Professional Documents

Culture Documents

Hazard Pages

Hazard Pages

Uploaded by

Shafique AsifCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazard Pages

Hazard Pages

Uploaded by

Shafique AsifCopyright:

Available Formats

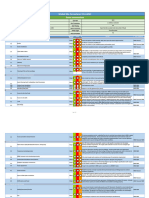

OCCUPATIONAL HEALTH AND SAFETY

Site Risk Assessment Checklist

Residual Risk Register

Form 2/2

Severity Likelihood Risk

A Death/Major injury or 1 Likely to occur AI/A2/B1 Unacceptable, Stop the work,

major damage to immediate action to reduce the

property or equipment risk, apply more

B Reportable injury (i.e. 2 Possible to occur A3/B2/C1 Urgent attention to reduce risk

Over 3 days absence)

C Minor Injury or damage 3 Slight chance of occurring B3/C2/C3 Attention is required. Frequent

to property or equipment review to

ensure risk is controlled

Risk Evaluation

Identified Hazards Additional Control Measures Severity Likelihood Priority

(uncontrolled)

Contractor: Assessment Date:

Site ID:

Site Name:

Site Type: Roof top /Monopole / Palm Tree / Shelter G.F Tower/ Other: ...............

Assessor Name: Title: Signature:

OCCUPATIONAL HEALTH AND SAFETY

Site Risk Assessment Checklist

Form 1/2

Important Note: This form must be assessed carefully according to job type, any marked questions with "Unsafe", you should go to form 2/2 named

Residual risk register" to re-assess the uncontrolled identified hazards, where additional control measures must be in place prior starting the job

Assessment Date:

Site ID:

Site Name:

Site type: Rooftop /Monopole / Palm Tree / Shelter G.F Tower / Other:.......................................

Contractor: Assessor Name: Title: Signature:

Status

Potential Hazards Yes

(Safe)

No

(Unsafe) NA

Person(s) who carry the job:

1-Are all team members are competent, certified and authorized to do the job?

People 2- Are all team members are medically fit to do the job they are assigned to?

3-Is a competent supervisor available on site?

4-Is any high risk activity by minimum of two personnel attending and at least one of them trained on

emergency procedures; (e.g. WAH rescue, emergency shutdown, first aid, firefighting...etc.?)

1-Is the site housekeeping in good condition?

2-Is the site secured and has limited access? And are all the warning and safety signage in place. (e.g.

General Electrical, limited access, climbing, radiation...etc.?

Site 3- Are the site & surrounding area free from flammable, combustible liquids, or gases, explosive agents,

vapors, fumes, dusts and mists?

Conditions

4- Are all the means (e.g. doors, road, stairs...etc.) allow safe access and egress?

5-Is there a safe distance from overhead electrical cables?

6- Is the site free of animals, snake, and other harmful attacks?

7-Is electromagnetic risk controlled?

8- Are all electrical conductors and apparatus passed visually inspection "isolated and working properly" (e.g.

wires, cables, switches, controls, generator, transformers, lamps, batteries, fuses, D.B protection, earth

means installed..etc.)?

9- Is there any further unsafe condition observed in site?

1- Is manual lifting used in accordance with good practices "e.g. planned, appropriate pulley’s system used,

drop zones marked, secured and done under supervision...etc."?

2- Are lifting operations planned before being undertaken and using suitable equipment, competent operator

who has a valid license and applying good work practices?

3- Are appropriate controls for WAH applied (e.g. only by trained and physically proven, two

Activity

riggers minimum, using fall arrestor or fall restraint system properly...etc.?

4-Is the rooftop safe (e.g. roof edge protected, no skylight, no fragile roof, no weak points)?

5-Safe load limits are calculated prior to start the work?

6-Is the area under loading clear and allow safe movements? Is drop zone barricaded?

7-Rigging equipment for material handling is inspected prior to use in each shift?

8- Are all Hot Works controls are applied (e.g. planned, trained on use and techniques ones, using proper

PPES, rescue and emergency plan developed and n place...etc.?

9-Are electrical work controls applied (e.g. no live electrical activity, proper PPES, Lockout/ Tag out, portable

hand tools grounded and double insulated, earth means, permanent wiring used instead of extension

cords...etc.?

1- Are appropriate PPEs used and pre-inspected as hazards are indicated?

PPE and 2- Are fall protection PPES and tools used in a good safe working condition (e.g. harness, lifelines and

Tools lanyards)?

3-Foot & head protection in a good safe working condition?

4-Are tools and equipment subject to appropriate system of pre-use/after use checks, visual examination and

are thy maintained in a safe condition, neatly stored, safely carried?

1-Do Vehicle used to transport employees comply with Vodafone requirements (e.g. airbag, ABS, seatbelts,

Vehicle equipped with emergency kits...etc.)?

and Safety 2-Is the vehicle driver trained on Safe driving techniques?

Vehicle Safety

3-Is there an inspection checklist inside the vehicle, signed by the site engineer?

Emergency Response

4- Are the vehicle daily inspection, preventive/corrective maintenance, driver evaluation done and proven?

5-Are there a speed monitoring system and carkit installed?

1- Is there an emergency response plan in place?

Emergenc 2- Are people well trained in the emergency plan?

y 3-Is the first aid kit fully loaded with all the required materials?

Response 4-Is there a certified fire fighter at the site?

5- Is there proper maintained 3kg fire extinguisher with the team?

6- Is there a certified working at height rescuer at the site?

7- Is there proper maintained recuse kit and prepared to use?

You might also like

- The Effective Security Officer's Training ManualFrom EverandThe Effective Security Officer's Training ManualRating: 4 out of 5 stars4/5 (10)

- Test 2 Answer Key, ReadingDocument7 pagesTest 2 Answer Key, ReadingRocio Martínez Carrió57% (7)

- Aircraft Safety: Accident Investigations, Analyses, & Applications, Second EditionFrom EverandAircraft Safety: Accident Investigations, Analyses, & Applications, Second EditionRating: 1.5 out of 5 stars1.5/5 (2)

- Dynamic Risk Analysis in the Chemical and Petroleum Industry: Evolution and Interaction with Parallel Disciplines in the Perspective of Industrial ApplicationFrom EverandDynamic Risk Analysis in the Chemical and Petroleum Industry: Evolution and Interaction with Parallel Disciplines in the Perspective of Industrial ApplicationNicola PaltrinieriRating: 5 out of 5 stars5/5 (1)

- Mobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSFrom EverandMobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSRating: 1 out of 5 stars1/5 (1)

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Emergency Response Guidebook: A Guidebook for First Responders during the Initial Phase of a Dangerous Goods/Hazardous Materials Transportation IncidentFrom EverandEmergency Response Guidebook: A Guidebook for First Responders during the Initial Phase of a Dangerous Goods/Hazardous Materials Transportation IncidentNo ratings yet

- Wireless Public Safety Networks Volume 1: Overview and ChallengesFrom EverandWireless Public Safety Networks Volume 1: Overview and ChallengesNo ratings yet

- Safety and Security Review for the Process Industries: Application of HAZOP, PHA, What-IF and SVA ReviewsFrom EverandSafety and Security Review for the Process Industries: Application of HAZOP, PHA, What-IF and SVA ReviewsRating: 4 out of 5 stars4/5 (1)

- Small Unit Leaders Operational Planning GuideFrom EverandSmall Unit Leaders Operational Planning GuideRating: 5 out of 5 stars5/5 (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Aviation Instructor's Handbook (2024): FAA-H-8083-9BFrom EverandAviation Instructor's Handbook (2024): FAA-H-8083-9BRating: 3.5 out of 5 stars3.5/5 (4)

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)

- AIR CRASH INVESTIGATIONS – THE CRASH OF VIRGIN GALACTIC SPACESHIP 2From EverandAIR CRASH INVESTIGATIONS – THE CRASH OF VIRGIN GALACTIC SPACESHIP 2No ratings yet

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- Port Cybersecurity: Securing Critical Information Infrastructures and Supply ChainsFrom EverandPort Cybersecurity: Securing Critical Information Infrastructures and Supply ChainsRating: 5 out of 5 stars5/5 (1)

- Machine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningFrom EverandMachine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningRating: 4.5 out of 5 stars4.5/5 (2)

- How to Survive a Terrorist Attack – Become Prepared for a Bomb Threat or Active Shooter Assault: Save Yourself and the Lives of Others - Learn How to Act Instantly, The Strategies and Procedures After the Incident, How to Help the Injured & Be Able to Provide First AidFrom EverandHow to Survive a Terrorist Attack – Become Prepared for a Bomb Threat or Active Shooter Assault: Save Yourself and the Lives of Others - Learn How to Act Instantly, The Strategies and Procedures After the Incident, How to Help the Injured & Be Able to Provide First AidNo ratings yet

- Bodyguards: How to Protect Others - Part 4.2 - Basic TacticsFrom EverandBodyguards: How to Protect Others - Part 4.2 - Basic TacticsRating: 5 out of 5 stars5/5 (3)

- Know the Risk: Learning from errors and accidents: safety and risk in today's technologyFrom EverandKnow the Risk: Learning from errors and accidents: safety and risk in today's technologyNo ratings yet

- How to Survive a Terrorist Attack: Become Prepared for a Bomb Threat or Active Shooter AssaultFrom EverandHow to Survive a Terrorist Attack: Become Prepared for a Bomb Threat or Active Shooter AssaultNo ratings yet

- Introduction to Emergency Evacuation: Getting Everybody Out When it CountsFrom EverandIntroduction to Emergency Evacuation: Getting Everybody Out When it CountsRating: 2 out of 5 stars2/5 (1)

- Computer Incident Response and Forensics Team Management: Conducting a Successful Incident ResponseFrom EverandComputer Incident Response and Forensics Team Management: Conducting a Successful Incident ResponseRating: 3.5 out of 5 stars3.5/5 (2)

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Personal Protective Equipment for Chemical, Biological, and Radiological Hazards: Design, Evaluation, and SelectionFrom EverandPersonal Protective Equipment for Chemical, Biological, and Radiological Hazards: Design, Evaluation, and SelectionNo ratings yet

- Pressing On: Unstable Approach Continuation BiasFrom EverandPressing On: Unstable Approach Continuation BiasRating: 5 out of 5 stars5/5 (1)

- CISA Exam-Testing Concept-Knowledge of Risk AssessmentFrom EverandCISA Exam-Testing Concept-Knowledge of Risk AssessmentRating: 2.5 out of 5 stars2.5/5 (4)

- IN-SITE: Keys to an Effective Site Safety and Security ProgramFrom EverandIN-SITE: Keys to an Effective Site Safety and Security ProgramNo ratings yet

- Business Continuity Management: Building an Effective Incident Management PlanFrom EverandBusiness Continuity Management: Building an Effective Incident Management PlanNo ratings yet

- Principles and Practices of Contamination Control and CleanroomsFrom EverandPrinciples and Practices of Contamination Control and CleanroomsNo ratings yet

- Assurance Technologies Principles and Practices: A Product, Process, and System Safety PerspectiveFrom EverandAssurance Technologies Principles and Practices: A Product, Process, and System Safety PerspectiveNo ratings yet

- Experience in the Management of Radioactive Waste After Nuclear Accidents: A Basis for PreplanningFrom EverandExperience in the Management of Radioactive Waste After Nuclear Accidents: A Basis for PreplanningNo ratings yet

- Gray Matter: Aviation Mechanics Most Frequently Asked QuestionsFrom EverandGray Matter: Aviation Mechanics Most Frequently Asked QuestionsNo ratings yet

- Building Secure Firmware: Armoring the Foundation of the PlatformFrom EverandBuilding Secure Firmware: Armoring the Foundation of the PlatformNo ratings yet

- Aviation Manager’s Toolkit: Understanding Safety Management Systems: Organizational Blindness in Aviation Management and LeadershipFrom EverandAviation Manager’s Toolkit: Understanding Safety Management Systems: Organizational Blindness in Aviation Management and LeadershipNo ratings yet

- Navigating the Dark Waters of Cybersecurity Incident ResponseFrom EverandNavigating the Dark Waters of Cybersecurity Incident ResponseNo ratings yet

- Security Leader Insights for Business Continuity: Lessons and Strategies from Leading Security ProfessionalsFrom EverandSecurity Leader Insights for Business Continuity: Lessons and Strategies from Leading Security ProfessionalsNo ratings yet

- Information Technology Risk Management in Enterprise Environments: A Review of Industry Practices and a Practical Guide to Risk Management TeamsFrom EverandInformation Technology Risk Management in Enterprise Environments: A Review of Industry Practices and a Practical Guide to Risk Management TeamsRating: 5 out of 5 stars5/5 (1)

- Disaster Risk Management: Scientific-Professional Society for Disaster Risk ManagementFrom EverandDisaster Risk Management: Scientific-Professional Society for Disaster Risk ManagementNo ratings yet

- Vehicle Checklist IkramDocument1 pageVehicle Checklist IkramShafique AsifNo ratings yet

- OHS OldDocument6 pagesOHS OldShafique AsifNo ratings yet

- CommandsDocument2 pagesCommandsShafique AsifNo ratings yet

- Driver PageDocument4 pagesDriver PageShafique AsifNo ratings yet

- 6297 Design Revision RequestDocument5 pages6297 Design Revision RequestShafique AsifNo ratings yet

- Vehicle Checklist AsgharDocument1 pageVehicle Checklist AsgharShafique AsifNo ratings yet

- 3258 GCLDocument5 pages3258 GCLShafique AsifNo ratings yet

- 2 - Accessing Mini-Link 6366 From Indoor UnitsDocument7 pages2 - Accessing Mini-Link 6366 From Indoor UnitsShafique AsifNo ratings yet

- 4153 GCLDocument5 pages4153 GCLShafique AsifNo ratings yet

- 3258 GCL NewDocument8 pages3258 GCL NewShafique AsifNo ratings yet

- Aftab CVDocument1 pageAftab CVShafique AsifNo ratings yet

- Asghar C.VDocument1 pageAsghar C.VShafique AsifNo ratings yet

- Aamir C.VDocument1 pageAamir C.VShafique AsifNo ratings yet

- GCL PDFDocument9 pagesGCL PDFShafique AsifNo ratings yet

- Manual SMR Rectifier 5308Document3 pagesManual SMR Rectifier 5308Shafique AsifNo ratings yet

- CSC Number SeriesDocument3 pagesCSC Number SeriesRaquel disomimbaNo ratings yet

- Quito Ciudad MilenariaDocument250 pagesQuito Ciudad MilenariaDaniel VegaNo ratings yet

- INTRODUÇÃO História Da ArquiteturaDocument6 pagesINTRODUÇÃO História Da ArquiteturaAugusto JuniorNo ratings yet

- Mapa y Caracterizacion de Procesos Del ProyectoDocument20 pagesMapa y Caracterizacion de Procesos Del ProyectoEdwar SamboniNo ratings yet

- Timetable Route BMTDocument9 pagesTimetable Route BMTAimi SyafiqahNo ratings yet

- Qué Es El Diseño InstruccionalDocument10 pagesQué Es El Diseño InstruccionalEdwin PiratovaNo ratings yet

- Catalogo Wild Fire EsguichosDocument16 pagesCatalogo Wild Fire EsguichosRodrigo VelásquezNo ratings yet

- English 10 With Tos and Keys (3RD)Document10 pagesEnglish 10 With Tos and Keys (3RD)Larren BelloNo ratings yet

- Examen Modulo 5 Sesion 6Document4 pagesExamen Modulo 5 Sesion 6vanesaNo ratings yet

- Dr. Vandana Gupta: EducationDocument3 pagesDr. Vandana Gupta: EducationMadhu DatarNo ratings yet

- Hack X Crack JavaDocument44 pagesHack X Crack JavaArmando Valeriano Hernandez100% (2)

- ELASTO Sweden AB - Sådan Vælger Du Termoplastiske Elastomerer (TPE)Document29 pagesELASTO Sweden AB - Sådan Vælger Du Termoplastiske Elastomerer (TPE)SkylarNo ratings yet

- Queisser 1998Document6 pagesQueisser 1998Christian RuizNo ratings yet

- Componentes de Un RobotDocument7 pagesComponentes de Un RobotMarilyn AlvaNo ratings yet

- Seduction Warfare Author No Bullsht Seduction (NBS)Document12 pagesSeduction Warfare Author No Bullsht Seduction (NBS)Silly BearNo ratings yet

- Experiencia de Aprendizaje Numero 6Document15 pagesExperiencia de Aprendizaje Numero 6Ruth VidalNo ratings yet

- 90003-152 - Tarea 2 - Jeniffer Juliana Toro OrtegaDocument14 pages90003-152 - Tarea 2 - Jeniffer Juliana Toro OrtegaJeniffer Juliana Toro OrtegaNo ratings yet

- Sat Practice Test 1 Answers DigitalDocument48 pagesSat Practice Test 1 Answers DigitalLinh Nguyễn GiaNo ratings yet

- Arte Ciencia y Tecnologia. Un Panorama Critico.-LibreDocument237 pagesArte Ciencia y Tecnologia. Un Panorama Critico.-LibrefzacobichNo ratings yet

- Vulcan RRE36DDocument2 pagesVulcan RRE36Ddstout74No ratings yet

- Plantilla ECBTI-IEEEDocument9 pagesPlantilla ECBTI-IEEEcdmancillaNo ratings yet

- Word Count Program With MapReduce and JavaDocument6 pagesWord Count Program With MapReduce and Javasheenu georgeNo ratings yet

- 2 TransformacionesDocument23 pages2 TransformacionesMatias MolleckerNo ratings yet

- Flowmeter Apparatus (Venturi, Orifice, Rotameter)Document10 pagesFlowmeter Apparatus (Venturi, Orifice, Rotameter)meghaparinNo ratings yet

- Symund Bauman (Daños Colaterales)Document2 pagesSymund Bauman (Daños Colaterales)joaquinrabassa100% (1)

- Detección de Necesidades de Capacitación (DNC) CursoDocument59 pagesDetección de Necesidades de Capacitación (DNC) Cursomontano23790% (1)

- Charla - Habilidades SocialesDocument3 pagesCharla - Habilidades SocialesMarié SuasnabarNo ratings yet

- EES Gas Emittance: P L - Shown Below Are Plots Based On The TablesDocument3 pagesEES Gas Emittance: P L - Shown Below Are Plots Based On The Tablesjesus arvizuNo ratings yet

- Sesion 01 TV Inicial 15-11-21Document10 pagesSesion 01 TV Inicial 15-11-21cesar adrian iturbide fernandoNo ratings yet