Professional Documents

Culture Documents

Mmbak 17

Uploaded by

Anond UseryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mmbak 17

Uploaded by

Anond UseryCopyright:

Available Formats

3430 Sacramento Dr.

, Unit D

San Luis Obispo, CA 93401

Telephone: 805/544-8748

Fax: 805/544-8645

www.maximummotorsports.com

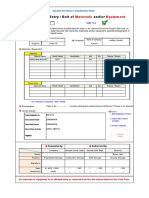

Master Cylinder Adapter Kit (MMBAK-17)

Pre-Installation

The brake booster pushrod must be adjusted before

installing the new master cylinder. Follow the steps

below if the pushrod has not been properly adjusted.

1. Measure the pushrod bore depth and record this

dimension as D1. Be sure to measure from the

back face of the master cylinder to the very bot-

tom of the radius in the pushrod bore.

Read all instructions before beginning work. Following in-

structions in the proper sequence will ensure the best and

easiest installation.

Thank you for purchasing the Maximum Motorsports

1993 Cobra/94-95 GT Master Cylinder Adapter Kit,

MMBAK-17. This adapter kit is required when install-

ing a 1993 Cobra/94-95 GT Mustang master cylinder

into a 1979-86 Mustang. The MMBAK-17 uses only

high pressure rated fittings and lines that are de-

signed for use in automotive brake systems. No cut-

ting or flaring of brake lines is needed with this kit.

2. Measure the distance from the back of the

The MMBAK-17 kit allows installing a 1993 Co- master cylinder to the back face of the mounting

bra/94-95 GT Mustang master cylinder in a 1979-86 flange and record this dimension as D2.

Mustang with the stock location proportioning valve.

It provides brake lines (with the proper fittings on

each end) that fit the master cylinder while retaining

the rest of the vehicle’s stock brake line routing.

NOTE: The master cylinder must be installed before

proceeding with the following installation steps. See

the pre-installation guide below.

NOTE: New master cylinders should always be

bench bled before installation.

NOTE: If you are unfamiliar with brake bleeding

techniques, consult a service manual for further 3. Subtract D2 from D1 and record this dimension

information on bleeding air from the brake system. as D3.

4. Measure the distance that the pushrod protrudes

from the master cylinder mating surface on the

brake booster. Be sure to measure to the tip of

MMBAK-17.indd 1 Copyright © 2010 Maximum Motorsports, Inc.

the pushrod. Adjust the length of the pushrod to 9. Thread the M12-1.0 bubble flare end of the “For-

be slightly less (.005” to .010” than D3 from Step ward Port” labeled brake hard line into the front

3. This will prevent accidental pre-load of the port of the master cylinder. Position the free end

master cylinder from the brake push rod. of the hard line above the stock proportioning

valve.

10. Thread the opposite end of the brake hard line

installed in Step 9 into the front port of the stock

proportioning valve (7/16-24 fitting).

NOTE: Due to vehicle production tolerances,

some of the supplied brake hard lines may need

to be slightly adjusted for final fitment.

5. Install the new master cylinder onto the brake

booster. Torque the nuts to 25 ft-lbs.

Installation

6. If still connected, remove the two brake hard

lines that connect to the top of the stock pro-

portioning valve, located on the driver side strut

tower.

7. Thread the M10-1.0 bubble flare end of the

“Rearward Port” labeled brake hard line into the

rear, side port of the master cylinder. Position

the free end of the brake hard line above the

stock proportioning valve.

8. Thread the free end of the brake hard line

installed in Step 7 into the rearward port of the 11. Tighten the ends of the brake hard lines to 12-16

stock proportioning valve (3/8-24 fitting). ft-lbs at the master cylinder and the proportion-

ing valve.

NOTE: Due to vehicle production tolerances,

some of the supplied brake hard lines may need 12. Bleed the brakes in the order shown below and

to be slightly adjusted for final fitment. check all fittings for leaks.

Front of Car

4 3

2 1

This kit contains:

1 M12-1.0 to 7/16-24 Forward Port Brake Hard Line

1 M10-1.0 to 3/8-24 Rearward Port Brake Hard Line

Copyright © 2010 Maximum Motorsports, Inc. 2 MMBAK-17.indd

You might also like

- MMBAK 3 2r1Document1 pageMMBAK 3 2r1Anond UseryNo ratings yet

- Brembo Catalogo PDFDocument116 pagesBrembo Catalogo PDFtd04gigsNo ratings yet

- MSD Pulse Ignition For Harley-DavidsonDocument12 pagesMSD Pulse Ignition For Harley-DavidsonFabio MachadoNo ratings yet

- Baldor Freno Electromagnetico IemsaDocument4 pagesBaldor Freno Electromagnetico Iemsajuventino vazquezNo ratings yet

- Distribution qsk19Document4 pagesDistribution qsk19Nizar SGHIRNo ratings yet

- Drum Brake Adjustment PDFDocument2 pagesDrum Brake Adjustment PDFY. VásquezNo ratings yet

- Descripcion y Operacion Del Sistema de Frenos Mazda Protege 1997Document30 pagesDescripcion y Operacion Del Sistema de Frenos Mazda Protege 1997gerber damianNo ratings yet

- Bolt Torque Sequence PDFDocument2 pagesBolt Torque Sequence PDFmilNo ratings yet

- Mazda 323Document31 pagesMazda 323franklin mowlaNo ratings yet

- MMBK8FDocument4 pagesMMBK8FAnond UseryNo ratings yet

- Infiniti Q50 Q60 Fuel Filter Install V3Document13 pagesInfiniti Q50 Q60 Fuel Filter Install V3Che MilsonNo ratings yet

- Remove Engine BrakeDocument14 pagesRemove Engine BrakejeremyNo ratings yet

- Front Disc Brake Pads Replacement PDFDocument4 pagesFront Disc Brake Pads Replacement PDFY. Vásquez0% (1)

- InstructionsDisc Brake InstallDocument2 pagesInstructionsDisc Brake InstallPeter JasonNo ratings yet

- Service Bulletin: Front Brakes Judder And/or SquealDocument3 pagesService Bulletin: Front Brakes Judder And/or SquealAndrzejNo ratings yet

- Vegistroke Pressure Test Procedures1Document31 pagesVegistroke Pressure Test Procedures1Dave RobersonNo ratings yet

- Dokumen - Tips - John Deere Powertech 68l Diesel Engines Mechanical Fuel Systems Component Service Repair Technical Manual ctm207Document15 pagesDokumen - Tips - John Deere Powertech 68l Diesel Engines Mechanical Fuel Systems Component Service Repair Technical Manual ctm207Valeriy Valkovets100% (1)

- Pro Comp Suspension: PN# 62170 1998-2010 Ford Ranger 4wd & Edge 2wd/4wd Torsion Bar Key KitDocument8 pagesPro Comp Suspension: PN# 62170 1998-2010 Ford Ranger 4wd & Edge 2wd/4wd Torsion Bar Key KitomarNo ratings yet

- Mds ManualDocument20 pagesMds ManualStefanHristozovNo ratings yet

- Installation InstructionsDocument5 pagesInstallation InstructionsmarranNo ratings yet

- EFI Installation Manual Rotax 4-1 Rev5Document26 pagesEFI Installation Manual Rotax 4-1 Rev5Esteban POPO ECHEVERRYNo ratings yet

- Supermatic Transmission (19260380, 19260961, 19299055 or 19329645) SpecificationsDocument11 pagesSupermatic Transmission (19260380, 19260961, 19299055 or 19329645) SpecificationsDennys TiapaNo ratings yet

- FordsonDocument9 pagesFordsonDalibor DušićNo ratings yet

- Hughes Torque Converter Installation InstructionsDocument3 pagesHughes Torque Converter Installation InstructionsMichael VasquezNo ratings yet

- DEXTADocument100 pagesDEXTATiago PaivaNo ratings yet

- 1-5 Dexta Verkstadshandbok 001-100Document100 pages1-5 Dexta Verkstadshandbok 001-100Tami CrouchNo ratings yet

- Unipump InstDocument2 pagesUnipump InstJuliaman NapituNo ratings yet

- Motor B411 Turbo MitsubishiDocument1 pageMotor B411 Turbo MitsubishiCarlos Alberto Lau SosaNo ratings yet

- Banks SidewinderDocument20 pagesBanks Sidewinderpino2234No ratings yet

- Duratec 16v tTI-VCTDocument40 pagesDuratec 16v tTI-VCTStarsky UrblejoNo ratings yet

- Fordson Dexta Shopmanual Sec WatDocument233 pagesFordson Dexta Shopmanual Sec WatElias JohanssonNo ratings yet

- Assembly Compression AirDocument3 pagesAssembly Compression Airaqshal candraNo ratings yet

- Fast4 164Document18 pagesFast4 164superado2kNo ratings yet

- Sum-Carb InstrDocument14 pagesSum-Carb InstrbobNo ratings yet

- Subject: Dodge Cummins 5.9L & 6.7L Cylinder Head Installation and Valve Lash AdjustmentDocument5 pagesSubject: Dodge Cummins 5.9L & 6.7L Cylinder Head Installation and Valve Lash Adjustmentbb bechNo ratings yet

- Compensaver Oil Delivery System Installation Instructions Revised 08-15Document5 pagesCompensaver Oil Delivery System Installation Instructions Revised 08-15Brian KilcreaseNo ratings yet

- Rear SealDocument9 pagesRear SealHammad Uddin JamilyNo ratings yet

- MCM Service BulletinDocument4 pagesMCM Service BulletinHammerheadhunter SmithNo ratings yet

- Ranger / BT50 2.5L & 3.0L TD: Oil Leak at Rear of The HeadDocument1 pageRanger / BT50 2.5L & 3.0L TD: Oil Leak at Rear of The HeadMaster Xeoto67% (3)

- QSB-6.7 BielaDocument4 pagesQSB-6.7 BielaCHEMA BASANNo ratings yet

- Instructions: Installation Instructions For Oil Restrictors (FORD 302 & 351W ENGINES)Document3 pagesInstructions: Installation Instructions For Oil Restrictors (FORD 302 & 351W ENGINES)Adauto PersonNo ratings yet

- 1991 Ford Technical Service BulletinsDocument147 pages1991 Ford Technical Service Bulletinsalexander pintoNo ratings yet

- Camshaft Installation and Degreeing Procedure: InstructionsDocument12 pagesCamshaft Installation and Degreeing Procedure: Instructionsluokla7No ratings yet

- MPI 5 Port Kit Fitting Instructions Aug 2020Document3 pagesMPI 5 Port Kit Fitting Instructions Aug 2020Angi RomanoNo ratings yet

- Replacing The Turob Pedistal Seals 7.3 DieselDocument3 pagesReplacing The Turob Pedistal Seals 7.3 DieselSt Julian LloydNo ratings yet

- Catalogo Brembo Competicion PDFDocument134 pagesCatalogo Brembo Competicion PDFmushu710% (1)

- Line LockDocument9 pagesLine LockStephane VerretNo ratings yet

- Twin Hydraulic Booster Assembly: PublicationDocument3 pagesTwin Hydraulic Booster Assembly: PublicationluismdmjNo ratings yet

- Bulletin #D12EDocument3 pagesBulletin #D12EPanos PanosNo ratings yet

- Fastener Tightening Specifications: Application Specification Metric EnglishDocument32 pagesFastener Tightening Specifications: Application Specification Metric EnglishkloNo ratings yet

- Instructions On Installation Operation and Maintenance For Kirloskar PumpDocument23 pagesInstructions On Installation Operation and Maintenance For Kirloskar Pumpmonuaspire4No ratings yet

- Cylinder Head Gasket (Hatchback) - Installation (05 - 2013 - ) (Cylinder Head Assembly) - Yaris HeadDocument9 pagesCylinder Head Gasket (Hatchback) - Installation (05 - 2013 - ) (Cylinder Head Assembly) - Yaris HeadFran SanchezNo ratings yet

- 001-008 Camshaft: InstallDocument6 pages001-008 Camshaft: InstallNaing Min HtunNo ratings yet

- MC 10245814 9999Document10 pagesMC 10245814 9999abdatmeh99No ratings yet

- REV. 1-14-2015 Installation Instructions: Description Part Number QtyDocument5 pagesREV. 1-14-2015 Installation Instructions: Description Part Number QtymetalcharlieNo ratings yet

- Brembo CatalogDocument54 pagesBrembo CatalogHandrito YudoNo ratings yet

- Titan Model 60: Surg-O-Matic Actuator For Trailer BrakesDocument12 pagesTitan Model 60: Surg-O-Matic Actuator For Trailer BrakesRob GustNo ratings yet

- Peec II - Peec III Brake Engine 10 P OkDocument10 pagesPeec II - Peec III Brake Engine 10 P OkEduardo AlvarezNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- US Val EuroVehicle 0W40 MO ENDocument1 pageUS Val EuroVehicle 0W40 MO ENAnond UseryNo ratings yet

- Tacoma Neck ResetDocument2 pagesTacoma Neck ResetAnond UseryNo ratings yet

- US Val EuroVehicle 0W40 MO ENDocument1 pageUS Val EuroVehicle 0W40 MO ENAnond UseryNo ratings yet

- NA US Mobil 1 FS 0W 40Document3 pagesNA US Mobil 1 FS 0W 40Anond UseryNo ratings yet

- MMBK8FDocument4 pagesMMBK8FAnond UseryNo ratings yet

- Foam Tote Trailer: FeaturesDocument3 pagesFoam Tote Trailer: FeaturesWork ForceNo ratings yet

- 3 4 W Control CablesDocument3 pages3 4 W Control CablesJaya SankaNo ratings yet

- 2023 Nissan Qashqai E-Power Owners ManualDocument514 pages2023 Nissan Qashqai E-Power Owners ManualJake SullivanNo ratings yet

- Catalogo Timing 2018Document152 pagesCatalogo Timing 2018OSCAR TORRES LOPEZNo ratings yet

- SRSuntour Workshop BookDocument170 pagesSRSuntour Workshop BookMark Johnston50% (2)

- Retenes Por Orden Numerico, Medidas, Diseños Y Marcas en Que Van UbicadosDocument21 pagesRetenes Por Orden Numerico, Medidas, Diseños Y Marcas en Que Van UbicadosJose Miguel Rodriguez CarreñoNo ratings yet

- Mustang: Quick Reference GuideDocument8 pagesMustang: Quick Reference GuideRoberto AparicioNo ratings yet

- Ford Motability PricingDocument10 pagesFord Motability Pricingayawe888888No ratings yet

- Your New: RevueltoDocument18 pagesYour New: RevueltoMr FiddleNo ratings yet

- Hose Management Guide: SN: 7KK Lines Group - Injector Hydraulic PumpDocument34 pagesHose Management Guide: SN: 7KK Lines Group - Injector Hydraulic PumpJose luis ConsuegraNo ratings yet

- Uromac Lacertis SV - BrochureDocument2 pagesUromac Lacertis SV - BrochureCristiano RonaldoNo ratings yet

- Grimme Masina de Recoltat CartofiDocument11 pagesGrimme Masina de Recoltat CartofiAdrian ChisNo ratings yet

- EV NotesDocument16 pagesEV Notesgaddala kaladharNo ratings yet

- Clutch Disc Thai AsahiDocument8 pagesClutch Disc Thai AsahiVipuchit SirikhemapornNo ratings yet

- 2007 Compatibility enDocument27 pages2007 Compatibility enSimon VincentNo ratings yet

- Start-Up & Shut Down Procedures: Off-Highway TrucksDocument1 pageStart-Up & Shut Down Procedures: Off-Highway TrucksJoel RodríguezNo ratings yet

- BicycleDocument4 pagesBicycleFaqih AbdussalamNo ratings yet

- Curiculum Vitae - Doc 2Document3 pagesCuriculum Vitae - Doc 2rodlabaclado3231100% (2)

- ApplBro LogHandl 21A1003717Document16 pagesApplBro LogHandl 21A1003717Bilal VURALNo ratings yet

- Door & Lock (Section DLK)Document232 pagesDoor & Lock (Section DLK)Gleydson Bahiense RamosNo ratings yet

- GT-50 Module 1 Introduction 82 SlidesDocument81 pagesGT-50 Module 1 Introduction 82 SlideslucholadeNo ratings yet

- 27 RegulatorsDocument23 pages27 RegulatorsRafael_jorge_7067% (3)

- HDFC Cashless GarageListDocument100 pagesHDFC Cashless GarageListArun KumarNo ratings yet

- Bus Seat PlanDocument1 pageBus Seat PlanTesa GDNo ratings yet

- Materials and Equipment Entry Exit Form - (Shoaiba RO Ph4) - RevisedDocument5 pagesMaterials and Equipment Entry Exit Form - (Shoaiba RO Ph4) - RevisedImran KhuraishiNo ratings yet

- Manuale Carrello A Gas 1.5-3.5 Tonnellate GRENDiA ESDocument17 pagesManuale Carrello A Gas 1.5-3.5 Tonnellate GRENDiA ESryo asg3No ratings yet

- Headlight Range Control Defective (Adaption/Basic Setting Not Performed)Document5 pagesHeadlight Range Control Defective (Adaption/Basic Setting Not Performed)greyNo ratings yet

- Kawasaki Full Line ATV CatalogDocument64 pagesKawasaki Full Line ATV CatalogWillie PennerNo ratings yet

- My ModsDocument4 pagesMy Modssk93677128No ratings yet

- Repro 31jul19sDocument183 pagesRepro 31jul19sGabriela Hernández RendilesNo ratings yet