Professional Documents

Culture Documents

Kohler 28EFOZD Specifications

Kohler 28EFOZD Specifications

Uploaded by

Kelvin YuenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kohler 28EFOZD Specifications

Kohler 28EFOZD Specifications

Uploaded by

Kelvin YuenCopyright:

Available Formats

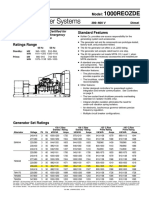

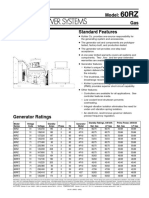

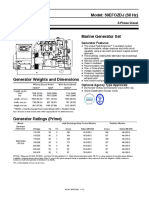

Model: 32EOZD 60 Hz

28EFOZD 50 Hz

1-Phase Diesel

Marine Generator Set

Engine Features

D Diesel fueled

D Four cylinder

D Four cycle

D U.S. Marine EPA Tier 2 (60 Hz model)

D Closed cooling system

D Heat exchanger

D Lifting eyes

D Electric fuel lift pump

Generator Features

D Remote start 12-pin connector

D Class H insulation

D Multivoltage adjustability

D Voltage regulation of 1.5%

Radio suppression

Generator Weights and Dimensions

D

Without With ADC 2100 Advanced Digital Control

Sound Shield Sound Shield Features

Weight, kg (lbs.) D Designed for today’s most sophisticated electronics

wet 583 (1285) 628 (1385) D Easy to read alpha-numeric display

dry 576 (1270) 621 (1370) D Compact, integrally mounted control

Length, mm (in.) 1188 (46.80) 1295 (51.00) D Potted boards/sealed connectors for maximum

Width, mm (in.) 635 (25.00) 635 (25.00) corrosion protection

Height, mm (in.) 767 (30.20) 810 (31.88) D SAE J-1939 CANbus output

D Remote monitoring of up to 13 fault conditions

Generator Ratings D Membrane keypad for configuration and

adjustment

Model D Programmed crank cycle

Generator 25_C (77_F) 25_C (77_F)

(Alternator) Voltage Hz Amps kW/kVA Ph

Optional Accessories

32EOZD D Sound shield

120/240 60 133 32/32 1

(4Q5W) D Remote digital gauge

115/230 50 122 28/28 1 D Siphon break

28EFOZD D Circuit breakers

230 50 122 28/28 1

(4Q5W)

240 50 117 28/28 1

RATINGS: Marine continuous ratings per ISO 3046, ISO 8528-1, and Kohler ISO rating

guideline 2.14. Obtain technical information bulletin (TIB-101) on ratings guidelines for complete

ratings definitions.

Availability is subject to change without notice. Kohler Co. reserves the right to change the design or

specifications without notice and without any obligation or liability whatsoever. Contact your local

Kohler generator distributor for availability.

G2-145 (32EOZD) 1/15d

Application Data

Engine Operation Requirements

Engine Specifications 60 Hz 50 Hz Air Requirements 60 Hz 50 Hz

Type 4 cycle, naturally aspirated Engine combustion air requirements 2680 2240

L/min. (cfm) (95) (79)

Cylinder, number 4

Engine/generator cooling requirements 15574 13025

Displacement, L (cu. in.) 3.319 (202.5) L/min. (cfm) (550) (460)

Bore and stroke, mm (in.) 98 (3.86) x 110 (4.33) Max. air intake restriction,

Compression ratio 18.5:1 kPa (mm H2O) 6.23 (635)

Combustion system Direct injection Exhaust flow, m3/min. (cfm) 7.0 (248) 5.5 (193)

Dry exhaust temp., C (F) 566 (1050) 510 (950)

Rated rpm 1800 1500

Max. allowed exhaust back pressure,

Max. power at rated rpm, HP 55.8 46.7 kPa (mm H2O) 15.30 (1560)

Cylinder block material Cast iron

Fuel Consumption 60 Hz 50 Hz

Cylinder head material Cast iron

Diesel, Lph (gph) at % load

Piston rings 2 compression/1 oil

100% 9.9 (2.69) 7.8 (2.05)

Crankshaft material Forged steel

75% 7.5 (1.99) 5.9 (1.56)

Connecting rod material Forged carbon steel

50% 5.5 (1.46) 4.2 (1.10)

Governor, type Centrifugal 25% 3.6 (0.96) 2.8 (0.74)

Frequency regulation, mechanical

governor

No load to full load (droop)

Steady state

5%

0.8%

Engine Features

D One-side serviceability of fuel system, lubrication system, seawater

pump, and air cleaner

Engine Electrical

D Low oil pressure shutdown

Engine Electrical System 60 Hz 50 Hz D High engine temperature shutdown

Battery, voltage 12 volt (standard) D Seawater pump impeller failure shutdown

24 volt (optional)

D Focused vibromounts

Battery, charging 40-amp alternator

D Belt guard

Battery, recommendation (minimum) 800 CCA 100 amp hr.

D Disposable oil filter

Starter motor 2.3 kW

D Oil drain valve and hose

Cooling

Alternator Features

Cooling System 60 Hz 50 Hz

D Brushless, rotating field design permits power to be obtained from

Capacity, L (U.S. qts.) (approx.) 7.57 (8) stationary leads.

Heat exchanger type 3 in. dia. 3 pass D Rotor and stator are vacuum impregnated and coated with

Seawater pump type Belt-driven, high-bond epoxy varnish. Varnish helps prevent corrosion in

10-blade impeller high-humidity areas.

Heat rejected to cooling water at rated D Rotors are dynamically balanced to minimize vibration.

kW, wet exhaust, kW (Btu/min.) 28.8 (1639) 24.1 (1373) D Copper windings ensure minimal heat buildup. Insulation meets

Engine water pump flow, Lpm (gpm) 55.9 (14.8) 45.0 (11.9) NEMA standards for class H insulation.

Seawater pump flow, Lpm (gpm) 22.7 (6) 18.9 (5) D Direct connected to the engine, the generator has sealed precision

ball bearings with a precision-machined steel sleeve in the end

bracket to prevent shaft misalignment and extend bearing life.

Fuel

D Mounted on a drip-proof tray.

Fuel System 60 Hz 50 Hz D Equipped with a four-lead reconnectable stator.

Fuel shutoff solenoid Electric D Capable of sustained line-to-neutral short circuit current of up to

Fuel pump Electric, rotary vane 300% of the rated current for up to 2 seconds. (IEC 60092-301

short-circuit performance.)

Fuel pump priming Electric

Maximum recommended fuel lift, m (ft.) 1.2 (4)

Lubrication

Lubricating System 60 Hz 50 Hz

Oil pan capacity with filter, L (U.S. qts.) 10.2 (10.78)

Oil pump type Pressure, trochoid pump

G2-145 (32EOZD) 1/15d

Application Data

ADC 2100 Control Features Accessories

Sound Shield

Provides for highly effective silencing, ease of access for

engine/generator servicing, low maintenance, excellent

durability, and safety. The sound shield’s customer

connection panel includes connections for the following:

d Battery (positive and negative)

d Equipment ground

d Fuel inlet and return

d Seawater inlet

d Water-cooled exhaust outlet

d Oil drain

d Customer load lead access

D LED display: d Customer interface

d Runtime hours

d Crank cycle status Siphon Break

d Diagnostics/fault codes/data Mandatory kit on generators installed below the waterline.

D Keypad Prevents the siphoning of flotation water into the engine.

d Secure access, password protected Line Circuit Breakers

d Voltage, gain, and speed adjustment

Protect the generator from extreme overload.

d Controller configuration (system voltage, phase, and

frequency settings, battery voltage, and generator set Ship-to-Shore Switch

model)

Allows immediate switching to KohlerR generator set

D Master control switch: run/off-reset/auto (engine start) power or shore power protecting the electrical system from

D Remote two-wire start/stop capability the possibility of simultaneous connection of both power

D Potted electronics and sealed connections sources. Available as a three-pole ship-to-shore switch.

D Voltage regulation ±1.5% Remote Digital Gauge

D Cyclic cranking: 15 seconds on, 15 seconds off Allows starting/stopping from a location remote from the

(3 cycles) generator set. Standard 76.2 mm (3 in.) dia. hole required

D Faults with shutdown: for mounting.

d High engine temperature

Oil Pressure Sender Kit

d Low oil pressure

d Loss of coolant Provides sender necessary to make digital gauge

functional.

d Overcrank safety

d Overspeed Remote Connection/Extension Harness

d Over/under voltage Provides wiring between the remote digital gauge and the

d Over/under frequency ADC connector. Extension limited to a total of four kits

d Auxiliary fault and 23 m (75 ft.). Available in 4.6 m (15 ft.) and 7.6 m

(25 ft.) lengths.

D Faults with warning:

d Low battery voltage 12-Inch Remote Wiring Harness

d High battery voltage Equipped with a 12-pin connector on one end that

D Power requirements: connects to the standard customer interface connector.

d 12 or 24 VDC with fuse protection Equipped on the other end with leads for connection to

d 200 mA @ 12VDC/100 mA @ 24 VDC customer-supplied wiring.

G2-145 (32EOZD) 1/15d

KOHLER CO., Kohler, Wisconsin 53044 USA

Phone 920-457-4441, Fax 920-459-1646

For the nearest sales and service outlet in the

US and Canada, phone 1-800-544-2444

KOHLERPower.com

ADV-7381a-a

ADV-7381b-a

DISTRIBUTED BY:

NOTE: Dimensions are shown in mm [in.].

NOTE: This drawing is provided for reference only and is not

intended for installation planning. Contact your local

distributor for more detailed information.

E 2008, 2010, 2011, 2014, and 2015 Kohler Co. All rights reserved.

G2-145 (32EOZD) 1/15d

You might also like

- Kohler Model 45rz 45kw Natural Gas Generator SetDocument4 pagesKohler Model 45rz 45kw Natural Gas Generator SetRebecca Winfrey100% (1)

- B/FL/FM 2011: Operation ManualDocument60 pagesB/FL/FM 2011: Operation Manualstephen prosser75% (4)

- Kohler 12.5EDocument4 pagesKohler 12.5EMike JacobsNo ratings yet

- Kohler 30REOZJB John Deere 3029TF150 Spec Sheet PDFDocument4 pagesKohler 30REOZJB John Deere 3029TF150 Spec Sheet PDFEric LaguipoNo ratings yet

- Operation Manual Steyr Edition 6 2016 PDFDocument134 pagesOperation Manual Steyr Edition 6 2016 PDFĐại DươngNo ratings yet

- MEK Marine MAN Engine Spare PartsDocument6 pagesMEK Marine MAN Engine Spare PartsMEK MarineNo ratings yet

- TrailBlazer 2006 PDFDocument719 pagesTrailBlazer 2006 PDFIvan Almeida100% (2)

- Promo129 CAT Selective Parts Guide Brochure - For Website - Smaller 1Document70 pagesPromo129 CAT Selective Parts Guide Brochure - For Website - Smaller 1RIZA BAKIRNo ratings yet

- Engines: Symbolisation 062356 B3 Symbolisation 062045 B5Document52 pagesEngines: Symbolisation 062356 B3 Symbolisation 062045 B5Hamid edris100% (2)

- Model: 23EOZD 20efozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 23EOZD 20efozd: 60 HZ 50 HZ 1-Phase DieselMaksym KlymenkoNo ratings yet

- Model: 15.5EOZD 13efozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 15.5EOZD 13efozd: 60 HZ 50 HZ 1-Phase Dieselabduallah muhammadNo ratings yet

- Model: 10EOZD 9efozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 10EOZD 9efozd: 60 HZ 50 HZ 1-Phase DieselTeszt Sdj100% (1)

- 9EKOZD SpecificationsDocument4 pages9EKOZD SpecificationsEfrain FlorezNo ratings yet

- Model: 6EKOD 5efkod: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 6EKOD 5efkod: 60 HZ 50 HZ 1-Phase Dieselyeng menNo ratings yet

- 6EKOD SpecificationsDocument4 pages6EKOD SpecificationsEfrain FlorezNo ratings yet

- 11EKOZD SpecificationsDocument4 pages11EKOZD SpecificationsEfrain FlorezNo ratings yet

- Model: 11EKOZD 9efkozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 11EKOZD 9efkozd: 60 HZ 50 HZ 1-Phase DieselEdgar MaldonadoNo ratings yet

- Kohler 24 Specs SheetDocument4 pagesKohler 24 Specs Sheetabduallah muhammadNo ratings yet

- 7.5EKD SpecificationsDocument4 pages7.5EKD SpecificationsEfrain FlorezNo ratings yet

- 5EKD Spec SheetDocument4 pages5EKD Spec Sheetluis.auNo ratings yet

- Model: 40EKOZD 35efkozd: 60 HZ 50 HZ 3-Phase DieselDocument4 pagesModel: 40EKOZD 35efkozd: 60 HZ 50 HZ 3-Phase DieselsebastianNo ratings yet

- Kohler 35EFKOZD SpecificationsDocument4 pagesKohler 35EFKOZD SpecificationsKelvin YuenNo ratings yet

- Kohler Model13ERGDocument4 pagesKohler Model13ERGWilliamBrown6No ratings yet

- Kohler Marine GensetDocument4 pagesKohler Marine GensetENG PTBBSNo ratings yet

- Kohler 100efozcjDocument6 pagesKohler 100efozcjoppa FadlyNo ratings yet

- Kohler 80efozcjDocument4 pagesKohler 80efozcjoppa FadlyNo ratings yet

- Kohler Marine 70efozd PDFDocument4 pagesKohler Marine 70efozd PDFĐại DươngNo ratings yet

- Model: 55EOZCJ (60 HZ) 45EFOZCJ (50 HZ) : 3-Phase DieselDocument4 pagesModel: 55EOZCJ (60 HZ) 45EFOZCJ (50 HZ) : 3-Phase DieselsebastianNo ratings yet

- Kohler Generator g2166Document4 pagesKohler Generator g2166philipNo ratings yet

- Kohler Moteur Johndeere 50EFOZDDocument4 pagesKohler Moteur Johndeere 50EFOZDzirra82No ratings yet

- 50EFOZDJ Technical DataDocument4 pages50EFOZDJ Technical DataĐặng MinhNo ratings yet

- Model: 500EOZCS (60 HZ) 450EFOZCS (50 HZ) : 3-Phase DieselDocument4 pagesModel: 500EOZCS (60 HZ) 450EFOZCS (50 HZ) : 3-Phase DieselPato DuhaldeNo ratings yet

- Reod/Reozd: ModelDocument4 pagesReod/Reozd: ModelGalindez JoséNo ratings yet

- Reozt Reozt: Model: ModelDocument4 pagesReozt Reozt: Model: Modelrendi valentinoNo ratings yet

- Kohler 50 PDFDocument4 pagesKohler 50 PDFĐại DươngNo ratings yet

- Model:: Residential GasDocument4 pagesModel:: Residential Gasapelectric100% (1)

- 1000REOZDEDocument4 pages1000REOZDELanh TranNo ratings yet

- Kohler 2000ROZD4 Spec SheetDocument4 pagesKohler 2000ROZD4 Spec SheetKhaled KamelNo ratings yet

- Model: 50EFOZCJ (50 HZ) : 3-Phase DieselDocument4 pagesModel: 50EFOZCJ (50 HZ) : 3-Phase DieselĐại DươngNo ratings yet

- BLOWER 10-10DD 0.50 CCW CV at 1075RPMDocument3 pagesBLOWER 10-10DD 0.50 CCW CV at 1075RPMDiego RomeroNo ratings yet

- Generator - Kohler Power SystemDocument4 pagesGenerator - Kohler Power SystemBrillyanNo ratings yet

- 1500REOZDBDocument4 pages1500REOZDBRodrigoNo ratings yet

- Kholer Generator 750REOZMD Spec SheetDocument4 pagesKholer Generator 750REOZMD Spec SheetNicholas BrennanNo ratings yet

- BLOWER 9-7DD 0.50 CCW CV at 1075RPMDocument3 pagesBLOWER 9-7DD 0.50 CCW CV at 1075RPMDiego RomeroNo ratings yet

- Kohler 60RZ Spec SheetDocument4 pagesKohler 60RZ Spec SheetRomanvi1980No ratings yet

- Kohler 800rozmc SpecDocument4 pagesKohler 800rozmc Speclilama45-1No ratings yet

- Reozjc: Standard Features Ratings RangeDocument4 pagesReozjc: Standard Features Ratings RangeJulio CesarNo ratings yet

- 50EFOZDJ3PH Specifications SheetDocument4 pages50EFOZDJ3PH Specifications SheetDavid GPNo ratings yet

- Detroit Diesel Spectrum 600DS 4 Spec Sheet PDFDocument4 pagesDetroit Diesel Spectrum 600DS 4 Spec Sheet PDF6PMK IecaNo ratings yet

- Reozje: ModelDocument4 pagesReozje: ModelLuis LunarNo ratings yet

- Model KSS: Automatic Transfer Switches Standard Specific-Breaker RatedDocument8 pagesModel KSS: Automatic Transfer Switches Standard Specific-Breaker RatedIvan RamosNo ratings yet

- Kohler 50rozj Spec SheetDocument4 pagesKohler 50rozj Spec SheetRomanvi1980No ratings yet

- Manual Kohler 30RYGDocument4 pagesManual Kohler 30RYGjtamez2009No ratings yet

- Models:: Multi-Fuel LP Vapor/Natural GasDocument4 pagesModels:: Multi-Fuel LP Vapor/Natural GasapelectricNo ratings yet

- G5318 10reodbDocument4 pagesG5318 10reodbsakrgeorge2000No ratings yet

- Datasheet 10reozdcDocument4 pagesDatasheet 10reozdcWilliam AlvaradoNo ratings yet

- 38RCLDocument4 pages38RCLAdmin BisnisNo ratings yet

- Kohler 20resl 14resl SpecificationsDocument4 pagesKohler 20resl 14resl SpecificationsapelectricNo ratings yet

- PDF-202312 US Kohler G11136g20g en-USDocument10 pagesPDF-202312 US Kohler G11136g20g en-USgarcia amaralNo ratings yet

- JCB 214e Series 4 Backhoe Loader: F A S T - F A C T SDocument8 pagesJCB 214e Series 4 Backhoe Loader: F A S T - F A C T SFanatrailer FanatrailerNo ratings yet

- Common Techinfo Single For Europe R410a 50hz Ver 1 6 TDBDocument200 pagesCommon Techinfo Single For Europe R410a 50hz Ver 1 6 TDBMohammad ShariqueNo ratings yet

- PVC PDFDocument1 pagePVC PDFfahemNo ratings yet

- 14resa (L) Spec Sheet 2019Document6 pages14resa (L) Spec Sheet 2019angelNo ratings yet

- Ss dfc7Document56 pagesSs dfc7ridipisaNo ratings yet

- Three-Phase Brushless Synchronous AlternatorsDocument2 pagesThree-Phase Brushless Synchronous AlternatorsĐại DươngNo ratings yet

- Synchronous Alternators9Document1 pageSynchronous Alternators9Đại DươngNo ratings yet

- Performance Data: Steady State Voltage VariationDocument1 pagePerformance Data: Steady State Voltage VariationĐại DươngNo ratings yet

- General PresentationDocument81 pagesGeneral PresentationĐại DươngNo ratings yet

- 7 PDFDocument1 page7 PDFĐại DươngNo ratings yet

- 2 PDFDocument1 page2 PDFĐại DươngNo ratings yet

- Synchronous Alternators: Three-Phase BrushlessDocument5 pagesSynchronous Alternators: Three-Phase BrushlessĐại DươngNo ratings yet

- 4 PDFDocument1 page4 PDFĐại DươngNo ratings yet

- 4 PDFDocument1 page4 PDFĐại DươngNo ratings yet

- Kohler Marine 70efozd PDFDocument4 pagesKohler Marine 70efozd PDFĐại DươngNo ratings yet

- Fast Vessels: ZWVS 440 - 930 - 350 - 3,082 KWDocument6 pagesFast Vessels: ZWVS 440 - 930 - 350 - 3,082 KWĐại DươngNo ratings yet

- Kohler 50 PDFDocument4 pagesKohler 50 PDFĐại DươngNo ratings yet

- Model: 50EFOZCJ (50 HZ) : 3-Phase DieselDocument4 pagesModel: 50EFOZCJ (50 HZ) : 3-Phase DieselĐại DươngNo ratings yet

- 2 PDFDocument1 page2 PDFĐại DươngNo ratings yet

- 960-0206B Onan MCG MDG Series Parts Spec A Spec D (4-2001) PDFDocument113 pages960-0206B Onan MCG MDG Series Parts Spec A Spec D (4-2001) PDFĐại Dương100% (1)

- Powertech 4.5L Engine Engine Performance Curve: 60 HZ - 148Hp (110Kw) at 1800 RPMDocument4 pagesPowertech 4.5L Engine Engine Performance Curve: 60 HZ - 148Hp (110Kw) at 1800 RPMĐại DươngNo ratings yet

- Terms and Conditions of PurchaseDocument4 pagesTerms and Conditions of PurchaseĐại DươngNo ratings yet

- 4045afm85 F 50hz-Proformance-Curve PDFDocument4 pages4045afm85 F 50hz-Proformance-Curve PDFĐại DươngNo ratings yet

- Items Part No. Designation UNI T QTYDocument10 pagesItems Part No. Designation UNI T QTYĐại DươngNo ratings yet

- SIL98-9B Service LetterDocument4 pagesSIL98-9B Service LettermahmoodchowdhuryNo ratings yet

- Parts CatalogDocument77 pagesParts CatalogBarıs AtayNo ratings yet

- Kubota Engines Shop Manual Parts CatalogDocument23 pagesKubota Engines Shop Manual Parts Catalogjeremiahsantos080191djm100% (76)

- Siemens Injector Test Data New6 PDFDocument20 pagesSiemens Injector Test Data New6 PDFJuan David Cepeda GonzalesNo ratings yet

- Parts Manual PDFDocument19 pagesParts Manual PDFDavid Gaytán SmithNo ratings yet

- Troubleshooting Fuel Dilution of Engine Oil PDFDocument2 pagesTroubleshooting Fuel Dilution of Engine Oil PDFmanu luvungaNo ratings yet

- Renr9346 06 00 AllDocument200 pagesRenr9346 06 00 Allgabriel garcia100% (1)

- CCFJ30J W TD226B 3Document2 pagesCCFJ30J W TD226B 3argodumilahNo ratings yet

- Optra 2006 ECM Connector PDFDocument3 pagesOptra 2006 ECM Connector PDFYulys Teresa Diaz Freites100% (1)

- A8000 - c9 12v Engine - En-UsDocument143 pagesA8000 - c9 12v Engine - En-UsAprendiz- Ivan CanoNo ratings yet

- Piston & Crankshaft - S130Document4 pagesPiston & Crankshaft - S130mnvijaybabuNo ratings yet

- Master Carburetion 1Document70 pagesMaster Carburetion 1digitaladhNo ratings yet

- 10 - Timing Chain - InstallationDocument7 pages10 - Timing Chain - Installation08088338No ratings yet

- Engine Performance Curve: Rating: Application:MarineDocument4 pagesEngine Performance Curve: Rating: Application:Marinekman548No ratings yet

- Engine Class-3 BD Question BankDocument11 pagesEngine Class-3 BD Question BankRakibul JubayerNo ratings yet

- Rotary Drilling Rig: Zoomlion Heavy Industry Science & Technology Co.,LtdDocument2 pagesRotary Drilling Rig: Zoomlion Heavy Industry Science & Technology Co.,LtdAkkhaded SrionNo ratings yet

- Moss PiecesDocument70 pagesMoss Piecesapi-3732333No ratings yet

- APU GuideDocument21 pagesAPU Guideavianova0% (1)

- 1-11/16" MSSTDocument1 page1-11/16" MSSTMcSOLA O100% (1)

- Engine Power DataDocument4 pagesEngine Power DataBlack TigerNo ratings yet

- Caterpillar C 9Document7 pagesCaterpillar C 9prakash buddhdevNo ratings yet

- Husaberg Fe 550-E 2007 MotorDocument28 pagesHusaberg Fe 550-E 2007 Motorjinxy06No ratings yet

- th414 enDocument2 pagesth414 enFelipe Andrés Camarada SilvaNo ratings yet

- Perkins - General Ti BulletinDocument65 pagesPerkins - General Ti BulletinUTEL CARTERNo ratings yet

- Woodward E6 Lean & Rich Burn Gas Engine ControlDocument22 pagesWoodward E6 Lean & Rich Burn Gas Engine ControlclaudioNo ratings yet