Professional Documents

Culture Documents

Plans Guidelines

Uploaded by

Magesh0 ratings0% found this document useful (0 votes)

1 views3 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views3 pagesPlans Guidelines

Uploaded by

MageshCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

GUIDELINES FOR PREPARATION OF PLANS

1. Plans shall be sent in triplicate (Blue prints only) prepared by a qualified

engineer/ draughtsman and duly signed by him and also by the applicant

showing.

I. Site plan drawn to a metric scale of 1:400 / 800 / 1200 showing the

details of neighborhood, location of all buildings/ sheds, plant and

machinery, storages, etc., access road indicating its width. The site

plans should indicate front, rear and side set-backs clearly along with

extent of site purchased for establishing the industry. North direction

shall be indicated in the site plan.

II. Detailed building plan, elevation and sectional views of the proposed

factory sheds/ buildings, plant and machinery, storages, etc., drawn to

scale 1:100 showing the layout and type of machinery proposed to be

installed in the particular shed with Horse Power. Materials to be used

for the construction or building and roofing shall be specified.

III. All dimensions shall be in metric system only.

2. Standard norms for the building / Sheds and Installation of Machinery.

I. The minimum height of the building in which the machinery / equipment

is to be installed should not be less than 4.27 mt (14 feet) and height of

Office rooms, godowns, stores etc., should not be less than 3.65 m (12

feet).

II. There should be a clear moving space of 0.9m (3 feet) from machine to

machine and machine to wall.

III. Ridge roof ventilator with an opening of 0.9mts (3 feet) width and 0.6m

(2 feet) height or sufficient number of turbo ventilators of adequate size

and capacity to ensure industrial ventilation as per Indian Standard

Code shall be provided over roofing of all the work halls. In case of

north light glazing an air gap of atleast 0.3m (1 foot) should be provided

between top of glazing and the roof of sheeting. Also the north light

glazing should invariably face north.

IV. The building should have masonary walls. If A.C sheet or metal sheets

are used as cladding they should be fixed in the form of louvers.

Vertical cladding of not more than 1 metre is permissible.

V. Sizes of doors and windows should not be less than 1.2 X 2.1 mts (4’ X

7’) and 0.9 X 1.5 mts (3’ X 5’) respectively. Ventilators should be

0.9X0.45 mts (3’X11/2’). The doors and windows should be so spaced

that they should not be located at a distance of more than 3 mts (10

feet) from centre. All windows should be fixed with their lower sill level

at 0.9 mts (3 feet) or less from the floor level. All doors should have

shutters opening outwards except when they are of sliding or rolling

type.

VI. In case any the minimum height at eaves of any machinery shed or

building is more than 6mts (20 feet), a second set of windows should

be provided directly above each door and window. These second set of

windows should not be less than 1.2X0.9 mts (4’X3’) in size.

VII. There shall be atleast 3.05 mts (10 feet) clear space between shed to

shed/ building. Further, a clear space 3.05 mts (10 feet) should be

maintained between the building and adjoining compound wall.

VIII. Verandah will be permitted on one side only. Width of verandah should

not exceed 3.65 mts (12 feet) and the height of the verandah at the

eaves not less than 3.65 mts (12 feet) No machines, equipment shall

be installed in the verandah. Verandah shall not be used as a place of

storage, which could block the windows etc.

IX. Toilets, Urinals separately for men and women, should be provided

away from the main work place. The number of toilets/ urinals

proposed to be provided shall be shown in the site plan and their

number shall not be less than number stipulated under the A.P. Factory

Rules. Generally one toilet seat for every 20 workers to be provided.

X. A minimum of two exits shall be provided to each of the manufacturing

buildings. In case of manufacturing buildings / godowns / stores, good

number of exits should be provided in such a manner to ensure that in

case of emergency a person need not travel a distance of more than

30 mts to get out of the building.

XI. Every factory shall be constructed with pucca masonary walls of bricks,

stone or other suitable material. The roofing materials used shall be of

non heat radiating and fire resistant type. Any other special

requirements in respect of building specific to the manufacturing

process should be implemented.

XII. Mechanical exhaust arrangements, dust collection systems etc., should

be provided wherever necessary.

XIII. A NOC/ Licence is required from the Fire service department in respect

of all places and trades involving risk fire. Factories such as match

factories, tile factories, Cold storage plants, fireworks manufacturing

and explosives manufacturing units, Tobacco grading and threshing

units, solvent extraction plants, cotton, jute, dyeing and printing paper,

saw and timber units require clearance from Fire Department. Similarly,

storage godowns for ground nuts, cashew nuts, gunny bags, paper,

timber, charcoal, liquors, spirits, and chemicals in solid, liquid and

gaseous form also require to obtain NOC.

XIV. If the unit is hazardous industry attracting provisions of Manufacturing

Storage and Import of Hazardous Chemicals Rules, 1989, the details of

Hazardous processes, the maximum quantity of chemicals stored in

the premises and material safety data sheets of all chemicals, hazard

analysis and risk assessment report and on site emergency plan shall

be enclosed to the application along with a consent for establishment

from APPCB.

XV. Clearance from the explosive authorities is necessary wherever

materials attracting the provisions of explosives act are handled/

processed/ stored.

XVI. If there are any residential developments near or around the site within

the radius of 400 mts, the applicant has to furnish no objection

certificate from the residents/ local authorities.

XVII. Ownership documents of the site and if the site is taken on lease the

copy of registered lease deed is to be furnished in case of private

plants and position certificate in case of APIIC allotment.

3. The following welfare amenities shall be shown in the plans of Factories

depending on the number of employees proposed to be employed therein:

a. If the woman employment exceeds 30, creche shall be provided as per

standards prescribed under Rule 73 of A.P, Factories Rules, 1950.

b. If the employment exceeds 150, rest room and lunch room shall be provided

as per standards prescribed under Rule 72 of A.P, Factories Rules, 1950.

c. If the employment exceeds 250 : canteen shall be provided as per standards

prescribed under Rules 65 - 71 of A.P, Factories Rules, 1950.

d. If the employment exceeds 500 : Ambulance room shall be provided as per

standards prescribed under Rule 64 of A.P, Factories Rules, 1950.

e. In case of factories carrying out hazardous process (as defined under Sec

2(cb) of Factories Act), an occupational health center shall be provided as per

scale prescribed in Rule 61 (SC) B of A.P, Factories Rules, 1950.

Note : Plans of ‘ New Factories’ shall be submitted through the Commissioner of

Industries, A.P / General Manager District Industries Center as per the

provisions of the A.P Industrial Single Window clearances Act, 2002.

You might also like

- JSA G20 Scaffolding (Erection, Dismantling)Document4 pagesJSA G20 Scaffolding (Erection, Dismantling)Kanchalida Champathong92% (12)

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- FIRE PROTECTION AND FIRE SAFETY REQUIREMENTS (Chap-7) PDFDocument29 pagesFIRE PROTECTION AND FIRE SAFETY REQUIREMENTS (Chap-7) PDFsorry2qaz100% (1)

- NEBOSH IGC Unit IGC1 Question & AnswerDocument241 pagesNEBOSH IGC Unit IGC1 Question & AnswerGTM100% (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- WinCatt 7 Tech Manual REV OCT2017Document92 pagesWinCatt 7 Tech Manual REV OCT2017Richard AldazNo ratings yet

- Airport Architecture and Building StandardsDocument4 pagesAirport Architecture and Building Standardssurya agungNo ratings yet

- CSS9 Q1 Module2Document16 pagesCSS9 Q1 Module2George GarciaNo ratings yet

- Sample Pre-Startup Safety Review ChecklistDocument4 pagesSample Pre-Startup Safety Review ChecklistPrem Shanker Rawat100% (4)

- Dormitory StandardsDocument9 pagesDormitory Standardssnow8villiers-167% (3)

- SC-11 Safety Code For BarricadingDocument15 pagesSC-11 Safety Code For BarricadingZayed SyedNo ratings yet

- Muscat Municipality Building Regs 2015 11 11 CH 2Document14 pagesMuscat Municipality Building Regs 2015 11 11 CH 2Raajeev NeelaNo ratings yet

- Linao Elem. School Contingency Planning 2019 2020Document21 pagesLinao Elem. School Contingency Planning 2019 2020Marvin AmancioNo ratings yet

- Food plant layout and design assignmentDocument8 pagesFood plant layout and design assignmentNeuro ToxinNo ratings yet

- SITXFSA008 Food Safety Program TemplateDocument26 pagesSITXFSA008 Food Safety Program Templateshanmugam thevapriyan50% (2)

- Impacts of floods and droughts in IndiaDocument6 pagesImpacts of floods and droughts in IndiaBinode Sarkar78% (41)

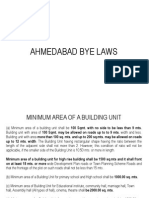

- Ahmedabad building byelaws minimum area rulesDocument11 pagesAhmedabad building byelaws minimum area rulesbizoooka75% (4)

- Fire & Emergency EvacuationDocument11 pagesFire & Emergency EvacuationCharisse KharyleNo ratings yet

- Rural Godown RequirementsDocument9 pagesRural Godown RequirementsNaimil Patel67% (3)

- PowerCube 1000 User ManualDocument341 pagesPowerCube 1000 User ManualDavid Chokani100% (1)

- Summary of CodesDocument14 pagesSummary of CodesSaRrah Yanzon100% (3)

- Factories and Industrial Building RegulationsDocument9 pagesFactories and Industrial Building Regulationsmani_aarthiNo ratings yet

- Machine Room/Job Site PreparationDocument2 pagesMachine Room/Job Site PreparationAldo Tolaba QuirogaNo ratings yet

- LitDocument8 pagesLitJustine John GersaliaNo ratings yet

- Palm Desert tent permit requirementsDocument5 pagesPalm Desert tent permit requirementsdarchmeNo ratings yet

- A) Planning Guidelines and Criteria For HypermarketsDocument19 pagesA) Planning Guidelines and Criteria For HypermarketsMaga-ao Charles100% (1)

- SECTION 809. Vent ShaftsDocument8 pagesSECTION 809. Vent ShaftsAnneth Mikaela MadronioNo ratings yet

- InstructionsDocument10 pagesInstructionsGoldmine MultitradeNo ratings yet

- How to get Dubai warehouse mezzanine approvalDocument2 pagesHow to get Dubai warehouse mezzanine approvalArul SankaranNo ratings yet

- Nat. Bldg. CodeDocument34 pagesNat. Bldg. Codedela rosaNo ratings yet

- Building Standard Office Design Criteria PDFDocument24 pagesBuilding Standard Office Design Criteria PDFIgnacio Jr Ramiento PaguyoNo ratings yet

- Dust Collection ChecklistDocument4 pagesDust Collection ChecklistbroedenNo ratings yet

- GUIDELINES FOR CINEMA HALL CONSTRUCTIONDocument12 pagesGUIDELINES FOR CINEMA HALL CONSTRUCTIONasdfgNo ratings yet

- Siting Criteria and Consent Conditions Notification PDFDocument20 pagesSiting Criteria and Consent Conditions Notification PDFPrince JoseNo ratings yet

- Epz Building CodeDocument9 pagesEpz Building CodeMd. Manzurul HassanNo ratings yet

- Commercial Buildings Requirements: Levels, Heights and Number of FloorDocument4 pagesCommercial Buildings Requirements: Levels, Heights and Number of FloormooolkaNo ratings yet

- Specifications For Godowns 1Document9 pagesSpecifications For Godowns 1Rahul BadgujarNo ratings yet

- Philippines Business Rules Engine SafetyDocument9 pagesPhilippines Business Rules Engine Safetymarlowechica100% (1)

- Building System Design: 2 Semester (SY 2021-2022)Document33 pagesBuilding System Design: 2 Semester (SY 2021-2022)Mae ManaogNo ratings yet

- 2013HO - MS177 A.P. Cinema Theatre RulesDocument7 pages2013HO - MS177 A.P. Cinema Theatre RulesRaghu RamNo ratings yet

- Rule 16 20 NBCDocument17 pagesRule 16 20 NBCMarc PadillaNo ratings yet

- INFRASTRUCTURE GADDocument14 pagesINFRASTRUCTURE GADerik francis laurenteNo ratings yet

- Literature Study-TNCDBR NormsDocument5 pagesLiterature Study-TNCDBR NormsAbrar Ul HaqNo ratings yet

- SHJ 17-90Document51 pagesSHJ 17-90Iveel PurevdorjNo ratings yet

- Rules Net Plot Area and Computation of FSIDocument21 pagesRules Net Plot Area and Computation of FSIsarangNo ratings yet

- Unit Test 2 P-7 H & E Legislation 23114Document11 pagesUnit Test 2 P-7 H & E Legislation 23114pankajsharma130No ratings yet

- Design Guidelines For Biomedical Waste IncineratorDocument4 pagesDesign Guidelines For Biomedical Waste IncineratorJeetendra KulkarniNo ratings yet

- 3361 Vol-IIDocument101 pages3361 Vol-IIPranjeet ChakravartyNo ratings yet

- Hanover OrdinanceDocument6 pagesHanover OrdinanceBlieber90No ratings yet

- MAHARASHTRA INDUSTRIAL DEVELOPMENT CORPORATION NOCDocument4 pagesMAHARASHTRA INDUSTRIAL DEVELOPMENT CORPORATION NOCSunil BhirudNo ratings yet

- Pakistan Factories Act 1934 - CHapter 3 HSE LawsDocument22 pagesPakistan Factories Act 1934 - CHapter 3 HSE Lawstahseenhassantirmizi100% (1)

- NBC AbridgedDocument12 pagesNBC AbridgedNaga AlabNo ratings yet

- SECTION 1213, 1214, 1215: Report By: Elibado T. MaureenDocument19 pagesSECTION 1213, 1214, 1215: Report By: Elibado T. MaureenJohnFred CativoNo ratings yet

- SystemDocument5 pagesSystemSandyNo ratings yet

- Factory Cleanliness and Worker Health StandardsDocument6 pagesFactory Cleanliness and Worker Health Standardseven0No ratings yet

- Safety RegulationsDocument7 pagesSafety Regulationssatish_althevNo ratings yet

- The Miller Bar, ClaremorrisDocument4 pagesThe Miller Bar, ClaremorrisJason JonesNo ratings yet

- Building BylawsDocument4 pagesBuilding Bylawspandhi2000No ratings yet

- Philippine Agricultural Engineering Standard Paes 420:2002 Agricultural Structures - Farm Workshop and Machinery ShedDocument10 pagesPhilippine Agricultural Engineering Standard Paes 420:2002 Agricultural Structures - Farm Workshop and Machinery ShedMario Labitad Anore Jr.No ratings yet

- Commercial Building CodesDocument5 pagesCommercial Building Codesanon_871836529No ratings yet

- Kerala Bye Laws - NeededDocument22 pagesKerala Bye Laws - NeededLantNo ratings yet

- CHAPTER III.-Health: Section 11. Cleanliness.Document15 pagesCHAPTER III.-Health: Section 11. Cleanliness.Himanshu JainNo ratings yet

- Licensing and Registration of Factories (Sec 6) : Previous Permission in WritingDocument25 pagesLicensing and Registration of Factories (Sec 6) : Previous Permission in WritingrajasekaransvnNo ratings yet

- IT Park Infrastructure Planning GuideDocument12 pagesIT Park Infrastructure Planning GuideBenin RejoNo ratings yet

- Pdis 102Document66 pagesPdis 102Dhirendra PatelNo ratings yet

- Bye Laws+nbc Report-Aakarshit JainDocument22 pagesBye Laws+nbc Report-Aakarshit JainAakarshit JainNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- FireDrill and Inspection Guide GujaratDocument35 pagesFireDrill and Inspection Guide GujaratMageshNo ratings yet

- Motor Vehicles Act SummaryDocument111 pagesMotor Vehicles Act SummarySardaar Harpreet Singh HoraNo ratings yet

- Fire Load and Fire Water Calculation As Per GFR 1963 R 66 ADocument5 pagesFire Load and Fire Water Calculation As Per GFR 1963 R 66 AMageshNo ratings yet

- Model Factories Rules As On 01.03.2019Document257 pagesModel Factories Rules As On 01.03.2019Latest Laws TeamNo ratings yet

- Model Factories Rules As On 01.03.2019Document257 pagesModel Factories Rules As On 01.03.2019Latest Laws TeamNo ratings yet

- The Gujarat Factories Rules 1963 PDFDocument365 pagesThe Gujarat Factories Rules 1963 PDFAlpesh ValaNo ratings yet

- Air Emissions and Air Emission Control SystemsDocument6 pagesAir Emissions and Air Emission Control SystemsMageshNo ratings yet

- Environmental Reduction ProgrammesDocument3 pagesEnvironmental Reduction ProgrammesMageshNo ratings yet

- Geo-Spatial Tools For Environment PlanningDocument13 pagesGeo-Spatial Tools For Environment PlanningAr Abhinav SrivastavNo ratings yet

- BOSH Hazard Analysis - GROUP 2Document3 pagesBOSH Hazard Analysis - GROUP 2Julius BoitizonNo ratings yet

- 3BSE036352-600 A en AC 800M 6.0 Controller Hardware Product Guide PDFDocument204 pages3BSE036352-600 A en AC 800M 6.0 Controller Hardware Product Guide PDFNguyễn Thanh Nga100% (1)

- Summative Assessment q4 w3Document3 pagesSummative Assessment q4 w3RosselAlcantaraNo ratings yet

- OHSE Management Plan GuideDocument43 pagesOHSE Management Plan GuiderumplestilkinsNo ratings yet

- Guidelines for Hazard Identification, Risk Assessment and Risk Control (HIRARCDocument34 pagesGuidelines for Hazard Identification, Risk Assessment and Risk Control (HIRARCEncik AhmadNo ratings yet

- Q I Module 1 GR 11 Week1Document7 pagesQ I Module 1 GR 11 Week1WilmerNo ratings yet

- JSEA-ICS-005-Erection Modification and Dismantling of ScaffoldingDocument17 pagesJSEA-ICS-005-Erection Modification and Dismantling of ScaffoldingJayson EscamillanNo ratings yet

- Quiz Duw10022Document2 pagesQuiz Duw10022Natasha KristyNo ratings yet

- Manual de Manutenção BSP-MT 1-8Document75 pagesManual de Manutenção BSP-MT 1-8Luis ClaudioNo ratings yet

- Scientific ReportDocument19 pagesScientific ReportClifford Jay LachicaNo ratings yet

- Examination Blueprint Changes in 2015Document8 pagesExamination Blueprint Changes in 2015avnuraNo ratings yet

- SPREP 2016 Strengthening EIA Guidelines For The PacificDocument64 pagesSPREP 2016 Strengthening EIA Guidelines For The PacificRyan GinNo ratings yet

- Safety Risk Aggregation: Understanding Total Risk ExposureDocument25 pagesSafety Risk Aggregation: Understanding Total Risk ExposureNizami ShirinovNo ratings yet

- Risk Management in The National System: A Practical GuideDocument16 pagesRisk Management in The National System: A Practical GuideNyadroh Clement MchammondsNo ratings yet

- Geo ChemistryDocument3 pagesGeo ChemistryBprNo ratings yet

- Example-OMI EN NMBY Pinjoint MDocument102 pagesExample-OMI EN NMBY Pinjoint Madewunmi olufemiNo ratings yet

- Appendix C - Environmental Sumary PDFDocument455 pagesAppendix C - Environmental Sumary PDFPava EdoardoNo ratings yet

- Project Information: Annex 6 (A) - Social and Environmental ScreeningDocument20 pagesProject Information: Annex 6 (A) - Social and Environmental ScreeningmoussaNo ratings yet

- HIRADCDocument29 pagesHIRADCimhayt100% (1)

- Show HSE Plan - Hitachi Power Europe GMBHDocument56 pagesShow HSE Plan - Hitachi Power Europe GMBHLounis BOURAINo ratings yet