Professional Documents

Culture Documents

Catalytic Synthesis of Acetone and Acetaldehyde From Acetylene in Fluoride-Based Catalysts

Uploaded by

hokagehashirama8Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catalytic Synthesis of Acetone and Acetaldehyde From Acetylene in Fluoride-Based Catalysts

Uploaded by

hokagehashirama8Copyright:

Available Formats

The American Journal of Interdisciplinary Innovations and Research IMPACT FACTOR

(ISSN–2642-7478) 2020: 5. 498

Published: September 30, 2020 | Pages: 89-100

Doi: https://doi.org/10.37547/tajiir/Volume02Issue09-15

Catalytic Synthesis Of Acetone And Acetaldehyde From

Acetylene In Fluoride-Based Catalysts

Fayzullaev N.I

Samarkand State University, Samarkand, Uzbekistan

Akmalaev K.A

Journal Website: Satbayev University, Almaty, Kazakhstan

http://usajournalshub.c

om/index,php/tajiir

Karjavov A

Copyright: Original Samarkand State University, Samarkand, Uzbekistan

content from this work

may be used under the

terms of the creative Akbarov H.I

commons attributes National University Of Uzbekistan, Uzbekistan

4.0 licence.

E.Qobilov

Satbayev University, Almaty, Kazakhstan

ABSTRACT

In the study, the catalytic hydration reaction of acetylene in the presence of catalysts based on local

raw materials was carried out under stationary conditions in a flow reactor made of stainless steel

with a diameter of 25 mm and a height of 1000 mm. The reaction products were analyzed

chromatographically. In the presence of the created fluoride catalyst, the conversion of acetylene is

75-80%, the yield of acetaldehyde is 93%, the yield of acetone is 2.5%. The reason for the high activity

of cadmium-zinc-aluminum catalysts is explained by the fact that they form the active center of ox

fluorides on the surface of the catalyst. The effect of temperature, volumetric velocity, acetylene:

water ratio, etc. on acetaldehyde yield in the presence of the selected catalyst was studied. When

the effect of temperature was studied in the range of 300–440oC, an increase in acetylene

conversion and a decrease in acetaldehyde selectivity were found with increasing temperature. X-ray

studies have established that cadmium-chromo-fluoro-aluminum catalysts have high activity in

polymorphic-crystalline state.

KEYWORDS

Acetylene, hydration, catalyst, acetone, acetaldehyde.

INTRODUCTION

Currently, acetone is mainly obtained in the 2) In the Kumol method. This method

industry by the following methods [1-2, 26]: consists of 3 steps:

1) Propen directly and indirectly;

The USA Journals Volume 02 Issue 09-2020 89

The American Journal of Interdisciplinary Innovations and Research IMPACT FACTOR

(ISSN–2642-7478) 2020: 5. 498

Published: September 30, 2020 | Pages: 89-100

Doi: https://doi.org/10.37547/tajiir/Volume02Issue09-15

C6 H 6 CH 3CH CH 2 C6 H 5CH CH 3 2 C6 H 5CH CH 3 2 O2

C6 H 5CH OOH СH 3 2 C6 H 5CH OOH CH 3 2 C6 H 5OH CH 3 2 CO

3) Acetone is obtained by oxidizing isopropanol at 450-650 0C in the presence of copper, silver,

nickel, platinum catalysts:

2 CH 3 2 CH OH O2 2 CH 3 2 CO 2H 2O

Acetaldehyde is obtained by dehydrogenating important to develop cheap and effective

ethanol, oxidizing ethylene, oxidizing С3/С4 methods of obtaining acetone and

hydrocarbon fractions, and catalytically acetaldehyde. Currently, effective catalysts

hydrating acetylene. Currently, the cheapest with high activity have been obtained for the

and most promising method of obtaining production of acetylene by catalytic hydro

acetone and acetaldehyde for the Republic of chlorination of vinyl chloride and chloroprene

Uzbekistan is the catalytic hydration of [8-9], acetylation of vinyl acetate [10-14] and

acetylene. Because today NAVOIAZOT JSC has hydration of acetone and acetaldehyde [15-

pyrolysis equipment with a production 25].

capacity of 30,000 tons of acetylene per year

The reaction for the production of

[3-7].

acetaldehyde by catalytic hydration of

Today, the global demand for acetone, acetylene was discovered in 1881 by MG

acetaldehyde, vinyl chloride and vinyl acetates Kucherov and has been used in industry for

is growing day by day. Therefore, it is the production of acetaldehyde [1-2]:

CH CH H 2O CH 3CHO,

4, HgSO HgO

H 2 SO4

H 298

0

150,1kJ / mol

The reaction is strongly exothermic and does decomposition reaction of acetaldehyde. The

not return to 300 0C. At temperatures above following additional reactions take place in

300 0C, the equilibrium shifts towards the the synthesis of acetaldehyde from acetylene:

The USA Journals Volume 02 Issue 09-2020 90

The American Journal of Interdisciplinary Innovations and Research IMPACT FACTOR

(ISSN–2642-7478) 2020: 5. 498

Published: September 30, 2020 | Pages: 89-100

Doi: https://doi.org/10.37547/tajiir/Volume02Issue09-15

2CH 3CHO CH 3 – CH CHCHO H 2O

CH3CHO H 2O CH3COOH 2H

Oxides and salts of various metals, including local raw materials, to study the kinetic laws

phosphates, tungstates, vanadates, of the process.

molybdates, chromates, have been tested as

EXPERIMENTAL PART

catalysts for this process. Among all tested

catalysts for the catalytic hydration of The specific surface area of the sample

acetylene to acetaldehyde, the obtained was calculated by the BET method,

CdHPO4∙Ca3(PO4)2 cadmium-calcium the mean size of the mesentery by the BJH

phosphate catalyst, developed by Yu.A.Gorin method. The spatial composition was studied

and S.M.Momozon, exhibits high activity and by diffractometer DRON-3 (CuKα radiation) by

stability [1-16]. This catalyst is active at 350- X-ray diffraction method. The dispersion

4000C and regenerates with air and water properties of the catalyst were examined

vapor at 400-4500C. The process is carried out under a scanning electron microscope (JSM-

under conditions of water vapor: acetylene 6510 LV). The catalytic activity of the obtained

volume ratios 7-10: 1. At this time, the sample was studied in the hydration reaction

conversion of acetylene is 45-50%, of acetylene. Experiments on the catalytic

acetaldehyde yield is 89%, croton aldehyde hydration of acetylene and its derivatives in

yield is 6-7%. Also in this process acetic acid the vapor phase were carried out under

(0.5-1.0%), acetone (0.3%) and various additives stationary conditions in a stainless steel

are formed. The activity of the catalyst reactor with a diameter of 25 mm and a height

decreases as a result of the formation of of 1000 mm. The qualitative and quantitative

resinous products and carbon (coke). composition of the reaction products was

Therefore, after 70-100 hours of catalyst studied by gas-liquid chromatographic

operation, the temperature is raised to 400- method under the following optimal

4100C. The catalyst is then regenerated. The conditions. Stationary phase 15% Apiezon- M in

productivity of the catalyst is 140-216 Tsvetochrome, column thermostat

kg/(m3∙cat∙h) on acetaldehyde. Disadvantages temperature 1000C, carrier gas nitrogen

of this catalyst: rapid loss of its activity, low consumption 40 ml / min, detector - DIP. The

selectivity, low product yield, thermal duration of the analysis is 12 minutes.

instability, etc. [1-3]. The aim of the work is to Quantitative analysis was performed using the

create high-activity catalysts for the catalytic internal standards method.

hydration reaction of acetylene on the basis of

The USA Journals Volume 02 Issue 09-2020 91

The American Journal of Interdisciplinary Innovations and Research IMPACT FACTOR

(ISSN–2642-7478) 2020: 5. 498

Published: September 30, 2020 | Pages: 89-100

Doi: https://doi.org/10.37547/tajiir/Volume02Issue09-15

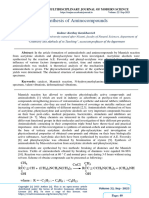

Figure 1. Chromatogram of the products of the catalytic hydration reaction of acetylene

The quantitative composition of the reaction products was determined by the following formula.

K i Si

C n

K S

i 1

i i

Ki - the correction factor

Si-the peak surface area of the determined components, mm2

RESULTS AND DISCUSSION Their stability is 1.5-2.0 times higher than that

of cadmium-calcium-phosphate catalyst. The

Fluoride catalysts with high activity, selectivity

catalyst promoted by up to 5.0% aluminum

and efficiency, high selectivity, thermally

fluoride has sufficient activity, mechanical

stable were selected by the suspension

strength and stability. A catalyst containing

method on the basis of local raw materials. In

10% to 20% cadmium fluoride ensures high

the presence of the selected catalyst, the

yields of acetaldehyde. When the reaction is

conversion of acetylene is 75-80%, the yield of

carried out at 300-4200C, the yield of

acetaldehyde is 93%, the yield of acetone is

acetaldehyde is 90% relative to the acetylene

2.5%. As can be seen from Table 1, the given

that reacts. Additional products include

catalysts ensure high acetylene conversion.

The USA Journals Volume 02 Issue 09-2020 92

The American Journal of Interdisciplinary Innovations and Research IMPACT FACTOR

(ISSN–2642-7478) 2020: 5. 498

Published: September 30, 2020 | Pages: 89-100

Doi: https://doi.org/10.37547/tajiir/Volume02Issue09-15

acetone, 3- oxybutanal, croton aldehyde,

butanal, ethyl acetate, and paraldehyde.

Table 1.

Composition and properties of synthesized cadmium- fluorine-aluminum catalysts.

(T=723 K)

Operatingtime

Specific

Catalyst components, before Productivity, Conversion of

surface area,

mass % regeneration, g / kg, cat ∙ h acetylene,%

m2 / g

daily

CdF2 – 20; Al2O3 -80 220 96 110 95

CdF2 – 15; Al2O3 - 85 165 120 85 82

CdF2 –11,2; AlF3 – 2,8

135 140 91 90

Al2O3 - 86

CdF2 – 15; AlF3 – 5

151 155 100 92

Al2O3 - 80

CdF2 – 10; AlF3 – 10

183 130 88 94

Al2O3 - 80

CdF2 – 5; ZnF2 - 10

201 160 84 86

AlF3 – 5; Al2O3 - 80

The reason for the high activity of cadmium- hand, form active centers on the catalyst

zinc-aluminum catalysts is explained by the surface. Ox fluorides cause the polarization of

fact that they form ox fluorides on the surface acetylene and water molecules:

of the catalyst. Ox fluorides, on the other

- +

H-C C-H

-0,35

-3,15

: :

H-O F

+1,7

Cd

Al2O3

Figure 2. Acetylene on the surface of an oxyfluoride catalyst polarization model of the molecule

The USA Journals Volume 02 Issue 09-2020 93

The American Journal of Interdisciplinary Innovations and Research IMPACT FACTOR

(ISSN–2642-7478) 2020: 5. 498

Published: September 30, 2020 | Pages: 89-100

Doi: https://doi.org/10.37547/tajiir/Volume02Issue09-15

The active particles react to form vinyl alcohol. etc. on acetaldehydrate yield was studied.

Vinyl alcohol is isomerizes to acetaldehyde. When the effect of temperature was studied

During the promotion of catalysts prepared by in the range of 300–4400C, an increase in

suspension on the basis of cadmium and zinc acetylene conversion and a decrease in

fluorides and other compounds, the formation acetaldehyde selectivity were found with

of hydroxyfluorides with the following increasing temperature. The study of the

composition: Сd(OH)F, Zn(OH)F, Al(OH)2F, effect of temperature on acetaldehyde yield

Al(OH)F2 was studied by radiographic analysis. showed that the relationship between

the formation of hydrofluorides was found to reaction reaction temperature and

lead to an increase in catalyst activity. Kinetics temperature in the range of 360-4400C is

of the catalytic hydration reaction of extreme and the yield has a maximum value at

acetylene. The effect of temperature, 4000C (Figure 3).

volumetric velocity, acetylene: water ratio,

3).

Figure 3. The effect of temperature on acetaldehyde yield

To maintain acetylene conversion at a acetylene volume rate on acetaldehyde yield

constant 80–85%, the temperature was and acetylene conversion was studied in the

increased to 100C for 15–20 h. The effect of 50–120 h-1 range.

The USA Journals Volume 02 Issue 09-2020 94

The American Journal of Interdisciplinary Innovations and Research IMPACT FACTOR

(ISSN–2642-7478) 2020: 5. 498

Published: September 30, 2020 | Pages: 89-100

Doi: https://doi.org/10.37547/tajiir/Volume02Issue09-15

Figure 4. Effect of acetylene volume rate on acetylene conversion.

Acetylene conversion and acetaldehyde yield temperature, catalyst size, reactor parameters

decreased when the volumetric rate of the and catalyst layer heights on the technological

acetylene and water vapor mixture was parameters of the process was studied.

increased from 250 to 500 h-1. The influence of

Figure 5. Influence of catalyst layer height on acetylene conversion rate.

The effect of the catalyst layer height on the The ratio of the height of the catalyst layer to

conversion rate of acetylene is shown in the diameter of the reactor is 50-60, and the

Figure 5: volumetric velocity of acetylene is 50-60

hours-1. Under these conditions, the catalyst

The USA Journals Volume 02 Issue 09-2020 95

The American Journal of Interdisciplinary Innovations and Research IMPACT FACTOR

(ISSN–2642-7478) 2020: 5. 498

Published: September 30, 2020 | Pages: 89-100

Doi: https://doi.org/10.37547/tajiir/Volume02Issue09-15

№4 (Table 2) operates for 120 hours with reaction of acetylene results in the formation

constant activity, after 16-24 hours of of acetaldehyde or acetone, depending on the

regeneration, the catalyst fully recovers its composition and nature of the catalyst used

activity. Studies have been conducted on the under the same conditions. In particular, in the

selection of polyfunctional mixed catalysts for presence of cadmium fluoride catalyst

the catalytic hydration reactions of acetylene containing 18 % CdF2, 2,0 % AlF3, 5% Cr2O3,75 %

to acetaldehyde and acetone. As a result, a Al2O3 acetylene reacts at 360-4400C in the

cadmium fluoride and chromium (III) oxide ratio: water = 1: 3-1: 5. The addition of zinc

catalyst soaked in aluminum oxide promoted oxide or fluoride (№5 catalysts) to the

with aluminum fluoride was selected for the cadmium-chromium-aluminum catalyst

acetaldehyde production process. The ensures the selectivity of the catalyst and

composition and properties of the synthesized directs the acetylene hydration reaction

catalysts are given in Table 2. The hydration towards the formation of acetone.

Table 2. Properties and composition of synthesized catalysts

Processing time

Specific Expectedproduct yield,%

before

№ Content, mass % surface area,

regeneration,

m2/g CH3CHO Acetone

hours

ZnO – 20; AlF3 – 3

1 135 72 10 82

Al2O3 – 77

2 CdF2-20; Al2O3-80 186 96 75 5

CdF2 – 18; AlF3 – 3

3 210 96 82 3

Al2O3 – 79

CdF2 – 18; AlF3 – 2

4 225 120 83 1,5

Cr2O3-5; Al2O3-75

ZnO – 18; CdF2 – 2

5 165 120 3 86

Cr2O3-5; Al2O3-75

As can be seen from Table 2, the yield of of this catalyst was studied. The yield of

acetone in the presence of № 5 catalyst was acetone formation, the selectivity increases to

86%, and the pre-regeneration time was 120 698 K. When the temperature exceeds 698 K,

hours. This indicates that the most suitable the yield of acetone formation and the

among the selected catalysts are zinc oxide, selectivity of the process decrease due to the

cadmium fluoride, chromium (III) oxide conversion to other substances. The

storage catalysts. Therefore, the effect of production of cadmium-chromium-fluorine-

temperature on acetone yield in the presence aluminum catalyst consists of the following

The USA Journals Volume 02 Issue 09-2020 96

The American Journal of Interdisciplinary Innovations and Research IMPACT FACTOR

(ISSN–2642-7478) 2020: 5. 498

Published: September 30, 2020 | Pages: 89-100

Doi: https://doi.org/10.37547/tajiir/Volume02Issue09-15

main stages: line for acid treatment and washed, and then the mass is dried at 95 0C

activation of expanded clay; mixing and for 3 hours (2). At this time, the mill (8) grinds

forming line; thermal treatment of the coal, zinc oxides and iron. The mixture of

catalyst. For acid treatment and activation is components is sent to the mixer (11) and, with

carried out in a reactor equipped with a vigorous stirring, ¾ part of the aqueous

mechanical stirrer. The calculated amount of solution of the peptizer is added (we use an

expanded clay is sent to the reactor (1) and a aqueous solution of extraction phosphoric

certain amount of 10% sulfuric acid is sent acid as a peptizer). Stirring continues until a

there. The components are stirred for 1 hour, homogeneous mass is obtained.

Figure 6. Technological scheme for the production of cadmium- chromium-fluorine-

The USA Journals Volume 02 Issue 09-2020 97

The American Journal of Interdisciplinary Innovations and Research IMPACT FACTOR

(ISSN–2642-7478) 2020: 5. 498

Published: September 30, 2020 | Pages: 89-100

Doi: https://doi.org/10.37547/tajiir/Volume02Issue09-15

ALUMINUM CATALYST 10 mm. The granules exiting the granulator

contain 20 - 25% moisture. Drying of the

1 - mixer-activator; 2 - bunker for expanded

contact mass is carried out in a dryer (13) at

clay; 3 - tank for 10% sulfuric acid; 4 - drying

cabinet; 5, 6, 7 - containers for iron oxide, zinc

and coal; 8 - ball mill; 9, 10 - containers for Heat treatment of the catalyst is carried out in

extraction phosphoric acid and distilled water; a drum-type furnace (14), while the flue gases

11 - lazy mixer; 12 - molding machine; 13 - and the raw material of the pellets must pass

conveyor dryer; 14 - shaft calcining furnace; 15 through the furnace in counterflow. The initial

- vibrating screens. temperature of calcination is 2000C, the

temperature is raised by 500C every 30

Pre-prepared carrier - activated acidic

minutes. up to 450 – 5000C. After calcining,

expanded clay after drying is crushed in a mill

the catalyst is sifted out for discard (14) and

(8) and sent to the mixer (11) for mixing with

sent to the finished product warehouse.

the rest of the components, and ¼ amount of

peptizer is added. Stirring continues for 30 - The processing of tree data according to

40 minutes, after which the mass is sent to the equations (1) - (3) show that the thermal

molds (12). For this, a screw molding machine decomposition of the cadmium-chromium-

was chosen, which allows to obtain granules fluoro-aluminum catalyst obeys equation (3).

with a diameter of 6 - 8 mm and a length of 8 -

1 d k E

ln ln (1)

(1 )2 / 3 dT g RT

1 d k0 E

ln n ln (2)

/1 2 dT g RT

1 d k E

ln ln 0 (3)

(1 ) dT g RT

where - degree of development, calculated on the curved TG woodcutogramme, A - parameter,

depending on the mechanism of the reaction speed of the formation of the formation and geometry

of the seed; E, R - energy activation and gas.

X-ray studies have established that cadmium-chromo-fluoro-aluminum catalysts have high activity in

polymorphic-crystalline state.

CONCLUSION analyzed chromatographically. In the presence

of the created fluoride catalyst, the conversion

In the study, the catalytic hydration reaction of

of acetylene is 75-80%, the yield of

acetylene in the presence of catalysts based on

acetaldehyde is 93%, the yield of acetone is

local raw materials was carried out under

2.5%. The reason for the high activity of

stationary conditions in a flow reactor made of

cadmium-zinc-aluminum catalysts is explained

stainless steel with a diameter of 25 mm and a

by the fact that they form the active center of

height of 1000 mm. The reaction products were

The USA Journals Volume 02 Issue 09-2020 98

The American Journal of Interdisciplinary Innovations and Research IMPACT FACTOR

(ISSN–2642-7478) 2020: 5. 498

Published: September 30, 2020 | Pages: 89-100

Doi: https://doi.org/10.37547/tajiir/Volume02Issue09-15

ox fluorides on the surface of the catalyst. The Research in Science, Engineering and

effect of temperature, volumetric velocity, Technology, 6(12).

acetylene: water ratio, etc. on acetaldehyde 7. Fayzullaev, N. I., Yusupov, D., &

yield in the presence of the selected catalyst Shirinov, X. Sh., Korotoev, AV.,

was studied. When the effect of temperature Umirzakov, RR. (2002). Catalytic

was studied in the range of 300–4400C, an vaporphase hydration of acetylene and

increase in acetylene conversion and a decrease its derivatives. Chemical Industry. N, 7,

in acetaldehyde selectivity were found with 1-33.

increasing temperature. X-ray studies have 8. Faizullaev, N. I., Sarimsakova, N. S., &

established that cadmium-chromo-fluoro- Bakieva, Kh. A. (2018). Metod

aluminum catalysts have high activity in polucheniya vinilkhlorida i khloroprena

polymorphic-crystalline state. iz atsetilena. Molodoi uchenyi, (24),

273-275.

REFERENCES

9. , N. I., Turobzhonov, S. M., & Omanov,

1. Timofeev, V. S., Serafimov, L. A., & B. Sh. (2018). Vinilatsetat sintezi

Timoshenko, A.V. (2010). Principles of reaktorini modellashtirish va zharaenni

basic organic and petrochemical makbullashtirish. I. Karimov nomidagi

synthesis technology. p. 408. Toshkent davlat tekhnika universiteti.

2. Temkin, O. N., Shestakov, G. K., & ToshDTU khabarlari.

Treger, Yu. A. (1991). Acetylene: 10. Fayzullayev, N. I., & Turobjonov, S. M.

Chemistry. Reaction mechanism. (2015). Catalytic Aromatization of

Technology. Chemistry. p. 416. Methane. International Journal of

3. Omanov, B. S., Fayzullaev, N. I., Chemical and Physical Science, 4, 27-34.

Musulmonov, N. K., Xatamova, M. S., & 11. Karjavov, A. R., Fayzullayev, N. I., &

Asrorov, D. A. (2020). Optimization of Musulmonov, N. X. (2020). Jointly

Vinyl Acetate Synthesis Process. Catalytic Synthesis of Vinyl Chloride and

International Journal of Control and Chloroprene from Acetylene.

Automation, 13(1), 231-238. International Journal of Control and

4. Faizullaev, N. I., Fozilov, S. F., Automation, 13(4), 55-62.

Ibodullaeva, M. N., & Khotamov, K. Sh. 12. Omanov, B. S., Fayzullayev, N. I., &

(2019). Geterogenno-kataliticheskii Xatamova, M. S. (2020). Catalytic

sintez vinilatsetata iz atsetilena. synthesis of acetylene ut of vynil

Nauchnyi aspekt, (1). acetate and texture characteristics of

5. Fayzullaev, N. I., Karjavov, A. R., & catalysts. Asian Journal of

Yusupova, S. S. (2020). Catalytic Multidimensional Research (AJMR).

Synthesis of Acetone Direct Acetylene Special Issue, March, 157-164.

Hydration. International Journal of 13. Omanov B.Sh., Khatamova M.S., &

Advanced Science and Technology, Faizullaev N.I. (2020). Tekhnologii

29(05), 4507-4514. proizvodstvennye vinilatsetat.

6. Omanov, B. S., Fayzullayev, N. I., & Innovatsionnaya nauka, (3), 10-12.

Xatamova, M. S. (2019). Vinylacetate 14. Omanov, B. Sh. U., & Faizullaev, N. I.

Production Out of acetylene. (2020). Parametry tekhnologicheskogo

International Journal of Advanced rezhima sinteza vinilatsetata.

Universum: khimiya i biologiya, (4 (70)).

The USA Journals Volume 02 Issue 09-2020 99

The American Journal of Interdisciplinary Innovations and Research IMPACT FACTOR

(ISSN–2642-7478) 2020: 5. 498

Published: September 30, 2020 | Pages: 89-100

Doi: https://doi.org/10.37547/tajiir/Volume02Issue09-15

15. Fozilov, S. F., Faizullaev, N. I., & (2016). Kataliticheskoe atsetilirovanie

Sodikova, M. M. (2019). atsetilena v parovoi fazevprisutstvii

Kataliticheskaya parofaznaya nanokatalizatora. Vestnik AING.

gidratatsiya atsetilena. Nauchnyi 22. Fayzullaev, N. I., Jumanazarov, R. B., &

aspekt, 8(1), 976-979. Turabjanov, S. M. (2015).

16. Sh, S. B. (2018). Rakhmatov Sh. B., Heterogeneous Catalytic Synthesis of

Fayzullayev NI High silicon zeolite Vinylchloride by Hydrochlorination of

preparation from kaolin. Scientific Acetylene. IJISET-International Journal

journal of SamSU, 5(109), 106-111. of Innovative Science, Engineering &

17. Omanov, B. S., Fayzullaev, N. I., & Technology, 2(9).

Xatamova, M. S. (2020). Vinyl Acetate 23. Faizullaev, N. I., & Tursunova, N. S.

Production Technology. International (2018). Poluchenie etilena iz metana s

Journal of Advanced Science and ispol'zovaniem marganets

Technology, 29(3), 4923-4930. soderzhashchego katalizatora. Khimiya i

18. Fayzullayev, N., Akmalaiuly, K., & khimicheskaya tekhnologiya, (1), 24-28.

Karjavov, A. (2020). Catalytic synthesis 24. Mukhamadiev, A. N., & Faizullaev, N. I.

of a line by acetylene hydration. News (2018). Gazokhromatograficheskoe

of the National Academy of Sciences of izuchenie reaktsii kataliticheskogo

the Republic of Kazakhstan, Series prevrashcheniya metana v metanol. In

chemistry and technology, 2(440), 23- XXXV Vserossiiskii simpozium molodykh

30. uchenykh po khimicheskoi kinetike. pp.

19. Fayzullaev, N. I., & Sh, S. B. (2018). 110-110.

Catalytic aromatization of methane 25. Omanov, B. S., Ibodullayevich, F. N.,

with non-mo-contained catalysts. Anorboevich, E. K., & Sattorovna, K. M.

Austrian Journal of Technical and (2020). Production of vinyl acetate from

Natural Sciences, (7-8). acetylene. ACADEMICIA: An

20. Fayzullaev, N. I., & Shukurov, B. S. International Multidisciplinary Research

(2017). Kinetics and Mechanism of the Journal, 10(6), 1031-1038.

Reaction of Catalytic 26. Fayzullaev, N. I., Akmalaev, K. A.,

Dehydroaromatization of Methane. Karjavov, A., Akbarov, H. I., & Qobilov,

International Journal of Oil, Gas and E. (2020). Vapor phase catalytic

Coal Engineering, 5(6), 124. hydratation of acetylene. ACADEMICIA:

21. Faizullaev, N. I., Kurbanov, A. M., An International Multidisciplinary

Shugaepov, N. A., & Turdiev, M. F. Research Journal, 10(7), 88-98.

(4)

The USA Journals Volume 02 Issue 09-2020 100

You might also like

- E3sconf Uesf2023 02015Document8 pagesE3sconf Uesf2023 02015hokagehashirama8No ratings yet

- Mistura Sílica e Alumina - Miteva (2019) - Characterisation of Fuel Produced From Polyolefin Waste Over Al2O3-SiO2Document9 pagesMistura Sílica e Alumina - Miteva (2019) - Characterisation of Fuel Produced From Polyolefin Waste Over Al2O3-SiO2Katiane MesquitaNo ratings yet

- Acetonitrile PDFDocument4 pagesAcetonitrile PDFmarcelompassosNo ratings yet

- Cucl2 Catalyst Ohashi2019Document11 pagesCucl2 Catalyst Ohashi2019Lester Jason ChengNo ratings yet

- Synthesis of Ethylene Oxide in A Catalytic Microreactor SystemDocument6 pagesSynthesis of Ethylene Oxide in A Catalytic Microreactor SystemcampellomottaNo ratings yet

- Minerals: Fabrication of Single-Crystalline Calcite Needle-Like Particles Using The Aragonite-Calcite Phase TransitionDocument9 pagesMinerals: Fabrication of Single-Crystalline Calcite Needle-Like Particles Using The Aragonite-Calcite Phase TransitionkrmktsNo ratings yet

- AmoolDocument12 pagesAmoolirfan k shahNo ratings yet

- 177-Article Text-501-1-10-20190430Document5 pages177-Article Text-501-1-10-20190430Rezha ApriansyahNo ratings yet

- Study of The Active Phase of Silver Catalysts For Ethylene EpoxidationDocument10 pagesStudy of The Active Phase of Silver Catalysts For Ethylene Epoxidationiris_2115No ratings yet

- Kinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide CatalystsDocument9 pagesKinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide Catalysts李国俊No ratings yet

- Aqua CatDocument4 pagesAqua Catlonely3No ratings yet

- Aqueous-Phase Hydrodeoxygenation of Sorbitol With PT SiO2 Al2O3Document12 pagesAqueous-Phase Hydrodeoxygenation of Sorbitol With PT SiO2 Al2O3Paulo CésarNo ratings yet

- The Use of Chitosan As A Solid Base Catalyst For TDocument8 pagesThe Use of Chitosan As A Solid Base Catalyst For TRicardo Fajardo DíazNo ratings yet

- Hydrogenolysis of Glycerol To 1,2-PropanediolDocument5 pagesHydrogenolysis of Glycerol To 1,2-PropanediolKesavan GovinathanNo ratings yet

- Blue Pigments Based On CoxZn1-xAl2O4 Spinels Synthesized by The Polymeric Precursor Method.1Document6 pagesBlue Pigments Based On CoxZn1-xAl2O4 Spinels Synthesized by The Polymeric Precursor Method.1Cáp Lộc Hàn VũNo ratings yet

- EmbeddDocument7 pagesEmbeddLUIS AUGUSTO BARBOSANo ratings yet

- ChemCatChem - 2012 - Yu - The Unique Role of CaO in Stabilizing The PT Al2O3 Catalyst For The Dehydrogenation ofDocument6 pagesChemCatChem - 2012 - Yu - The Unique Role of CaO in Stabilizing The PT Al2O3 Catalyst For The Dehydrogenation ofSangHao NgNo ratings yet

- Catalytic Reduction of Nitric Oxide On PT and RH Catalysts Supported On Alumina and Titania Synthesized by The Sol-Gel MethodDocument7 pagesCatalytic Reduction of Nitric Oxide On PT and RH Catalysts Supported On Alumina and Titania Synthesized by The Sol-Gel MethodHarun AydınNo ratings yet

- Electrochemical Behavior of Layered Solid Solution Li Mno 2limo (M 5 Ni, MN, Co) Li-Ion Cathodes With and Without Alumina CoatingsDocument7 pagesElectrochemical Behavior of Layered Solid Solution Li Mno 2limo (M 5 Ni, MN, Co) Li-Ion Cathodes With and Without Alumina CoatingsEYERUSALEM TADESSENo ratings yet

- Ghita Danuta 1 16Document5 pagesGhita Danuta 1 16Anonymous p52JDZOdNo ratings yet

- Thermogravimetric Study On Pyrolysis of Biomass With Cu Al2O3 CatalystsDocument5 pagesThermogravimetric Study On Pyrolysis of Biomass With Cu Al2O3 CatalystsMikael SalamancaNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Korus: 2004 of Gas ONDocument5 pagesKorus: 2004 of Gas ONKarla LopezNo ratings yet

- The Intermetallic Catalysts For Oxidative Esterification of Methacrolein To Methyl MethacrylateDocument5 pagesThe Intermetallic Catalysts For Oxidative Esterification of Methacrolein To Methyl MethacrylatePau ZalazarNo ratings yet

- (2019-11p) IOP MSE - Subcritical Water...Document7 pages(2019-11p) IOP MSE - Subcritical Water...ClearyNo ratings yet

- Manufacture of Sulfuric Acid: S.R.M. Engineering CollegeDocument76 pagesManufacture of Sulfuric Acid: S.R.M. Engineering CollegeCharles RiosNo ratings yet

- Assessment of Gas Production and Electrochemical FDocument22 pagesAssessment of Gas Production and Electrochemical FBrayan HHNo ratings yet

- The Transport Process in The Catalytic Dehydrogenation of Ethyl AlcoholDocument23 pagesThe Transport Process in The Catalytic Dehydrogenation of Ethyl AlcoholFiqkyAkbarNo ratings yet

- Investigation of The Use of The Magnetic Field Method in The Obtaining of Superactive AdditivesDocument5 pagesInvestigation of The Use of The Magnetic Field Method in The Obtaining of Superactive AdditivesResearch ParkNo ratings yet

- A.balla Rev - Chim.2015Document7 pagesA.balla Rev - Chim.2015abderrahimnNo ratings yet

- Zeolite From Fly AshDocument14 pagesZeolite From Fly AshpriyaNo ratings yet

- Acrylic AcidDocument11 pagesAcrylic AcidhazimraadNo ratings yet

- Benzyl Chloride KineticsDocument6 pagesBenzyl Chloride KineticsReo Aditya MahesaNo ratings yet

- Zhang 2014Document5 pagesZhang 2014oviabeautyNo ratings yet

- Activated Metal Bi and La Modified SAPO-34 MoleculDocument15 pagesActivated Metal Bi and La Modified SAPO-34 MoleculaliNo ratings yet

- IR Ni LanthanaDocument6 pagesIR Ni LanthanaNelly RojasNo ratings yet

- AbbasDocument9 pagesAbbasOmer AijazNo ratings yet

- Carbon Capture Technologies for Gas-Turbine-Based Power PlantsFrom EverandCarbon Capture Technologies for Gas-Turbine-Based Power PlantsNo ratings yet

- Factor Affecting Microwave Assisted Preparation ofDocument11 pagesFactor Affecting Microwave Assisted Preparation ofeva reysitaNo ratings yet

- Applied Catalysis A: General: Sukriti Singh, Anjali Patel, Pravya PrakashanDocument10 pagesApplied Catalysis A: General: Sukriti Singh, Anjali Patel, Pravya PrakashanValentina Vargas VargasNo ratings yet

- Temperature-Programmed Oxidation of Coked Noble Metal Catalysts After Autothermal Reforming of N-HexadecaneDocument9 pagesTemperature-Programmed Oxidation of Coked Noble Metal Catalysts After Autothermal Reforming of N-HexadecaneImran KhanNo ratings yet

- Aluminum Corrosion TestDocument12 pagesAluminum Corrosion Testatique islamNo ratings yet

- Vapour Phase Hydrogenation of Naphthalene On A Novel Ni-Containing Mesoporous Aluminosilicate CatalystDocument6 pagesVapour Phase Hydrogenation of Naphthalene On A Novel Ni-Containing Mesoporous Aluminosilicate Catalystioanaandra5690No ratings yet

- Ken Dell 2010Document18 pagesKen Dell 2010Juan CamiloNo ratings yet

- Ethylene Dichloride Production by Oxychlorination in A Fluidized Bed Reactor With CFD ModelDocument14 pagesEthylene Dichloride Production by Oxychlorination in A Fluidized Bed Reactor With CFD ModelJam ImtiazNo ratings yet

- Wei Li, Shan Tan, Yun Shi, Sujing Li: SciencedirectDocument8 pagesWei Li, Shan Tan, Yun Shi, Sujing Li: SciencedirectAnindita IndrianaNo ratings yet

- A Kinetic Study of The Thermal Degradation of Chitosan-Metal ComplexesDocument10 pagesA Kinetic Study of The Thermal Degradation of Chitosan-Metal ComplexesFernanda Stuani PereiraNo ratings yet

- Production of Hydrogen by Steam Reforming of Ethanol Over A Ni/Zno CatalystDocument6 pagesProduction of Hydrogen by Steam Reforming of Ethanol Over A Ni/Zno Catalystpetro121No ratings yet

- Synthesis of AminocompoundsDocument7 pagesSynthesis of AminocompoundsAcademic JournalNo ratings yet

- Zhang (2018) - Acetaldehyde Oxidation at Low and Intermediate TemperatureDocument11 pagesZhang (2018) - Acetaldehyde Oxidation at Low and Intermediate TemperatureFernanda MoncadaNo ratings yet

- WO3-Based Catalysts Prepared by Non-Hydrolytic Sol-Gel For The Production of Propene by Cross-Metathesis of Ethene and 2-ButeneDocument8 pagesWO3-Based Catalysts Prepared by Non-Hydrolytic Sol-Gel For The Production of Propene by Cross-Metathesis of Ethene and 2-ButeneaegosmithNo ratings yet

- Catalyst For Complex Flue GasesDocument19 pagesCatalyst For Complex Flue GasesbekkuNo ratings yet

- IJE - Volume 15 - Issue 3 - Pages 235-240Document6 pagesIJE - Volume 15 - Issue 3 - Pages 235-240hardiknanera25No ratings yet

- Tungsten Carbide Nanofibers Prepared by Electrospinning With High Electrocatalytic Activity For Oxygen ReductionDocument7 pagesTungsten Carbide Nanofibers Prepared by Electrospinning With High Electrocatalytic Activity For Oxygen ReductionBosco BeloNo ratings yet

- Shells 3Document8 pagesShells 3Donna HayesNo ratings yet

- Recovering Hydrogen Sulfide From Sulfurous Waters With PEM Fuel Cells 2016 Energy ProcediaDocument6 pagesRecovering Hydrogen Sulfide From Sulfurous Waters With PEM Fuel Cells 2016 Energy ProcediathaightNo ratings yet

- Hydrogen Production by A PEM ElectrolyserDocument7 pagesHydrogen Production by A PEM ElectrolyserAdrián HerreroNo ratings yet

- Ettringite Dependace in Thaumasite FormationDocument7 pagesEttringite Dependace in Thaumasite FormationJose Blas HerreroNo ratings yet

- Art:10.1007/s10562 012 0831 3 PDFDocument8 pagesArt:10.1007/s10562 012 0831 3 PDFThemba MasukuNo ratings yet

- Iso 4049 2019Document12 pagesIso 4049 2019rdepaivaNo ratings yet

- Bio Battery: A Fuel of Next Generation .Document16 pagesBio Battery: A Fuel of Next Generation .ashishNo ratings yet

- Tweg 2Document30 pagesTweg 2davpaffNo ratings yet

- Typical Ball Valve Material SelectionDocument12 pagesTypical Ball Valve Material SelectionabsherlockNo ratings yet

- Turbidimetric and Nephelometric Flow Analysis Concepts and ApplicationsDocument34 pagesTurbidimetric and Nephelometric Flow Analysis Concepts and ApplicationsJesus Mesias IsraelNo ratings yet

- Sulfonation Reactions Behind The Fate of White Wine'sDocument10 pagesSulfonation Reactions Behind The Fate of White Wine'sNicolas MossoNo ratings yet

- Dws Info 316 Stainless Steel SlicklineDocument1 pageDws Info 316 Stainless Steel SlicklineBrayan GallosoNo ratings yet

- DFT Calculations of Molecular Magnetic Properties of Coordination CompoundsDocument23 pagesDFT Calculations of Molecular Magnetic Properties of Coordination CompoundslitespaklaNo ratings yet

- IGCSE 14 MomentumDocument39 pagesIGCSE 14 MomentumHakim Abbas Ali Phalasiya36% (11)

- Ashtabandhanam 5Document11 pagesAshtabandhanam 5tagoreboopathy100% (1)

- Solar PV Module Manufacturing DtbarkiDocument22 pagesSolar PV Module Manufacturing DtbarkiRamNo ratings yet

- Oxy-Fuel Glass MeltingDocument19 pagesOxy-Fuel Glass MeltingKroze100% (1)

- Phys 10010 Formula Sheet Modified For 2018 Rev 8Document4 pagesPhys 10010 Formula Sheet Modified For 2018 Rev 8Ayşegül AbdelalNo ratings yet

- Pamphlet 5 Bulk Storage of Liquid Chlorine - CiDocument29 pagesPamphlet 5 Bulk Storage of Liquid Chlorine - Cifagb1978No ratings yet

- Calculation of The Remaining Lifetime of Power Transformer Paper InsulationDocument8 pagesCalculation of The Remaining Lifetime of Power Transformer Paper InsulationadepomaNo ratings yet

- 04 - AbsorbersDocument11 pages04 - AbsorbersRafael ReyesNo ratings yet

- Corrosion in Petroleum IndustryDocument56 pagesCorrosion in Petroleum Industryandreeaelena0930100% (2)

- 46 Sim Minerals Processing Unit ModelsDocument3 pages46 Sim Minerals Processing Unit ModelsalinoriNo ratings yet

- Paraloid km-334Document5 pagesParaloid km-334Naseer MianNo ratings yet

- 02-04-2023 SR - Super60 Nucleus & All BT Jee-Main-Gtm-33 Key & Sol'sDocument14 pages02-04-2023 SR - Super60 Nucleus & All BT Jee-Main-Gtm-33 Key & Sol'sK R I S HNo ratings yet

- BS en 12396-1-1999Document12 pagesBS en 12396-1-1999DoicielNo ratings yet

- Spiral Weld PipeDocument52 pagesSpiral Weld PipePRASHANTNo ratings yet

- Report Alps PDFDocument25 pagesReport Alps PDFRohit SinghNo ratings yet

- 6 Eccecntric FootingDocument21 pages6 Eccecntric FootingDeep ZaveriNo ratings yet

- Fullbody Step: Tiles OF IndiaDocument15 pagesFullbody Step: Tiles OF Indiakishan bhimaniNo ratings yet

- Certificate of Analysis: Liaoning Oxiranphex IncDocument1 pageCertificate of Analysis: Liaoning Oxiranphex IncDilawar BakhtNo ratings yet

- Technical Information ASSET DOC LOC 1543316Document1 pageTechnical Information ASSET DOC LOC 1543316inbNo ratings yet

- Ganache Formulation PDFDocument4 pagesGanache Formulation PDFtavibasti100% (1)

- Losses in PipesDocument19 pagesLosses in Pipesphanirajinish100% (1)