Professional Documents

Culture Documents

003 9351 FL 56_003-0985-00-K-58030846

Uploaded by

rahul chakurCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

003 9351 FL 56_003-0985-00-K-58030846

Uploaded by

rahul chakurCopyright:

Available Formats

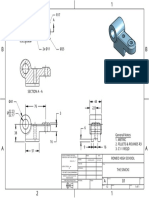

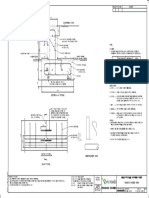

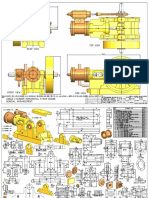

12 11 10 9 8 7 6 5 4 3 2 1

LET ECN REVISION DRAWN APPROVED DATE

K 43288 SEE ECN FOR DETAILS MLL WP 1/7/16

H H

0.862

0.856

(BLADE ONLY) NOTES:

1. ROTATING BEARING SURFACE MUST

BE FREE FROM NICKS AND

SCRATCHES.

G SEE NOTE 2 G

2. ROTATING SEALING SURFACE: A

POLISHED, BURNISHED OR

EQUIVALENT FINISH IS REQUIRED TO

15.219 REMOVE SHARP TOOL PATTERN.

15.157 SCRATCHES, NICKS OR SIMILAR

FLAWS ACROSS THE LAY WILL

3.343 1.187 2.937 2.375 PREVEN SEALING AND CANNOT BE

3.281 1.062 2.813 2.250 ALLOWED, PER JS-11.

F F

3. IDENTIFY MATERIAL PER JS-01.

1.093

1.031 1.200 SEE NOTE 1

1.180 0.140 4. JMATERIAL MUST CONFORM TO

TYP. 0.120 ALL CHEMICAL, PHYSICAL, HEAT

125 32 63 125 63 TREATMENT AND PERFORMANCE

0.005 A REQUIREMENTS OF THE CURRENT

REVISION OF THE SPECIFICATION

LISTED IN THE MATERIAL COLUMN.

20°

E 10° 5. ALL "FL" MATERIAL SHAFTS MUST BE

E

0.625 PROVIDED WITH SHOT PEENING.

0.621 SPECIAL SHAFTS AND DRAWINGS

SEE NOTE 3 ARE TO BE USED FOR SHOT PEENING

0.794 SEE VIEW BELOW FOR 0.869

0.788 SLOT DIMENSIONS 0.869 OPERATION. FOR THIS DIAMETER

SHAFT USE 003 9351 FL.

0.005 A -A-

0.006

D D

0.070 0.070 50°

R0.020 OR 0.020 X 40° CHAMFER TYP. K 4J DUPLEX. S.S. ASTM A-479, A-276 UNS S31803 4J 1.10

0.070

0.050 X 50 /40 0.040

R0.020 TYP.

50° FL INCONEL SEE NOTE 5 FL 1.16

40° TYP. ALLOY 718

INCONEL

2A ASTM B-637 UNS N07750 TYPE 2 2A 1.18

X-750

INCONEL ASTM B-446 ANNEALED 60 KSI MIN. 4F

4F 1.20

625 YIELD

C BREAK SHARP CORNERS TYP. 0.703 HASTELLOY

73 ASTM B-574 N10276 35 HRC MAX. 73 1.24 C

6° A 0.693 C

4° QQ-N-286 SOLUTION ANNEAL &

71 K-MONEL AGE HARDEN OR HOT FINISHED & K 1.19

AGE HARDENED. 35 HRC MAX.

43

ASTM A-564 TYPE 630 CONDITION OR

43 17-4PH H150M 33 HRC MAX. UNS S17400 "P" 1.11

ASTM A-479 TYPE 317; COLD

37 317 ST. ST'L. WORKED/STRAIN HARDENED AS 37 1.11

A REQUIRED FOR 50 KSI MIN. YIELD

B B

SECTION A-A 36 316 ST. ST'L.

ASTM A-479 TYPE 316; COLD

WORKED/STRAIN HARDENED AS

36

OR 1.11

DR.

THIS VIEW FOR PIN SLOT REQUIRED FOR 50 KSI MIN. YIELD PT.

DIMESNIONS ONLY 4.010

ASTN B-473, UNS-N080020 22 HRC

3.990 35 ALLOY 20 MAX. 35 1.15

MATERIAL MATERIAL MATERIAL SPECIFICATION IDENT WEIGHT

CODE TYPE MARK (kg)

VOLUME OF PART IS 141.92 cm3

6.572

6.552 THIS DRAWING AND ALL INFORMATION

CONTAINED HEREIN ARE THE PROPERTY

SPECIFICATIONS

TO BE USED IN

CONJUNCTION WITH

MAKE FROM PART NO.

INTERNAL

OF METSO AND ARE NOT TO BE USED

THIS DRAWING

A EXCEPT AS AUTHORIZED IN WRITING

BY METSO

JS-01

TITLE: DRAWN DATE

A

RWB 6/18/85

UNLESS OTHERWISE NOTED JS-11 SHAFT

DIMENSIONING, TOLERANCING, & DRAWING 6" 830 W/L MOD. C APPVD. DATE

INTERPRETATION IS IN ACCORDANCE

WITH ASME Y14.5M 250

W/S VALVE WR 6/20/85

ANGLES = ±5° FINISH = SIZE DWG NO REV

003 0985 00

REMOVE SHARP EDGES AND CORNERS TO .02 -.03

12 11 10 9 8 7 6 5 RADIUS OR CHAMFER, DIMENSIONS IN INCHES. D K

SHREWSBURY, MASSACHUSETTS SHEET 1 OF 1

You might also like

- The Sinicki - Cameron JosephDocument1 pageThe Sinicki - Cameron Josephapi-537725393No ratings yet

- Blife SD STR BorepileDocument8 pagesBlife SD STR BorepileAgung EngineeringNo ratings yet

- Narrowly Focused Title on Document ContentDocument3 pagesNarrowly Focused Title on Document ContentSartika Hariani100% (1)

- Electrical Schematic DiagramDocument3 pagesElectrical Schematic DiagramLeopoldo LiriosNo ratings yet

- 288POP8083-A1 POP Assembly 2.88 EUE L-80 FMSDocument1 page288POP8083-A1 POP Assembly 2.88 EUE L-80 FMSdurvis romeroNo ratings yet

- Clarkson Kga+ Dn1200 Nps48 HC RDC 08.ADocument1 pageClarkson Kga+ Dn1200 Nps48 HC RDC 08.AAlejandro Pupunovich RodriguezNo ratings yet

- AB 036090 001 Joints For Cement Lined Pipe PDFDocument1 pageAB 036090 001 Joints For Cement Lined Pipe PDFfdfazfzNo ratings yet

- 1236 - We - Ab - CD - PJW - 0096 - Fit - 02 - A - PMT ApprovedDocument1 page1236 - We - Ab - CD - PJW - 0096 - Fit - 02 - A - PMT Approvedjesarvin.zapanta.hannresortsNo ratings yet

- P23008-St-Ti Tree Ice Room-Rvt21-001 - Sheet - 7m-5650-S-00008 - Ice Room Foundation PlanDocument1 pageP23008-St-Ti Tree Ice Room-Rvt21-001 - Sheet - 7m-5650-S-00008 - Ice Room Foundation Planmaodcb5No ratings yet

- Tpl-Yiapl-Ph1&2-An-39 R0Document1 pageTpl-Yiapl-Ph1&2-An-39 R0Ramesh BabuNo ratings yet

- Section Aa Detail at A Key Plan: CopingDocument1 pageSection Aa Detail at A Key Plan: CopingnikiNo ratings yet

- Detail A: PT Assy, Layout - JB34GDocument3 pagesDetail A: PT Assy, Layout - JB34GmatiasNo ratings yet

- Motc 09 Gen Aec Ar 9010Document1 pageMotc 09 Gen Aec Ar 9010Abid AyubNo ratings yet

- Conestoga College Doon Campus Site PlanDocument1 pageConestoga College Doon Campus Site PlancalvinNo ratings yet

- Cardiology - Burwood - Issue 8Document1 pageCardiology - Burwood - Issue 8greedygutzNo ratings yet

- Me-07 Battery Charge & Discharge BoardDocument20 pagesMe-07 Battery Charge & Discharge Boardvuhoan84No ratings yet

- Denah LagiDocument1 pageDenah Laginisa yolanda23No ratings yet

- Tpl-Yiapl-Ph1&2-An-35 R1Document1 pageTpl-Yiapl-Ph1&2-An-35 R1Ramesh BabuNo ratings yet

- G - 1 - A1 General Arrangment DrawingDocument1 pageG - 1 - A1 General Arrangment Drawingjonodo89No ratings yet

- Pro Engineer: DescriptionDocument1 pagePro Engineer: DescriptionGonzalo GalvezNo ratings yet

- 固定式42主机Document2 pages固定式42主机lly521002No ratings yet

- Latch Assy: Perkone Mer'"Document1 pageLatch Assy: Perkone Mer'"edgarNo ratings yet

- 739 DenahDocument1 page739 DenahRochmad MNo ratings yet

- ZCP4015Document1 pageZCP4015Juan Andres RacinesNo ratings yet

- South Dakota Circuit LayoutDocument1 pageSouth Dakota Circuit LayoutDarshani RajkumarNo ratings yet

- Toughened Fin: Section A-A Section A-ADocument1 pageToughened Fin: Section A-A Section A-ASACHIDANANDA SNo ratings yet

- Wall Types and NotesDocument1 pageWall Types and NotesAbid AyubNo ratings yet

- Ist Floor Punch Layout With Beam-Layout1Document1 pageIst Floor Punch Layout With Beam-Layout1A.K.M Shafiq MondolNo ratings yet

- p23008 ST Ti Tree Amenities Rvt21 001 Sheet 7m 5650 S 00007 Amenities Foundation PlanDocument1 pagep23008 ST Ti Tree Amenities Rvt21 001 Sheet 7m 5650 S 00007 Amenities Foundation Planmaodcb5No ratings yet

- F:/CAD Files/Attachments/Brgy. Bonbon - JPG: Vicinity Map Site Development PlanDocument1 pageF:/CAD Files/Attachments/Brgy. Bonbon - JPG: Vicinity Map Site Development PlanDon ManigosNo ratings yet

- Ifc-Issued For Construction-Rev-0: Ground Floor PlanDocument1 pageIfc-Issued For Construction-Rev-0: Ground Floor PlanemadNo ratings yet

- 03.Stc Rop Ofc SB 1 Ac 03Document1 page03.Stc Rop Ofc SB 1 Ac 03MadhankumarNo ratings yet

- Cardiology - Burwood - Issue 5Document1 pageCardiology - Burwood - Issue 5greedygutzNo ratings yet

- ZCP13385Document1 pageZCP13385Juan Andres RacinesNo ratings yet

- Plano Mudulo Puertas Q21-1050Document2 pagesPlano Mudulo Puertas Q21-1050Dilfre MartinezNo ratings yet

- Roof top solution for Globe TowerDocument15 pagesRoof top solution for Globe TowerChris AtayNo ratings yet

- Mass Private Villa A Layout PlanDocument1 pageMass Private Villa A Layout Planneysa auliaNo ratings yet

- General Arrangement, AIR COOLED (R90-110) 23539836 GDocument7 pagesGeneral Arrangement, AIR COOLED (R90-110) 23539836 GCarlos JiménezNo ratings yet

- Control building layoutDocument1 pageControl building layoutSIMBOLON RIMBANGNo ratings yet

- Cardiology - Burwood - Issue 4Document1 pageCardiology - Burwood - Issue 4greedygutzNo ratings yet

- Emaar Plot A017 Icon Bay Residential Tower On DCH Island DistrictDocument1 pageEmaar Plot A017 Icon Bay Residential Tower On DCH Island DistrictZeeZ HNo ratings yet

- Cardiology - Burwood - Issue ADocument1 pageCardiology - Burwood - Issue AgreedygutzNo ratings yet

- 1802 A 260-1 B TYPICAL CEILING FRAME DETAILS at KITCHEN BULKHEAD 20201214Document1 page1802 A 260-1 B TYPICAL CEILING FRAME DETAILS at KITCHEN BULKHEAD 20201214binti Abdul Majid Intan SyananieNo ratings yet

- Davao Doctors Care Center As-Built PlanDocument17 pagesDavao Doctors Care Center As-Built Planjossan doplaynaNo ratings yet

- 2 STOREY 6mX24m BARRACKS (ARDANE) SHOP DRAWING 08-20-2020Document8 pages2 STOREY 6mX24m BARRACKS (ARDANE) SHOP DRAWING 08-20-2020jayson egeniasNo ratings yet

- Detail A - With Cooler Option: Pro EngineerDocument1 pageDetail A - With Cooler Option: Pro EngineerGonzalo GalvezNo ratings yet

- Compas Swing FF-02Document1 pageCompas Swing FF-02mohd azizul SabaranNo ratings yet

- Order Pintu Sandwich Panel (StarPanel)Document1 pageOrder Pintu Sandwich Panel (StarPanel)game elswordNo ratings yet

- Tangki Pendam Single Wall 20 KLDocument1 pageTangki Pendam Single Wall 20 KLalfianNo ratings yet

- Standard Drawing 4201 High Profile Barrier Kerb Midwest Barrier KerbDocument1 pageStandard Drawing 4201 High Profile Barrier Kerb Midwest Barrier Kerbpresley.siaNo ratings yet

- Standard Drawing 3903 Concrete Barriers F Shape Manufacture Precast Dec 2020Document1 pageStandard Drawing 3903 Concrete Barriers F Shape Manufacture Precast Dec 2020Mhd ThrNo ratings yet

- Revisions C: AG9 REDRAWN PER ECO-19-005708 BKW SFDocument1 pageRevisions C: AG9 REDRAWN PER ECO-19-005708 BKW SFMarcos MoraisNo ratings yet

- Tpl-Yiapl-Ph1&2-An-15 R1Document1 pageTpl-Yiapl-Ph1&2-An-15 R1Ramesh BabuNo ratings yet

- Single cylinder steam engine general arrangementDocument4 pagesSingle cylinder steam engine general arrangementJorge Luis Villegas ValdiviaNo ratings yet

- Fortune BuildersDocument5 pagesFortune Buildersromeo pedranoNo ratings yet

- Covered Walkway Wall-AttachedDocument1 pageCovered Walkway Wall-AttachedErnesto LopezNo ratings yet

- Sika Crete 211 structural repair guideDocument1 pageSika Crete 211 structural repair guidePatricia TicseNo ratings yet

- Asy13144Document87 pagesAsy13144Oz DemonNo ratings yet

- Lifting Specification RexDocument1 pageLifting Specification Rexsamir.ahmed7577No ratings yet

- Multistoreyed Building 3Document26 pagesMultistoreyed Building 3V.m. RajanNo ratings yet

- CalcinationDocument6 pagesCalcinationRogerio CannoniNo ratings yet

- Aoac 975.08 FluorurosDocument1 pageAoac 975.08 FluorurosNeidys Sanchez100% (1)

- Piping Material SpecificationDocument50 pagesPiping Material Specificationroxym123456No ratings yet

- The Effect of Heat On Matter (Melting&Freezing) .Ppt2Document17 pagesThe Effect of Heat On Matter (Melting&Freezing) .Ppt2Farah Dinah HassanNo ratings yet

- E01 EFieldEquiPotentialDocument9 pagesE01 EFieldEquiPotentialVea CalpoturaNo ratings yet

- PLANES, FORMS, AND RECIPROCAL LATTICEDocument9 pagesPLANES, FORMS, AND RECIPROCAL LATTICEvijayNo ratings yet

- NCERT Solutions For Class 9 ScienceDocument33 pagesNCERT Solutions For Class 9 ScienceShivang MohtaNo ratings yet

- Vtpsewage PDFDocument6 pagesVtpsewage PDFDóriclo FernandesNo ratings yet

- Explore the Balmer Series of Hydrogen Emission SpectraDocument5 pagesExplore the Balmer Series of Hydrogen Emission SpectraEddie WinterNo ratings yet

- Materials Science and Engineering - A First Course - V. RaghavanDocument53 pagesMaterials Science and Engineering - A First Course - V. RaghavanDhvani Rakeshkumar Shah 4-Yr B.Tech. Chemical Engg., IIT(BHU), VaranasiNo ratings yet

- Alloy 286Document6 pagesAlloy 286shivam.kumarNo ratings yet

- GFGHHJDocument18 pagesGFGHHJsssadangiNo ratings yet

- Silane Adhesion Promoters: Edwin P. PlueddemannDocument3 pagesSilane Adhesion Promoters: Edwin P. PlueddemannTamo LokoNo ratings yet

- 2.5.5. Peroxide ValueDocument4 pages2.5.5. Peroxide ValuejjtedyNo ratings yet

- Subramanian Aasha Research PaperDocument18 pagesSubramanian Aasha Research Paperapi-357907235No ratings yet

- 3M Electronic Grade CoatingDocument4 pages3M Electronic Grade Coatingganasaii3882No ratings yet

- Ammonia, Sulfur, Air N Water - 1Document2 pagesAmmonia, Sulfur, Air N Water - 1bilalNo ratings yet

- CAR RUBBER TESTING PARAMETERSDocument3 pagesCAR RUBBER TESTING PARAMETERSBharat ChatrathNo ratings yet

- Water The Universal Solvent 3Document14 pagesWater The Universal Solvent 3Kasey NelmsNo ratings yet

- JC2 (05/06) Physics Common Test 2006 Suggested Answers: Paper 1Document13 pagesJC2 (05/06) Physics Common Test 2006 Suggested Answers: Paper 1wangks1980No ratings yet

- Badger RCDL DatasheeDocument2 pagesBadger RCDL Datasheeابزار دقیقNo ratings yet

- PTE Catalogue 2021Document28 pagesPTE Catalogue 2021PP043No ratings yet

- Reliably detect materials with variable electrical properties using a highly sensitive vibration type level switchDocument8 pagesReliably detect materials with variable electrical properties using a highly sensitive vibration type level switchHoàngViệtAnhNo ratings yet

- Curzard's Worm CYOADocument9 pagesCurzard's Worm CYOAMortuus EstNo ratings yet

- Atoms and Atomic StructureDocument6 pagesAtoms and Atomic StructureJim GoetzNo ratings yet

- ACI Mix Design Example - Pavement InteractiveDocument5 pagesACI Mix Design Example - Pavement InteractiveAbu RaeesNo ratings yet

- Lectut CHN-102 PDF ReactiveDocument4 pagesLectut CHN-102 PDF ReactiveTanmaysainiNo ratings yet

- EIILM University MaterialsDocument18 pagesEIILM University MaterialsPawan SainiNo ratings yet

- Form Six Chemistry 1Document6 pagesForm Six Chemistry 1abubakarimuyanaNo ratings yet