Professional Documents

Culture Documents

ASTM E18 (2019) - Part35

Uploaded by

david4231993Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM E18 (2019) - Part35

Uploaded by

david4231993Copyright:

Available Formats

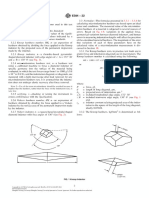

E18 − 19

the mean” of the hardness measurement values. This is reference test block value is traceable. This uncertainty con-

calculated as the standard deviation of the hardness values, tributes to the measurement uncertainty of hardness machines

divided by the square-root of the number of measurements as: calibrated or verified with the reference test blocks. Note that

STDEV~ H T1 , H T2 , …, H Tn! the uncertainty reported on reference test block certificates is

u Rep& NU 5 (X2.8) typically stated as an expanded uncertainty. As indicated by Eq

=n T X2.4, the expanded uncertainty is calculated by multiplying the

where HT1, HT2, ..., HTn are the nT measurement values. standard uncertainty by a coverage factor (often 2). This

analysis uses the standard uncertainty and not the expanded

X2.5.4 Uncertainty Due to Lack of Reproducibility uncertainty value. Thus, the uncertainty value due to the

(uReprod)—The day-to-day variation in the performance of the uncertainty in the certified value of the reference test block

hardness machine is known as its level of reproducibility. usually may be calculated as:

Variations such as different machine operators and changes in

the test environment often influence the performance of the U RefBlk

u RefBlk 5 (X2.11)

hardness machine. The level of reproducibility is best deter- k RefBlk

mined by monitoring the performance of the hardness machine where URefBlk is the reported expanded uncertainty of the

over an extended period of time during which the hardness certified value of the reference test block, and kRefBlk is the

machine is subjected to the extremes of variations in the testing coverage factor used to calculate the uncertainty in the certified

variables. It is very important that the test machine be in value of the reference standard (usually 2).

control during the assessment of reproducibility. If the machine

is in need of maintenance or is operated incorrectly, the lack of X2.5.8 Measurement Bias (B)—The measurement bias is

reproducibility will be over estimated. the difference between the hardness measurement values as

displayed by the hardness machine and the “true” hardness of

X2.5.5 An assessment of a hardness machine’s lack of a material. The measurement bias B may be estimated by the

reproducibility should be based on periodic monitoring mea- “error” determined as part of the indirect verification as:

surements of the hardness machine, such as daily verification

H2H

B5H H (X2.12)

measurements made on the same test block over time. The RefBlk

uncertainty contribution may be estimated by the standard where H̄ is the mean hardness value as measured by the

deviation of the average of each set of monitoring values, as: hardness machine during the indirect verification, and H̄RefBlk is

u Reprod 5 STDEV~ M 1 , M 2 , …, M n ! (X2.9) the certified average hardness value of the reference test block

standard used for the indirect verification.

where M1, M2, ..., Mn are individual averages of each of the

n sets of multiple monitoring measurement values. X2.6 Procedure for Calculating Uncertainty: Indirect

NOTE X2.7—The uncertainty contribution due to the lack of Verification

reproducibility, as calculated in Eq X2.10, also includes a contribution due

to the machine’s lack of repeatability and the non-uniformity of the X2.6.1 As part of an indirect verification, the “error” of the

monitoring test block; however, these contributions are based on the hardness machine is determined from the average value of

average of multiple measurements and should not significantly over-

measurements made on a reference test block (see 3.2.2). This

estimate the reproducibility uncertainty.

value provides an indication of how well the hardness machine

X2.5.6 Uncertainty Due to the Resolution of the Hardness can measure the “true” hardness of a material. Since there is

Measurement Display (uResol)—The finite resolution of the always uncertainty in a hardness measurement, it follows that

hardness value display prevents the hardness machine from there must be uncertainty in the determination of the average

providing an absolutely accurate hardness value. However, the value of the measurements, and thus the determination of the

influence of the display resolution on the measurement uncer- machine “error.” This section provides a procedure that can be

tainty is usually only significant when the hardness display used, for example by a field calibration agency, to estimate the

resolution is no better than 0.5 Rockwell hardness units, such uncertainty UMach in the measurement “error” of the hardness

as for some dial displays. The uncertainty contribution uResol, machine determined as the difference between the average of

due to the influence of the display resolution, may be described the measurement values and the certified value of the reference

by a rectangular distribution and estimated as: block used for the verification.

r/2 r X2.6.2 The contributions to the standard uncertainty of the

u Resol 5 5 (X2.10)

=3 =12 measurement “error,” uMach, are (1) uRep& NU (Ref. Block), the

uncertainty due to the lack of repeatability of the hardness

where r is the resolution limit that a hardness value can be machine combined with the uncertainty due to the non-

estimated from the measurement display in Rockwell hardness uniformity in the reference test block (Eq X2.9), which is

units. determined from the hardness measurements made on a refer-

X2.5.7 Standard Uncertainty in the Certified Average Hard- ence test block to determine the “error” of the hardness

ness Value of the Reference Test Block (uRefBlk)—Reference test machine, (2) uResol, the uncertainty due to the resolution of the

blocks provide the link to the Rockwell standard to which hardness machine measurement display (Eq X2.11), and (3)

traceability is claimed. The certificate accompanying reference uRefBlk, the standard uncertainty in the certified value of the

test blocks should provide an uncertainty in the stated certified reference test block (Eq X2.12). The notation (Ref. Block) is

value, and should state to which Rockwell standard the added to the term uRep& NU to clarify that the uncertainty is

Copyright ASTM International

Provided by IHS Markit under license with ASTM

35

No reproduction or networking permitted without license from IHS

You might also like

- MsaDocument25 pagesMsaMonu SharmaNo ratings yet

- Technical Sheet: Uncertainty of Test ResultDocument6 pagesTechnical Sheet: Uncertainty of Test ResultDatHoNo ratings yet

- Qa - 1 MCQDocument11 pagesQa - 1 MCQKeyur Popat67% (3)

- T-Test For Correlated SampleDocument13 pagesT-Test For Correlated SampleElijah LiuNo ratings yet

- Solution Manual Measurement and Instrume PDFDocument14 pagesSolution Manual Measurement and Instrume PDFHamza YousafNo ratings yet

- (Springer Series in Statistics) Sadanori Konishi, Genshiro Kitagawa - Information Criteria and Statistical Modeling (2008, Springer) PDFDocument282 pages(Springer Series in Statistics) Sadanori Konishi, Genshiro Kitagawa - Information Criteria and Statistical Modeling (2008, Springer) PDFNurdiAfribi100% (2)

- Calculation of Measurement Uncertainty in Environnemental Laboratories PDFDocument55 pagesCalculation of Measurement Uncertainty in Environnemental Laboratories PDFThusith WijayawardenaNo ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- ASTM E18 (2019) - Part36Document1 pageASTM E18 (2019) - Part36david4231993No ratings yet

- ASTM E18 (2019) - Part33Document1 pageASTM E18 (2019) - Part33david4231993No ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- Anova GumDocument6 pagesAnova GumGLORIA JIMENEZNo ratings yet

- ASTM E18 (2019) - Part4Document1 pageASTM E18 (2019) - Part4david4231993No ratings yet

- On The Uncertainty in The Immunity Standards of The IEC 61000-4-x SeriesDocument4 pagesOn The Uncertainty in The Immunity Standards of The IEC 61000-4-x SeriesS.V.SubrahmanyamNo ratings yet

- ASTM E18 (2019) - Part37Document1 pageASTM E18 (2019) - Part37david4231993No ratings yet

- Hardness Uncertainty EADS HRC 5 IndentsDocument11 pagesHardness Uncertainty EADS HRC 5 IndentsPinto CarlosNo ratings yet

- EUROLAB Cook Book - Doc No 8 Determination of Conformance - Rev. 2017Document3 pagesEUROLAB Cook Book - Doc No 8 Determination of Conformance - Rev. 2017Pataki SandorNo ratings yet

- EMCH 361 - Mechanical Engineering Lab I: Linear Measurements, Uncertainty, Probability and Error Propagation ObjectivesDocument4 pagesEMCH 361 - Mechanical Engineering Lab I: Linear Measurements, Uncertainty, Probability and Error Propagation ObjectivesIcy45No ratings yet

- Vickers Calibration DetailsDocument1 pageVickers Calibration DetailstomychalilNo ratings yet

- Chapter 15 of Dar Al Handasah Manual Concrete QC 1668530999Document13 pagesChapter 15 of Dar Al Handasah Manual Concrete QC 1668530999Eslam EmamNo ratings yet

- EA 10 16rev00 PDFDocument25 pagesEA 10 16rev00 PDFSaraswantoNo ratings yet

- Experimental ErrorDocument7 pagesExperimental ErrorKatlego MogotsakgotlaNo ratings yet

- Application of ISO 5725-1-5725-6 For The Validation of Ultrasonic TestingDocument6 pagesApplication of ISO 5725-1-5725-6 For The Validation of Ultrasonic TestingGustavo SánchezNo ratings yet

- CookBook 15 Assessment Trueness Measurement Procedure by Use of RM - 10-2018 PDFDocument3 pagesCookBook 15 Assessment Trueness Measurement Procedure by Use of RM - 10-2018 PDFJacek SobczykNo ratings yet

- E319-85 (2014) Standard Practice For The Evaluation of Single-Pan Mechanical BalancesDocument9 pagesE319-85 (2014) Standard Practice For The Evaluation of Single-Pan Mechanical BalancesAhmed AlzubaidiNo ratings yet

- 4 - St4nd4rd T3st M3th0d f0r Pull0ut Str3ngth of H4rd3n3d Co0ncr3teDocument1 page4 - St4nd4rd T3st M3th0d f0r Pull0ut Str3ngth of H4rd3n3d Co0ncr3teJOSE CANTERONo ratings yet

- Quality Data Statistics (QDS) (9) : Microcomputer Operator's ManualDocument26 pagesQuality Data Statistics (QDS) (9) : Microcomputer Operator's ManualmikadoturkNo ratings yet

- ASTM E384 (2022) - Part10Document1 pageASTM E384 (2022) - Part10david4231993No ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- D5682 PDFDocument4 pagesD5682 PDFEmilio HipolaNo ratings yet

- EEG383 Measurement - Chapter 2 - Characteristics of Measuring InstrumentsDocument26 pagesEEG383 Measurement - Chapter 2 - Characteristics of Measuring Instrumentsايهاب غزالة100% (1)

- Electrical Measurement and InstrumentDocument72 pagesElectrical Measurement and InstrumentDũng Nguyễn ViệtNo ratings yet

- PresentationDocument13 pagesPresentationabhishekNo ratings yet

- ASTM E18 (2019) - Part14Document1 pageASTM E18 (2019) - Part14david4231993No ratings yet

- Is 1828-2 (Iso 7500-2) - 10Document1 pageIs 1828-2 (Iso 7500-2) - 10Svapnesh ParikhNo ratings yet

- Computers and Structures: D. Degrauwe, G. de Roeck, G. LombaertDocument8 pagesComputers and Structures: D. Degrauwe, G. de Roeck, G. LombaertMahmoud SamiNo ratings yet

- Chapter Two Static XtcsDocument26 pagesChapter Two Static XtcsAgirma girmaNo ratings yet

- XO PS41282 Oxsas Measurement Uncertainty Material Conformance ProbabilityDocument4 pagesXO PS41282 Oxsas Measurement Uncertainty Material Conformance ProbabilitySantiago JacoboNo ratings yet

- Statistics and MeasurementDocument74 pagesStatistics and MeasurementAthinaNo ratings yet

- ASTM E384 (2022) - Part8Document1 pageASTM E384 (2022) - Part8david4231993No ratings yet

- Computer-Based System For Calibration of Temperature Transmitter Using RTDDocument5 pagesComputer-Based System For Calibration of Temperature Transmitter Using RTDVignesh RamakrishnanNo ratings yet

- Minimizing Risk in Instrument CalibrationDocument8 pagesMinimizing Risk in Instrument CalibrationfaheemqcNo ratings yet

- ASTM E18 (2019) - Part13Document1 pageASTM E18 (2019) - Part13david4231993No ratings yet

- Imeko TC3 2017 016Document5 pagesImeko TC3 2017 016boborg8792No ratings yet

- Alwash2017 PDFDocument10 pagesAlwash2017 PDFp.c19.22No ratings yet

- Traceability of Hardness Measurements: (UKAS Publication Ref: LAB 25)Document5 pagesTraceability of Hardness Measurements: (UKAS Publication Ref: LAB 25)gizemNo ratings yet

- 4 How To Estimate Parameters of A Weibull DistributionDocument6 pages4 How To Estimate Parameters of A Weibull DistributionCesar ChpNo ratings yet

- Chapter 4 - Inspection and Sampling PlansDocument22 pagesChapter 4 - Inspection and Sampling Plansrachel greyNo ratings yet

- Incertidumbre Synek 2006 SesgoDocument11 pagesIncertidumbre Synek 2006 SesgoChuckPeter MartinorrisNo ratings yet

- ASTM E18 (2019) - Part9Document1 pageASTM E18 (2019) - Part9david4231993No ratings yet

- Chapter 2 I&PCDocument78 pagesChapter 2 I&PCshmyeNo ratings yet

- 3.3 Area MeasurementDocument1 page3.3 Area Measurementnate anantathatNo ratings yet

- Is 1828-2 (Iso 7500-2) - 8Document1 pageIs 1828-2 (Iso 7500-2) - 8Svapnesh ParikhNo ratings yet

- Calculation of Measurement Uncertainty For Stiffness Modulus of Asphalt MixtureDocument9 pagesCalculation of Measurement Uncertainty For Stiffness Modulus of Asphalt Mixture100livNo ratings yet

- The Uncertainty Evaluation of NPL'S Hardness Facility: G.C. Stanbury and F.A. DavisDocument6 pagesThe Uncertainty Evaluation of NPL'S Hardness Facility: G.C. Stanbury and F.A. DavisOmar OdNo ratings yet

- FragilityDocument10 pagesFragilitypriyanaNo ratings yet

- Exp 11 and 12 Rockwell Hardness Testing and Universal Testing MachineDocument5 pagesExp 11 and 12 Rockwell Hardness Testing and Universal Testing MachineAhsan FarooqNo ratings yet

- Uncertainties and CFD Code Validation: H. W. ColemanDocument9 pagesUncertainties and CFD Code Validation: H. W. ColemanLuis Felipe Gutierrez MarcantoniNo ratings yet

- t22 PDFDocument18 pagest22 PDFRaunak TimilsinaNo ratings yet

- Experimental Results Obtained in The Vibrating Intrinsic Reverberation ChamberDocument6 pagesExperimental Results Obtained in The Vibrating Intrinsic Reverberation Chamberjohn BronsonNo ratings yet

- Dealing with Data: The Commonwealth and International Library: Physics DivisionFrom EverandDealing with Data: The Commonwealth and International Library: Physics DivisionRating: 5 out of 5 stars5/5 (1)

- ASTM E384 (2022) - Part6Document1 pageASTM E384 (2022) - Part6david4231993No ratings yet

- ASTM E384 (2022) - Part2Document1 pageASTM E384 (2022) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part39Document1 pageASTM E18 (2019) - Part39david4231993No ratings yet

- ASTM E18 (2019) - Part29Document1 pageASTM E18 (2019) - Part29david4231993No ratings yet

- ASTM E384 (2022) - Part1Document1 pageASTM E384 (2022) - Part1david4231993No ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- ASTM E18 (2019) - Part27Document1 pageASTM E18 (2019) - Part27david4231993No ratings yet

- ASTM E18 (2019) - Part2Document1 pageASTM E18 (2019) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part11Document1 pageASTM E18 (2019) - Part11david4231993No ratings yet

- ASTM E18 (2019) - Part20Document1 pageASTM E18 (2019) - Part20david4231993No ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- ASTM E18 (2019) - Part3Document1 pageASTM E18 (2019) - Part3david4231993No ratings yet

- Data Pre Test Post TestDocument4 pagesData Pre Test Post TestELI KUSUMANo ratings yet

- Summative ExamDocument2 pagesSummative ExamAndrilyn Bulanon100% (1)

- Baio Bayesian Health Economics PDFDocument67 pagesBaio Bayesian Health Economics PDFferNo ratings yet

- Random Variable: Chapter 3: Probability DistributionDocument11 pagesRandom Variable: Chapter 3: Probability DistributioncharliewernerNo ratings yet

- Mid-Semester Test With Solution 2018Document7 pagesMid-Semester Test With Solution 2018madhavNo ratings yet

- DAILY TEST Statistics+probabilityDocument4 pagesDAILY TEST Statistics+probabilityDujdjdidmdn JajjsNo ratings yet

- Foundations of StatisticsDocument10 pagesFoundations of Statisticslodderig4466No ratings yet

- 03 ProbabilityDocument12 pages03 ProbabilityJoseNo ratings yet

- StatisticsDocument33 pagesStatisticsdlabdon0310No ratings yet

- XSTKDocument4 pagesXSTKNam NguyenNo ratings yet

- Queueing Theory and Stochastic Teletraffic Models - Moshe ZukermanDocument217 pagesQueueing Theory and Stochastic Teletraffic Models - Moshe ZukermanwoodksdNo ratings yet

- AU1 External Audit - Module 6Document58 pagesAU1 External Audit - Module 6umgilkinNo ratings yet

- 1 StatDocument30 pages1 StatbutardoandreanicoleNo ratings yet

- StudentDocument15 pagesStudentVia AbadNo ratings yet

- Lecture 1Document22 pagesLecture 1Jay MenonNo ratings yet

- Essential Statistics 2nd Edition Gould Test Bank Full Chapter PDFDocument28 pagesEssential Statistics 2nd Edition Gould Test Bank Full Chapter PDFTonyDonaldsonjmdye100% (13)

- ZipfpreDocument4 pagesZipfpreBrian SwansonNo ratings yet

- Lecture 3 - Hypothesis TestingDocument20 pagesLecture 3 - Hypothesis TestingsulthanramizNo ratings yet

- Hypothesis TestingDocument210 pagesHypothesis TestingShreya50% (2)

- Megan Bryant Hw2Document14 pagesMegan Bryant Hw2meganNo ratings yet

- Practical - Week - 04.2 - Solution - ManualDocument10 pagesPractical - Week - 04.2 - Solution - Manualaman guptaNo ratings yet

- Ex. Sheet 3 - Sol.Document4 pagesEx. Sheet 3 - Sol.ebbamorkNo ratings yet

- 191HS42 - Probability & Statistics - Question Bank PDFDocument7 pages191HS42 - Probability & Statistics - Question Bank PDFKaleesNo ratings yet

- STAT-II Week EndDocument57 pagesSTAT-II Week Endsifan Mirkena100% (2)

- Unit-4 - Confidence Interval and CLTDocument29 pagesUnit-4 - Confidence Interval and CLTRohan PatelNo ratings yet

- Block 1Document42 pagesBlock 1dalkota motaNo ratings yet