Professional Documents

Culture Documents

2022-V13I775

Uploaded by

Ibrahim Tuhin PICUCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2022-V13I775

Uploaded by

Ibrahim Tuhin PICUCopyright:

Available Formats

Journal of Engineering Sciences Vol 13 Issue 7,JULY/2022, ISSN:0377-9254

BEHAVIOUR OF CONCRETE BY PARTIAL

REPLACEMENT OF FINE AGGREGATE WITH

RECYCLED PLASTIC

Mr. A. KARTHIK, GAMINI THILAK HEMANTH KUMAR, MUNIKUNTLA MADHAVA NATH GOUD, RATHOD SWATHI

Asst. professor, Department of Civil Engineering, Aurora’s Technological & Research Institute, Hyderabad, India.

1

student, Department of Civil Engineering, Aurora’s Technological & Research Institute, Hyderabad, India.

2

student, Department of Civil Engineering, Aurora’s Technological & Research Institute, Hyderabad, India.

3

student, Department of Civil Engineering, Aurora’s Technological & Research Institute, Hyderabad, India.

avulakarthik@atri.edu.in

thilak.hemanth03@gmail.com

madhavgoudmunikuntla@gmail.com

swathirathod123ss@gmail.com

Abstract— In this paper we are using recycled plastic granules wastes require large areas of land for storage and cannot be

because plastic is a non-biodegradable material and it is hazardous

fully recycled at once Every year, approximately 6.5 billion

tons of plastic waste and discarded rubber are generated

to the environment so to decrease the land pollution caused by the globally; the disposal of these plastics poses a considerable

plastic we are using them in concrete to increase the strength. threat to the environment due to their long degradation

periods from different perspectives, waste reuse is important

Disposal of used plastics is one of the major problems faced in the

because it helps to recycle and conserve energy in the

present era of world. Day by day the the usage of plastic is production process, reduces environmental pollution, and

increasing. The non-biodegradability of plastic makes it very helps sustain and conserve non-renewable natural

resources Using plastic waste in the materials industry is an

harmful to the environment. In this work to reduce waste plastic

environmental solution to minimize the proportion of

we partially replacing the fine aggregate by recycled plastic landfills used in waste incineration studies have shown that

granules at 2%,4%,6%, 8% in M30 grade of concrete. The plastic can be used in concrete this type of material has

become a major research subject in recent years

compressive, split tensile strengths are determined after 7 day and

28 days of water curing. II. LITERATURE REVIEW

Key Words: Eco-friendly concrete, environmental solution, Fine

[1] “Recycled Plastics as Coarse Aggregate for

aggregate, recycled plastic.

Structural Concrete”: Praveen Mathew, Shibi Varghese,

Thomas Paul, Eldho Varghese (2013)

I. INTRODUCTION The use of plastic is increasing day by day, although steps

Plastic is a very common material in our day to day life. were taken to reduce its consumption. This creates

Lack of proper disposal methods for waste plastic is one of substantial garbage every day which is much unhealthy. A

the hazards faced by the present world. Because of the non- healthy and sustainable reuse of plastics offers a host of

biodegradability it causes the environmental pollution. The advantages.

use of waste or recycled plastic in concrete in an effective

manner can reduce the pollution to a certain extent. [2] “Recycled plastics used as coarse aggregate for

Solid waste is one of the many factors that negatively affect constructional concrete” SJB Institute of Technology,

the environment. Problems stem from factors such as Bangalore

difficulty of waste recycling and limited reuse. Plastic is an Landfill sites are becoming overcrowded and expensive for

important type of solid waste with a strong environmental waste disposal, efforts are made to minimize the quantities

impact. This study aims to investigate the effects of utilising of materials that are delivered to landfills. The threat due to

low density polyethylene (LDPE) as a partial substitute for leaching of non-biodegradable materials like waste plastics,

sand in concrete. The effects of this material on the physical scrap tyres. E-waste may contaminate the soil and ground

and mechanical properties of concrete were examined. water

Concrete was cast to determine the behaviour of fresh and

hardened concrete in terms of workability, unit [3] “Studies on Concrete containing E plastic waste”

weight, compressive strength. Lakshmi.R, K.L.N.College of Information Technology,

Increasing consumption of various types of plastic Sivagangai Nagan.S, Thiagarajar College of

products is one of the most important challenges in Engineering, Madurai (2010)

environmental protection. Large quantities of plastic waste Utilization of waste materials and by-products is a partial

and low biodegradability of these quantities negatively affect solution to environmental and ecological problems. Use of

the environment. All types of plastic used by humans in daily these materials not only helps in getting them utilized in

life eventually becomes waste; several tons of these plastic cement, concrete and other construction materials, it helps in

XXX-X-XXXX-XXXX-X/XX/$XX.00 ©20XX IEEE

www.jespublication.com Page 581

Journal of Engineering Sciences Vol 13 Issue 7,JULY/2022, ISSN:0377-9254

reducing the cost of cement and concrete manufacturing, but Water:-

also has numerous indirect benefits such as reduction in Water is essential for concrete production. Concrete needs

land•fill cost, saving in energy, and protecting the water to form a strong bond with sand and gravel. If there is

environment from possible pollution effects too much water, the mixture will become too wet and

harden before it sets. If there is too little water, the mixture

[4] “Utilization of e-waste and plastic bottle waste in won't hold together properly. To ensure that the mix stays

concrete” Ankit Arora, UG student, Dr. Urmil V. Dave, workable, you need to add an appropriate amount of water.

Senior Professor, Institute of Technology, Nirma You also need to keep an eye out for any signs of bleeding,

University,Ahmedabad (2013) which could indicate that the mix is too dry.

E-waste and plastic waste are the major problem in today

scenario as these are non- biodegradable. Attempts were

Test details

made in past to use them in concrete by grinding them. But

it failed to give good strength because grinded particle has A. Compressive strength test

flattened shape. Grinded plastic and e waste mixed with The compressive strength test is used to determine the

concrete is a good way to dispose them with cheap concrete strength of concrete. The sample dimensions are

production. 150mm×150mm×150mm. Generally compressive strength

III. MATERIALS USED conducted on samples of concrete at 3days, 7days, 14days,

28days, 56days and 90days. In this project, the compressive

Cement :- strength test performed at 7days and 28days. The procedure

Cement is one the major component in the manufacturing of compressive strength followed in this project according to

process of concrete. It has the property to stick to any other IS-516:1959. The compressive strength conducted on 3

raw material added in the preparation process of concrete, samples for each temperature condition cured of concrete.

especially when comes in contact with water and hence The values of every sample cube cured under different

produces a good paste. Here, OPC 53 grade cement is used . temperatures were noted. The average values of 3 samples

of concrete taken as final value of strength.

Coarse aggregates :- Compressive Strength (N/mm2) = Failure load/cross

Coarse aggregate is another fundamental raw material which sectional area.

gives strength, hardness and increases the volume of the 𝜎 = 𝑃/𝐴

concrete. Here, coarse aggregate of size 20 mm and angular Where, P=Applied load, A= Cross-sectional Area

crushed shape is chosen

Fine aggregate:-

Sand is a type of rock that is made up of tiny grains of stone

or other minerals. Sand is often used in construction because

it is easy to shape and mold into any desired form. Sand is

also used in making glass, ceramics, paper, paint, cosmetics,

and pharmaceuticals.

Platic Granules:-

The thermoplastic LDPE (low-density polyethylene) is

manufactured from the monomer ethylene. Imperial

Chemical Industries (ICI) produced the first grade of

polyethylene in 1933 using a high-pressure free radical

polymerization technique. The same procedure is still used

to make it now. According to the Environmental Protection

Agency, 3.3.7 per cent of LDPE (recycling number 4) is

recycled. LDPE remains a popular plastic grade despite

competition from more contemporary polymers .The global

LDPE market reached a volume of roughly $1 billion in

2013. Low-density polyethylene (LDPE) is

a thermoplastic made from the monomer ethylene. It was the Figure 1: COMPRESSIVE STRENGTH TESTING

first grade of polyethylene, produced in 1933 by Imperial MACHINE

Chemical Industries (ICI) using a high pressure process

via free radical polymerization. Its manufacture employs the

B. Split tensile strength test

same method today. The EPA estimates 5.7% of LDPE

(resin identification code 4) is recycled in the United Split tensile strength is applying a diametric compressive

States. Despite competition from more modern polymers, load along the entire length until failure occurs. This loading

LDPE continues to be an important plastic grade. In 2013 induces tensile stresses on the plane containing the applied

the worldwide LDPE market reached a volume of about load and compressive stresses in the area around the applied

US$33 billion. load. In this experiment, split tensile strength test is

performed for 7&28 days on the cylinders. The procedure

www.jespublication.com Page 582

Journal of Engineering Sciences Vol 13 Issue 7,JULY/2022, ISSN:0377-9254

for split tensile strength is followed according to IS

5816:1999. Compressive strength for 7 Days

30

24.44

24.06

23.33

25

21.4

20

20

20

20

20

load

15

10

Figure 2: SPLIT TENSILE STRENGTH TEST 5

Split rigidity was determined by conducting split tensile

strength test.

𝑆 = 2𝑃/𝜋𝐷𝐿

0

Where, P = Failure Load (KN), D = Diameter of Specimen

(150 mm), L = Length of Specimen (300 mm) 0% & 2% 0% & 4% 0% & 6% 0% & 8%

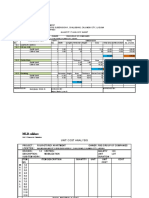

IV. RESULTS AND DISCUSSIONS Normal Replaced

S. NO % OF AVERAGE AVERAGE SPLIT

PLASTIC COMPRESSIVE TENSILE

GRANULES STRENGTH STRENGTH

(N/MM2) (N/MM2) Compressive Strength 28 DAYS

7 DAYS 28 7 DAYS 28 40

35.7

DAYS DAYS 31.6

35

29.62

29.07

1 0% 20 27.4 1.56 2.4

27.4

27.4

27.4

30 27.4

2 2% 21.4 29.62 1.7 2.61

25

3 4% 23.33 29.07 1.66 2.68

load

20

4 6% 24.06 31.6 1.8 2.54

15

5 8% 24.44 35.7 1.89 2.61

10

0

0% &2% 0% & 4% 0% & 6% 0% & 8%

Normal Replaced

www.jespublication.com Page 583

Journal of Engineering Sciences Vol 13 Issue 7,JULY/2022, ISSN:0377-9254

strength also decreases. From the results, the 28 days

Spli Tensile strength For 7 Days compressive strength for 0% is 27.4 MPa, 2% is 29.62

MPa, 4% is 29.07 MPa, 6% is 31.6 MPa,8% is 35.7

2 1.89

1.8 MPa . It clearly shows that if we increase the

1.8 1.7 1.66

1.56 1.56 1.56 1.56 percentage of plastics

1.6 It has been found that replacing sand by 2 % of plastic

1.4 sand is substituted by 14.48 Kg .Replacing sand by 4

1.2 % of plastic sand is substituted by 14.19 kg. Replacing

1 sand by 6 % of plastic sand is substituted by 13.89 Kg

,Replacing sand by 8% Plastic sand is substituted by

0.8

13.6 kg.So, when it would be used in large scale in

0.6

construction site, there would be a significant way to

0.4 control this huge amount of plastic

0.2 From the literature survey we are concluding that in

0 the fine aggregate the optimum replacement of plastic

0% & 2% 0% & 4% 0% & 6% 0% & 8% can be up to 8% . Beyond that if we increase the

percentage of plastic it may leads to decrease in the

Normal Replaced strength of the plastic

REFERENCES

Split Tensile Strength for 28 days International Journal of Engineering &

2.75 Technology, 7 (4.20) (2018) 449-452

2.7 2.68

D. Aditya Sai Ram, Ch. Surendra Reddy ISSN:

2.65 2.61 2.61

2349-084

2.6

2.54

2.55 Pankaj Thakur, Khushpreet SinghVolume: 05

2.5 Issue: 03 Mar-2018 p-ISSN: 2395-0072

2.45 2.4 2.4 2.4 2.4

International Research Journal of Engineering and

2.4

2.35 Technology (IRJET) e-ISSN: 2395-0056 Volume:

2.3 08 Issue: 07 July 2021 p-ISSN: 2395-0072

2.25

0% & 2% 0% & 4% 0% & 6% 0% & 8% International Research Journal of Engineering and

Technology (IRJET) e-ISSN: 2395-0056 p-ISSN:

Normal Replaced

2395-0072 Volume: 08 Issue: 04 Apr 2021

Indian J. Sci. Res. 17 (1): 100-106, 2017

CONCLUSION International Journal of Innovative Research in

Science, Engineering and Technology, Volume 3,

The experimental findings show the usage of waste

plastic materials in making mortar/concrete can provide an Issue 1, January 2014

alternative solution for minimizing the environmental

International Journal of Civil Architectural

impacts of disposing waste plastics. The following

conclusions were made. Structural and Construction Engineering Volume: 8

The physical properties and compressive strength of

No: 3, 2014

concrete with different plastic contents (0%,2%, 4%,

6% and 8%) were tested. Sun Mingqing (1999) “Thermal self -monitoring of

The waste plastic used for the experiment is made of

carbon fibre reinforced concrete”, Cement and

LDPE (low density polyethylene), the size is less than

4.5 mm, and the specific gravity of the waste plastic is Concrete Research vol.no. 29 (1999) PP. 769 –

0.92.

771.

Comparing the compressive strength of the test

concrete with that of ordinary concrete it was found Dragos-Marian Bontea (2000) “Damage in carbon

that the compressive strength of concrete with plastic

fibre-reinforced concrete, monitored by electrical

waste mixtures up to 8% (replacing fine aggregate)

was up to 10%. resistance measurement”, Cement and Concrete

With the increase in percentage of plastics that is used

Research vol.no. 30 (2000), PP 651659

as a partial replacement of sand the compressive

www.jespublication.com Page 584

Journal of Engineering Sciences Vol 13 Issue 7,JULY/2022, ISSN:0377-9254

Mingqing Sun (2000) “Piezoelectric properties of Umit Serdar Camli and Baris Binici (2007)

carbon fibre reinforced concrete and plain cement “Strength of carbon fibre reinforced polymers

paste during dynamic loading”, Cement and bonded to concrete and masonry”, Construction

Concrete Research vol.no.30 (2000) PP.1593-1595 and Building Materials vol.no. 21 (2007) PP.1431

Zeng- Qiang Shi and D. D. L. Chung (1999) – 1446

“Carbon fibre-reinforced concrete for traffic

monitoring and weighing in motion”, Cement and

Concrete Research Vol.no. 29 (1999) PP.435 – 439

www.jespublication.com Page 585

You might also like

- 2022-V13I7247Document5 pages2022-V13I7247Ibrahim Tuhin PICUNo ratings yet

- Eco-Friendly Concrete Containing Recycled Plastic As Partial Replacement For SandDocument13 pagesEco-Friendly Concrete Containing Recycled Plastic As Partial Replacement For SandSofii VictoriannaNo ratings yet

- Ijert1 PDFDocument5 pagesIjert1 PDFSHUBHAMNo ratings yet

- A Study On Plastic Waste For Replacement of Coarse Aggregate With Soft and Hard Plastic in ConcreteDocument3 pagesA Study On Plastic Waste For Replacement of Coarse Aggregate With Soft and Hard Plastic in ConcreteInternational Journal of Innovative Science and Research Technology100% (1)

- Utilization of Plastic Waste For MakingDocument4 pagesUtilization of Plastic Waste For MakingObaNo ratings yet

- Implementation of Plastic Waste in Manufacturing of Paving Blocks For Different ShapesDocument2 pagesImplementation of Plastic Waste in Manufacturing of Paving Blocks For Different ShapesEditor IJTSRDNo ratings yet

- Use of Waste Plastics in Cement-Based Co PDFDocument11 pagesUse of Waste Plastics in Cement-Based Co PDFClariza Tan100% (1)

- Use of Waste Plastics in Cement-Based Composite For Lightweight Concrete ProductionDocument12 pagesUse of Waste Plastics in Cement-Based Composite For Lightweight Concrete ProductionU No MiNo ratings yet

- Experimental Investigation of Waste Plastic Fiber in Reinforced Cement Concrete Using Recycled Coarse AggregateDocument12 pagesExperimental Investigation of Waste Plastic Fiber in Reinforced Cement Concrete Using Recycled Coarse AggregateInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigation On Reinforced Concrete With Plastic FiberDocument6 pagesExperimental Investigation On Reinforced Concrete With Plastic FiberIJRASETPublicationsNo ratings yet

- Experimental Study On Strength Behaviour of Plastic Sand BricksDocument4 pagesExperimental Study On Strength Behaviour of Plastic Sand Brickstesfalem kiros100% (1)

- Experimental Investigation On The Properties of Concrete With Plastic Pet Bottle Fibers As Partial Replacement of Fine AggregatesDocument7 pagesExperimental Investigation On The Properties of Concrete With Plastic Pet Bottle Fibers As Partial Replacement of Fine AggregatesEditor IJTSRDNo ratings yet

- .Utilization of Plastic Waste and Artificial Sand in Manufacturing of Eco BricksDocument3 pages.Utilization of Plastic Waste and Artificial Sand in Manufacturing of Eco BricksSande NasNo ratings yet

- Edmund 2019 IOP Conf. Ser. Earth Environ. Sci. 357 012018Document8 pagesEdmund 2019 IOP Conf. Ser. Earth Environ. Sci. 357 012018Faye AudanNo ratings yet

- Block StrengthDocument12 pagesBlock StrengthNaveen Gowda k sNo ratings yet

- 1-s2.0-S2214785322023707-mainDocument6 pages1-s2.0-S2214785322023707-mainGMC SEMECNo ratings yet

- Use of Plastic Waste in Road ConstructionDocument3 pagesUse of Plastic Waste in Road ConstructionriyaNo ratings yet

- 1 s2.0 S2213138822007706 MainDocument7 pages1 s2.0 S2213138822007706 MainDEEPAK SHARMANo ratings yet

- Utilisation of Waste Plastic in Manufacturing of Bricks and Paver BlocksDocument6 pagesUtilisation of Waste Plastic in Manufacturing of Bricks and Paver BlocksParmvir SinghNo ratings yet

- litreatrature_review RakshitDocument9 pageslitreatrature_review Rakshitparasajit89No ratings yet

- A Review On Behaviour of Concrete by Partial Replacement of Coarse Aggregate With Waste PlasticDocument12 pagesA Review On Behaviour of Concrete by Partial Replacement of Coarse Aggregate With Waste PlasticIJRASETPublicationsNo ratings yet

- A Review On Behaviour of Concrete by Partial Replacement of Coarse Aggregate With Waste PlasticDocument12 pagesA Review On Behaviour of Concrete by Partial Replacement of Coarse Aggregate With Waste PlasticIJRASETPublicationsNo ratings yet

- Thesis ProposalDocument7 pagesThesis ProposalMEHIDE HASANNo ratings yet

- SKN Sinhgad College of Engineering, Korti-Pandharpur 1Document21 pagesSKN Sinhgad College of Engineering, Korti-Pandharpur 1Muhib BagwanNo ratings yet

- SKN Sinhgad College of Engineering, Korti-Pandharpur 2Document42 pagesSKN Sinhgad College of Engineering, Korti-Pandharpur 2Muhib BagwanNo ratings yet

- Final JournalDocument4 pagesFinal Journalpavan v vNo ratings yet

- An Experimental Study On Waste Plastic Aggregate Based Concrete - An Initiative Towards Cleaner EnvironmentDocument5 pagesAn Experimental Study On Waste Plastic Aggregate Based Concrete - An Initiative Towards Cleaner Environmentshalom napoleonNo ratings yet

- Irjet V8i1154Document6 pagesIrjet V8i1154Kirby LabadanNo ratings yet

- A Review On Utilization of Processed Inorganic Mixed Municipal Solid Waste by Mechanical Device in Manufacturing of BricksDocument6 pagesA Review On Utilization of Processed Inorganic Mixed Municipal Solid Waste by Mechanical Device in Manufacturing of BricksIJRASETPublicationsNo ratings yet

- Waste RubberDocument6 pagesWaste RubberSanjay YadavNo ratings yet

- Utilization of Waste Polythene As Low Cost and Eco-Friendly Material in PPC ConcreteDocument5 pagesUtilization of Waste Polythene As Low Cost and Eco-Friendly Material in PPC ConcreteEditor IJTSRDNo ratings yet

- Group 4 - 12 ESTEM E6Document14 pagesGroup 4 - 12 ESTEM E6justinjoyhamo21No ratings yet

- Use of Plastic Aggregates in Concrete: Azad Khajuria, Puneet SharmaDocument7 pagesUse of Plastic Aggregates in Concrete: Azad Khajuria, Puneet Sharmamanayagamaryjoy9No ratings yet

- Experimental Investigation On Waste-Plastic Reinforced Concrete BrickDocument5 pagesExperimental Investigation On Waste-Plastic Reinforced Concrete BrickInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Survey On Use of Non-Recyclable Waste in ConstructionDocument9 pagesA Survey On Use of Non-Recyclable Waste in ConstructionIJRASETPublicationsNo ratings yet

- 2020aplicación de Materiales de Desecho Domésticos e Industriales en El Hormigón Una RevisiónDocument6 pages2020aplicación de Materiales de Desecho Domésticos e Industriales en El Hormigón Una RevisiónYudy Alejandra Buitrago MuñozNo ratings yet

- Construction and Building Materials: Ankur C. Bhogayata, Narendra K. AroraDocument9 pagesConstruction and Building Materials: Ankur C. Bhogayata, Narendra K. AroraYara MounaNo ratings yet

- Use of Waste Plastic As A Construction Material: Anand Daftardar, Rashmi Patel, Ronak Shah, Parth Gandhi, Himanshu GargDocument4 pagesUse of Waste Plastic As A Construction Material: Anand Daftardar, Rashmi Patel, Ronak Shah, Parth Gandhi, Himanshu GargGelineGayleUgasNo ratings yet

- Concept of Green Concrete Using Construction Demolished Waste As Recycled Coarse AggregateDocument6 pagesConcept of Green Concrete Using Construction Demolished Waste As Recycled Coarse AggregateseventhsensegroupNo ratings yet

- Effects of Glass Waste On Compressive Strength of ConcreteDocument21 pagesEffects of Glass Waste On Compressive Strength of ConcreteRachit SharmaNo ratings yet

- An Overview of Use of Waste Plastic in Road Construction: April 2018Document4 pagesAn Overview of Use of Waste Plastic in Road Construction: April 2018Manohar SimhadriNo ratings yet

- Construction of Paving Blocks by Using Plastic WasteDocument8 pagesConstruction of Paving Blocks by Using Plastic WasteInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Stress-Strain Behaviour and Mechanical Strengths of Concrete Incorporating Mixed Recycled PlasticsDocument22 pagesStress-Strain Behaviour and Mechanical Strengths of Concrete Incorporating Mixed Recycled PlasticsbharatpradhanNo ratings yet

- Experimental Investigation of Using Plastic Waste to Replace Fine Aggregate in Brick ManufacturingDocument8 pagesExperimental Investigation of Using Plastic Waste to Replace Fine Aggregate in Brick ManufacturingNoel100% (1)

- Utilizing plastic waste in brick manufacturingDocument6 pagesUtilizing plastic waste in brick manufacturingDinesh ChintuNo ratings yet

- Use of waste plastics in cement concreteDocument12 pagesUse of waste plastics in cement concreteAngel AngelNo ratings yet

- Parative Analysis of Tiles Made From Recyclable LDPE Plastic WasteDocument5 pagesParative Analysis of Tiles Made From Recyclable LDPE Plastic WasteRachel DelosreyesNo ratings yet

- Study On Experimental Behavior of Plastic Based Fiber As Secondary Reinforcement in Concrete PavementDocument13 pagesStudy On Experimental Behavior of Plastic Based Fiber As Secondary Reinforcement in Concrete PavementIJRASETPublicationsNo ratings yet

- Soil Stabilization Using Plastic FiberDocument4 pagesSoil Stabilization Using Plastic FiberIJSTENo ratings yet

- Irjet V7i4845Document9 pagesIrjet V7i4845N SanthoshNo ratings yet

- .A Review of Literature On Stabilization of Black Cotton Soil Using Waste Pet BottlesDocument2 pages.A Review of Literature On Stabilization of Black Cotton Soil Using Waste Pet BottlesRocky BhaiNo ratings yet

- Iravanian 2021Document7 pagesIravanian 2021Alejandro MerinoNo ratings yet

- Partially replacing aggregates in concrete with plastic waste reviewDocument6 pagesPartially replacing aggregates in concrete with plastic waste reviewStephenNo ratings yet

- A Review Paper On Replacement of Fine AggregateDocument5 pagesA Review Paper On Replacement of Fine AggregateIJRASETPublicationsNo ratings yet

- Recycling/reuse of Plastic Waste As Construction Material For Sustainable Development: A ReviewDocument24 pagesRecycling/reuse of Plastic Waste As Construction Material For Sustainable Development: A ReviewselvakumarNo ratings yet

- Reusing Plastic Bottles as Construction MaterialDocument6 pagesReusing Plastic Bottles as Construction MaterialmujeebNo ratings yet

- Waste As Road MaterialDocument24 pagesWaste As Road MaterialEbenezer EffisahNo ratings yet

- 346experimental Study On Concrete by Partial Replacement of Marble Dust Powder With Cement Quarry Dust With Fine PDFDocument5 pages346experimental Study On Concrete by Partial Replacement of Marble Dust Powder With Cement Quarry Dust With Fine PDFMichael ShioNo ratings yet

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- The Sustainable Solution: Plastic Granulate Production in Action: Money from trashFrom EverandThe Sustainable Solution: Plastic Granulate Production in Action: Money from trashNo ratings yet

- Design Manual Chapter 6 - Geotechnical 6G - Subsurface Drainage SystemsDocument11 pagesDesign Manual Chapter 6 - Geotechnical 6G - Subsurface Drainage Systemsbilisuma sebokaNo ratings yet

- ScariDocument64 pagesScariancutza_schNo ratings yet

- Saic L 1004Document2 pagesSaic L 1004Hussain Nasser Al- NowiesserNo ratings yet

- Ex-10 - Laboratory Vane Shear Test in Cohesive SoilDocument10 pagesEx-10 - Laboratory Vane Shear Test in Cohesive Soilmathirenga88No ratings yet

- Daikin AHU technical report for BPOM Surabaya projectDocument6 pagesDaikin AHU technical report for BPOM Surabaya projectbrian ekiNo ratings yet

- Pushover Analysis of Asymmetric Ordinary Moment R.C Frames Designed According To The Iranian CodesDocument10 pagesPushover Analysis of Asymmetric Ordinary Moment R.C Frames Designed According To The Iranian CodesGelbert SilotNo ratings yet

- Simpson - 01 - Information About Institution of Civil EngineersDocument3 pagesSimpson - 01 - Information About Institution of Civil EngineersJacky TamNo ratings yet

- MaterialExam1 SolutionsDocument4 pagesMaterialExam1 SolutionslarasmoyoNo ratings yet

- Water Tank Design Summary for 8 Judge – KHAYPER SiteDocument4 pagesWater Tank Design Summary for 8 Judge – KHAYPER Sitemahmoud IbrahemNo ratings yet

- Sleek Wall-Hung Toilet with Tornado FlushDocument1 pageSleek Wall-Hung Toilet with Tornado Flushnishant81No ratings yet

- Cebex 100 grout expands and strengthens construction jointsDocument2 pagesCebex 100 grout expands and strengthens construction jointsmathi vijayNo ratings yet

- ISO - DIS - 11295 - Rehab ClassifficationDocument70 pagesISO - DIS - 11295 - Rehab ClassifficationRosa Ana CampoNo ratings yet

- Bond - MB-100 (WB) : WATER DILUTABLE Transparent Water Repellent SystemDocument3 pagesBond - MB-100 (WB) : WATER DILUTABLE Transparent Water Repellent SystemSukhwinder SinghNo ratings yet

- Evacuation Center (Design of Beam2)Document35 pagesEvacuation Center (Design of Beam2)jerick calingasanNo ratings yet

- Aluminum Bracket SpecificationsDocument4 pagesAluminum Bracket SpecificationsAndrei GheorghicaNo ratings yet

- CH 7 Doors & WindowsDocument75 pagesCH 7 Doors & WindowsAnuwar BuserNo ratings yet

- BP 220 - Part 02 PDFDocument26 pagesBP 220 - Part 02 PDFJohann Sebastian M MontalesNo ratings yet

- A41-108R Gemini IIDocument6 pagesA41-108R Gemini IItbachelardNo ratings yet

- Engineered Natural Fibre Composites For Oil and Gas Application: A ReviewDocument25 pagesEngineered Natural Fibre Composites For Oil and Gas Application: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Precommissioning Checklist ReviewDocument13 pagesPrecommissioning Checklist ReviewvladimirNo ratings yet

- Corian Exterior Cladding: Technical BulletinDocument6 pagesCorian Exterior Cladding: Technical BulletinnaheedahmedNo ratings yet

- Processing PeekDocument12 pagesProcessing PeekSh.nasirpurNo ratings yet

- Land Reclamation in SingaporeDocument27 pagesLand Reclamation in SingaporeAbdul JabbarNo ratings yet

- Input EchoDocument62 pagesInput EchoAkhil JoseNo ratings yet

- Four-Storey Apartment Project Cost AnalysisDocument109 pagesFour-Storey Apartment Project Cost AnalysisKiesha SantosNo ratings yet

- Eurocode 2 Faqs: 2 Min CdevDocument5 pagesEurocode 2 Faqs: 2 Min CdevkrishnakumarNo ratings yet

- AH36Document3 pagesAH36Abu ZahidNo ratings yet

- Updated Product List 30.09.2021Document10 pagesUpdated Product List 30.09.2021sabhay2No ratings yet

- CHART Cold Box Installation Operation and Maintenance PDFDocument16 pagesCHART Cold Box Installation Operation and Maintenance PDFBrinto VargheseNo ratings yet

- Composite Construction Design (ULS Only)Document93 pagesComposite Construction Design (ULS Only)CawanNeroMiranio100% (1)