Professional Documents

Culture Documents

BT IL Datasheet Min

Uploaded by

Stas VoloboiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BT IL Datasheet Min

Uploaded by

Stas VoloboiCopyright:

Available Formats

Datasheet

Smaller footprint Additional bearing in the Pump manufactured Available with

than an equivalent pump head to share the strain of in Spain with materials brackets to make

performing gear pump operation and increase robustness from own foundry pump vertical

Interchangeable Competitively

spare parts with priced in the

other Azcue market compared

models to reduce to other small

stock holding screw pumps

available

Bearings Able to handle

greased for life lubricating fluids

with bearing under fluctuating

replacement at flow, pressure and

35,000 intervals viscosities without

losing efficiency

Marine type Magnetic coupling on request Spacer coupling between pump Built in relief valve

approved by to prevent the leaking of a & motor to enable maintenance for pump protection

all classification mechanical seal - enhances without having to remove the

societies e.g. service life when used for pump or motor from the Pump is reversible

Lloyds/ABS critical applications pipework first on request

Series BT-IL

Triple Screw Pump – Spacer Coupled

W castlepumps.com | T +44 (0) 1773 533 283 | E sales@castlepumps.com

BT-IL Triple Screw Pump – Spacer Coupled

Performance:

Max Flow rate 35 m3/h

Max Pressure 16 bar

Sizes Available DN50 - DN100 Outlet

Maximum Fluid Temperature:

Normal 100°C

MT 130°C

HT-TS 155°C

Description

BT-IL 52 D 3 F HT E

25

32 Special

Series 38 design

45

52

60 1

D

70 2 MT

T

80 3 HT

C Inner discharge valve

90 4 TS

100

110 E Outer discharge valve

125

140 S Without vavlve

Central screw Ø -

Pump size

Materials

Pressure range

Normal

Modifications to M. Medium

Screw lead

original design F. Small

B. Rough

Available Options -

• ATEX approved

• Magnetic coupling - To prevent the leaking that can occur with worn mechanical seals.

Enhances service life when used for critical applications

• Reversible operation

Common Applications -

• Diesel • Fuel oil cargo loading/unloading

• Kerosene • Lube oil transfer

• Petroleum • Lubricant circulation

• Fuel oil • Fuel oil separatin

• Marine fuel transfer (MGO, HFO)

Pg. 2 W castlepumps.com | T +44 (0) 1773 533 283 | E sales@castlepumps.com

Benefits -

• Manufactured in Spain by manufacturer with over 100 years' experience, using materials from their own foundry for complete control

• Marine type approved by all classification societies e.g. Lloyds/ABS for independent verification the pump meets quality standards

• Fitted with a lantern bracket to separate the pump head from the motor, so should the seal fail fluid is prevented from entering the

motor and causing damage to this part

• Compact and space saving design with smaller footprint compares to equivalent performing gear pump, making it ideal for installations

which have limited space

• Separate shafts in pump head and motor, which means that there is no need to replace entire pump and motor if shaft wears, saving

costs

• Able to handle lubricating fluids under fluctuating flow, pressure and viscosities without lose efficiency

• Interchangeable spare parts with other Azcue models to reduce stock holding required

• Spares available for a minimum of 15 years after model discontinuation for long term servicing even if the pump is no longer produced

• Bearings are greased for life with long service intervals to reduce maintenance costs – bearings replaced at 30,000 hours

• Integrated manually adjustable pressure relief valve for pump protection

• Motors are tropicalized as standard for operation up to 45ºC meaning the motor is designed continue operating during higher than

average temperature

• Can be reversible upon request for tank to tank transfer and for emptying the discharge line

• Magnetic coupling on request to prevent the leaking that can occur with worn mechanical seals and enhance service life when used for

critical applications.

• ATEX approved version for hazardous environments and flammable fluids

Materials

Standard MT HT TS

Pump casing GG25 GGG40 GGG40

Driving

Nitrided Steel Nitrided Steel Nitrided Steel

spindle

Idler spindles GG30 Nitrided GG30 Nitrided GG30 Nitrided

Graphite Graphite Carb. silic. Carb. silic.

Mechanical

Hardened Steel Hardened Steel Carb. silic. Carb. silic.

seal

Viton Viton Viton Viton

Pg. 3 W castlepumps.com | T +44 (0) 1773 533 283 | E sales@castlepumps.com

Performance Curves

(USgmp) (l/min)

Q (m3/h)

500 DF 140T-B Ref.

2000 8000 10

DF 140T

7000 400 DF 125T

1500 6000

5000 300 DF 125T-F

1250

DF 110T

4000 250 DF 110T-F

1000

125T

200

3000 125-F

700

150 110T

110T-F

500 2000

100T

100

400 100T-F

1500

80

300 70

1000 60

900

800 50

200

700 40

600 35

750 1000 1100 1200 1500 1800 2000 min-1

(USgmp) (l/min)

Q (m3/h)

1600 100 90T

400 90T-F

80

300 80T

1000 60 80T-F 70D

200 50

750 70D-F

40

150 60D

500 30 60D-F 52D

100 52D-F

20

75 300 45D

45D-F

50 200 38D

10

40 150 8 38D-F

30

100 6 32D

20 75 32D-F

4

15

50 3 25D

10

8 2 25D-F

30

6

20

1

4 15

12 0,7

750 1000 1200 1500 1800 2000 2500 3000 3500 min-1

Pg. 4 W castlepumps.com | T +44 (0) 1773 533 283 | E sales@castlepumps.com

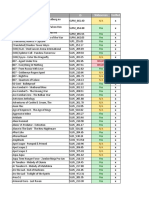

Dimensions

a

e c b h h

u

w

DNd

DNa

øD

g

j ISO G1/4 (2) ISO G1/4 (2)

ør k

s

o q m

(2) Manometer connection. (1) Vacuometer connection.

DIN 2501, Pn10/16

øD

DNa

øK DNd 50 65 80 100

K Ø

125 145 160 180

DØ 165 185 200 220

Nº 4 4 8 8

d2 18 18 18 18

N ød2

DNa/DNd

Motor

Pump Type R.p.m. / t/min. a b c D e g h j k m n q o r s DNa DNd u w kg

725 950 1.450 2.900 (*)

90-S 0,37 0,75 1,1 1,5 681 270

279 200 42

90-L 0,55 1,1 1,5 2,2 681 270

IL 100-L 0,75-1,1 1,5 2,2-3 3 732 310 152 160 110 48 200 225 120 65 162 14 18 50 50 140 50

45D3 279 250 45

112-M 1,5 2,2 4 4 732 310

132-S - 3 5,5 5,5-7,5 842 385 305 300 52

90-L 0,55 1,1 1,5 2,2 718 270

100-L 0,75-1,1 1,5 2,2-3 3 758 310 298 250 50

IL 112-M 1,5 2,2 4 4 758 310

159 160 122,5 48 200 225 135 80 176 14 18 65 65 170 50

52D3 132-S 2,2 3 5,5 5,5-7,5 868 385

324 300 58

132-M - 4-5,5 7,5 - 868 385

160-M - - - 11-15 1043 530 354 350 66

Power

100-L 0,75-1,1 1,5 2,2-3 3 846 310

324 250 70

112-M 1,5 2,2 4 4 846 310

IL 132-S 2,2 3 5,5 5,5-7,5 947 385 180 190 140 48 225 250 145 90 201 14 18 80 80 170 60

60D3 350 300 78

132-M 3 4-5,5 7,5 - 947 385

160-M - 7,5 11 11-15 1122 530 380 350 86

112-M 1,5 2,2 4 4 842 310 349 250 80

132-S 2,2 3 5,5 5,5-7,5 952 385

375 300 88

IL 132-M 3 4-5,5 7,5 - 952 385

192 190 150 48 225 250 145 90 227 14 18 100 100 170 60

70D3 160-M 4-5,5 7,5 11 11-15 1127 530

405 350 96

160-L - 11 15 18,5 1127 530

180-M - - 18,5 22 1177 580 405 350 105

( * ) The stated weight does not include the motor

Pg. 5 W castlepumps.com | T +44 (0) 1773 533 283 | E sales@castlepumps.com

Sectional Drawing

2170.2 2170.1 2160 2930 6544.2 3861 6810.1 6577.1 5230 1510.1 2160 4510.2

1510.2

5252

5256

1110

2540 6544.1 1680.2 3011 1680.1 4510.1 4200 1110 5250 6810.3 5251.1 6810.2 4610.2

Coupling

7414

7200.2 7414 7200.1

7200.2

Pg. 6 W castlepumps.com | T +44 (0) 1773 533 283 | E sales@castlepumps.com

Sectional Drawing

Description Ref.

Pump casing 1110

Pump casing insert 1130

Cover 1480.1

Cover 1480.2

Pump cover 1510.1

Pump cover 1510.2

Pump cover 1510.3

Spacer bush 1680.1

Spacer bush 1680.2

Spacer bush 1680.3

Flange 1690.1

Flange 1690.2

Pump foot 1720

Driving spindle 2160

Idler spindle 2170.1-2

Solidary shaft 2161

Bush 2187.1

Bush 2187.2

Thrower 2540

Loose collar shoulder ring 2930

Radial ball bearing 3011

Grease retaining cover 3575.1

Grease retaining cover 3575.2

Bearing bush 3610.1-2

Bearing nut 3850

Bearing nut 3850.1

Bearing nut 3850.2

Grease nipple 3861

Mechanical seal 4200

Mechanical seal cover 4213

Joint 4510.1

Joint 4510.2

Joint 4510.3

Joint 4510.4

Joint 4510.5

Joint 4510.6

O-ring 4610.1

O-ring 4610.2

O-ring 4610.3

O-ring 4610.4

O-ring 4610.5

O-ring 4610.6

O-ring 4610.7

O-ring 4610.8

Ball valve 5120

Compensanting valve 5150

Valve body 5200

Valve ball 5230

Valve seat 5240.1

Valve seat 5240.2

Valve piston 5250

Valve spring 5251.1

Valve spring 5251.2

Valve spring 5251.3

Valve spring plate 5252

Regulating spindle 5256

Valve spacer sleeve 5257

Lockwasher 6540.1

Lockwasher 6540.2

Circlip 6544.1

Circlip 6544.2

Circlip 6544.3

Grub screw 6577.1

Grub screw 6577.2

Grub screw 6577.3

Grub screw 6577.4

Grub screw 6577.5

Screwed plug 6578.1

Screwed plug 6578.2

Guide pin 6584

Pin 6810.1

Pin 6810.2

Pin 6810.3

Filter 6900

Coupling half 7200.1

Coupling half 7200.2

Coupling bush 7414

Pg. 7 W castlepumps.com | T +44 (0) 1773 533 283 | E sales@castlepumps.com

You might also like

- Assignment 2 Grammar Lesson PlanDocument26 pagesAssignment 2 Grammar Lesson PlanKesia Kerspay100% (1)

- Book - Sefer Yetzira - Book of Creation - Free KabbalahDocument3 pagesBook - Sefer Yetzira - Book of Creation - Free KabbalahJoshuaNo ratings yet

- ENIRAM - Guide To Dynamic Trim Optimization 280611 PDFDocument14 pagesENIRAM - Guide To Dynamic Trim Optimization 280611 PDFPhineas MagellanNo ratings yet

- Solution PDFDocument20 pagesSolution PDFVard FarrellNo ratings yet

- BT HM Datasheet MinDocument7 pagesBT HM Datasheet MinAymen BabourNo ratings yet

- Suntec TA3 Pump SpecificationDocument2 pagesSuntec TA3 Pump Specificationsayda MaowiaNo ratings yet

- RPH RO - Tech. ManualDocument16 pagesRPH RO - Tech. ManualEdgar CalatayudNo ratings yet

- RGFA Full en Metric LetterDocument4 pagesRGFA Full en Metric LetteressamNo ratings yet

- A10VO 28-60 (5 Series)Document16 pagesA10VO 28-60 (5 Series)Ovh MaquinariasNo ratings yet

- 2-Latest EIC-C-1002-0 (Pilot Operated Relief Valve)Document14 pages2-Latest EIC-C-1002-0 (Pilot Operated Relief Valve)Lin LeninNo ratings yet

- DBAFMCV924 Full en Metric LetterDocument6 pagesDBAFMCV924 Full en Metric LetterMechanical2022No ratings yet

- DMBF Full en Metric LetterDocument4 pagesDMBF Full en Metric LetterRonaldNo ratings yet

- Contrabalance SunHydraulicDocument2 pagesContrabalance SunHydraulicMatias Oñate ArriagadaNo ratings yet

- Product Data Sheet Damcos BRC 250 en 60334Document4 pagesProduct Data Sheet Damcos BRC 250 en 60334Конструкторский отдел РосНефтеГазИнструментNo ratings yet

- CBEALAN Full Es Metric LetterDocument2 pagesCBEALAN Full Es Metric Letternicole tapiaNo ratings yet

- Vane Pumps-1 PDFDocument83 pagesVane Pumps-1 PDFMusaferNo ratings yet

- Enerpac High Pressure Pumps CatalogDocument2 pagesEnerpac High Pressure Pumps CatalogTitanplyNo ratings yet

- EMV 64-60-70x115Document3 pagesEMV 64-60-70x115Huy NguyễnNo ratings yet

- RDHA Full en Metric LetterasdDocument2 pagesRDHA Full en Metric LetterasdessamNo ratings yet

- Ken40 317 PDFDocument1 pageKen40 317 PDFArjun BharambeNo ratings yet

- Technical Data Sheet: Customer: Ref.Document1 pageTechnical Data Sheet: Customer: Ref.Luis Lapo RomeroNo ratings yet

- RBFA Full en Metric LetterDocument2 pagesRBFA Full en Metric LetteressamNo ratings yet

- NM CataloguesDocument6 pagesNM CataloguessuinpeNo ratings yet

- TRHE32-20, 45, 60 Bomba de VacioDocument7 pagesTRHE32-20, 45, 60 Bomba de VacioJavier Mendoza V.No ratings yet

- Suntec Fuel Oil PumpDocument2 pagesSuntec Fuel Oil PumpkmthongNo ratings yet

- 261 PDFDocument2 pages261 PDFJOSE INESNo ratings yet

- Pomp EtaprimeDocument22 pagesPomp EtaprimeMarnix VanbavinckhoveNo ratings yet

- Oil Pump Type T GEAR SIZES 2-3-4-5Document2 pagesOil Pump Type T GEAR SIZES 2-3-4-5Eden Ben100% (1)

- RDDA - Direct-Acting Relief ValveDocument3 pagesRDDA - Direct-Acting Relief ValveD ŠpokauskasNo ratings yet

- Sec - 320 - Series 475Document7 pagesSec - 320 - Series 475JOSE INESNo ratings yet

- Oil Pump Type RSA Size 28, 40, 60, 95, 125: Data SheetDocument4 pagesOil Pump Type RSA Size 28, 40, 60, 95, 125: Data SheetJhonNo ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24ADocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24AАндрей9No ratings yet

- Model Fully Adjustable Needle Valve: SERIES 4 / CAPACITY: 60 GPM (.56 Inch) / CAVITY: T-18ADocument2 pagesModel Fully Adjustable Needle Valve: SERIES 4 / CAPACITY: 60 GPM (.56 Inch) / CAVITY: T-18AErasmo LimaNo ratings yet

- K3 V280 SpecsDocument1 pageK3 V280 SpecsJuan AcostaNo ratings yet

- Direct-Acting Relief Valve: DownloadDocument2 pagesDirect-Acting Relief Valve: Downloadaristi51No ratings yet

- RBDA Full en Metric LetterDocument3 pagesRBDA Full en Metric LetteressamNo ratings yet

- 21 RR NOV 300TP-8 Technical Data SheetsDocument2 pages21 RR NOV 300TP-8 Technical Data Sheetsnoha azamaliNo ratings yet

- Rating 5.4 m3h - 120m - MV 5-24 - 3.7kW-2900rpm-380V-3Ph-50Hz PDFDocument3 pagesRating 5.4 m3h - 120m - MV 5-24 - 3.7kW-2900rpm-380V-3Ph-50Hz PDFTrung TrịnhNo ratings yet

- En3672640Document3 pagesEn3672640M YasserNo ratings yet

- CD250M Dri-Prime Pump: Features SpecificationsDocument2 pagesCD250M Dri-Prime Pump: Features SpecificationsMohamed Badian TraoreNo ratings yet

- Oil Pump Type Aj Gear Sizes 4-6: ApplicationsDocument2 pagesOil Pump Type Aj Gear Sizes 4-6: Applicationsr_cristiNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- Model Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10ADocument2 pagesModel Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10AHassan KhattabNo ratings yet

- HA 1 0VSO Series Variable Displacement Pump: C S W A e N oDocument68 pagesHA 1 0VSO Series Variable Displacement Pump: C S W A e N ojose salvadorNo ratings yet

- Motors: Single and Multiple Vane Pumps & Vane MotorsDocument120 pagesMotors: Single and Multiple Vane Pumps & Vane Motorsmephir666No ratings yet

- Hanbell Spec Sheet RC2-230B PDFDocument1 pageHanbell Spec Sheet RC2-230B PDFDaniel Naoe FestinNo ratings yet

- RDFALWN-CAM S Full en Us LetterDocument5 pagesRDFALWN-CAM S Full en Us LetterJustinNo ratings yet

- Pump Type Aj: This Is A General Specification Leaflet For Specific Applications Not Covered Herein, Contact SuntecDocument2 pagesPump Type Aj: This Is A General Specification Leaflet For Specific Applications Not Covered Herein, Contact Suntecbobi gorgievskiNo ratings yet

- B C N (None) : C-Spool H-SpoolDocument2 pagesB C N (None) : C-Spool H-SpoolPasqualeNo ratings yet

- Product Data Sheet Damcos BRC 500 en 60338Document4 pagesProduct Data Sheet Damcos BRC 500 en 60338cvfNo ratings yet

- SS Series (Wiring System: Central Terminal Box) Wet Type Solenoid ValveDocument12 pagesSS Series (Wiring System: Central Terminal Box) Wet Type Solenoid ValveMarcelo Partes de OliveiraNo ratings yet

- Electrobomba Centrifuga Vertical CRIDocument28 pagesElectrobomba Centrifuga Vertical CRICristianSalazarRamirezNo ratings yet

- High OutputDocument36 pagesHigh Outputxmen norNo ratings yet

- EN NM TD 50HzDocument72 pagesEN NM TD 50Hzlee marvin BilongNo ratings yet

- SV1-10-4/4M/4R: - Solenoid ValveDocument2 pagesSV1-10-4/4M/4R: - Solenoid ValveCORTOCIRCUITANTENo ratings yet

- Large Bore High Pressure Hydraulic Cylinders SeriesDocument18 pagesLarge Bore High Pressure Hydraulic Cylinders SeriesHYDRAULICGURUNo ratings yet

- SiliDocument7 pagesSiliBojez zZzNo ratings yet

- Dynaflo: Rugged, Single Stage Centrifugal PumpDocument2 pagesDynaflo: Rugged, Single Stage Centrifugal Pumptvshow zeeNo ratings yet

- TCMO-TSMC en PDFDocument2 pagesTCMO-TSMC en PDFFendy TnNo ratings yet

- Manual Bomba EspumaDocument108 pagesManual Bomba EspumaFrancisco ManriquezNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- Oil Pump Type Ta: For Fuel Oil #2 To #6 ApplicationsDocument2 pagesOil Pump Type Ta: For Fuel Oil #2 To #6 Applicationsmochammad RezaNo ratings yet

- 141 ISACA NACACS Auditing IT Projects Audit ProgramDocument86 pages141 ISACA NACACS Auditing IT Projects Audit Programkautaliya100% (6)

- Cooling and Sealing Air System: Gas Turbine Training ManualDocument2 pagesCooling and Sealing Air System: Gas Turbine Training ManualVignesh SvNo ratings yet

- Delonghi Pinguino Water To Air Pac We125 Instruction Manual 715678Document21 pagesDelonghi Pinguino Water To Air Pac We125 Instruction Manual 715678Luis AlbertoAlmeidaSilva100% (1)

- Interjections NotesDocument2 pagesInterjections NotesKanna ImuiNo ratings yet

- Union Metal SemiconductorDocument4 pagesUnion Metal SemiconductorskinhugoNo ratings yet

- MiningDocument3 pagesMiningDherick RaleighNo ratings yet

- Strategic Cost AnalysisDocument24 pagesStrategic Cost AnalysisBusiness Expert Press100% (10)

- Animal Defenses TestDocument3 pagesAnimal Defenses TestNermine MouallemNo ratings yet

- 1802SupplementaryNotes FullDocument235 pages1802SupplementaryNotes FullCourtney WilliamsNo ratings yet

- Python - Data EngineeringDocument34 pagesPython - Data EngineeringChetan PatilNo ratings yet

- Malraux Anti-MemoiresDocument9 pagesMalraux Anti-MemoiresNevenaRistićNo ratings yet

- MT4400 STRG Flo Amp ValveDocument7 pagesMT4400 STRG Flo Amp ValveBrian Careel0% (1)

- An Introduction To EFTDocument24 pagesAn Introduction To EFTkunjammuNo ratings yet

- C7 On-Highway Engine Electrical System: Harness and Wire Electrical Schematic SymbolsDocument2 pagesC7 On-Highway Engine Electrical System: Harness and Wire Electrical Schematic SymbolsFeDe Aavina Glez100% (3)

- Template 3 - MATH 3-REGULAR-DIAGNOSTICDocument2 pagesTemplate 3 - MATH 3-REGULAR-DIAGNOSTIClailanie CervantesNo ratings yet

- PC-ABS Bayblend FR3010Document4 pagesPC-ABS Bayblend FR3010countzeroaslNo ratings yet

- Chapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Document27 pagesChapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Randy DookheranNo ratings yet

- Steam TableDocument3 pagesSteam TableMUHAMAD SAUKINo ratings yet

- Burnay, Bushman & Laroi - 2019Document10 pagesBurnay, Bushman & Laroi - 2019TinyjurshNo ratings yet

- Fuses f150Document7 pagesFuses f150ORLANDONo ratings yet

- WideScreen Code For PS2 GamesDocument78 pagesWideScreen Code For PS2 Gamesmarcus viniciusNo ratings yet

- THE INDIAN NAVY - Artificer Apprentice & Senior Secondary Recruit PDFDocument3 pagesTHE INDIAN NAVY - Artificer Apprentice & Senior Secondary Recruit PDFUjjwalNo ratings yet

- IES 2001 - I ScanDocument20 pagesIES 2001 - I ScanK.v.SinghNo ratings yet

- Mech Syllabus R-2017 - 1Document110 pagesMech Syllabus R-2017 - 1goujjNo ratings yet

- HVS Hotel Cost Estimating Guide 2021Document124 pagesHVS Hotel Cost Estimating Guide 2021pascal rosasNo ratings yet

- The First-Fourth Books of The HitopadésaDocument116 pagesThe First-Fourth Books of The HitopadésaMiguel RosaNo ratings yet