Professional Documents

Culture Documents

Vickers Calibration Details

Uploaded by

tomychalilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vickers Calibration Details

Uploaded by

tomychalilCopyright:

Available Formats

E 92 – 82 (2003)e2

hardness using a test force or forces as specified by the user 20. Manufacture

with the test force applied for 12 s. 20.1 Each metal block to be standardized shall be not less

15.2.3 Vickers hardness testing machines shall be consid- than 1⁄4 in. (6 mm) in thickness.

ered verified if the mean diagonal for five hardness impressions 20.2 Each block shall be specially prepared and heat treated

meets the requirements of 17.2. to give the necessary homogeneity and stability of structure.

16. Procedure for Periodic Checks by the User 20.3 Each block, if of steel, shall be demagnetized by the

manufacturer and maintained demagnetized by the user.

16.1 Verification by the standardized test block method

20.4 The lower surface of the test block shall have a fine

(15.2.2) is too lengthy for daily use. Instead the following is

ground finish.

recommended:

20.5 The test (upper) surface shall be polished and free of

16.1.1 Make at least one routine check each day that the

scratches which would interfere with measurements of the

testing machine is used.

diagonals of the impression.

16.1.2 Before making the check, verify that the zero reading

of the measuring apparatus is correctly adjusted. 20.5.1 The mean surface roughness height rating shall not

16.1.3 Make at least five hardness readings on a standard- exceed 4 µin. (0.0001 mm) center line average.

ized hardness test block on the scale and at the hardness level 20.6 To ensure that no material is subsequently removed

at which the machine is being used. If the values fall within the from the test surface of the standardized test block, an official

range of the standardized hardness test block the machine may mark or the thickness at the time of calibration shall be marked

be regarded as satisfactory; if not the machine should be on the test surface to an accuracy of 60.005 in.(60.1 mm).

verified as described in 15.2.2.

21. Standardizing Procedure

17. Repeatability and Error 21.1 The standardized hardness test blocks shall be cali-

17.1 Repeatability: brated on a Vickers hardness testing machine verified in

17.1.1 For each standardized block, let d1, d2, ··· d5 be the accordance with the requirements of 13.1.1.

arithmetic means of the two diagonals of the indentations, 21.2 The mechanism that controls the application of force

arranged in increasing order of magnitude. should either:

17.1.2 The repeatability of the machine under the particular 21.2.1 Employ a device such as a spring to reduce the

verification conditions is expressed by the quantity d5 − d1. velocity of indentation of the indenter during the period of

17.2 Error: indentation, or

17.2.1 The error of the machine under the particular verifi- 21.2.2 Employ a device to maintain a constant velocity of

cation conditions is expressed by the quantity d̄ − d, where d̄ indentation of the indenter.

= (d1 + d2 + ··· d5)/5, and d is the reported mean diagonal of 21.3 The full test force shall be applied for 12 s.

impressions on the standardized hardness test block.

18. Assessment of Verification 22. Number of Indentations

18.1 Repeatability—The repeatability of the machine veri- 22.1 At least five and preferably ten randomly distributed

fied is considered satisfactory if it satisfies the conditions given indentations shall be made on each test block.

in Table 7.

18.2 Error—The mean diagonal for five impressions should 23. Measurement of the Diagonals of the Indentation

not differ from the mean diagonal corresponding to the Vickers 23.1 The illuminating system of the measuring microscope

hardness of the standardized test block by more than 2 % or 0.5 shall be adjusted to give uniform intensity over the field of

µm (0.0005 mm), whichever is greater. view and maximum contrast between the indentation and the

undistributed surface of the block.

C. CALIBRATION OF STANDARD HARDNESS TEST

23.2 The measuring microscope shall be graduated to read

BLOCKS FOR VICKERS HARDNESS MACHINES

0.001 mm with estimates made to the nearest 60.0002 mm.

19. Scope 23.3 The measuring microscope shall be checked by a stage

19.1 Part C covers the calibration of standardized hardness micrometer, or by other suitable means, to ensure that the

test blocks for the verification of Vickers hardness testing difference between readings corresponding to any two divi-

machines as described in Part B. sions of the instrument is correct within 6 0.0005 mm.

23.4 It is recommended that each indentation be measured

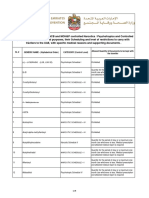

TABLE 7 Repeatability of Machines by two observers.

Range of

The Repeatability of

Standardized Examples of Equivalents in

Hardness of Test

the Machine Should

Hardness Units

24. Repeatability

be Less Than:

Blocks 24.1 Let d1, d2,··· dn be the mean values of the measured

100 to 240, incl 4 % of d A,B 8 at 100 HV; 16 at 200 HV diagonals as determined by one observer, arranged in increas-

Over 240 to 600, incl 3 % of d A,B 18 at 300 HV; 36 at 600 HV ing order of magnitude.

Over 600 2 % of d A,B 28 at 700 HV

A

24.2 The repeatability of the hardness readings on the block

d = (d1 + d2 + ... + d5)/5.

B

In all cases the repeatability is the percentage given or 1 µm (0.001 mm), is defined as (d10 − d1), when ten readings have been made or

whichever is the greater. 1.32 (d5 − d1) when five readings are taken on the block.

You might also like

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- ASTM E18 (2019)_Part15Document1 pageASTM E18 (2019)_Part15david4231993No ratings yet

- Instruction Manual: Hardness TesterDocument22 pagesInstruction Manual: Hardness TesterAziz OstencoNo ratings yet

- ASTM CRD - c164 PDFDocument4 pagesASTM CRD - c164 PDFAdnan Hariadi BustamiNo ratings yet

- ASTM E18 (2019)_Part14Document1 pageASTM E18 (2019)_Part14david4231993No ratings yet

- E13 Test Requirements For Rotating Machines E13Document5 pagesE13 Test Requirements For Rotating Machines E13Anshul NautiyalNo ratings yet

- Ur E13rev3corr1Document6 pagesUr E13rev3corr1Maan MrabetNo ratings yet

- Simpson Mold Hardness TesterDocument1 pageSimpson Mold Hardness TesterSaif UllahNo ratings yet

- Traceability of Hardness Measurements: (UKAS Publication Ref: LAB 25)Document5 pagesTraceability of Hardness Measurements: (UKAS Publication Ref: LAB 25)gizemNo ratings yet

- 7.4 Eddy Current Testing - 2015R1 - SNS NEWDocument4 pages7.4 Eddy Current Testing - 2015R1 - SNS NEWsaenal rapi100% (1)

- Ultrasonic Testing Procedure for WeldsDocument19 pagesUltrasonic Testing Procedure for Weldsparag wadekarNo ratings yet

- Verifying loads applied by creep testing machinesDocument1 pageVerifying loads applied by creep testing machinesSvapnesh ParikhNo ratings yet

- ASTM D1005-95 (Measurement of Dry-Film Thickness)Document3 pagesASTM D1005-95 (Measurement of Dry-Film Thickness)Daison PaulNo ratings yet

- Standard Test Method For Vickers Indentation Hardness of Advanced CeramicsDocument8 pagesStandard Test Method For Vickers Indentation Hardness of Advanced CeramicsJosué Licona MármolNo ratings yet

- ASTM E18 (2019)_Part35Document1 pageASTM E18 (2019)_Part35david4231993No ratings yet

- ASTM E384 (2022)_Part7Document1 pageASTM E384 (2022)_Part7david4231993No ratings yet

- Flexural Strength of Concrete (Using Simple Beam With Center-Point Loading)Document3 pagesFlexural Strength of Concrete (Using Simple Beam With Center-Point Loading)Edmundo Jaita CuellarNo ratings yet

- Core FrequencyDocument1 pageCore FrequencymahiNo ratings yet

- Rebound Hammer TestDocument12 pagesRebound Hammer Testmahmood hunar100% (4)

- Ur-W27rev1 - Cast Steel PropellersDocument9 pagesUr-W27rev1 - Cast Steel PropellersJohnNo ratings yet

- ASTM E18 (2019)_Part17Document1 pageASTM E18 (2019)_Part17david4231993No ratings yet

- ASTM E384 (2022)_Part5Document1 pageASTM E384 (2022)_Part5david4231993No ratings yet

- D 1186 - 01nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied To A Ferrous Base1Document4 pagesD 1186 - 01nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied To A Ferrous Base1kyeong cheol leeNo ratings yet

- Compressive Strength of Cylindrical Concrete Specimens: Standard Method of Test ForDocument6 pagesCompressive Strength of Cylindrical Concrete Specimens: Standard Method of Test ForEvert RiveraNo ratings yet

- 5249.dynamic Properties of SoilDocument13 pages5249.dynamic Properties of SoilBibhu PrasadNo ratings yet

- Magnetic Particle Standards Guide & Dry Film Thickness MethodsDocument5 pagesMagnetic Particle Standards Guide & Dry Film Thickness MethodsMilenita Paez AcuñaNo ratings yet

- Description of Gages: 3.3 Area MeasurementDocument1 pageDescription of Gages: 3.3 Area Measurementnate anantathatNo ratings yet

- Failure End Point in Accelerated and Outdoor Weathering of Bituminous MaterialsDocument3 pagesFailure End Point in Accelerated and Outdoor Weathering of Bituminous MaterialsMohammad YaseenNo ratings yet

- D5682 PDFDocument4 pagesD5682 PDFEmilio HipolaNo ratings yet

- ASTM E18 (2019)_Part13Document1 pageASTM E18 (2019)_Part13david4231993No ratings yet

- Micro Hardness Tester Manual Book HVD-1000AP MPDocument38 pagesMicro Hardness Tester Manual Book HVD-1000AP MPDaisy HeNo ratings yet

- ROUTINE TEST PLAN FOR SUBSTATIONDocument8 pagesROUTINE TEST PLAN FOR SUBSTATIONNguyen ngoc thongNo ratings yet

- ASTM E384 (2022)_Part10Document1 pageASTM E384 (2022)_Part10david4231993No ratings yet

- ASTM E18 (2019)_Part10Document1 pageASTM E18 (2019)_Part10david4231993No ratings yet

- Method FOR V-Erification of Rockwell Superficial Hardness Testing Machines (Scales 15N, 30N, 45N, 15T, 30T AND 45T) (Document5 pagesMethod FOR V-Erification of Rockwell Superficial Hardness Testing Machines (Scales 15N, 30N, 45N, 15T, 30T AND 45T) (Pushpendra ChouhanNo ratings yet

- AWSD1 1 Procedure UtDocument19 pagesAWSD1 1 Procedure UtGhilman0529No ratings yet

- Astm D1005 95 2001Document1 pageAstm D1005 95 2001Marco Tulio Montiel RubioNo ratings yet

- Tension StiffeningDocument14 pagesTension StiffeningOlesea NesterencoNo ratings yet

- 001-SSPC Pa 02 2004 Measurement of Dry Coating Thickness With Magnetic GagesDocument11 pages001-SSPC Pa 02 2004 Measurement of Dry Coating Thickness With Magnetic GagesIka Sundari SunNo ratings yet

- DM Specs For Surge Vessel PDFDocument6 pagesDM Specs For Surge Vessel PDFatadanleventNo ratings yet

- Haryana Vidyut Prasaran Nigam LimitedDocument6 pagesHaryana Vidyut Prasaran Nigam LimitedasdfghjklNo ratings yet

- Astm D1186-01 PDFDocument5 pagesAstm D1186-01 PDFCalidad - TGINo ratings yet

- 2013 Asme VIII Acceptance CriteriaDocument8 pages2013 Asme VIII Acceptance CriteriaSiggy LaiNo ratings yet

- Standard Specification For Straight-Beam Ultrasonic Examination of Plain and Clad Steel Plates For Special ApplicationsDocument6 pagesStandard Specification For Straight-Beam Ultrasonic Examination of Plain and Clad Steel Plates For Special ApplicationsRupam BaruahNo ratings yet

- C293 PDFDocument3 pagesC293 PDFHassan MokhtarNo ratings yet

- Burnt Clay Building Bricks - Methods of Test: Indian StandardDocument8 pagesBurnt Clay Building Bricks - Methods of Test: Indian StandardDevesh Kumar PandeyNo ratings yet

- Civil Engineering Instrumentation For Infrastructure, Road & Highways, Building Material TestingDocument2 pagesCivil Engineering Instrumentation For Infrastructure, Road & Highways, Building Material TestingAimilNo ratings yet

- C78 PDFDocument3 pagesC78 PDFNgayxuan NguyenNo ratings yet

- Astm c78Document4 pagesAstm c78Budi PrakosoNo ratings yet

- SSPC - PA 2Document11 pagesSSPC - PA 2marciobispoalmeidaNo ratings yet

- 05 Ultrasonic Test Procedure 500405Document11 pages05 Ultrasonic Test Procedure 500405Sefa KasapogluNo ratings yet

- Flexural Strength of Concrete (Using Simple Beam With Third-Point Loading)Document3 pagesFlexural Strength of Concrete (Using Simple Beam With Third-Point Loading)Jhon Paul EstopinNo ratings yet

- Cast Aluminum Alloy Railing Posts: Standard Specification ForDocument2 pagesCast Aluminum Alloy Railing Posts: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Compression Testing Machine Used For Testing of Concrete and Mortar - RequirementsDocument9 pagesCompression Testing Machine Used For Testing of Concrete and Mortar - RequirementsUppala Krishna ChaitanyaNo ratings yet

- Astm c78Document4 pagesAstm c78Elkin GonzalezNo ratings yet

- Duramin IndenterDocument6 pagesDuramin IndenterJoão Torres SilvaNo ratings yet

- SOP-030 - Rev0 Mic10 Mic20Document2 pagesSOP-030 - Rev0 Mic10 Mic20Stephen LewellenNo ratings yet

- Concrete masonry testing standardsDocument4 pagesConcrete masonry testing standardsHaniAminNo ratings yet

- Lndian Standard: Plastics - Methods of TestingDocument9 pagesLndian Standard: Plastics - Methods of Testinggini associatesNo ratings yet

- Sos SystemDocument50 pagesSos SystemtomychalilNo ratings yet

- Fluorokote 1 2200 Hour Salt Fog TestDocument3 pagesFluorokote 1 2200 Hour Salt Fog TesttomychalilNo ratings yet

- Timing Belt Tooth Profiles and PitchesDocument3 pagesTiming Belt Tooth Profiles and PitchestomychalilNo ratings yet

- SOP-Attachment 3b - CNL JV-EGTL SWP 401 - Permit To Work - Dec12Document20 pagesSOP-Attachment 3b - CNL JV-EGTL SWP 401 - Permit To Work - Dec12tomychalilNo ratings yet

- HPCL Material Preservation GuidelinesDocument7 pagesHPCL Material Preservation GuidelinespaimpillyNo ratings yet

- SOP-Attachment 7 - General Project ProceduresDocument42 pagesSOP-Attachment 7 - General Project ProcedurestomychalilNo ratings yet

- Sos SystemDocument50 pagesSos SystemtomychalilNo ratings yet

- HPCL Material Preservation GuidelinesDocument7 pagesHPCL Material Preservation GuidelinespaimpillyNo ratings yet

- SADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)Document3 pagesSADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)tomychalilNo ratings yet

- Dr2 - Spec - Non-Destructive Examination Req of PipingDocument20 pagesDr2 - Spec - Non-Destructive Examination Req of Pipingtomychalil100% (1)

- Annex C Robust Analysis: (Normative)Document1 pageAnnex C Robust Analysis: (Normative)tomychalil0% (1)

- UAE travel restrictions on controlled drugsDocument25 pagesUAE travel restrictions on controlled drugstomychalilNo ratings yet

- Building LayoutDocument1 pageBuilding LayouttomychalilNo ratings yet

- F DST 216 Bakery Confectionery ProductsDocument127 pagesF DST 216 Bakery Confectionery ProductsAdil Anwar0% (1)

- CNC Table Waterjet Cutting MachineDocument9 pagesCNC Table Waterjet Cutting MachinetomychalilNo ratings yet

- Guidance PT IlcDocument11 pagesGuidance PT IlcAurelia BucurNo ratings yet

- NCHM Jee 2018 SeatsDocument5 pagesNCHM Jee 2018 SeatsAnonymous 05nABj8m100% (1)

- Interlaboratory Comparison of FatigueDocument26 pagesInterlaboratory Comparison of FatiguetomychalilNo ratings yet

- COMPANY NAME> Business Continuity PlanDocument12 pagesCOMPANY NAME> Business Continuity PlantomychalilNo ratings yet

- SADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)Document3 pagesSADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)tomychalilNo ratings yet

- Interlaboratory Comparison of FatigueDocument26 pagesInterlaboratory Comparison of FatiguetomychalilNo ratings yet

- Gallery Pages PDFDocument1 pageGallery Pages PDFtomychalilNo ratings yet

- Lab Temp - MonitoringDocument28 pagesLab Temp - MonitoringtomychalilNo ratings yet

- 1 Business Environment PDFDocument6 pages1 Business Environment PDFtomychalilNo ratings yet

- Lab Temp - MonitoringDocument28 pagesLab Temp - MonitoringtomychalilNo ratings yet

- List of FTTH Cities PDFDocument3 pagesList of FTTH Cities PDFSaurabh KumarNo ratings yet

- F2-01 Accounting For Management PDFDocument10 pagesF2-01 Accounting For Management PDFtomychalilNo ratings yet

- Annealingnormalizingquenchingmartensitictransformation1 140326023046 Phpapp02Document22 pagesAnnealingnormalizingquenchingmartensitictransformation1 140326023046 Phpapp02Immanuel Budiman PasaribuNo ratings yet

- Liworiz 3rd ShiftingDocument10 pagesLiworiz 3rd ShiftingKATHLEEN CALALANGNo ratings yet

- Maths in Focus Chapter 11Document52 pagesMaths in Focus Chapter 11eccentricftw450% (2)

- Library Management System Midterm ProjectDocument12 pagesLibrary Management System Midterm ProjectMuhammad Zain ZafarNo ratings yet

- Topic 5 DLL Elem LowerDocument4 pagesTopic 5 DLL Elem LowerLethBan100% (3)

- PE Exam Structure and Content BreakdownDocument6 pagesPE Exam Structure and Content BreakdownJose Carlos ArgeñalNo ratings yet

- FreedsDocument2 pagesFreedsSudenNo ratings yet

- Extremes Desert Science PDFDocument24 pagesExtremes Desert Science PDFMia SamNo ratings yet

- CV Summary: Climate Expert with Extensive Research ExperienceDocument12 pagesCV Summary: Climate Expert with Extensive Research ExperienceObey SipusiengmesekmesekNo ratings yet

- Genei SpecDocument3 pagesGenei SpecKaren Pachchigar 1No ratings yet

- Dissertation Explicative Le HorlaDocument8 pagesDissertation Explicative Le HorlaWriteMyPaperOneDaySingapore100% (1)

- Understanding the Concept and Nature of ManagementDocument9 pagesUnderstanding the Concept and Nature of Managementtihsrahlayog50% (2)

- Commodore Basic 3.5 ManualDocument84 pagesCommodore Basic 3.5 ManualGergő SzőkeNo ratings yet

- The Informal Communication NetworkDocument9 pagesThe Informal Communication NetworkSujata KumariNo ratings yet

- Computational MHDDocument66 pagesComputational MHDverthex20992828No ratings yet

- VIP Hacks MenuDocument49 pagesVIP Hacks MenuDharmesh KhadiyaNo ratings yet

- Study in Germany in English - Top UniversitiesDocument21 pagesStudy in Germany in English - Top UniversitiesMona AliNo ratings yet

- Ridc ManualDocument434 pagesRidc ManualYeisonCastellanosNo ratings yet

- IIM Jammu - Summer Placement Brochure 2016Document16 pagesIIM Jammu - Summer Placement Brochure 2016Ram BallampalliNo ratings yet

- Kigali Report - Web Version (Oct 2014)Document64 pagesKigali Report - Web Version (Oct 2014)HarisNeophytouNo ratings yet

- Unit 1-MECHATRONICS, SENSORS AND TRANSDUCERSDocument55 pagesUnit 1-MECHATRONICS, SENSORS AND TRANSDUCERSRamanathanDurai100% (3)

- XSLT Multiple Name Spaces in XML DocumentsDocument12 pagesXSLT Multiple Name Spaces in XML DocumentsFinnbarr P. MurphyNo ratings yet

- Interview Strengths and WeaknessesDocument1 pageInterview Strengths and Weaknessesunur6628No ratings yet

- Astm 3441Document6 pagesAstm 3441Todor Ivanov YankovNo ratings yet

- Sample Questions For CeedDocument3 pagesSample Questions For CeedShashank KasliwalNo ratings yet

- Effects of Computer Usage On Students PerformanceDocument18 pagesEffects of Computer Usage On Students PerformanceAbdul-Fatawu Ibn Ibrahim Doctah67% (3)

- Malcolm Bowie-Psychoanalysis and The Future of Theory (Bucknell Lectures in Literary Theory) (1993)Document174 pagesMalcolm Bowie-Psychoanalysis and The Future of Theory (Bucknell Lectures in Literary Theory) (1993)ph_ufpb4314100% (3)

- Spectrum TRD3 Tests EOT2 SpeakingDocument1 pageSpectrum TRD3 Tests EOT2 SpeakingTTNLittleGeniusNo ratings yet

- English Assignment4Document4 pagesEnglish Assignment4Nadia SofiaNo ratings yet

- Oral-Com - Q1 - Module-4 Functions of CommunicationDocument19 pagesOral-Com - Q1 - Module-4 Functions of CommunicationLucky Heart Joy BaniquedNo ratings yet