Professional Documents

Culture Documents

Polymer

Uploaded by

mmmd.krmv.00Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polymer

Uploaded by

mmmd.krmv.00Copyright:

Available Formats

Polymer Floods

Water is generally less viscous than oil, so it is more mobile, and waterfloods may be unstable. This

means that small heterogeneities in the formation can lead to early breakthrough of water. First we look

at fluid mobilities, which were mentioned in Topic 5.

What are the benefits with polymer flooding?

The method produces additional oil by improving the displacement efficiency and increasing the volume

of reservoir that is contacted by increasing the viscosity of the water.

What are the problems with polymer flooding?

The adsorption in polymer flooding can be severe, as it is irreversible, and the adsorbed polymer

occupies a large pore volume. In this case, it is hard to recover a considerable amount of oil and the

formation permeability is decreased, leading to less recovery factor.

Mobility is defined as relative permeability divided by viscosity:

where f is fluid (o or w).

Then the mobility ratio for two fluids (e.g., oil and water) is defined as:

If M < 1 a flood is stable, but if M > 1 it is unstable. Of course, the relative permeability varies with

saturation. Usually M is evaluated using the end-point relative permeabilities – i.e. the maximum values.

For example, if krw,max = 0.25, kro,max = 0.85, w = 1 and o = 3, then M = 0.88, which is stable.

However, if krw,max = 0.25, kro,max = 0.85, w = 1 and o = 10, then M = 2.94, which is unstable.

Buckley-Leverett Theory and Polymers

In practice, there are several effects that arise when polymer is injected into a reservoir. For example, the

polymer may be adsorbed onto the grains of rock, the relative permeability to water may be reduced or

the polymer viscosity may be lowered due to shearing. These effects can be taken into account in

commercial numerical simulators. Here we look at a simple example to show the effect of increasing the

water viscosity in Buckley-Leverett displacement.

Figure 11 shows the resulting fractional flow curves for different viscosities. The solid fw curve (red, in

colour) is for a low viscosity oil (o = 2.5 cP) and water (w = 1.0 cP); the fw curve with the short dashes

(blue) is for a more viscous oil (o = 10.0 cP), and the same water viscosity; thirdly, the fw curve with the

long dashes (green) is also for the more viscous oil, but the water viscosity has been increased (w = 8.0

cP) to represent water with polymer. Compare the Welge tangents for these three curves (Topic 2,

Section 5), and then estimate what the flood profiles should look like.

From Figure 12 you can see that the case with the water flood with the heavy oil has a lower shock front

height and water breaks through earlier. On the other hand, the case with the polymer flood has a high

shock front height and breaks through later.

Note though, that in reality, fractional flow theory for the injection of polymer into a reservoir is slightly

more complex, because there will be a connate water “bank” preceding the front of water with polymer.

You might also like

- Compositional Ripening of Particle-And Surfactant-Stabilised Emulsions: A ComparisonDocument8 pagesCompositional Ripening of Particle-And Surfactant-Stabilised Emulsions: A ComparisonChemtobNo ratings yet

- Lecture Rock PropertiesDocument5 pagesLecture Rock PropertiesDavid Alfonso CaraballoNo ratings yet

- 3 Improved Oil Recovery PDFDocument30 pages3 Improved Oil Recovery PDFhawar abdul-khaliq80% (5)

- Polymer Flooding ReviewDocument5 pagesPolymer Flooding ReviewChristian PradaNo ratings yet

- SPE 152290 A Comparative Study of Emulsion Flooding and Other IOR Methods For Heavy OilDocument8 pagesSPE 152290 A Comparative Study of Emulsion Flooding and Other IOR Methods For Heavy OilAnand aashishNo ratings yet

- Amphiphilic Mixtures Versus Surfactant Structures With Smooth Polarity Transition Across Interface To Improve Solubilization PerformanceDocument9 pagesAmphiphilic Mixtures Versus Surfactant Structures With Smooth Polarity Transition Across Interface To Improve Solubilization Performancelab biofarcoNo ratings yet

- Wettability Approach in Rock SystemDocument59 pagesWettability Approach in Rock SystemAchmad Rafiq Alfaruqi100% (2)

- Irreducible WaterDocument22 pagesIrreducible WaterMax Odeh100% (1)

- 3a - Effective and Relative Permeability and MeasurementDocument9 pages3a - Effective and Relative Permeability and MeasurementTHE TERMINATORNo ratings yet

- Fluid saturationModeling-Haider KDocument43 pagesFluid saturationModeling-Haider KHaider Al-hassanNo ratings yet

- Prof. Dr. / Hamid M. KhatabDocument14 pagesProf. Dr. / Hamid M. KhatabAhmed M. Saad100% (1)

- Fluid Pressure Gradients in Tight FormationsDocument16 pagesFluid Pressure Gradients in Tight FormationsvigneshNo ratings yet

- 3b - Interfacial Tension, Wettability and Capillary PressureDocument28 pages3b - Interfacial Tension, Wettability and Capillary PressureTHE TERMINATORNo ratings yet

- Chemical FloodingDocument26 pagesChemical FloodingFranklyn FrankNo ratings yet

- Evaporation of An Emulsion Trapped in A Yield Stress UidDocument17 pagesEvaporation of An Emulsion Trapped in A Yield Stress UidjafrezNo ratings yet

- Emulsion Stability and TestingDocument2 pagesEmulsion Stability and TestingVictor Lopez100% (1)

- Enhanced Oil Recovery Techniques: Jntu Iv Year B.Tech Petroleum EngineeringDocument38 pagesEnhanced Oil Recovery Techniques: Jntu Iv Year B.Tech Petroleum Engineeringavula43No ratings yet

- Lecture # 2 Saturation ResistivityDocument8 pagesLecture # 2 Saturation ResistivitySaroo BastkyNo ratings yet

- Relative Permeability: Aw Ao AgDocument3 pagesRelative Permeability: Aw Ao AgNizar AliNo ratings yet

- Imbibition of Surfactant SolutionsDocument4 pagesImbibition of Surfactant SolutionsKarolinaNo ratings yet

- Spe 17140 Pa PDFDocument5 pagesSpe 17140 Pa PDFJose RamirezNo ratings yet

- Relative PermeabilityDocument4 pagesRelative PermeabilityArturo VasquezNo ratings yet

- Ionic Liquids As Surfactants - Applications As Demulsifiers of Petroleum EmulsionsDocument22 pagesIonic Liquids As Surfactants - Applications As Demulsifiers of Petroleum EmulsionsHAFIZUL FURQANNo ratings yet

- 2004 B.P. Binks, C.P. WhitbySilica Particle-Stabilized Emulsions of Silicone Oil and Water Aspects of Emulsification LangmuirDocument8 pages2004 B.P. Binks, C.P. WhitbySilica Particle-Stabilized Emulsions of Silicone Oil and Water Aspects of Emulsification Langmuir10_DAVID_10No ratings yet

- Hysteretic Relative Permeability EffectsDocument8 pagesHysteretic Relative Permeability Effectshfdshy12No ratings yet

- Enhanced Oil Recovery in Shale and Tight Reservoirs - CH 9Document9 pagesEnhanced Oil Recovery in Shale and Tight Reservoirs - CH 9John DoeNo ratings yet

- Factors Affecting Relative Permeability ReportDocument10 pagesFactors Affecting Relative Permeability Reportroaa ahmedNo ratings yet

- TPE Immiscible DisplacementDocument22 pagesTPE Immiscible DisplacementAriel DjonthuNo ratings yet

- MF Глава 5 с. 301-311Document11 pagesMF Глава 5 с. 301-311Диёр РахимовNo ratings yet

- Chapter Six: Boundary Tension and Wettability WettabilityDocument24 pagesChapter Six: Boundary Tension and Wettability WettabilityAlimahmood BahraniNo ratings yet

- EOR ProcessesDocument34 pagesEOR ProcessesNikhil TomarNo ratings yet

- Case Study Numerical Simulation of Surfactant Flooding in Low Permeability Oil Filed PDFDocument11 pagesCase Study Numerical Simulation of Surfactant Flooding in Low Permeability Oil Filed PDFDavid LópezNo ratings yet

- Rock WettabilityDocument12 pagesRock Wettabilityحسين رامي كريم A 12No ratings yet

- Pharmaceutical Emulsions and SuspensionsDocument55 pagesPharmaceutical Emulsions and SuspensionsdrugdrugNo ratings yet

- Polymer Flooding: ChallengesDocument11 pagesPolymer Flooding: Challengesحسين رامي كريم A 12No ratings yet

- The Application of Fractional Flow Theory To Enhanced Oil RecoveryDocument15 pagesThe Application of Fractional Flow Theory To Enhanced Oil RecoveryPablo DavidNo ratings yet

- 00 Book Salager Chap2Document56 pages00 Book Salager Chap2Jose Alejandro Dapena RiveroNo ratings yet

- LSW With PolymerDocument24 pagesLSW With PolymertsanshineNo ratings yet

- Defining Wettability PDFDocument2 pagesDefining Wettability PDFroastNo ratings yet

- Chapter 10: Emulsion & Oil/Water Separation: I. Oil Export SpecificationDocument21 pagesChapter 10: Emulsion & Oil/Water Separation: I. Oil Export SpecificationThanh Tùng PhạmNo ratings yet

- Three Phase CalculationDocument11 pagesThree Phase CalculationKhalid Al-RawiNo ratings yet

- 06 - Effective and Relative PermeabilityDocument13 pages06 - Effective and Relative PermeabilityMohamed IbrahimNo ratings yet

- Chapter10 PDFDocument14 pagesChapter10 PDFyazidNo ratings yet

- Indian School of Mines, Dhanbad: Reservoir AssignmentDocument4 pagesIndian School of Mines, Dhanbad: Reservoir AssignmentUtkarsh AkashNo ratings yet

- EmulsionsDocument14 pagesEmulsionsPaolo CavaioniNo ratings yet

- EOR ProcessesDocument35 pagesEOR ProcessesPurabiBoraNo ratings yet

- Enhanced Oil Recovery PE 510: Dr. Mohamed El-HouniDocument28 pagesEnhanced Oil Recovery PE 510: Dr. Mohamed El-HouniClyde San VicenteNo ratings yet

- Lab 6 Water SaturationDocument15 pagesLab 6 Water SaturationFadh At-Tarf100% (4)

- Chapter 10 Relative PermeabilityDocument27 pagesChapter 10 Relative PermeabilityAndrew Guo100% (1)

- Super-Absorbant Polymers PDFDocument13 pagesSuper-Absorbant Polymers PDFGayathri SelvarajNo ratings yet

- Properties of Oilfield WatersDocument7 pagesProperties of Oilfield WatersMaisam AbbasNo ratings yet

- PET 441E Enhanced Oil Recovery: by Dr. Murat Çınar Fall 2016Document13 pagesPET 441E Enhanced Oil Recovery: by Dr. Murat Çınar Fall 2016serro34No ratings yet

- Introduction to Applied Colloid and Surface ChemistryFrom EverandIntroduction to Applied Colloid and Surface ChemistryNo ratings yet

- The Mechanics of Water-Wheels - A Guide to the Physics at Work in Water-Wheels with a Horizontal AxisFrom EverandThe Mechanics of Water-Wheels - A Guide to the Physics at Work in Water-Wheels with a Horizontal AxisNo ratings yet

- Solution To ChECal MRII BookDocument15 pagesSolution To ChECal MRII BookKristineNo ratings yet

- Bdpho Sample ProblemsDocument64 pagesBdpho Sample ProblemsShayan Shanzui ZamanNo ratings yet

- Depreciation Rate Chart As Per Companies Act 2013 With Related LawDocument23 pagesDepreciation Rate Chart As Per Companies Act 2013 With Related Lawfintech ConsultancyNo ratings yet

- RESOLUTION NO. - , Series of 2021Document3 pagesRESOLUTION NO. - , Series of 2021Christie Anne ConalesNo ratings yet

- DO-C10073-CT Performance and Efficiency Monitoring (Issue 14)Document12 pagesDO-C10073-CT Performance and Efficiency Monitoring (Issue 14)Wisnu PrambudiNo ratings yet

- Sabre Technology Development: Status and UpdateDocument8 pagesSabre Technology Development: Status and Updates rNo ratings yet

- Unit2 Electrical and Electronic Technology Past PapersDocument17 pagesUnit2 Electrical and Electronic Technology Past Papersalbertvalerie742No ratings yet

- Replacement Battery Cartridges - APCRBC140Document2 pagesReplacement Battery Cartridges - APCRBC140Germán HinojosaNo ratings yet

- UnyeziDocument881 pagesUnyeziBonolo Ndamane93% (28)

- 3 079 16 - TherkelsenDocument11 pages3 079 16 - Therkelsenmohanad.taimourNo ratings yet

- Boq Assessment TrafoDocument2 pagesBoq Assessment TrafoWahyu HidayatNo ratings yet

- Electrical Component LocatorDocument47 pagesElectrical Component Locatorgentiles mdqNo ratings yet

- Ball Mills: Quantum Nanostructures (QDS) : AnDocument24 pagesBall Mills: Quantum Nanostructures (QDS) : AnBibhuti Bhusan RoulNo ratings yet

- Electrical SectionDocument142 pagesElectrical Sectionclaudiux78No ratings yet

- AadhyaDocument2 pagesAadhyavibhor354357No ratings yet

- Self-Assessment Exercise 1Document3 pagesSelf-Assessment Exercise 1Deniz YiğitNo ratings yet

- Bonding A LevelDocument2 pagesBonding A LevelHamzah ArabicaNo ratings yet

- Trouble Shooting in Paper MillDocument20 pagesTrouble Shooting in Paper MillLarsNo ratings yet

- Avtron-K575a DatasheetDocument2 pagesAvtron-K575a DatasheetKarlos Miguel Lopez GomezNo ratings yet

- Impact APCIEEETSTEDocument11 pagesImpact APCIEEETSTEJorgeLabraCanalesNo ratings yet

- Energies - 20 January 2021 - FinalDocument26 pagesEnergies - 20 January 2021 - FinalIrena FrycNo ratings yet

- 9866 0134 01 COP 44 Service Poster - HIGHDocument1 page9866 0134 01 COP 44 Service Poster - HIGHEmrah MertyürekNo ratings yet

- SP-M72 Series 335 W - 380 W Key Features: 22 % 1500 V 10 Year 25 YearDocument2 pagesSP-M72 Series 335 W - 380 W Key Features: 22 % 1500 V 10 Year 25 YearscribdgineerNo ratings yet

- Analisis Pengaruh Kadar Air (Total Moisture) Batubara Terhadap Nilai Kalori Batubara Di Front PenambanganDocument12 pagesAnalisis Pengaruh Kadar Air (Total Moisture) Batubara Terhadap Nilai Kalori Batubara Di Front PenambanganDaeng LupusNo ratings yet

- Nterview QuestionDocument79 pagesNterview QuestionYudha kurniawanNo ratings yet

- Manual OC350 (Hand) - en - ID1555626543872274241092-18Document119 pagesManual OC350 (Hand) - en - ID1555626543872274241092-18khanh khanhNo ratings yet

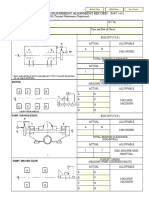

- Horizontal Rotating Equipment Alignment Record: Save Data... Email Data... Reset DataDocument5 pagesHorizontal Rotating Equipment Alignment Record: Save Data... Email Data... Reset DataGovind Jha100% (1)

- Carbon Capture Project ANNUAL REPORT 2017Document21 pagesCarbon Capture Project ANNUAL REPORT 2017Liang Yann YUANNo ratings yet

- Centrifugal Pump Vs Reciprocating Pump 1619353778Document1 pageCentrifugal Pump Vs Reciprocating Pump 16193537784A28Sparsh JainNo ratings yet

- Applied Thermal Engg. 15ME52TDocument23 pagesApplied Thermal Engg. 15ME52TMr Omkar PatilNo ratings yet