Professional Documents

Culture Documents

Valvula de Balanceo Automatica Conexion Bridada

Uploaded by

jackpillaca4Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valvula de Balanceo Automatica Conexion Bridada

Uploaded by

jackpillaca4Copyright:

Available Formats

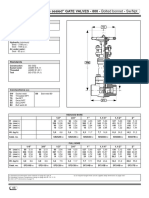

FlowCon Wafer

Automatic Balancing Valve - Pre-Set Insert(s)

50-1000 mm / 2”-40”

SPECIFICATIONS

Static pressure: DN50-80: 2500 kPa / 360 psi

DN100+: 3400 kPa / 493 psi

Media temperature: DN50-80: -20°C to +135°C / -4°F to +275°F

DN100+: -20°C to +175°C / -4°F to +347°F

Material:

- Housing: Ductile iron ASTM A536, Grade 60-40-18

- Insert(s): AISI type 304 stainless steel

AISI type 17-7 PH stainless steel spring

- Retainer clip: DN50-80: AISI type 302 stainless steel

- O-ring: DN50-80: EPDM (DN50-80)

Flow rate range: 0.883-2286.9 l/sec / 14-36248 GPM

End connections: DN50-80: EN1092-1, PN10+

DN100-250: EN1092-1, PN25+

DN300: EN1092-1, PN40+

DN350-1000: EN1092-1, PN25+

2”: ANSI B 16.5 300lb class flanges+

2 1/2”-8”: ANSI B 16.5 150lb class flanges+

10”: ANSI B 16.5 300lb class flanges+

12”-18”: ANSI B 16.5 150lb class flanges+

20”-24”: ANSI B 16.5 300lb class flanges+

30”: ANSI B 16.47 300lb class flanges+

32”-40”: ANSI B 16.47 150lb class flanges+

Flanges are not supplied by FlowCon

Studs and nuts are available upon request

Body taps: 1/4” NPT

Tech note · april 2020 · www.flowcon.com Page 1 of 5

DIMENSIONS AND WEIGHT (NOMINAL)

Model Valve size Insert D2 D3 L H Weight1 Max no.

no. D1 size (±1%) of inserts

per wafer

mm mm mm mm mm mm kgs.

(in) (in) (in) (in) (in) (in) (lb)

50 107 165 174 90 4.15

F325X 12

(2) (4.21) (6.5) (6.85) (3.54) (9.15)

65 117 185 174 90 6.65 12

(2 1/2) (4.61) (7) (6.85) (3.54) (14.7)

F326X

80 117 200 174 90 6.65 12

(3) (4.61) (7.5) (6.85) (3.54) (14.7)

100 172 235 197 90 15.7

F332X 22

(4) (6.77) (9) (7.76) (3.54) (34.6)

150 219 285 184 90 19.7

F334X 4

(6) (8.62) (11) (7.24) (3.54) (43.4)

200 276 360 184 90 26.7

F337X 7

(8) (10.9) (13.5) (7.24) (3.54) (58.9)

250 341 425 203 90 36.7

F368X 11

(10) (13.4) (17.5) (8.00) (3.54) (80.9)

300 406 515 203 90 61.7

F369X 15

(12) (16.0) (19) (8.00) (3.54) (136)

350 80 448 555 203 90 69.7

F339X (3) 19

(14) (17.6) (21) (8.00) (3.54) (154)

400 511 620 241 90 103

F384X 24

(16) (20.1) (23.5) (9.49) (3.54) (227)

4503 546 640 241 90 115

F385X 31

(18)3 (21.5) (25) (9.49) (3.54) (254)

5003 607 715 279 90 164

F338X (20)3 (23.9) (30.5) (11.0) (3.54) (362) 37

6003 714 840 279 90 218

F386X (24)3 (28.1) (36) (11.0) (3.54) (481) 55

8003 1015

(30)3 883 (43) 432 90 402

F330X (34.8) (17.0) (3.54) (886) 85

8003 1015

(32)3 (41.75)

9003 1030 1185 432 90 706

F370X (36)3 (40.6) (46) (17.0) (3.54) (1560) 97

10003 1140 1320 438 90 841

F395X (40)3 (44.9) (53) (17.2) (3.54) (1850) 121

Note 1: Nominal weight, including inserts and p/t plugs, exact weight is dependent on inserts.

Note 2: Hi-flow inserts do not fit in this wafer size.

Note 3: 450mm (18”) and larger supplied with eyebolt for lifting.

D2 D1

D3

Tech note · FlowCon Wafer · april 2020 · www.flowcon.com Page 2 of 5

MODEL NUMBER SELECTION

F3 B

______ ______ ______

Insert body size:

25=DN50, 2” 26=DN65/80, 2 1/2” / 3” 32=DN100, 4” 34=DN150, 6”

37=DN200, 8” 68=DN250, 10” 69=DN300, 12” 39=DN350, 14”

84=DN400, 16” 85=DN450, 18” 38=DN500, 20” 86=DN600, 24”

30=DN800, 30”/32” 70=DN900, 36”, 95=DN1000, 40”

Insert pressure range:

0=None

STANDARD/HI-CAP: 1=10-135 kPaD (1.5-20 psid) and 28-135 kPaD (4.0-20 psid)

2=22-210 kPaD (3.2-30 psid) and 55-210 kPaD (8.0-30 psid)

4=40-390 kPaD (5.8-57 psid)

8=90-880 kPaD (13-128 psid)

HI-FLOW : 4 3=20-125 kPaD (2.9-18 psid)

5=35-220 kPaD (5.1-32 psid)

6=55-220 kPaD (8.0-32 psid)

Insert p/t plug requirement:

B=Pressure/temperature plugs (standard)

Example: F3370B=Wafer for 200 mm (8”) flanges with p/t plugs and no inserts.

Note: Please specify flow requirements as per selection chart when ordering with insert(s).

Note 4: Not possible for DN50-100 (2”-4”).

Tech note · FlowCon Wafer · april 2020 · www.flowcon.com Page 3 of 5

FLOW RATE TABLE PER TYPE OF INSERT

80mm · 3” · stainless steel insert, standard flow

Pressure range, ΔP: 10-135 kPaD 22-210 kPaD 40-390 kPaD 90-880 kPaD

1-20 psid 2-32 psid 4-57 psid 8-128 psid

Type 1 Type 2 Type 4 Type 8

Size Size Max no. of min. available l/sec 0.883 1.10 1.47 2.21

(mm) (“) inserts l/sec increments 0.127 0.16 0.21 0.31

50 2 1 3.79 4.73 6.31 9.46

65 2 1/2 1 3.79 4.73 6.31 9.46

80 3 1 3.79 4.73 6.31 9.46

100 4 2 7.58 9.46 12.6 18.9

150 6 4 15.2 18.9 25.2 37.8

200 8 7 26.5 33.1 44.2 66.2

250 10 11 41.7 52.0 69.4 104

300 12 15 56.9 71.0 94.7 142

350 14 19 max. available l/sec 72.0 89.9 120 180

400 16 24 91.0 114 151 227

450 18 31 117 147 196 293

500 20 37 140 175 233 350

600 24 55 208 260 347 520

30

800 85 322 402 536 804

32

900 36 97 368 459 612 918

1000 40 121 459 572 764 1144

Accuracy: ±5% of controlled flow rate.

80mm · 3” · stainless steel insert, high capacity

Pressure range, ΔP: 28-135 kPaD 55-210 kPaD

4-20 psid 8-32 psid

Type 1 Type 2

Size Size Max no. of min. available l/sec 5.68 6.94

(mm) (“) inserts l/sec increments 1.26 1.58

50 2 1 8.20 10.1

65 2 1/2 1 8.20 10.1

80 3 1 8.20 10.1

100 4 2 16.4 20.2

150 6 4 32.8 40.4

200 8 7 57.4 70.7

250 10 11 90.2 111

300 12 15 123 152

350 14 19 max. available l/sec 156 192

400 16 24 197 242

450 18 31 254 313

500 20 37 303 374

600 24 55 451 556

30

800 85 697 859

32

900 36 97 795 980

1000 40 121 992 1222

Accuracy: ±5% of controlled flow rate.

80mm · 3” · stainless steel insert, high flow

Pressure range, ΔP: 20-125 kPaD 35-220 kPaD 55-220 kPaD

3-18 psid 5-32 psid 8-32 psid

Type 3 Type 5 Type 6

Size Size Max no. of min. available l/sec 6.31 8.52 18.9

(mm) (“) inserts l/sec increments n/a n/a5 n/a

150 6 4 25.2 50.4 75.6

200 8 7 44.2 88.2 132

250 10 11 69.4 139 208

300 12 15 94.7 189 284

350 14 19 120 239 359

400 16 24 151 302 454

450 18 31 196 391 586

500 20 37 233 466 699

600 24 55 347 693 1040

30

800 85 536 1071 1607

32

900 36 97 612 1222 1833

1000 40 121 764 1525 2287

Accuracy: ±5% of controlled flow rate.

Note 5: For flow rates in between min. and max. please contact FlowCon.

Tech note · FlowCon Wafer · april 2020 · www.flowcon.com Page 4 of 5

FLANGE MATCH

ASME B16.5 weld neck EN1092-1 weld neck

Model Flange size Flange size

no. (inch) (mm)

CIass 150 CIass 300 PN10 PN16 PN25 PN40

F325X 2 50

2 1/2 65

F326X

3 80

F332X 4 100 6 6

F334X 6 150

F337X 8 200

F368X 10 250

F369X 12 300

F339X 14 350

F384X 16 400

F385X 18 450

F338X 20 500

F386X 24 600

ASME B16.47A weld neck

30 7

F330X 800

32 7 7

F370X 36 7 7 900

F395X 40 7 1000

Note 6: Fits PN25 and PN40 flanges with M18 studs or studs from ACC3320BD25.

Note 7: According to ASME B16.47 series A.

GENERAL SPECIFICATIONS

1. AUTOMATIC BALANCING VALVES - FLOWCON WAFER

1.1. Contractor shall install automatic balancing valves where indicated in drawings.

1.2. Valve shall consist of dynamic, flow limiting device.

2.VALVE HOUSING

2.1. Valve housing shall consist of ductile iron ASTM A536, grade 60-40-18, rated at no less than 2500 kPa

(360 psi) static pressure and +135°C (+275°F).

2.2. Valve shall be permanently marked to show direction of flow.

2.3. Housing shall be for installation between flanges.

Valve housing shall be compatible with ANSI 150lb/300lb steel flanges (depending on size) according to

ASME B16.5/16.47 and be compatible to DIN PN10/PN16/PN25/PN40+ flanges (depending on size)

according to EN1092-1.

2.4. Dual pressure/temperature test plugs for verifying accuracy of flow performance shall be standard on

all valve sizes.

2.5. Sizes DN450 (18”) and larger supplied with eyebolt for lifting.

2.6. Identification label shall be available for all valves.

3.FLOW REGULATOR / AUTOMATIC BALANCING UNIT

3.1. Flow regulation unit assembly shall be manufactured of AISI type 304 stainless steel and stainless

steel 17-7 spring.

3.2. Flow regulation unit shall be available in 4 different kPaD operational range; minimum range shall be

capable of being activated by minimum 10 kPaD (1 psid). Further, the flow regulation unit shall be capa-

ble of controlling flow within ±5% of rated flow.

UPDATES

For latest updates please see www.flowcon.com

FlowCon International can accept no responsibility for possible errors in any printed material.

All rights reserved.

Tech note · FlowCon Wafer · april 2020 · www.flowcon.com Page 5 of 5

You might also like

- SAE Housing and Flywheel SizesDocument3 pagesSAE Housing and Flywheel SizesVinoth KumarNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Determining The Generator Adaptation Required From The Engine SuppliedDocument2 pagesDetermining The Generator Adaptation Required From The Engine SuppliedolumideNo ratings yet

- An Introduction To Closed Loop MarketingDocument40 pagesAn Introduction To Closed Loop MarketingGeorgiana VasilescuNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Life Lines RequirementsDocument2 pagesLife Lines RequirementsAnsarMahmoodNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- YASHICA MAT-124 User's ManualDocument34 pagesYASHICA MAT-124 User's Manuallegrandew100% (1)

- Britain, Germany and Colonial Violence in South-West Africa, 1884-1919Document238 pagesBritain, Germany and Colonial Violence in South-West Africa, 1884-1919Саша ШестаковаNo ratings yet

- New TIP Course 4 (DepEd Teacher)Document58 pagesNew TIP Course 4 (DepEd Teacher)Venessa Mulig100% (2)

- Bank Automation ProjectDocument75 pagesBank Automation Projectyathsih24885No ratings yet

- Caliber F7500 Catalog 010422Document12 pagesCaliber F7500 Catalog 010422ArleyTrujillo1224No ratings yet

- DBB Vb04 Series, Ms-02-210 r2Document4 pagesDBB Vb04 Series, Ms-02-210 r2herysyam1980No ratings yet

- Vibration Eliminators: Refrigeration ConnectorsDocument4 pagesVibration Eliminators: Refrigeration ConnectorsIskandar FirdausNo ratings yet

- Mine-X Oxidation Catalytic Purifier Dimensions: Last Revised: April 25, 2007 X0001-0000-05Document1 pageMine-X Oxidation Catalytic Purifier Dimensions: Last Revised: April 25, 2007 X0001-0000-05zeck28No ratings yet

- Pipe Clamps & Hangers Spec SheetDocument1 pagePipe Clamps & Hangers Spec SheetAlejandro Ayrton Zambrano CinceNo ratings yet

- Catalogue DARCO Flottant ENDocument20 pagesCatalogue DARCO Flottant ENScipp ZengNo ratings yet

- Kelken US Metric Chart ASTM A615 Grade 60 RebarDocument1 pageKelken US Metric Chart ASTM A615 Grade 60 RebarAvsin CevaNo ratings yet

- CPVC pipes and fittings standardsDocument3 pagesCPVC pipes and fittings standardsAsif S KhanNo ratings yet

- EBRO EGF Ve EGD Typ Globe ValvesDocument2 pagesEBRO EGF Ve EGD Typ Globe ValvesKananbayRustamliNo ratings yet

- ESAB Dual Shield 7100 UltraDocument3 pagesESAB Dual Shield 7100 UltrahaldunNo ratings yet

- Sec19 Sebd0350Document92 pagesSec19 Sebd0350pmcisissengueNo ratings yet

- Traslapos - Ganchos - NSR-10Document14 pagesTraslapos - Ganchos - NSR-10CARLOS JULIO RODRIGUEZ BELLONo ratings yet

- FT 854715.11 - (Vortex)Document2 pagesFT 854715.11 - (Vortex)Alejo SilvaNo ratings yet

- Dimensional Drawings: Single Transmitter Dimensions and WeightsDocument2 pagesDimensional Drawings: Single Transmitter Dimensions and WeightsAlejo SilvaNo ratings yet

- FabCO Excel Arc71Document2 pagesFabCO Excel Arc71Yousab CreatorNo ratings yet

- MKIII TECH BULLETIN - Pump and Baseplate DimensionsDocument1 pageMKIII TECH BULLETIN - Pump and Baseplate DimensionsZainal MuzidNo ratings yet

- 16 284-294 PVC FA - Indd PDFDocument11 pages16 284-294 PVC FA - Indd PDFKok WaiNo ratings yet

- D65 Vs D6TDocument4 pagesD65 Vs D6TAlex BravoNo ratings yet

- Flanged Swing Check Valve PDFDocument2 pagesFlanged Swing Check Valve PDFuki12345No ratings yet

- Tru Bolt Technical DataDocument4 pagesTru Bolt Technical Databeautiful womanmanNo ratings yet

- R.1.05.01 Insert Type HoldersDocument2 pagesR.1.05.01 Insert Type HoldersbondsivamaniNo ratings yet

- Dynaset HKR - Data - Sheet - v1.1Document8 pagesDynaset HKR - Data - Sheet - v1.1gulam husseinNo ratings yet

- Grinnell Mechanical Products Figure 909 Plain End Coupling For Steel Pipe - Patented & Patents Pending General Description Technical DataDocument4 pagesGrinnell Mechanical Products Figure 909 Plain End Coupling For Steel Pipe - Patented & Patents Pending General Description Technical DataСергей КолесниковNo ratings yet

- Fig 883 Pipe Flange SupportDocument1 pageFig 883 Pipe Flange SupportJosé Antônio CardosoNo ratings yet

- Y Strainer 2022-CMPDocument5 pagesY Strainer 2022-CMPMohanrajaNo ratings yet

- LRFD 1.5BA 36 1.5BIA 36 1.5PLBA 36 - GR50 - Acoustical - Roof - DeckDocument2 pagesLRFD 1.5BA 36 1.5BIA 36 1.5PLBA 36 - GR50 - Acoustical - Roof - DeckXiomara M Santiago OramaNo ratings yet

- Bellows Sealed GATE VALVES - 800 - Bolted Bonnet - SW PDFDocument1 pageBellows Sealed GATE VALVES - 800 - Bolted Bonnet - SW PDFkhasim15No ratings yet

- Excel-Arc 71 Welding Wire GuideDocument2 pagesExcel-Arc 71 Welding Wire GuidegizaloNo ratings yet

- Serie 523 - ISO 15552Document69 pagesSerie 523 - ISO 15552NixiusNo ratings yet

- 2009 Motor Specifications: Thru Tubing and Adjustable Housing DetailsDocument88 pages2009 Motor Specifications: Thru Tubing and Adjustable Housing DetailsSinghtoFCNo ratings yet

- Cast and Forged: Gate, Globe & Check ValvesDocument4 pagesCast and Forged: Gate, Globe & Check ValvesDinesh ChouguleNo ratings yet

- Polymer suspension insulator catalog for 69kV to 765kV systemsDocument12 pagesPolymer suspension insulator catalog for 69kV to 765kV systemsThiyagarajan VaratharajanNo ratings yet

- Dyna Bolt Technical DataDocument1 pageDyna Bolt Technical DataSulthan AriNo ratings yet

- BHA#2 Trip TPN - DZ 20.6 (TPN-223)Document1 pageBHA#2 Trip TPN - DZ 20.6 (TPN-223)Setya AminNo ratings yet

- Armstrong 4030 3x1.5x10 LDocument3 pagesArmstrong 4030 3x1.5x10 LzantyfcsNo ratings yet

- Rhinoflex Metal Seated Unidirectional Knife Gate Valve-Rfs - 37-10Document3 pagesRhinoflex Metal Seated Unidirectional Knife Gate Valve-Rfs - 37-10Yerson JuarezNo ratings yet

- Installation Manual for Midea Air Conditioner Models KFR-26GW/BP2DN1Y-PA402(A3), KFR-32GW/BP2DN1Y-PA402(A3), and KFR-35GW/BP2DN1Y-PA402(A3Document40 pagesInstallation Manual for Midea Air Conditioner Models KFR-26GW/BP2DN1Y-PA402(A3), KFR-32GW/BP2DN1Y-PA402(A3), and KFR-35GW/BP2DN1Y-PA402(A3mr.aikidoNo ratings yet

- HS CatalogDocument8 pagesHS CatalogvijaykumarnNo ratings yet

- HS 1.5 Thru 015 SpecsDocument8 pagesHS 1.5 Thru 015 SpecsvijaykumarnNo ratings yet

- HS CatalogDocument8 pagesHS CatalogMahesh NanayakkaraNo ratings yet

- Centron GRE CasingDocument4 pagesCentron GRE Casingargonzales11100% (1)

- SF-71 en EngDocument2 pagesSF-71 en EngbvbarcNo ratings yet

- ValveDocument2 pagesValveRamKS80No ratings yet

- SSL Comparison List/ TECH - DETAILS OF SKID STEER LOADERSDocument80 pagesSSL Comparison List/ TECH - DETAILS OF SKID STEER LOADERSHuseyin TASKINNo ratings yet

- Coppa Del Mondo XCO 2022 - #3 Nove Mesto - Men Elite - OverallDocument4 pagesCoppa Del Mondo XCO 2022 - #3 Nove Mesto - Men Elite - OverallMTB-VCONo ratings yet

- High-performance double vane pump specsDocument7 pagesHigh-performance double vane pump specsVincentNo ratings yet

- Handbook - Cored Wire Products PDFDocument1 pageHandbook - Cored Wire Products PDFtuna61No ratings yet

- ShopTek-US - 5-50hp LittDocument2 pagesShopTek-US - 5-50hp LittPierre-André MarcouxNo ratings yet

- Slip-On Flanges Class 150: ANSI B 16.5 / B16.47 ADocument1 pageSlip-On Flanges Class 150: ANSI B 16.5 / B16.47 ABastian VillarroelNo ratings yet

- Danflo-N2 Operated BulletinDocument8 pagesDanflo-N2 Operated Bulletinresp0312No ratings yet

- B03 TAI WelldewateringDocument4 pagesB03 TAI WelldewateringchinhNo ratings yet

- Dyna Drill Spec SheetsDocument105 pagesDyna Drill Spec SheetsDon BraithwaiteNo ratings yet

- Operation and Safety Manual: Ansi As/NzsDocument116 pagesOperation and Safety Manual: Ansi As/NzsMuhammad AwaisNo ratings yet

- BJT AmplifiersDocument21 pagesBJT AmplifiersAligato John RayNo ratings yet

- El 5036 V2 PDFDocument86 pagesEl 5036 V2 PDFCriss TNo ratings yet

- Quality Assurance AnalystDocument2 pagesQuality Assurance AnalystMalikNo ratings yet

- SFRM Commissioning and Field Testing - Structural Fire Resistance Content From Fire Protection EngineeringDocument6 pagesSFRM Commissioning and Field Testing - Structural Fire Resistance Content From Fire Protection EngineeringRichard HollidayNo ratings yet

- 2018 General Education Reviewer Part 10 - 50 Questions With Answers - LET EXAM - Questions & AnswersDocument10 pages2018 General Education Reviewer Part 10 - 50 Questions With Answers - LET EXAM - Questions & AnswersScribdNo ratings yet

- SP-1127 - Layout of Plant Equipment and FacilitiesDocument11 pagesSP-1127 - Layout of Plant Equipment and FacilitiesParag Lalit SoniNo ratings yet

- Test Paper Trigonometric Functions and Equations PDFDocument9 pagesTest Paper Trigonometric Functions and Equations PDFkaushalshah28598No ratings yet

- Pre-Admission Interview Slip TemplateDocument1 pagePre-Admission Interview Slip TemplateLeaniel SilvaNo ratings yet

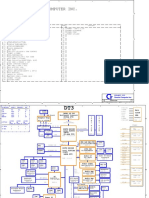

- LCD LG (M17,1917S-BNN E)Document34 pagesLCD LG (M17,1917S-BNN E)Ion IonutNo ratings yet

- 19bcd7246 Assignment2 L27+L28+L31+L32Document7 pages19bcd7246 Assignment2 L27+L28+L31+L32Sriharshitha DeepalaNo ratings yet

- Atoms and MoleculesDocument4 pagesAtoms and MoleculesShwetaNo ratings yet

- Acer Aspire 1710 (Quanta DT3) PDFDocument35 pagesAcer Aspire 1710 (Quanta DT3) PDFMustafa AkanNo ratings yet

- Ryan Ashby DickinsonDocument2 pagesRyan Ashby Dickinsonapi-347999772No ratings yet

- CLASS 10 CH-1 ECO DEVELOPMENT Question AnswersDocument8 pagesCLASS 10 CH-1 ECO DEVELOPMENT Question AnswersDoonites DelhiNo ratings yet

- Part IIDocument281 pagesPart IILeng SovannarithNo ratings yet

- hts336555 Philips Manual PDFDocument35 pageshts336555 Philips Manual PDFSalomão SouzaNo ratings yet

- UntitledDocument1 pageUntitledMoizur RahmanNo ratings yet

- Castro DW 32Document3 pagesCastro DW 32Jeetu GosaiNo ratings yet

- Z22 Double-Suction Axially-Split Single-Stage Centrifugal PumpDocument2 pagesZ22 Double-Suction Axially-Split Single-Stage Centrifugal Pumpmartín_suárez_110% (1)

- Scope of WorkDocument4 pagesScope of WorkMathivanan AnbazhaganNo ratings yet

- Media Shout 2.0 User GuideDocument106 pagesMedia Shout 2.0 User GuideGlenn MartinNo ratings yet

- Domestic Water-Supply - TheoryDocument19 pagesDomestic Water-Supply - Theoryyarzar17No ratings yet

- Ada4891 1 - 4891 2 - 4891 3 - 4891 4Document24 pagesAda4891 1 - 4891 2 - 4891 3 - 4891 4dsotmNo ratings yet