Professional Documents

Culture Documents

Couplings 201901170717

Uploaded by

iamhariharan0 ratings0% found this document useful (0 votes)

3 views1 pageCoupling

Original Title

Couplings_201901170717

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCoupling

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageCouplings 201901170717

Uploaded by

iamhariharanCoupling

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

ORTANT—

DO NOT FAIL t put oil in Coupling before

putting machines in operation.

DO NOT FAIL te replace the oil plugs tight

enough so that the oil cannot

throw out of the coupling

when machines are in motion.

OIL FILLING HOLE

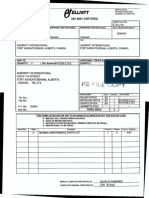

USE THIS METHOD OF ALIGNMENT THIS No. ( 31/2 ) COUPLING HOLDS ( 3/ ) PINTS OF OIL

“FAST’S” SELF-ALIGNING COUPLINGS

A flexible Coupling is not a universal joint. The same care should be taken in the

alignment of equipment using flexible couplings as if solid couplings were to be used.

INSTRUCTIONS FOR INSTALLING

The sleeve (A) should be entered over shaft end before the hub (B) is forced on and keyed.

The key must fit on its sides for the entire length of the hub. It must not bear on top or bottom.

The hubs of this No.( 31/2 —) coupling must be separated ( 1*3/16 "), (0). This

dimension will be found stamped on the alignment faces of the hubs.

Shafts should then be lined up by using a straight edge and inside calipers at (D) on

alignment faces on hubs as shown above.

The Flanges of the sleeve should be cleaned and gaskets examined to insure oil seal

and then bolted solidly together.

Through one of the two holes provided in the flange of the coupling, put in( 3/4, )

pints of any good fluid lubricant, no lighter than heavy engine oil (S.A.E. 70) or heavier than

heavy gear oil. (1000 seconds Saybolt viscosity at 212°F.) DO NOT USE GREASE. At the

point marked “Oil Level” on the above sketch, oil will run out when the coupling is at rest

if more than the necessary amount is put in. Be sure to replace plugs tightly, using wrench

provided with the coupling for that purpose.

Coupling should be checked periodically to insure that proper amount of oil is maintained

at all times.

“KEEP COUPLINGS OILED”

This Coupling Serial Nol! Connects. ae

S zo TASH OSE Sag PANY, INC.

0P=275939 — FAST’S COUPLING DEPARTMENT

BALTIMORE - 3, MD.

You might also like

- Manual 201507271302Document37 pagesManual 201507271302iamhariharanNo ratings yet

- Materials of Construction - 201901170715Document6 pagesMaterials of Construction - 201901170715iamhariharanNo ratings yet

- ManualDocument68 pagesManualiamhariharanNo ratings yet

- Technical Manual - 201503051122 - 202305191035Document181 pagesTechnical Manual - 201503051122 - 202305191035iamhariharanNo ratings yet

- Gen Oil Filter Manual - 201712041100Document7 pagesGen Oil Filter Manual - 201712041100iamhariharanNo ratings yet

- Exploitation of Consumers in The MarketDocument32 pagesExploitation of Consumers in The MarketiamhariharanNo ratings yet

- Shaybah NGL Project Gas Treat Division: This Week'S TopicDocument4 pagesShaybah NGL Project Gas Treat Division: This Week'S TopiciamhariharanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)