Professional Documents

Culture Documents

Tullis Tullis 2001 Real World Projects Reinforce Fundamentals in The Classroom

Uploaded by

tguarin23Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tullis Tullis 2001 Real World Projects Reinforce Fundamentals in The Classroom

Uploaded by

tguarin23Copyright:

Available Formats

REAL-WORLD PROJECTS REINFORCE FUNDAMENTALS

IN THE CLASSROOM

By Blake P. Tullis1 and J. Paul Tullis2

ABSTRACT: In academia, achieving a balance between teaching fundamental principles and the application of

those principles continues to be a challenge. One of the purposes of education is to teach fundamental principles

and the thought process. Graduating engineers, however, also need experience and competence in real-world

engineering problems. All engineering courses should be based on fundamental principles, but some courses

should also demonstrate how to apply engineering concepts to practical engineering problems. This paper is

Downloaded from ascelibrary.org by Universidad Industrial de Santander on 03/22/24. Copyright ASCE. For personal use only; all rights reserved.

directed primarily at courses that are more applied in nature. One of the factors complicating the implementation

of applied courses is the lack of practical engineering by some faculty. If the faculty member goes from graduate

student to assistant professor without experience in the profession, it may be difficult for the faculty member to

generate meaningful classroom examples. Quality, real-world design problems can often be gleaned from re-

search projects, consulting projects, or supplied by engineering firms. Another challenge is finding appropriate

textbooks that address practical problems encountered in real-world engineering. Engineering students should

be exposed to projects that require a meaningful analysis, allowing the students to exhibit creativity in their

design and analysis without getting bogged down with too many details. The problems should be closely co-

ordinated with the course material so the student has the proper background information. This paper discusses

one such project used by the authors in teaching hydraulic design at a senior/graduate student level and some

general suggestions for developing design projects.

INTRODUCTION sign or problem-solving experiences has been recognized as a

We feel that engineering students should be exposed to one valuable part of a student’s education. These are design-ori-

or more real engineering experiences before graduating. For ented experiences that attempt to simulate real-world engi-

some, this comes with part-time employment while attending neering. In addition to this experience, the authors feel that at

school or summer internship. Others do not have this oppor- least one engineering design problem should be included in

tunity. Students are often faced with much theory and little applied design courses. Selecting a meaningful and yet man-

practical information on the application of basic principles. ageable design project can be a challenge unless the professor

Consequently, some students feel uncomfortable approaching has practical engineering experience.

their first job, wondering if they really know how to engineer The authors have had the opportunity of teaching a senior/

anything. graduate-level course on applied hydraulic design. The course

For an engineering design course to be successful, it should is a three-credit, lecture-based course, which uses ‘‘Hydraulics

include the appropriate theoretical background information of Pipelines: Pumps, Valves, Cavitation, Transients’’ as the

and some practical applications of the theory. One helps re- textbook (Tullis 1989). In the course, we expand upon the

inforce the other. Without the theory, students will likely not fundamentals taught in the basic fluid mechanics courses (en-

be able to apply what they have learned to new situations. ergy, momentum, continuity, fluid properties, flow resistance

Without the practical applications, they may not be able to in pipes, minor losses, discharge coefficients, etc.); introduce

apply their theory to anything. It is very important that uni- some new concepts (pump and valve characteristics, cavita-

versity professors gain sufficient practical engineering expe- tion, hydraulic transients, and economic analysis); and provide

rience so that they can develop meaningful, real-world appli- a design experience.

cations for their courses. One of the arguments for allowing The course differs from a typical senior design course in

college professors to engage in private consulting is that it that the design project is not the core part of the course. The

adds real-world engineering flavor to the classroom and can project is implemented as a series of extended, out-of-class

be the source of needed case studies. homework assignments, with one part building on another.

It should be noted that many engineering subjects are more Some in-class time is used to address project questions and

theoretical in nature than others and that these subjects or for student presentations, however, most of the in-class time

courses play an important role in the overall educational ex- is devoted to traditional lectures by the instructor. The design

perience. Many courses taught in civil engineering, however, experiences are normally adapted from a consulting or a re-

present information that is very applicable with respect to cur- search-related project. The class project is broad enough to

rent, real-world engineering practices. Giving students the op- allow individual creativity by providing a number of challeng-

portunity to apply principles learned to solving a real-world ing, nonstandard, hydraulic problems. The students are given

problem can significantly increase the overall value of their support during the project, but are not ‘‘herded’’ toward a com-

education. Senior design experiences have been implemented mon solution.

at many universities where the need for hands-on student de- The example discussed in this paper is one such student

design project. It involves analysis of a water supply system

1

Res. Asst. Prof., Utah Water Research Laboratory, Utah State Uni- for the City of San Luis Obispo, California. The example dem-

versity, Logan, UT 84322-8200. onstrates the level of analysis required of the students. The

2

Emeritus Prof., Utah Water Research Laboratory, Utah State Univer- project is designed to be challenging to the students and to

sity, Logan, UT 84322-8200. allow flexibility in finding appropriate solutions.

Note. Discussion open until May 1, 2002. To extend the closing date

one month, a written request must be filed with the ASCE Manager of

Journals. The manuscript for this paper was submitted for review and GUIDELINES FOR DESIGNING A STUDENT PROJECT

possible publication on May 23, 2000; revised June 25, 2001. This paper

is part of the Journal of Hydraulic Engineering, Vol. 127, No. 12, De- For a student design project to achieve its objective, the

cember, 2001. 䉷ASCE, ISSN 0733-9429/01/0012-0992–0995/$8.00 ⫹ project must be applicable, interesting, and representative of

$.50 per page. Paper No. 22339. real-world applications. The success of the design project is

992 / JOURNAL OF HYDRAULIC ENGINEERING / DECEMBER 2001

J. Hydraul. Eng., 2001, 127(12): 992-995

also dependent upon the manner in which the project is inte- line, the booster pumps, and the intermediate reservoir are

grated into the course and how the project is administered. each discussed to give the students background information on

The following is a list of suggestions to assist in developing the purpose and operation of the reservoir. For example, the

and administering a student design project: low-level valves are required for sediment flushing, flood con-

trol, and to maintain flow in the stream. Flow in the transmis-

1. Divide the problem into small, manageable parts, each sion lines is to be provided at one of three specified flow rates,

focusing on a specific principle. Each part should fit log- regardless of the elevation of the reservoir. The three flow rates

ically into the total design project and be coordinated are set by how many pumps are in operation at the interme-

with course material so that the students have the proper diate reservoir. The pump station at the reservoir is needed

background and tools for each phase of the project. when the reservoir level is too low to provide the required

2. The primary goal of the project is to take the student flow to the transmission line by gravity flow.

beyond the basic ‘‘canned’’ problem typically assigned

Downloaded from ascelibrary.org by Universidad Industrial de Santander on 03/22/24. Copyright ASCE. For personal use only; all rights reserved.

for homework. Be sure to have some open-ended com- Outlet Valves

ponents of the project to challenge the students and allow

creativity. The students are required to consider the different types of

3. Have the project broad enough to represent a real-life free discharge valves currently available for this type of use

engineering experience, but do not allow it to consume and select the one most appropriate for this installation. The

excessive amounts of time or create frustration. Quality, flow range varies considerably, requiring multiple valves of

not quantity, should be emphasized. different sizes (two 24-in. and one 12-in. valve is a typical

4. Require progress reports to keep the students on-track selection for the design). A redundant valve (one of the 24-in.

and have students discuss parts of their analyses with the valves) is required for reliability. The limitations and advan-

class to evaluate their approach and share ideas. These tages of each valve type are discussed, including: cavitation

can be either formal or informal class presentations. potential, plugging problems, and relative cost. They are

5. Require a comprehensive final report that includes the guided in their selection towards using multiple butterfly

key parts of the analysis/design but does not require un- valves with specially designed aeration hoods to prevent cav-

necessary details. The report should be sufficiently com- itation and control the discharge jets. The reasons for selecting

plete so that it can serve as a useful resource or reference the butterfly valves for this installation are discussed. The

for the students when they encounter related applications valves need to be oversized and the maximum valve opening

in the workplace. limited to prevent excessive velocities through the valve and

piping and allow efficient aeration to prevent cavitation. The

TYPICAL DESIGN PROJECT outlet valves also require remote operation and flow meters

with remote reading capability.

The following discussion is presented to demonstrate our

approach to student design projects. The information for this Pipeline Control Valves

project includes a general description of the system, a discus-

sion of each component of the system, the given information The flow in the transmission line was controlled, in the past,

and problem statements for a typical course assignment, and with a single butterfly valve. It experienced cavitation. We

general comments. The students are not required to produce consider different options including different types of valves

project specifications and plans. and valves in a series. Problems influencing valve selection

include potential for plugging, cavitation, controllability, re-

Hydraulic System Description mote operation, and cost. The students are directed to select a

hydraulically actuated globe valve in series with a remotely

Water is supplied to the City of San Luis Obispo, California, operated butterfly valve. The students are required to deter-

from a reservoir via a pipeline conveyance system originating mine the proper distribution of pressure drop between the two

from a small dam. The system includes: valves to minimize cavitation. The hydraulically actuated

globe valve is used to maintain a constant downstream pres-

• A reservoir formed by a concrete arch dam.

sure. The butterfly valve is used for setting the flow rate. They

• An overflow spillway.

have to analyze the valve operation scheme for the full range

• Four low-level outlet valves for maintaining minimum

of reservoir operation. They have to decide on valve sizes,

stream flows and sediment flushing.

which valve would be located upstream, and the spacing be-

• Multiple connections to the reservoir with trash racks.

tween them.

• A several mile-long pipeline with control valves, a surge

tank, numerous high points, and multiple air release

valves. Reservoir Pump Station

• A pump station at the reservoir for use at low reservoir The piping for the pumps was designed so the pumps could

levels. be bypassed when there was adequate reservoir head available.

• An intermediate reservoir and second booster pump sta- The piping also had to allow the pumps to be operated in a

tion to lift the water over a mountain. series or parallel. Students are required to develop head-dis-

charge equations from the supplied pump curves. The students

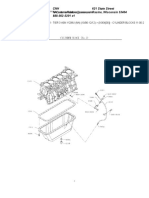

A schematic of the system is shown in Fig. 1. are also required to develop a schedule for pump operation

that identifies the reservoir elevation at which the pumps

System Components would be needed to supply the required flow, the number of

The following discussion describes the types of problems pumps required, and if they should be in a series or parallel.

the students have been asked to consider in their designs. Note

that not all of the components are assigned for each course. Operation of Pipeline

The analysis of the pipeline hydraulics goes beyond the ba-

Reservoir Operation

sics of friction calculations and selection of pipe diameter. The

The role of the service spillway, low-level outlet valves, the pipe flows full at maximum flow but flows open channel in

multiple-level outlets, the trash racks, the transmission pipe- parts of the pipe at the two lower flow rates. This is one of

JOURNAL OF HYDRAULIC ENGINEERING / DECEMBER 2001 / 993

J. Hydraul. Eng., 2001, 127(12): 992-995

Downloaded from ascelibrary.org by Universidad Industrial de Santander on 03/22/24. Copyright ASCE. For personal use only; all rights reserved.

FIG. 1. Salinas Dam Project Overview

the reasons why this particular pipeline was selected. The to- the water over a small mountain. This station has three pumps

pography of the pipeline creates a situation where the flow (plus one spare) and operates with one, two, or three pumps,

downstream from the high point runs open channel at low flow depending on the demand from the city. The flow from these

rates for some distance. This presents a situation that students pumps sets the three flows for the transmission pipeline. No

have probably not been exposed to, yet they should possess design work is done for this part of the system. We do discuss

all of the fundamental skills required for analyzing the prob- the size of the reservoir and its role in the hydraulic analysis

lem. Students must analyze hydraulic grade lines for both full and operation of the pipeline.

pipe and the combination of full and open channel pipe flow.

They must also determine what controls the flow rate through Representative Given Information and Problem

the system when the pipe flows partially full (i.e., the down- Statements

stream control point is no longer the downstream reservoir

elevation). They also derive the system equations for both

types of operation. These system equations are used with the Given Information

pump equations to determine the required valve openings for

every combination of flow and reservoir elevation. We discuss 1. Flow rate in the system is controlled by the pumping

the need and function of the automatic air release valves at all capacity of the booster pump station. The pipeline can

high points for both full pipe and open channel operation. The only be operated at one of the following three flow

system is analyzed for transients, and the function and need for rates:

a surge tank located near the reservoir pump station is dis-

cussed. They are required to determine the necessary height of • 13,628 m3/day (3.6 mgd) with one booster pump op-

the tank to prevent spilling, or determine the range of valve erating.

openings for which a surge tank of a given height will not spill. • 23,848 m3/day (6.3 mgd) with two booster pumps op-

erating.

Intermediate Reservoir • 34,826 m3/day (9.2 mgd) with three booster pumps

operating.

The transmission pipeline discharges into a 1 million gallon

reservoir. A second pump station is located at this point to lift 2. The maximum reservoir elevation is 402.3 m (1,320 ft).

994 / JOURNAL OF HYDRAULIC ENGINEERING / DECEMBER 2001

J. Hydraul. Eng., 2001, 127(12): 992-995

3. The downstream storage reservoir elevation, at the charge. Note that the calculation is different when the

booster station, is 350.5 m (1,150 ft). pipe does not flow full.

4. Pump curve data are provided for the two parallel 3. Draw the hydraulic grade line for 13,627.5 m3/day (3.6

pumps located at the dam. mgd) flow and explain what is going on in the pipe.

4. At 13,627.5 m3/day (3.6 mgd) and maximum reservoir,

• 16.76 m@0 m3/s (55 ft@0 gpm) what is the pressure differential (⌬P) across a single but-

• 15.24 m@0.095 m3/s (50 ft@1,500 gpm) terfly valve? What is the downstream pressure? Calculate

• 12.19 m@0.19 m3/s (40 ft@3,000 gpm) sigma (cavitation). Do you think the valve will cavitate?

5. Energy losses through the reservoir pump station can (Look for valve cavitation data in Chapter 6 of the text-

be ignored when the pumps are not operating because book. Include scale effect considerations.) Incorporate

the flow can be bypassed around the pumps. cavitation analysis into your spreadsheet.

6. The pipe centerline elevation at the reservoir pump sta- 5. Provide a brief write-up.

Downloaded from ascelibrary.org by Universidad Industrial de Santander on 03/22/24. Copyright ASCE. For personal use only; all rights reserved.

tion and control valve is 373.7 m (1,226 ft).

7. The pump station and control valve are located approx- Part C

imately 61 m (200 ft) downstream from the reservoir.

8. A 0.61-m (2-ft) diameter surge tank is located 6.1 m 1. Find the required valve openings to provide 34,826 m3/

(20 ft) downstream from the control valve with the top day (9.2 mgd) from 402.3 m (1,320 ft) to the minimum

at elevation 389.2 m (1,277 ft). possible using reservoir elevation increments of 3 m.

9. The pipe length from the pump station/control valve to 2. Find the lowest reservoir that can supply 34,826 m3/day

the booster pump station is 14,484 m (47,520 ft). The (9.2 mgd) with the valve fully open.

pipe inside diameter is 0.61 m (2 ft), and the roughness 3. What is the lowest reservoir elevation at which the res-

height of the pipe material, e, is 0.0102 cm (0.004 in). ervoir can operate and maintain a full pipe? What is the

The water temperature is 15.6⬚C (60⬚F). corresponding flow rate (i.e., control valve will be fully

10. The elevation of the pipe’s highest point = 381 m open)?

(1,250 ft) and is located 1,371.6 m (4,500 ft) down- 4. What is the function of a surge tank and why was one

stream of the pump station/control valve. included in this system?

11. The pipe has numerous high points. Vacuum breaker

valves are installed at each high point. Part D

12. The control valve is a butterfly valve with the following

discharge coefficient equation: 1. Write the system and pump equations. Determine the

pump head-discharge relation (H-Q equation) for one

b and two pumps in parallel.

Cd = a ⫹ 2. Modify the spreadsheet program to solve for the flow

1 ⫹ e(x⫺c)/d

with two pumps operating in parallel.

where a = ⫺0.0157, b = 0.889, c = 55.61, d = 14.77, 3. Starting at reservoir elevation 387.1 m (1,270 ft), find

and x is the valve opening in degrees. the approximate valve opening that will provide 34,826

13. Cavitation information for the control valves is avail- m3/day (9.2 mgd) with the pumps operating.

able from the textbook used in the class (Tullis 1989). 4. What is the lowest reservoir elevation that can supply

34,826 m3/day (9.2 mgd) with two pumps operating.

Problem Statements

CLOSING COMMENTS

Part A

The design project is spread over much of the course with

1. Set up a spreadsheet to calculate the flow for each 5⬚ of new components being added as new material is introduced.

valve opening. Determine the maximum flow rate that Each part of the project is submitted and evaluated as com-

can be supplied to the downstream storage reservoir via pleted and returned to the students. Students also have the

the pipeline with the upstream reservoir at maximum res- opportunity to compare their analysis with other students in

ervoir elevation. the class. We also talk about possible modifications that could

2. What controls the maximum allowable flow rate and improve the design of the system. At the end of the project,

what is the valve opening required to produce it? the students submit a concise, comprehensive report. With our

3. What will happen to flow in the pipe when the flow is approach, the students are able to bring together many of the

less than the maximum allowed? hydraulic principles taught in the course into a comprehensive

4. At reservoir elevation = 402.3 m (1,320 ft), what is the project. The time required to complete the project replaces

required head differential (⌬H) across the control valve time normally spent on typical homework problems. Conse-

at the maximum allowable flow rate? quently, the students should not feel overburdened. They ac-

5. List the equations and assumptions and provide a brief tually find the experience quite rewarding. Students frequently

write-up. comment that this design/analysis experience was one of the

most meaningful parts of their education, and that it gives

Part B them confidence that they can actually apply their education

to real-world engineering problems. We encourage all engi-

1. At the maximum reservoir elevation, find the smallest neering curricula to include one or more such projects for the

flow and required valve opening that keeps the pipe full. senior/graduate engineering students in applied engineering

What criteria determine this condition? Use the spread- classes.

sheet program developed (part A) to help with your anal-

ysis. REFERENCE

2. For valve openings (and flows) below the full pipe flow, Tullis, J. P. (1989). Hydraulics of pipelines: Pumps, valves, cavitation,

use the correct approach to determine the system dis- transients, Wiley, New York.

JOURNAL OF HYDRAULIC ENGINEERING / DECEMBER 2001 / 995

J. Hydraul. Eng., 2001, 127(12): 992-995

You might also like

- Methodologies For Problem Solving An Engineering ADocument13 pagesMethodologies For Problem Solving An Engineering AZzzdddNo ratings yet

- M.Tech Design Engineering PDFDocument11 pagesM.Tech Design Engineering PDFdhamumechNo ratings yet

- Architectural Design Pedagogy PDFDocument5 pagesArchitectural Design Pedagogy PDFKayfi Akram MawlanNo ratings yet

- CE 412 CE Project I Course SyllabusDocument5 pagesCE 412 CE Project I Course SyllabusNiko ChavezNo ratings yet

- Benchmarking Engineering Curricula With The CDIO SyllabusDocument13 pagesBenchmarking Engineering Curricula With The CDIO SyllabussatishNo ratings yet

- The Role of The Laboratory in Design Engineering EducationDocument7 pagesThe Role of The Laboratory in Design Engineering EducationYahyaHassaniNo ratings yet

- BSIE - 2ndyr - 2ndsem - IE - PE - 221 - Project ManagementDocument8 pagesBSIE - 2ndyr - 2ndsem - IE - PE - 221 - Project ManagementDelfa CastillaNo ratings yet

- 618195.fertalj Milasinovic Nizetic Ttem 8 1Document11 pages618195.fertalj Milasinovic Nizetic Ttem 8 1MICHELLE ALEJANDRA BACA GUZMANNo ratings yet

- Mapúa University: Department of MathematicsDocument7 pagesMapúa University: Department of MathematicsJuan Miguel GaddiNo ratings yet

- Integrating Diversity, Equity and Inclusion Concepts Into An Introductory Engineering CourseDocument6 pagesIntegrating Diversity, Equity and Inclusion Concepts Into An Introductory Engineering CourseJeya Prakash KNo ratings yet

- Aj48 The-Normative-Contents-Of-Engineering-Formation PDFDocument20 pagesAj48 The-Normative-Contents-Of-Engineering-Formation PDFyeneNo ratings yet

- Best Practices For Case Studies in Construction Engineering and Management ResearchDocument14 pagesBest Practices For Case Studies in Construction Engineering and Management ResearchneckitoNo ratings yet

- Reverse Engineering and Redesign CoursesDocument12 pagesReverse Engineering and Redesign CoursesYatin NgadiyonoNo ratings yet

- SYLLABI DRW01 Engineering Drawing AY 2020 2021Document5 pagesSYLLABI DRW01 Engineering Drawing AY 2020 2021Mayce OngNo ratings yet

- Practice EngineeringDocument10 pagesPractice EngineeringMuhammad Noor Ikmal ZaidanNo ratings yet

- Learning From The Architecture Studio: Implications For Project-Based PedagogyDocument4 pagesLearning From The Architecture Studio: Implications For Project-Based PedagogyinkognitaNo ratings yet

- Idp ElectricalDocument6 pagesIdp ElectricalZulkarnain DahalanNo ratings yet

- Aj16 Professional Engineering WorkDocument20 pagesAj16 Professional Engineering WorkyeneNo ratings yet

- Final Year Projects - A Means of Adding Value To Graduate AttributesDocument6 pagesFinal Year Projects - A Means of Adding Value To Graduate Attributesrajesh jamesNo ratings yet

- Page 1 of 12 2021: Chemistry For EngineersDocument12 pagesPage 1 of 12 2021: Chemistry For EngineersSweetie CagangNo ratings yet

- Mini-Projects in Chemical Engineering Laboratory: A. Cancela, A. Sanchez and R. MaceirasDocument5 pagesMini-Projects in Chemical Engineering Laboratory: A. Cancela, A. Sanchez and R. MaceirasAnonymous zWhjd8No ratings yet

- Criterion 3 Course Outcomes and Program Outcomes 120Document26 pagesCriterion 3 Course Outcomes and Program Outcomes 120elavarasansivaNo ratings yet

- A Study On The Application of The "Residential Interior Design" Course Based On Flipped Classroom With The Joint Efforts of Schools and EnterprisesDocument7 pagesA Study On The Application of The "Residential Interior Design" Course Based On Flipped Classroom With The Joint Efforts of Schools and EnterprisessubrataNo ratings yet

- Assessment Item 1: Sequence of Lesson Plans Value: Due Date: Return Date: Submission Method OptionsDocument5 pagesAssessment Item 1: Sequence of Lesson Plans Value: Due Date: Return Date: Submission Method Optionsapi-402868357No ratings yet

- College of Engineering & Architecture: Cebu Institute of Technology - UniversityDocument5 pagesCollege of Engineering & Architecture: Cebu Institute of Technology - UniversityKen Dela CernaNo ratings yet

- Professional and Ethical Issues of Software EngineDocument9 pagesProfessional and Ethical Issues of Software EngineNiraj khadkaNo ratings yet

- Reverse Engineering and Redesign: Courses To Incrementally and Systematically Teach DesignDocument13 pagesReverse Engineering and Redesign: Courses To Incrementally and Systematically Teach DesignMichael OrtizNo ratings yet

- Engineering Education Reform With CDIODocument15 pagesEngineering Education Reform With CDIONarong NanthakusolNo ratings yet

- Math156 Ie Feb 2019Document7 pagesMath156 Ie Feb 2019Josef CatiggayNo ratings yet

- Caldwell 1994Document6 pagesCaldwell 1994Monica PnzNo ratings yet

- Practical Teaching and Its Importance in Teaching Civil EngineeringDocument4 pagesPractical Teaching and Its Importance in Teaching Civil EngineeringP.PENCHALA REDDY Structures HeadNo ratings yet

- Bits Pilani Engg Tech PDFDocument8 pagesBits Pilani Engg Tech PDFAnirban PalNo ratings yet

- CM011 SyllabusDocument12 pagesCM011 SyllabusJaniah EconarNo ratings yet

- Bohol Island State UniversityDocument7 pagesBohol Island State UniversityVALERIE JADE PIAOANNo ratings yet

- Program SpecificationDocument10 pagesProgram Specificationae045296No ratings yet

- A Balanced View of Sustainability in Civil Engineering and ConstructionDocument11 pagesA Balanced View of Sustainability in Civil Engineering and ConstructionGap SeamanNo ratings yet

- A Psychomotor Skills Extension To BloomDocument6 pagesA Psychomotor Skills Extension To Bloompedro nuñezNo ratings yet

- ICTIEE Paper How To Train An EngineerDocument4 pagesICTIEE Paper How To Train An EngineercontgautamNo ratings yet

- Engineering Design: BeginDocument5 pagesEngineering Design: BeginJohan MayaNo ratings yet

- BCE 321L Rev 0Document10 pagesBCE 321L Rev 0Khing Harold E. AsentosNo ratings yet

- Engg. Management SyllabusDocument9 pagesEngg. Management SyllabusMariel SibuloNo ratings yet

- Mapúa University: Program Educational ObjectivesDocument6 pagesMapúa University: Program Educational ObjectivesMyca Moli100% (1)

- Waregbsdghgfvfvjk HKJHKL AgfgteqgmnghDocument6 pagesWaregbsdghgfvfvjk HKJHKL Agfgteqgmnghyash the donNo ratings yet

- College of Engineering Education Bce 222 - Course SyllabusDocument12 pagesCollege of Engineering Education Bce 222 - Course SyllabusfrancessichNo ratings yet

- Mapúa Institute of Technology (Abet Version) : School of Mechanical and Manufacturing EngineeringDocument3 pagesMapúa Institute of Technology (Abet Version) : School of Mechanical and Manufacturing EngineeringMiGz ShiinaNo ratings yet

- BCE 314L - Rev 0Document19 pagesBCE 314L - Rev 0Euler RedobleNo ratings yet

- PMP 6 EditionDocument10 pagesPMP 6 EditionMohanNo ratings yet

- Exploring Outdoor Education and Research in ArchitectureDocument10 pagesExploring Outdoor Education and Research in ArchitectureEman AshrafNo ratings yet

- BES 6EE Module 1 IntroductionDocument14 pagesBES 6EE Module 1 IntroductionEric John CruzNo ratings yet

- Cohen 1991 Cladding Design Whose ResponsibilityDocument11 pagesCohen 1991 Cladding Design Whose ResponsibilityPratik BhavsarNo ratings yet

- Module Information Booklet: Bachelor of Arts (Honours) Interior ArchitectureDocument10 pagesModule Information Booklet: Bachelor of Arts (Honours) Interior ArchitectureJocyeTeeNo ratings yet

- PEE 9 - Electrical Machines 2 Lec CoEDocument6 pagesPEE 9 - Electrical Machines 2 Lec CoEfen.barlisanNo ratings yet

- Teaching Methods in Architectural Design BasicsDocument9 pagesTeaching Methods in Architectural Design BasicsAdriana EdithNo ratings yet

- Bits Pilani Design EnggDocument11 pagesBits Pilani Design Enggsinghrashmi1857No ratings yet

- STEN 43053 Dam EngineeringDocument10 pagesSTEN 43053 Dam EngineeringClarize MikaNo ratings yet

- 2016 To 2010 Spec Comparison FinalDocument8 pages2016 To 2010 Spec Comparison FinalNiranjanAryanNo ratings yet

- Norwich MCE BrochureDocument8 pagesNorwich MCE BrochureTavares PrestonNo ratings yet

- CENG 125 Course Syllabus - RevSept - 2020Document10 pagesCENG 125 Course Syllabus - RevSept - 2020Christian ActerNo ratings yet

- Teaching Research in Design: Guidelines for Integrating Scientific Standards in Design EducationFrom EverandTeaching Research in Design: Guidelines for Integrating Scientific Standards in Design EducationNo ratings yet

- Drilling Products Overview CatalogDocument64 pagesDrilling Products Overview CatalogSinghtoFC100% (1)

- Best Training For FlowDocument6 pagesBest Training For FlowCrispin HungNo ratings yet

- Manual 2500Document32 pagesManual 2500Jesus GBNo ratings yet

- Rotary Screw Compressors SM Series: With The World-Renowned SIGMA PROFILEDocument5 pagesRotary Screw Compressors SM Series: With The World-Renowned SIGMA PROFILEBruno QuintinoNo ratings yet

- 15 IRC Plumbing Final ChecklistDocument3 pages15 IRC Plumbing Final ChecklistImam Pujo SusenoNo ratings yet

- Catterpilar RENR9980 330d Esquema HidráulicoDocument2 pagesCatterpilar RENR9980 330d Esquema HidráulicoJoana MellerNo ratings yet

- Check Valve c400sDocument3 pagesCheck Valve c400sPatricio Antonio Cortés PeñaNo ratings yet

- Cryogenic Service Valves: Gate, Globe & BallDocument16 pagesCryogenic Service Valves: Gate, Globe & BallraulNo ratings yet

- High Pressure Technology That Sets The StandardDocument12 pagesHigh Pressure Technology That Sets The StandardAlejandro GilNo ratings yet

- Widearea Eye/Face Washes G1796: Guardian EquipmentDocument2 pagesWidearea Eye/Face Washes G1796: Guardian Equipmenteisenbarger5607No ratings yet

- CEP May 09 Piping and Instrument Diagrams COADEDocument8 pagesCEP May 09 Piping and Instrument Diagrams COADERupshaBNo ratings yet

- Preventive Maintenance Manual - DRFDocument115 pagesPreventive Maintenance Manual - DRFmliugong100% (8)

- Simboluri HidrauliceDocument12 pagesSimboluri Hidrauliceali_levent86No ratings yet

- Audi TT-AJQ-ecu99Document10 pagesAudi TT-AJQ-ecu99Julien BollyNo ratings yet

- IMaRQ 2023 TSADocument68 pagesIMaRQ 2023 TSAkarthick rajaNo ratings yet

- Nimco Monoblock Control ValvesDocument66 pagesNimco Monoblock Control ValvesHui ChenNo ratings yet

- 3051Document84 pages3051Tamy AlexNo ratings yet

- Q2 Series Spring Return Actuators: Install-Operate-MaintainDocument20 pagesQ2 Series Spring Return Actuators: Install-Operate-Maintainalanwar general contracting&suppliesNo ratings yet

- 924HZ Wheel Loader JZZ00001-UP (MACHINE) POWERED BY C6 PDFDocument8 pages924HZ Wheel Loader JZZ00001-UP (MACHINE) POWERED BY C6 PDFAhmed HamdyNo ratings yet

- Data Sheet T 8384-3 EN: Type 3730-3 Electropneumatic Positioner With HART CommunicationDocument12 pagesData Sheet T 8384-3 EN: Type 3730-3 Electropneumatic Positioner With HART CommunicationThiago Rodrigo Oliveira SantosNo ratings yet

- Air Compressor Plant PDFDocument162 pagesAir Compressor Plant PDFissam elmoharirNo ratings yet

- Eldex: Eldex® Optos Metering Pumps Operator's ManualDocument41 pagesEldex: Eldex® Optos Metering Pumps Operator's ManualrezaroohollahiNo ratings yet

- Leak Tightness TestingDocument2 pagesLeak Tightness TestingSamantha HarveyNo ratings yet

- G 962 1188 - BomDocument8 pagesG 962 1188 - BomDibyendu ChakrabortyNo ratings yet

- Necta Brio 200-User Manual-EngDocument40 pagesNecta Brio 200-User Manual-EngMihai PopNo ratings yet

- Chart Your Way To Easy Steering PDFDocument52 pagesChart Your Way To Easy Steering PDFZa'im SaidiNo ratings yet

- Cylinder Blocks 11-00-2 (Hino Engine Type J08etm-Ksda)Document3 pagesCylinder Blocks 11-00-2 (Hino Engine Type J08etm-Ksda)Oecox Cah DjadoelNo ratings yet

- Controlling Centrifugal PumpsDocument12 pagesControlling Centrifugal PumpsDan AngheleaNo ratings yet

- NEL Best Practice - Impulse Lines For DP FTs PDFDocument8 pagesNEL Best Practice - Impulse Lines For DP FTs PDFnasirmuzaffar0% (1)

- Codes Standards and Regulation For Instrumentation EngineeringDocument3 pagesCodes Standards and Regulation For Instrumentation Engineeringbodlarakesh0% (1)