Professional Documents

Culture Documents

ASTM E18 (2019) - Part2

Uploaded by

david4231993Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM E18 (2019) - Part2

Uploaded by

david4231993Copyright:

Available Formats

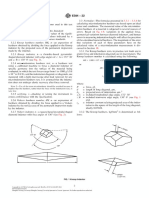

E18 − 19

A883 Test Method for Ferrimagnetic Resonance Linewidth ISO/IEC 17011 Conformity Assessment—General Require-

and Gyromagnetic Ratio of Nonmetallic Magnetic Mate- ments for Accreditation Bodies Accrediting Conformity

rials Assessment Bodies5

A956 Test Method for Leeb Hardness Testing of Steel ISO/IEC 17025 General Requirements for the Competence

Products of Testing and Calibration Laboratories5

A1038 Test Method for Portable Hardness Testing by the 2.4 Society of Automotive Engineers (SAE) Standard:

Ultrasonic Contact Impedance Method SAE J417 Hardness Tests and Hardness Number Conver-

B19 Specification for Cartridge Brass Sheet, Strip, Plate, sions6

Bar, and Disks

B36/B36M Specification for Brass Plate, Sheet, Strip, And 3. Terminology and Equations

Rolled Bar 3.1 Definitions:

B96/B96M Specification for Copper-Silicon Alloy Plate, 3.1.1 calibration—determination of the values of the sig-

Sheet, Strip, and Rolled Bar for General Purposes and nificant parameters by comparison with values indicated by a

Pressure Vessels reference instrument or by a set of reference standards.

B103/B103M Specification for Phosphor Bronze Plate, 3.1.2 standardization—to bring in conformance to a known

Sheet, Strip, and Rolled Bar standard through verification or calibration.

B121/B121M Specification for Leaded Brass Plate, Sheet,

Strip, and Rolled Bar 3.1.3 verification—checking or testing to assure confor-

B122/B122M Specification for Copper-Nickel-Tin Alloy, mance with the specification.

Copper-Nickel-Zinc Alloy (Nickel Silver), and Copper- 3.1.4 Rockwell hardness test—an indentation hardness test

Nickel Alloy Plate, Sheet, Strip, and Rolled Bar using a verified machine to force a diamond spheroconical

B130 Specification for Commercial Bronze Strip for Bullet indenter or tungsten carbide (or steel) ball indenter, under

Jackets specified conditions, into the surface of the material under test,

B134/B134M Specification for Brass Wire and to measure the difference in depth of the indentation as the

B152/B152M Specification for Copper Sheet, Strip, Plate, force on the indenter is increased from a specified preliminary

and Rolled Bar test force to a specified total test force and then returned to the

B370 Specification for Copper Sheet and Strip for Building preliminary test force.

Construction 3.1.5 Rockwell superficial hardness test—same as the Rock-

B647 Test Method for Indentation Hardness of Aluminum well hardness test except that smaller preliminary and total test

Alloys by Means of a Webster Hardness Gage forces are used with a shorter depth scale.

E29 Practice for Using Significant Digits in Test Data to 3.1.6 Rockwell hardness number—a number derived from

Determine Conformance with Specifications the net increase in the depth of indentation as the force on an

E74 Practices for Calibration and Verification for Force- indenter is increased from a specified preliminary test force to

Measuring Instruments a specified total test force and then returned to the preliminary

E92 Test Methods for Vickers Hardness and Knoop Hard- test force.

ness of Metallic Materials

E110 Test Method for Rockwell and Brinell Hardness of 3.1.7 Rockwell hardness machine—a machine capable of

Metallic Materials by Portable Hardness Testers performing a Rockwell hardness test and/or a Rockwell super-

E140 Hardness Conversion Tables for Metals Relationship ficial hardness test and displaying the resulting Rockwell

Among Brinell Hardness, Vickers Hardness, Rockwell hardness number.

Hardness, Superficial Hardness, Knoop Hardness, Sclero- 3.1.7.1 Rockwell hardness testing machine—a Rockwell

scope Hardness, and Leeb Hardness hardness machine used for general testing purposes.

E384 Test Method for Microindentation Hardness of Mate- 3.1.7.2 Rockwell hardness standardizing machine—a Rock-

rials well hardness machine used for the standardization of Rock-

E691 Practice for Conducting an Interlaboratory Study to well hardness indenters, and for the standardization of Rock-

Determine the Precision of a Test Method well hardness test blocks. The standardizing machine differs

2.2 American Bearings Manufacturer Association Stan- from a regular Rockwell hardness testing machine by having

dard: tighter tolerances on certain parameters.

ABMA 10-1989 Metal Balls4 3.1.7.3 portable Rockwell hardness testing machine—a

2.3 ISO Standards: Rockwell hardness testing machine that is designed to be

ISO 6508-1 Metallic Materials—Rockwell Hardness Test— transported, carried, set up, and operated by the users, and that

Part 1: Test Method (scales A, B, C, D, E, F, G, H, K, N, measures Rockwell hardness by the Rockwell indentation

T)5 hardness test principle.

3.1.7.4 movable Rockwell hardness testing machine—a

Rockwell hardness testing machine that is designed to be

4

Available from American Bearing Manufacturers Association (ABMA), 2025

M Street, NW, Suite 800, Washington, DC 20036.

5 6

Available from American National Standards Institute (ANSI), 25 W. 43rd St., Available from Society of Automotive Engineers (SAE), 400 Commonwealth

4th Floor, New York, NY 10036, http://www.ansi.org. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright ASTM International

Provided by IHS Markit under license with ASTM

2

No reproduction or networking permitted without license from IHS

You might also like

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Determination of the Mechanical and Technological Properties of MetalsFrom EverandDetermination of the Mechanical and Technological Properties of MetalsNo ratings yet

- Astm E18 Pdqv6897Document14 pagesAstm E18 Pdqv6897Nayth Andres GalazNo ratings yet

- Astm E18Document38 pagesAstm E18Danish HandaNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument38 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForochableNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument38 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForRajan SteeveNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument38 pagesRockwell Hardness of Metallic Materials: Standard Test Methods Foramit84indNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument38 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForRafael Tournier VianaNo ratings yet

- E18 Rockwell Hardness PDFDocument22 pagesE18 Rockwell Hardness PDFAna Laura GonzálezNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument37 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForCristian DíazNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument37 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForOscar RincónNo ratings yet

- Astm E-18Document38 pagesAstm E-18Kiran100% (1)

- E384.3173 Esp 1 5Document38 pagesE384.3173 Esp 1 5Mariela BelénNo ratings yet

- ASTM E18-02 Standar Test Methods For Rockwell HasdnessDocument15 pagesASTM E18-02 Standar Test Methods For Rockwell HasdnessCarlos Raul Caballero LeonNo ratings yet

- Silicon Nitride Bearing Balls: Standard Specification ForDocument8 pagesSilicon Nitride Bearing Balls: Standard Specification ForkrutikNo ratings yet

- Astm E-18 PDFDocument22 pagesAstm E-18 PDFEnriqueVe100% (2)

- B294-10 Standard Test Method For Hardness Testing of Cemented Carbides PDFDocument8 pagesB294-10 Standard Test Method For Hardness Testing of Cemented Carbides PDFdiego rodriguezNo ratings yet

- 06.e 18 ¿ 03 - Rte4 PDFDocument22 pages06.e 18 ¿ 03 - Rte4 PDFWladimir Franz Rodríguez SaloméNo ratings yet

- E 18 - 02 - Rte4ltay PDFDocument16 pagesE 18 - 02 - Rte4ltay PDFvinoth kumar SanthanamNo ratings yet

- ASTM Hardness Standards DescriptionDocument3 pagesASTM Hardness Standards DescriptionSales HBS SolutionsNo ratings yet

- Macro-Rockwell Hardness Testing of Metallic Materials: Standard Test Method ForDocument6 pagesMacro-Rockwell Hardness Testing of Metallic Materials: Standard Test Method FortuanNo ratings yet

- ASME Secc II A SA47 Specif For Ferritic Malleable Iron CastiDocument8 pagesASME Secc II A SA47 Specif For Ferritic Malleable Iron CastiEduardo ArrietaNo ratings yet

- Application Note Hardness TestingDocument12 pagesApplication Note Hardness TestingJonathan FloresNo ratings yet

- Lndian Standard: Plastics - Methods of TestingDocument9 pagesLndian Standard: Plastics - Methods of Testinggini associatesNo ratings yet

- Standard Test Method For Vickers Indentation Hardness of Advanced CeramicsDocument8 pagesStandard Test Method For Vickers Indentation Hardness of Advanced CeramicsJosué Licona MármolNo ratings yet

- E448 1578226-1 PDFDocument5 pagesE448 1578226-1 PDFEmmanuel Garces VazquezNo ratings yet

- E448-82 (2008) Standard Practice For Scleroscope Hardness Testing of Metallic MaterialsDocument5 pagesE448-82 (2008) Standard Practice For Scleroscope Hardness Testing of Metallic MaterialsislamakthamNo ratings yet

- DS 1 VOL 3 4TH Parte Dos PDFDocument8 pagesDS 1 VOL 3 4TH Parte Dos PDFsushilNo ratings yet

- Vickers Indentation Hardness of Advanced Ceramics: Standard Test Method ForDocument8 pagesVickers Indentation Hardness of Advanced Ceramics: Standard Test Method ForAndres Cantillo S.No ratings yet

- B277Document2 pagesB277eliiiiiiNo ratings yet

- Astm EDocument32 pagesAstm EE Hammam El MissiryNo ratings yet

- Astm E448-82 R02 E02 PDFDocument5 pagesAstm E448-82 R02 E02 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- ASTM A1038 Hardness UltrsonicDocument7 pagesASTM A1038 Hardness Ultrsonicjohnrojas950% (2)

- Sa 47Document8 pagesSa 47daniel pacheco do nascimento PachecoNo ratings yet

- Ferritic Malleable Iron Castings: Standard Specification ForDocument5 pagesFerritic Malleable Iron Castings: Standard Specification ForAdán Cogley CantoNo ratings yet

- Vickers Indentation Hardness of Advanced Ceramics: Standard Test Method ForDocument8 pagesVickers Indentation Hardness of Advanced Ceramics: Standard Test Method ForRedV1rusNo ratings yet

- Knoop and Vickers Hardness of Materials: Standard Test Method ForDocument42 pagesKnoop and Vickers Hardness of Materials: Standard Test Method ForCaroline SosaNo ratings yet

- A 327Document3 pagesA 327Rajnish SrivastavaNo ratings yet

- Ferritic Malleable Iron Castings: Standard Specification ForDocument5 pagesFerritic Malleable Iron Castings: Standard Specification ForBorza DorinNo ratings yet

- Astm d5873 Esclerometro PDFDocument4 pagesAstm d5873 Esclerometro PDFJulio Oyola Salvador100% (1)

- Pre ASTM E18-20Document5 pagesPre ASTM E18-20Ranga100% (1)

- IS16651 2017 SS - SteelDocument18 pagesIS16651 2017 SS - Steelmanager.nhai.cochin2No ratings yet

- Nickel-Copper Alloy Rod, Bar, and Wire: Standard Specification ForDocument9 pagesNickel-Copper Alloy Rod, Bar, and Wire: Standard Specification Forkrishnamoorthy SrinivasanNo ratings yet

- Astm A427-74 (1996)Document2 pagesAstm A427-74 (1996)FeteneNo ratings yet

- Ferritic Malleable Iron Castings: Standard Specification ForDocument5 pagesFerritic Malleable Iron Castings: Standard Specification Forrohit kumarNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument39 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForJones Pereira NetoNo ratings yet

- ASTM F606 - 05 Fastener Test MethodsDocument15 pagesASTM F606 - 05 Fastener Test MethodsFernado RinconNo ratings yet

- Asme Section Ii B SB-42Document10 pagesAsme Section Ii B SB-42Monica SuarezNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument39 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForSandipGangurdeNo ratings yet

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument39 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForrugthierNo ratings yet

- F3122 14Document6 pagesF3122 14senthilNo ratings yet

- ASTM E384-11e1Document43 pagesASTM E384-11e1vangoetheNo ratings yet

- Knoop and Vickers Hardness of Materials: Standard Test Method ForDocument43 pagesKnoop and Vickers Hardness of Materials: Standard Test Method ForPaulo MoraisNo ratings yet

- Astm A47 - A47m 99 PDFDocument5 pagesAstm A47 - A47m 99 PDFJavier Ricardo Romero BohorquezNo ratings yet

- Analisis Metalografico ASTM E3-11Document42 pagesAnalisis Metalografico ASTM E3-11mechis0w8No ratings yet

- Astm F2924 - 14Document9 pagesAstm F2924 - 14SergiyNo ratings yet

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- ASTM E18 (2019) - Part36Document1 pageASTM E18 (2019) - Part36david4231993No ratings yet

- ASTM E384 (2022) - Part2Document1 pageASTM E384 (2022) - Part2david4231993No ratings yet

- ASTM E384 (2022) - Part6Document1 pageASTM E384 (2022) - Part6david4231993No ratings yet

- ASTM E18 (2019) - Part39Document1 pageASTM E18 (2019) - Part39david4231993No ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- ASTM E384 (2022) - Part1Document1 pageASTM E384 (2022) - Part1david4231993No ratings yet

- ASTM E18 (2019) - Part27Document1 pageASTM E18 (2019) - Part27david4231993No ratings yet

- ASTM E18 (2019) - Part33Document1 pageASTM E18 (2019) - Part33david4231993No ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- ASTM E18 (2019) - Part29Document1 pageASTM E18 (2019) - Part29david4231993No ratings yet

- ASTM E18 (2019) - Part29Document1 pageASTM E18 (2019) - Part29david4231993No ratings yet

- ASTM E18 (2019) - Part27Document1 pageASTM E18 (2019) - Part27david4231993No ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- ASTM E18 (2019) - Part11Document1 pageASTM E18 (2019) - Part11david4231993No ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- ASTM E18 (2019) - Part20Document1 pageASTM E18 (2019) - Part20david4231993No ratings yet

- ASTM E18 (2019) - Part3Document1 pageASTM E18 (2019) - Part3david4231993No ratings yet

- Pupc 2022 ExamDocument7 pagesPupc 2022 ExamSrivatsa RameahNo ratings yet

- SNI 1727 2020 enDocument336 pagesSNI 1727 2020 enlisnzerNo ratings yet

- Ligand: HistoryDocument1 pageLigand: HistorySyimah UmarNo ratings yet

- Quick Start: Isothermal Titration Calorimetry (ITC) : MCAPN-2016-1Document5 pagesQuick Start: Isothermal Titration Calorimetry (ITC) : MCAPN-2016-1AliNo ratings yet

- Solar Swimming Pool HeatingDocument9 pagesSolar Swimming Pool HeatingAtmesh PoudyalNo ratings yet

- Shear Wall and Diagrid SystemDocument47 pagesShear Wall and Diagrid SystemAashi GuptaNo ratings yet

- Algebra 1 (Algebra - FM 2016)Document3 pagesAlgebra 1 (Algebra - FM 2016)Gayatri KaripayaNo ratings yet

- Design of Flanges Tongue Groove TypeDocument19 pagesDesign of Flanges Tongue Groove TypeJunaid MateenNo ratings yet

- Lesson Plan 3 ChemistryDocument10 pagesLesson Plan 3 ChemistryLeslayy CelizNo ratings yet

- Apollon 1Document42 pagesApollon 1Munteanu Maria-MagdalenaNo ratings yet

- CHAPTER 3 - Crystalline Structure of SolidsDocument63 pagesCHAPTER 3 - Crystalline Structure of SolidsAlex HunterNo ratings yet

- 2015 16Document34 pages2015 16bvniaptanveshikaNo ratings yet

- P-Block Elements Sheet Final Send 1639993272187Document38 pagesP-Block Elements Sheet Final Send 1639993272187Melon KingNo ratings yet

- Neet 2023 Question Paper h2 - EAGTK0FDocument42 pagesNeet 2023 Question Paper h2 - EAGTK0Fbishnuprasadmohapatra01No ratings yet

- Renasys™ Ez Plus: Smith&nephewDocument21 pagesRenasys™ Ez Plus: Smith&nephewBlanca Haydée Mesías Inostroza100% (1)

- Odi2-065r17m18j-Gq V2 DS 1-0-4Document4 pagesOdi2-065r17m18j-Gq V2 DS 1-0-4morten.eriksenNo ratings yet

- TDS Byk-1780 enDocument2 pagesTDS Byk-1780 enabhijit.home2022No ratings yet

- Updated Tables of MNBC 2020 Chapter 3Document6 pagesUpdated Tables of MNBC 2020 Chapter 3dsk50772No ratings yet

- Prilling TowerDocument5 pagesPrilling TowerChaudhry BrothersNo ratings yet

- BFT Catalogue 2012 SMDocument199 pagesBFT Catalogue 2012 SMnoufalmindster0% (1)

- Kinematics of CM 04 Material Time Derivatives PDFDocument4 pagesKinematics of CM 04 Material Time Derivatives PDFOgunfuye Samuel AbimbolaNo ratings yet

- MVP Scope and SequenceDocument28 pagesMVP Scope and SequenceMadhavi VangipurapuNo ratings yet

- RS 04Document5 pagesRS 04Essenam GOLINo ratings yet

- Tagore Engineering College Department of ECE: Unit Test - IIDocument1 pageTagore Engineering College Department of ECE: Unit Test - IIbhuvi2312No ratings yet

- Sugar Plant Specifications 5000 TCD-7500 TCDDocument104 pagesSugar Plant Specifications 5000 TCD-7500 TCDtsrinivasan508375% (4)

- ANZ MEGEN1 Quick Start Guide 139184-200505Document2 pagesANZ MEGEN1 Quick Start Guide 139184-200505林No ratings yet

- IBDP Yr1 Sem 1paper1Document3 pagesIBDP Yr1 Sem 1paper1RafiNo ratings yet

- Mechanical Engineering Principles, Bird and Ross, ISBN 9780415517850Document9 pagesMechanical Engineering Principles, Bird and Ross, ISBN 9780415517850Julius KipropNo ratings yet

- Cu ElectrofacetingDocument12 pagesCu ElectrofacetingClark ChenNo ratings yet

- Introduction To Fluid Mechanics and Properties of FluidsDocument27 pagesIntroduction To Fluid Mechanics and Properties of FluidsAyumi QuiomNo ratings yet