcrete" Exposed Aggregate: Insitu Coloured Flooring: Using A Screed System, For External FloorsRietta Du ToitNo ratings yet

- INSTALLGUIDE CementDocument6 pagesINSTALLGUIDE CementvelevveraNo ratings yet

- TDS - Mastertile 30 - WPMDocument2 pagesTDS - Mastertile 30 - WPMVenkata RaoNo ratings yet

- Handlamination PDFDocument3 pagesHandlamination PDFKamlesh DalavadiNo ratings yet

- Methodology For Installation of Paver Block WorkDocument3 pagesMethodology For Installation of Paver Block Workkunalji_jain50% (6)

- Repair Concrete Cracks Injection GroutsDocument18 pagesRepair Concrete Cracks Injection Grouts153-B RAKSHITHANo ratings yet

- Pine cladding installation guideDocument6 pagesPine cladding installation guideAndrew LeeNo ratings yet

- Mastertop 195 thin-set concrete floor re-surfacingDocument2 pagesMastertop 195 thin-set concrete floor re-surfacingFrancois-No ratings yet

- VinyLok Application GuidelineDocument4 pagesVinyLok Application GuidelinemutazsalihNo ratings yet

- 05 - TDS - Mastertop 300Document4 pages05 - TDS - Mastertop 300Vimal KakNo ratings yet

- Adhesives GuideDocument8 pagesAdhesives Guidejoslynmagro7713No ratings yet

- Ocbre Spec.Document12 pagesOcbre Spec.Rana MahatoNo ratings yet

- Cico Surface HardenerDocument2 pagesCico Surface HardenerSunil100% (1)

- 9 Gerbur Vinyl Click Herringbone BrochureDocument17 pages9 Gerbur Vinyl Click Herringbone BrochureLeyjan JacobNo ratings yet

- Masterpren Masterpren Masterpren Masterpren 1000 1000 1000 1000Document2 pagesMasterpren Masterpren Masterpren Masterpren 1000 1000 1000 1000Lemark R.No ratings yet

- A Guide For Durable Quality Residential Concrete Flatwork 2016 RevisionDocument4 pagesA Guide For Durable Quality Residential Concrete Flatwork 2016 RevisionMICHAELNo ratings yet

- LIC 15 Pothole Repairs - HMA ColdMixDocument5 pagesLIC 15 Pothole Repairs - HMA ColdMixIshmael JonathanNo ratings yet

- 31 Ultralite Rapid Flex s1 Uk NoRestrictionDocument4 pages31 Ultralite Rapid Flex s1 Uk NoRestrictionFloorkitNo ratings yet

- MASTERTOP 100 Dry Shake Floor Hardener Test ResultsDocument3 pagesMASTERTOP 100 Dry Shake Floor Hardener Test ResultsVenkata RaoNo ratings yet

- Geocell SDI Install MIS456 Iss3 Feb 12Document2 pagesGeocell SDI Install MIS456 Iss3 Feb 12Anas IaNo ratings yet

- Technical Specification For TravertineDocument3 pagesTechnical Specification For TravertineGezim Gezim0% (1)

- Technical Specifications of Kerrogres Vitrified TilesDocument3 pagesTechnical Specifications of Kerrogres Vitrified Tilesamitdey_dey18164No ratings yet

- AMS Jointseal PU April2012 SWDocument1 pageAMS Jointseal PU April2012 SWringlove97No ratings yet

- Rheomix 157 Pds Asean 311209Document2 pagesRheomix 157 Pds Asean 311209Gabriel LimNo ratings yet

- Basf Masterseal NP 474 TdsDocument3 pagesBasf Masterseal NP 474 Tdstally3tallyNo ratings yet

- Nitoproof 100-120Document4 pagesNitoproof 100-120kalidindivenkatarajuNo ratings yet

- Fiber Cement Board Installation InstructionsDocument24 pagesFiber Cement Board Installation InstructionsAnu dasNo ratings yet

- A Guide To Epoxy GroutingDocument17 pagesA Guide To Epoxy GroutingCloudy DayNo ratings yet

- 02 - TDS - Masterflow Cementitious GroutsDocument3 pages02 - TDS - Masterflow Cementitious GroutsAlexi ALfred H. TagoNo ratings yet

- Official Smartdrop Install Instructions - 2019Document2 pagesOfficial Smartdrop Install Instructions - 2019nbarratt2No ratings yet

- Nitoseal MS100Document4 pagesNitoseal MS100Balasubramanian AnanthNo ratings yet

- Durakol G HMDocument3 pagesDurakol G HMpbodooNo ratings yet

- Durafit Installation GuideDocument3 pagesDurafit Installation GuideBrian EnderwitzNo ratings yet

- B Tech FLOOR FINISHSDocument13 pagesB Tech FLOOR FINISHSGabby ChebetNo ratings yet

- Ficha Técnica Seal-N-GripDocument4 pagesFicha Técnica Seal-N-GripGhislaine SousaNo ratings yet

- Glass-Resin Ratio (HLU)Document3 pagesGlass-Resin Ratio (HLU)Kamlesh DalavadiNo ratings yet

- Maccaferri IG UK Green Terramesh Apr07Document2 pagesMaccaferri IG UK Green Terramesh Apr07John SmithNo ratings yet

- Sadlerstone Technical BulletinDocument21 pagesSadlerstone Technical BulletinParashuram ChauhanNo ratings yet

- Concrete Pavement RepairDocument10 pagesConcrete Pavement Repairgorafd449No ratings yet

- Portland Cement GroutingDocument18 pagesPortland Cement Groutingapoorv mishraNo ratings yet

- Method Statement Cementitious GroutingDocument3 pagesMethod Statement Cementitious Groutingmahmoud husseinNo ratings yet

- BRICK Book7Document167 pagesBRICK Book7nextomegagenNo ratings yet

- Constructive Details Handbook Full FillDocument57 pagesConstructive Details Handbook Full Fillnico Dela RamaNo ratings yet

- 25 - 24 06 14 - A5 Guide 05 14 WebDocument104 pages25 - 24 06 14 - A5 Guide 05 14 WebnextomegagenNo ratings yet

- BRICK Book1Document73 pagesBRICK Book1nextomegagenNo ratings yet

- Vehicle Tracking GuidelineDocument32 pagesVehicle Tracking GuidelinenextomegagenNo ratings yet

- MVL - Planning Vs B.Regs - 1Document4 pagesMVL - Planning Vs B.Regs - 1nextomegagenNo ratings yet

- 2015 05891 Nmat-Typical Bay Study-1584101Document1 page2015 05891 Nmat-Typical Bay Study-1584101nextomegagenNo ratings yet

- Guide Kingframe SFSDocument100 pagesGuide Kingframe SFSCommercial MarocNo ratings yet

- External Product Information - Ggu Integra ElectricDocument9 pagesExternal Product Information - Ggu Integra ElectricnextomegagenNo ratings yet

- UK MKT DOC The Brick Book 13th EditionDocument144 pagesUK MKT DOC The Brick Book 13th EditionPragati SinghalNo ratings yet

- 33 Party Wall Fire Breaks For Low Reise PropertiesDocument1 page33 Party Wall Fire Breaks For Low Reise PropertiesnextomegagenNo ratings yet

- 11 Extending Window Sill With Under Sill ProfileDocument1 page11 Extending Window Sill With Under Sill ProfilenextomegagenNo ratings yet

- Parking Standards - Annex B - Cycle Parking Design Details - Planning PortalDocument4 pagesParking Standards - Annex B - Cycle Parking Design Details - Planning PortalnextomegagenNo ratings yet

- Give Me Five 6 Pupils BookDocument129 pagesGive Me Five 6 Pupils BookAdrian Gonzalez100% (5)

- Remote Sensing Mineral Exploration LithiumDocument16 pagesRemote Sensing Mineral Exploration LithiumGerald Darshan MogiNo ratings yet

- Schutz - Subnotes PDFDocument47 pagesSchutz - Subnotes PDFJarryd RastiNo ratings yet

- Process Modeling in The Pharmaceutical Industry Using The Discrete Element MethodDocument29 pagesProcess Modeling in The Pharmaceutical Industry Using The Discrete Element MethodRonaldo MenezesNo ratings yet

- Acute Pain - Mastectomy - Breast CADocument2 pagesAcute Pain - Mastectomy - Breast CAAngie MandeoyaNo ratings yet

- Presidential Decree No. 1616 establishes Intramuros AdministrationDocument22 pagesPresidential Decree No. 1616 establishes Intramuros AdministrationRemiel Joseph Garniel BataoNo ratings yet

- OK - EndUserGuideHoseSafetyInstituteDocument8 pagesOK - EndUserGuideHoseSafetyInstituteSunil GhosalkarNo ratings yet

- DD 24 DD 22Document2 pagesDD 24 DD 22evega97No ratings yet

- Assessing A Peripheral PulseDocument5 pagesAssessing A Peripheral Pulsecrrfrnc0% (1)

- ERT Techniques for Volunteer Fire BrigadesDocument45 pagesERT Techniques for Volunteer Fire BrigadesZionNo ratings yet

- Namma Kalvi 12th Maths Book Back 1 Mark Questions em 216251Document29 pagesNamma Kalvi 12th Maths Book Back 1 Mark Questions em 21625111B CHARAN ANANDNo ratings yet

- IV Solution Cheat Sheet: Type Description Osmolality Use MiscellaneousDocument1 pageIV Solution Cheat Sheet: Type Description Osmolality Use MiscellaneousKristine Castillo100% (2)

- Comparison and Contrast EssayDocument2 pagesComparison and Contrast Essayputri fadillahNo ratings yet

- Build A Borz Practical Scrap Metal Small Arms Vol9Document23 pagesBuild A Borz Practical Scrap Metal Small Arms Vol9Gia Linh Văn100% (2)

- Topic 1 - Textile Finishing - 2020 PDFDocument11 pagesTopic 1 - Textile Finishing - 2020 PDFSadaf SweetNo ratings yet

- Replacing The Volvo Oil Trap and Oil Pan SumpDocument6 pagesReplacing The Volvo Oil Trap and Oil Pan SumpsaifrulNo ratings yet

- 456/1 Mathematics Paper 1 June /july 2012 HoursDocument4 pages456/1 Mathematics Paper 1 June /july 2012 HoursBaguma MichaelNo ratings yet

- Fiat Type 199 Punto Evo 3 PDFDocument9 pagesFiat Type 199 Punto Evo 3 PDFGestione SportivaNo ratings yet

- 17 The Tarrying TimeDocument22 pages17 The Tarrying Timeapi-303147801100% (1)

- 016 Muscoril COPPDocument3 pages016 Muscoril COPPTheRoom23No ratings yet

- Des 415 Research 01Document29 pagesDes 415 Research 01Just scribble me For funNo ratings yet

- MTD Big Bore Engines 78 277cc 83 357cc 90 420cc Repair Manual PDFDocument136 pagesMTD Big Bore Engines 78 277cc 83 357cc 90 420cc Repair Manual PDFGiedrius MalinauskasNo ratings yet

- ReviewerDocument2 pagesReviewerFrank Jomari MurilloNo ratings yet

- Heidegger and RhetoricDocument202 pagesHeidegger and RhetoricMagda AliNo ratings yet

- Syngo MR E11 OncoDocument64 pagesSyngo MR E11 OncoLuís GuerraNo ratings yet

- Natural ResourcesDocument5 pagesNatural ResourcesAsrock Loop100% (1)

- Vammika Sutta - Mahasi SayadawDocument108 pagesVammika Sutta - Mahasi SayadawtravelbootsNo ratings yet

- MiG 21Document29 pagesMiG 21Zoran Vulovic100% (2)

- Open Fracture Classification and TreatmentDocument70 pagesOpen Fracture Classification and TreatmentKelly Khesya100% (1)

- AP Calculus AB 4.1A Worksheet Key ConceptsDocument44 pagesAP Calculus AB 4.1A Worksheet Key ConceptsDavid Joseph100% (1)