Professional Documents

Culture Documents

Mechanical Metigurical Dimensional

Uploaded by

Paviter SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Metigurical Dimensional

Uploaded by

Paviter SinghCopyright:

Available Formats

SCOPE OF ACCREDITATION TO ISO/IEC 17025:2005

LABORATORY TESTING, INC.

2331 Topaz Drive

Hatfield, PA 19440

Frank Peszka Phone: 800 219 9095

MECHANICAL

Valid Until: March 31, 2013 Certificate Number: 117.02

In recognition of the successful completion of the A2LA evaluation process, accreditation is granted to this

laboratory to perform the following metal and fastener tests:

Mechanical Testing

Test Test Method

Compression Test of Washers ASTM F959

Hardness

Brinell ASTM E10

Rockwell (A, B, C, E, F) ASTM E18; NASM-1312-6

Superficial (15, 30, 45 N & T) ASTM E18; NASM-1312-6

Vickers (1-10kg) ASTM E384

Microhardness (Knoop, Vickers (25-1000g)) ASTM E384; NASM-1312-6

Shore (A, B, C, D) ASTM E2240 (N)

Tensile and Proof Load (<= 400klbs, <=2100 oF) ASTM E8/E8M, E9, E21, A370, B557,

F606/F606M, F835, NASM-1312-8; EN 2002-1,

10002-1, 1025-02; ISO 6892-1

Jominy Hardenability ASTM A255

Expansion (Pin Test) of Copper and Copper ASTM B153

Alloy Piping and Tubing

Compressible-Washer-Type Direct Tension ASTM F959

Indicators for Use with Structural Fasteners

Flattening ASTM A999, A530

Conductivity BAC 5946 (N)

Flare Testing AMS 5557, 5576

Fastener Testing ASTM A370, F606; SAE J429; NASM-1312-18

(Dplication acceptable)

Bend Testing ASTM E290, E190, A370

Stress Rupture ASTM E139, E292; NASM-1312-10

(A2LA Cert. No. 117.02) Revised 02/17/2012 Page 1 of 3

Test Test Method

Stress Durability (Hydrogen Embrittlement) NASM-1312-5A

Impact (Charpy) ASTM E23, ISO 148

Drop Weight ASTM E208

Metallographic Evaluation

Preparation ASTM E3

Grain Size ASTM E112, E930, E1181, E1382; GE E50TF133

Micro Exam (including Alpha Case) ASTM E407; GE P3TF19; PWA E142;

AMS-T-9046 section 4.4.2

Macro Exam ASTM E340, E381, A604

Intergranular Corrosion Susceptibility ASTM A262 (Practices A & E (micro))

Intergranular Attack & End Grain Pitting BSS 7219

Case Depth SAE J423

Delta Ferrite Determination AMS 2315

Steel Self-Drilling Tapping Screws SAE J78

Microhardness of Electroplated Coatings ASTM B578

Inclusion Content ASTM E45; SAE J422

Plating Thickness ASTM B487; NASM-1312-12

Depth of Decarburization ASTM E1077, E384; SAE J121

EDM & Laser Evaluation (Recast / Remelt) CPW 425; PWA E167

Weld and Braze Evaluation ASME IX; API 1104; AWS D1.1/1.1M, 1.2/1.2M,

D1.3, D1.4, D1.5, D1.6, D9.1/9.1M,

D14.1/14.1M, D14.3/14.3M. D14.4, D14.6,

D15.1, D17.1; ISO 15614-1; BS EN 287-1, 287-2,

910, 288-4; New York State Steel Construction

Manual; AMS-STD-1595; ASTM A488; MIL-

STD-248D; NAVSEA S9674-AQ-GIB-010;

ANSI/AASHTO

Failure Analysis ASM Handbook 11 (N)

Dimensional Testing

Parameter/Equipment Range CMC1 (±) Comments

Thread Inspection –

Tri-roll Gauging: (0 to 1⅞) in 0.00028 in

External Threads FED-STD H28/20A (systems 21, 22,

& 23); AS8879C

Bi-Element: #10 to 1⅝ in 0.00026 in

Internal Threads MIL-DTL-1222J; FEDSTD H28/20;

ANSI/ASME B1.1M

External Threads: (0 to 1½) in 0.00019 in

Ring Gauges MIL-S-8879; ANSI/ASME B1.3M

(Go-No-Go)

Internal Threads: #10 to 1⅝ in 0.00015 in MIL-S-007742C

Thread Plug Pratt & Whitney Supermicrometer®

(A2LA Cert. No. 117.02) Revised 02/17/2012 Page 2 of 3

Parameter/Equipment Range CMC1, 2 (±) Comments

Length2 (0 to 20) in (19 + 3.4L) μin UMM

Angle 0° to 360° 0°, 1’, 57” Video measuring machine

Radius Up to 6 in (150 + 6L) μin Video measuring machine

_____________________________________________

1

Calibration and Measurement Capability (CMC) is the smallest uncertainty of measurement that a

laboratory can achieve within its scope of accreditation when performing more or less routine calibrations

of nearly ideal measurement standards or nearly ideal measuring equipment. Calibration and

Measurement Capabilities represent expanded uncertainties expressed at approximately the 95 % level of

confidence, usually using a coverage factor of k = 2. The actual measurement uncertainty of a specific

calibration performed by the laboratory may be greater than the CMC due to the behavior of the

customer’s device and to influences from the circumstances of the specific calibration.

2

In the statement of CMC, L is the numerical value of the nominal length of the device measured in inches.

(A2LA Cert. No. 117.02) Revised 02/17/2012 Page 3 of 3

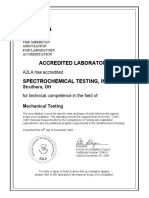

A2LA has accredited

LABORATORY TESTING, INC.

Hatfield, PA

for technical competence in the field of

Mechanical Testing

This laboratory is accredited in accordance with the recognized International Standard ISO/IEC 17025:2005 General Requirements for

the Competence of Testing and Calibration Laboratories. This accreditation demonstrates technical competence for a defined scope and the

operation of a laboratory quality management system (refer to joint ISO-ILAC-IAF Communiqué dated 8 January 2009).

Presented this 8th day of June 2011.

_______________________

President & CEO

For the Accreditation Council

Certificate Number 117.02

Valid to March 31, 2013

For the tests or types of tests to which this accreditation applies, please refer to the laboratory’s Mechanical Scope of Accreditation.

You might also like

- AC7122.2 Rev A - 1Document46 pagesAC7122.2 Rev A - 1Namelezz ShadowwNo ratings yet

- Hot Oil SystemDocument20 pagesHot Oil SystemMohamad PizulNo ratings yet

- AMS 2658 Hardness Conductivity, Aluminum AlloysDocument8 pagesAMS 2658 Hardness Conductivity, Aluminum AlloysJesse Krebs100% (1)

- ASTM A352 18aDocument7 pagesASTM A352 18aKelly BatesNo ratings yet

- State of The Practice of MSE Wall Design For Highway StructuresDocument21 pagesState of The Practice of MSE Wall Design For Highway StructuresKyle MoolmanNo ratings yet

- Astm F519Document19 pagesAstm F519unknown1711No ratings yet

- Appendix B3-10 Welding Procedure Specification EPI-11-WP6 Rev.1 - A4A2E9Document24 pagesAppendix B3-10 Welding Procedure Specification EPI-11-WP6 Rev.1 - A4A2E9Tahir AliNo ratings yet

- Project Report of PVC PipesDocument7 pagesProject Report of PVC PipesRajesh KumarNo ratings yet

- Engineering Material Specification: Controlled Document at Page 1 of 7Document7 pagesEngineering Material Specification: Controlled Document at Page 1 of 7Reginaldo SantosNo ratings yet

- Hump Hydraulics CalculationsDocument13 pagesHump Hydraulics CalculationsrutujaNo ratings yet

- A240m 14Document14 pagesA240m 14AFQBAVQ2EFCQF31FNo ratings yet

- Perno A325 HDG 5-8 X 1 1-4 (TKR+D7042279)Document1 pagePerno A325 HDG 5-8 X 1 1-4 (TKR+D7042279)Alexander Ortiz CarrionNo ratings yet

- Engineering Material Specification: Printed Copies Are UncontrolledDocument8 pagesEngineering Material Specification: Printed Copies Are UncontrolledaldairlopesNo ratings yet

- List of NDT StandardsDocument3 pagesList of NDT Standardskiki270977No ratings yet

- Grundfos Alignment-White PaperDocument21 pagesGrundfos Alignment-White PaperDelfinshNo ratings yet

- Lecture 4 (Dirk Mohr, ETH, Integration Algorithms in Plasticity)Document34 pagesLecture 4 (Dirk Mohr, ETH, Integration Algorithms in Plasticity)mehtabpathanNo ratings yet

- EN 10204/3.1 1546708 Pag. /: Mill Test Certificate DOC - CREDIT N. M04091506NU00250Document4 pagesEN 10204/3.1 1546708 Pag. /: Mill Test Certificate DOC - CREDIT N. M04091506NU00250Paviter SinghNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Usa Mechanical1046-01Document5 pagesUsa Mechanical1046-01Rick HenbidNo ratings yet

- Coatings Testing - ASTM StandardsDocument3 pagesCoatings Testing - ASTM StandardsthuronNo ratings yet

- Test Description Astm OtherDocument3 pagesTest Description Astm OtherchandraNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)Document1 pageNingbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)GLORIA MONSALVE SALAZARNo ratings yet

- Product Certification FabCo 811N1 Lot 01873Document1 pageProduct Certification FabCo 811N1 Lot 01873Sleyda MunozNo ratings yet

- 0850 02Document5 pages0850 02janiNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)Document1 pageNingbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)GLORIA MONSALVE SALAZARNo ratings yet

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- Accredited Laboratory: A2LA Has AccreditedDocument2 pagesAccredited Laboratory: A2LA Has AccreditedRene Alfonso BeltranNo ratings yet

- Memo 097.7 - 122719 - Item 454 Tunnel WaterproofingDocument6 pagesMemo 097.7 - 122719 - Item 454 Tunnel WaterproofingBai Alleha MusaNo ratings yet

- Duplex Grades CentravisDocument3 pagesDuplex Grades Centravisemperor_vamsiNo ratings yet

- A2LA 1101 01 Valid To February 28 2017Document4 pagesA2LA 1101 01 Valid To February 28 2017QA LAB ISMNo ratings yet

- 21TR1 E1a2-20200401Document6 pages21TR1 E1a2-20200401toddflyNo ratings yet

- 07 VESDA-E VEA Microbore Tubes Fittings UL TDS A4 IE LoresDocument2 pages07 VESDA-E VEA Microbore Tubes Fittings UL TDS A4 IE LoresLídia FlorenzianoNo ratings yet

- High Strength Steel Castings in Heavy Sections: Standard Specification ForDocument5 pagesHigh Strength Steel Castings in Heavy Sections: Standard Specification ForDarwin DarmawanNo ratings yet

- Astm F1387 99 2012Document10 pagesAstm F1387 99 2012edzmar86No ratings yet

- Mechanical Properties: Chemical CompositionDocument1 pageMechanical Properties: Chemical CompositionHERSON FARID BUENO PIÑEROSNo ratings yet

- Gridmesh Anchor Test Report ANSI Z359.18Document14 pagesGridmesh Anchor Test Report ANSI Z359.18IMIXCINo ratings yet

- Sae Ams2368cDocument6 pagesSae Ams2368cfarhad pashaei mehrNo ratings yet

- Qualitest - ISO 17025 ScopeDocument3 pagesQualitest - ISO 17025 ScopeKhemaraj PathmalingamNo ratings yet

- ME 205 - 432 - Assignment 1Document6 pagesME 205 - 432 - Assignment 1سلمان العتيبيNo ratings yet

- Unigear s3 Industrial Gear Oil SeriesDocument2 pagesUnigear s3 Industrial Gear Oil SeriesAnya J PamungkasNo ratings yet

- Steel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature ServiceDocument7 pagesSteel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature Serviceist93993No ratings yet

- ME 205 - 432 - Assignment 1Document9 pagesME 205 - 432 - Assignment 1جعفر السلطانNo ratings yet

- Centrifugally Cast Ferritic/Austenitic Stainless Steel Pipe For Corrosive EnvironmentsDocument4 pagesCentrifugally Cast Ferritic/Austenitic Stainless Steel Pipe For Corrosive EnvironmentsJerry BeanNo ratings yet

- Perno GR2 Unc HDG 5-8 X 1 1-2 (Tkr+hy7129220)Document1 pagePerno GR2 Unc HDG 5-8 X 1 1-2 (Tkr+hy7129220)Naomi Mascco VilchezNo ratings yet

- Masdar Technical Supplies: Inspection and Test PlanDocument1 pageMasdar Technical Supplies: Inspection and Test PlanmaqboolNo ratings yet

- 074 - ANPAM EnggDocument1 page074 - ANPAM EnggvinuNo ratings yet

- Parker Test BarDocument1 pageParker Test BarTechnical A-Star Testing & Inspection MalaysiaNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- A878A878M-05 (2011) Standard Specification For Steel Wire, Modified Chromium Vanadium Valve Spring QualityDocument4 pagesA878A878M-05 (2011) Standard Specification For Steel Wire, Modified Chromium Vanadium Valve Spring Qualitytjt4779No ratings yet

- A 232 - A 232M - 05 (2011) E1 PDFDocument4 pagesA 232 - A 232M - 05 (2011) E1 PDFأسامة وحيد الدين رمضانNo ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- Perno A325 HDG 5-8 X 1 3-4 (Ciser+7599055)Document1 pagePerno A325 HDG 5-8 X 1 3-4 (Ciser+7599055)Alexander Ortiz CarrionNo ratings yet

- Reference Nondestructive TestingDocument3 pagesReference Nondestructive TestingRino SutrisnoNo ratings yet

- List of Test (Updated November 2015)Document10 pagesList of Test (Updated November 2015)kmiqdNo ratings yet

- FPD190 - Differential Pressure - Restriction Orifice PlatesDocument12 pagesFPD190 - Differential Pressure - Restriction Orifice PlatesPeter MarkwellNo ratings yet

- Wimpey - Wacg-22-222-5Document6 pagesWimpey - Wacg-22-222-5jaas jawadNo ratings yet

- Vinyl-Coated Steel Wire and Welded Wire Reinforcement: Standard Specification ForDocument11 pagesVinyl-Coated Steel Wire and Welded Wire Reinforcement: Standard Specification ForDarwin DarmawanNo ratings yet

- ABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Steam and Gas Turbine Materials Used For Fasteners & Hardware Supplied by PpiDocument4 pagesSteam and Gas Turbine Materials Used For Fasteners & Hardware Supplied by PpidislocationNo ratings yet

- ASTM A240-A240M-07e1Document12 pagesASTM A240-A240M-07e1NadhiraNo ratings yet

- Certificado EsparragosDocument8 pagesCertificado EsparragosJesus CondoriNo ratings yet

- TS TestMethod REV7 0706Document55 pagesTS TestMethod REV7 0706revelkNo ratings yet

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- Is 1079 2009Document13 pagesIs 1079 2009Kings ParkNo ratings yet

- Is 209Document2 pagesIs 209Paviter SinghNo ratings yet

- Mak Quenching Oil CDocument1 pageMak Quenching Oil CPaviter SinghNo ratings yet

- Useful FormulasDocument2 pagesUseful FormulasPaviter SinghNo ratings yet

- Is.12262.1988 Steel Wire For Spring WashersDocument7 pagesIs.12262.1988 Steel Wire For Spring WashersPaviter SinghNo ratings yet

- Sample Test Report - SaraswatiDocument1 pageSample Test Report - SaraswatiPaviter SinghNo ratings yet

- Newsletter 13 e 01Document1 pageNewsletter 13 e 01Paviter SinghNo ratings yet

- Metallography Bwelch11Document9 pagesMetallography Bwelch11Paviter SinghNo ratings yet

- Surya ELectrodes - PDF LeafletDocument4 pagesSurya ELectrodes - PDF LeafletPaviter SinghNo ratings yet

- 2015 METEC ESTAD Javurek Pickling Flow TurbulenceDocument6 pages2015 METEC ESTAD Javurek Pickling Flow TurbulencePaviter SinghNo ratings yet

- Met 1 Ferrite Grain Size 1Document3 pagesMet 1 Ferrite Grain Size 1Paviter SinghNo ratings yet

- DK. BMT Lab ManualDocument46 pagesDK. BMT Lab ManualPaviter SinghNo ratings yet

- The Engineer and Grain-Size Control in SteelDocument24 pagesThe Engineer and Grain-Size Control in SteelPaviter SinghNo ratings yet

- Lecture09 - Hubert - Annealing and TemperingDocument72 pagesLecture09 - Hubert - Annealing and TemperingPaviter SinghNo ratings yet

- Wickeder Cold Rolled Steel Strip PDFDocument14 pagesWickeder Cold Rolled Steel Strip PDFPaviter SinghNo ratings yet

- Unclassified: Nondestructive Determination of Grain Size MetalsDocument36 pagesUnclassified: Nondestructive Determination of Grain Size MetalsPaviter SinghNo ratings yet

- Bureau of Indian Standards: Cold-Rolled Steel Strips For SpringsDocument10 pagesBureau of Indian Standards: Cold-Rolled Steel Strips For SpringsPaviter SinghNo ratings yet

- SchanemanAllen (MS 2009)Document123 pagesSchanemanAllen (MS 2009)Paviter SinghNo ratings yet

- Ismail 2016 IOP Conf. Ser. Mater. Sci. Eng. 114 012108Document10 pagesIsmail 2016 IOP Conf. Ser. Mater. Sci. Eng. 114 012108Paviter SinghNo ratings yet

- STI59864Document6 pagesSTI59864Paviter SinghNo ratings yet

- Cold-Rolled Steel Strip EN 20170331 PDFDocument21 pagesCold-Rolled Steel Strip EN 20170331 PDFPaviter SinghNo ratings yet

- Pump Lecture 1Document7 pagesPump Lecture 1juan villarroelNo ratings yet

- Determination of The Tensile Strength of Elongated TabletsDocument7 pagesDetermination of The Tensile Strength of Elongated TabletsMargareth ChristyNo ratings yet

- Phase2 Analysis Information Tajeo Esperanza NV 920: Project SummaryDocument5 pagesPhase2 Analysis Information Tajeo Esperanza NV 920: Project SummarysanchezmendozaaNo ratings yet

- Physics 73 3rd LE SamplexDocument16 pagesPhysics 73 3rd LE SamplexMiguel Panagsagan100% (1)

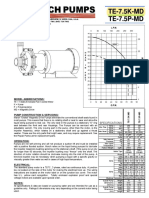

- MANUAL BOMBA MARCH-TE - 7,5kDocument2 pagesMANUAL BOMBA MARCH-TE - 7,5kjoseNo ratings yet

- Marsh Brown Clr-BrochureDocument4 pagesMarsh Brown Clr-BrochureأبوإسلامNo ratings yet

- FT Sandvik-DX700Document3 pagesFT Sandvik-DX700Misti FuriosoNo ratings yet

- The Two Methods Used To Feed The Pulverized Fuel To The Combustion Chamber of The Power PlantDocument5 pagesThe Two Methods Used To Feed The Pulverized Fuel To The Combustion Chamber of The Power PlantubabNo ratings yet

- FT450 FT550 Ft550lite FT600Document152 pagesFT450 FT550 Ft550lite FT600Osman GutierrezNo ratings yet

- Hyundai HD78 Wheels and TiresDocument19 pagesHyundai HD78 Wheels and TiresBigfair HD78No ratings yet

- Hold DownsDocument1 pageHold DownsswoinkerNo ratings yet

- 41 Bending of WeldsDocument27 pages41 Bending of WeldsSaarvin VignesvaranNo ratings yet

- 9 Chemistry: Chapter 1-Matter in Our SurroundingsDocument9 pages9 Chemistry: Chapter 1-Matter in Our SurroundingsPrabha SinghNo ratings yet

- Design of Planted Shear Walls of Tall BuldingDocument5 pagesDesign of Planted Shear Walls of Tall BuldingLuisito Sta. InesNo ratings yet

- Optimass 1400 Tech DatasheetDocument32 pagesOptimass 1400 Tech DatasheetAbid Hossain RupamNo ratings yet

- AJVS - Pfeiffer HiPace - 80 - PMP03943 - Sales - and - RepairDocument1 pageAJVS - Pfeiffer HiPace - 80 - PMP03943 - Sales - and - RepairAgustin CesanNo ratings yet

- Kubota Super UDT2 Fluid PI SheetDocument2 pagesKubota Super UDT2 Fluid PI Sheetcamilo ZambranoNo ratings yet

- Ijser: Design and Fabrication of Paper Shredder MachineDocument8 pagesIjser: Design and Fabrication of Paper Shredder MachineDaiNguyenNo ratings yet

- Case Study Sulfuric Acid Supply Line PDFDocument11 pagesCase Study Sulfuric Acid Supply Line PDFKuldeep28883No ratings yet

- Honda Serie B Table de TorquesDocument4 pagesHonda Serie B Table de TorquesDoom Bringer65No ratings yet

- CGAM Chiller Technical Details PDFDocument8 pagesCGAM Chiller Technical Details PDFoumar gadjigoNo ratings yet

- Copeland Tae1244Document14 pagesCopeland Tae1244jaspergoldNo ratings yet

- Spreading and Cutting Equipments: Spme-IiDocument23 pagesSpreading and Cutting Equipments: Spme-IiNeetek SahayNo ratings yet

- Critical Heat FluxDocument4 pagesCritical Heat FluxAshish VermaNo ratings yet