Professional Documents

Culture Documents

NYAB - Same - Part No. 778991 - Diff Size Diff Part No

Uploaded by

Gopi NadhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NYAB - Same - Part No. 778991 - Diff Size Diff Part No

Uploaded by

Gopi NadhanCopyright:

Available Formats

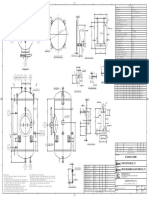

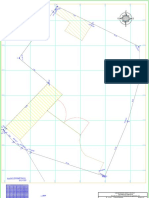

8 7 6 5 4 3 2 1

THIS DRAWING IS THE PROPERTY OF STRATO, INC.

THIS DRAWING IS LOANED UPON THE EXPRESS CONDITION THAT IT

SHALL NOT BE REPRODUCED IN ANY MANNER, AND SHALL BE RETURNED

UPON DEMAND. IT IS SUBMITTED FOR EVALUATION PURPOSES ONLY.

INFORMATION CONTAINED THEREIN, SHALL NOT BE USED, OR

DISCLOSED TO THIRD PARTIES WITHOUT THE WRITTEN CONSENT OF BODY CENTERING SHOULDERS 95°

STRATO, INC DIAMETERS DEFINED ON DRAWING HS

3 1/2"

CAST POSITIVE IN 1/4" LETTERS 12°

30° "H" & STRATO LOGO

D K H 30° D

3/16"

7/16"

H 47°

E L

5/8" 9/16"

29°

5/16" L

E K

SECTION K-K 1 3/4"

15° VIEW G-G 3/4"

9/32"±1/16"

TYP

SECTION J-J G G LEAD IN

GUARD ARM R1/32" MAX LIP CHAMFERS

35° VIEW H-H

11/16"

3" 65°

+.043

2.049 60°

3/16" MIN - .036

C E01 +1/32"

R1" 4.716 C

R15/16" - 1/32"

R2 9/16"

11/16"

MIN R1/4" 1/32 A B M

R1/2" C GUARD ARM

R1/32" GUARD ARM

2 7/16" 2PLCS STOP LUG

1 23/32" RECESSED

FOUNDRY ID &

R1/4" R9/16" CAVITY # J

R.06 1 1/4"

1 1/8" R.13

R1/16" 7/8"

R15/16" 1/4" 3/4" 1 3/32"

1/8"

R1/16" 3/8"

2 1/4" 11/16"

150° R.06 MIN

B 31/32" 1/4"

R.03 B

SECTION L-L 15.75°

J R.06 F +3/64"

1/32"

- 1/64"

3 PLCS

RAIE RIBS 1/4" 5/16"

HIGH MIN. X 1/4"

THK. ±1/16"

NOTES: 41.50° A .45

1.MATERIAL: ASTM A-47 GR32510 MALLEABLE IRON OR +.08

ASTM A-536 GR60-40-18 DI .50

E03 2.E-COAT PER SS-112 - .03

DETAIL F

3.PRESSURE TEST AIR UNDER WATER TO 100 PSI FOR 30 R.03

SECONDS, NO LEAKS ALLOWED E02

4.REFERENCE DRAWING "HS" FOR MACHINING DETAIL & GAGING .005 A

5.ALL UNSPECIFIED RADII TO BE 1/16" B 1 1/4"

6.PARTING LINE MIS-MATCH NOT TO EXCEED .015" OR FLASH & SECTION E-E

MUST BE GROUND SMOOTH

7.MINIMUM WALL THICKNESS MUST BE 3/16" IN ALL AREAS EXCEPT

HOSE BARB STATUS

8.REMOVE ALL BURRS AND SHARP EDGES RELEASED 100 New England

9.CHECK GUARD ARM & STOP LOCATION WITH GAGE G566 Avenue Piscataway,

REFERENCE DRAWINGS N.J. 08854

10.INTERNAL BORE TO BE CONCENTRIC WITH OUTSIDE CASTING

WITHIN 1/32" E03 7/30/2018 CHANGE NOTE 2 TO E-COAT 2356 SP DL Quality Railroad Products SD-4 REV. F

A A

DESCRIPTION

E02 4/5/2017 CHANGE TOLERANCE TO +.08/.03 2200 DB TJ H GLADHAND, PUSH ON WITH

INTEGERAL HOSE BARB

UNLESS OTHERWISE SPECIFIED

TOLERANCES ARE AS FOLLOWS:

E01 3/5/2012 ADDED BILATERAL TOLERANCE 1/32" 1660 MH IS FRACTIONS ±1/32"

TWO PLACES ±0.010

DRAWN BY CHECKED BY DATE

E 03/08/11 60° - 65° WAS 55º 1537 EJ LH

THREE PLACES ±0.005 EJ KMCK 04/15/03

ANGLES ±2°

±1% O.A.L.

NONE DWG. NO.

HOSE ASSY. SCALE REV

INTIATED APPRVD 125

HP215R

MACHINED SURFACE

REV. DATE DESCRIPTION ECN E03

BY BY BREAK EDGES: 0.02" MAX.

FILLETS: R0.03" MAX. SHEET 1 OF 1

8 7 6 5 4 3 2 1

You might also like

- P94-1986 Inversor NGPDocument2 pagesP94-1986 Inversor NGPGonzalo GalvezNo ratings yet

- 0274 Lead SheetDocument5 pages0274 Lead SheetHåkan Bjuvenstedt100% (1)

- ObradorsDel Cabello Mas Sutil - Guitar - G MajorDocument2 pagesObradorsDel Cabello Mas Sutil - Guitar - G MajorEstrella Cuello100% (1)

- Fire Water Storage Tank PDFDocument2 pagesFire Water Storage Tank PDFsky7No ratings yet

- Spying From Space - Constructing America's Satellite Command and Control Systems (PDFDrive)Document230 pagesSpying From Space - Constructing America's Satellite Command and Control Systems (PDFDrive)MohammadNo ratings yet

- Shear and Diagonal Tension in BeamDocument16 pagesShear and Diagonal Tension in BeamMouy PhonThornNo ratings yet

- "Yo Quisiera": I TromboneDocument2 pages"Yo Quisiera": I TromboneSantiago Guerra0% (1)

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Section: NW2060CVB-IV (M) General ArrangementDocument1 pageSection: NW2060CVB-IV (M) General Arrangementdarko1969No ratings yet

- 040CH 2 130405 IMPERIAL Quarter Inch To Foot PLANS ARCH C PortraitDocument7 pages040CH 2 130405 IMPERIAL Quarter Inch To Foot PLANS ARCH C PortraitOszi1967No ratings yet

- BLUE POLYNESIA TRUSES-ModelDocument1 pageBLUE POLYNESIA TRUSES-ModelXixi XuNo ratings yet

- Stuffing 1790Document1 pageStuffing 1790Gileno DiasNo ratings yet

- Rueda Tensora Sennbogen 6100Document2 pagesRueda Tensora Sennbogen 6100john rubianoNo ratings yet

- T400, T700 Temp. Switch Installation and Maintenance ManualDocument2 pagesT400, T700 Temp. Switch Installation and Maintenance ManualHuan Trinh VanNo ratings yet

- Amort Biddlehouse TN 20230329smDocument16 pagesAmort Biddlehouse TN 20230329smapi-455371619No ratings yet

- Curb & Curb and Gutter: 2006 FDOT Design StandardsDocument1 pageCurb & Curb and Gutter: 2006 FDOT Design StandardsJan Lawrence AlbertoNo ratings yet

- ABUTEC 20 MTF 0.7 GADesquema - QuemadorDocument1 pageABUTEC 20 MTF 0.7 GADesquema - QuemadorAndrea Ninia RebelNo ratings yet

- Bomba Electrica 1500gpm 300HP (Medidas)Document1 pageBomba Electrica 1500gpm 300HP (Medidas)Fire ChileNo ratings yet

- Assy RaillingDocument1 pageAssy RaillingVEZZ RIDE25No ratings yet

- E G Min A C Min/d A Min/g A Min/f F Min/f G Min/e C-6 /D C-6Document5 pagesE G Min A C Min/d A Min/g A Min/f F Min/f G Min/e C-6 /D C-6goorguerNo ratings yet

- Swing Jaw Plate - TCMDocument1 pageSwing Jaw Plate - TCMmoderate machines pvt. ltd.No ratings yet

- Polyelectrolyte Solution TankDocument2 pagesPolyelectrolyte Solution TankHarish GundaNo ratings yet

- AzimuthalMap PDFDocument1 pageAzimuthalMap PDFCarlos Hugo CastilloNo ratings yet

- '86-'88 Suzuki Samurai - Us Model, Ecu Deleted: Wire Color ChartDocument1 page'86-'88 Suzuki Samurai - Us Model, Ecu Deleted: Wire Color ChartChuck LNo ratings yet

- Wire Color Chart: CONNECTOR - GROUNDDocument1 pageWire Color Chart: CONNECTOR - GROUNDChuck L100% (1)

- A-814-Flooring Layout First Floor - MosqueDocument1 pageA-814-Flooring Layout First Floor - MosqueEmmanuel InfanteNo ratings yet

- 0G29170ST03Document1 page0G29170ST03Alejandro NietoNo ratings yet

- DR MUSHTAQ SB JATOI HOSPITAL ModelDocument1 pageDR MUSHTAQ SB JATOI HOSPITAL ModelShahzaman SbNo ratings yet

- Este Instante (Lead Sheet)Document16 pagesEste Instante (Lead Sheet)MiaNo ratings yet

- CocarroiDocument1 pageCocarroiesteveNo ratings yet

- Solid Works Sheet MetalDocument1 pageSolid Works Sheet MetalKeith PetersonNo ratings yet

- Bach Fugue N in C Minor BWV Well Tempered Clavier Saxophone TrioDocument4 pagesBach Fugue N in C Minor BWV Well Tempered Clavier Saxophone Trio김대호 / 학생 / 국악과No ratings yet

- Site B LatestDocument1 pageSite B Latestarkitek pppntNo ratings yet

- Harta Azimutala Pe CampinaDocument1 pageHarta Azimutala Pe CampinaAnonymous XoW23y58ONo ratings yet

- Option A: One Way Road: Lake Street Shared TrailDocument1 pageOption A: One Way Road: Lake Street Shared TrailNeenNo ratings yet

- Nota Nahu Syarh Ibn AqilDocument28 pagesNota Nahu Syarh Ibn Aqilsafiyah205No ratings yet

- R1 Donor Cut Tower: Hexane Drum Item No. D-755Document1 pageR1 Donor Cut Tower: Hexane Drum Item No. D-755NoppolNorasriNo ratings yet

- 10" Suction 8" Discharge: DRN: App'D: Drawn Scale: N/A Pump Model: Td20 Motor HPDocument1 page10" Suction 8" Discharge: DRN: App'D: Drawn Scale: N/A Pump Model: Td20 Motor HPKarim TarekNo ratings yet

- SD2.1 1Document1 pageSD2.1 1Andres PeñaNo ratings yet

- Bailemos Otra Vez - 01 Baritono - SibDocument2 pagesBailemos Otra Vez - 01 Baritono - SibRafael Villacorta SanchezNo ratings yet

- ASM - A330 - IBE - Rev. Num - 48 - 01-Jan-2024 - Figure 34-12-02 SCH 02 P 0013 (SHEET 1) - NAVIGATIONDocument1 pageASM - A330 - IBE - Rev. Num - 48 - 01-Jan-2024 - Figure 34-12-02 SCH 02 P 0013 (SHEET 1) - NAVIGATIONEl Tortugo HD/appsNo ratings yet

- Port Pig 50M H4 MSTDocument1 pagePort Pig 50M H4 MSTShaikh Muhammad AteeqNo ratings yet

- Eep000093 14700510 Mearr 0006 - 00Document1 pageEep000093 14700510 Mearr 0006 - 00Simran singhNo ratings yet

- Profil Make New Gland Cylinder Boom PC1250SP-8Document1 pageProfil Make New Gland Cylinder Boom PC1250SP-8Ahmad RhamdaniNo ratings yet

- D D E E: Vms ApprovalDocument3 pagesD D E E: Vms ApprovalLuong LeNo ratings yet

- Q22140010804 New.Document1 pageQ22140010804 New.QUARK AUTOMATIONNo ratings yet

- Vishal Singh Autocad-Model - PDF FOOTING PLANDocument1 pageVishal Singh Autocad-Model - PDF FOOTING PLANvishalsinghthakur345No ratings yet

- Dilermando Reis Noite de Lua1Document7 pagesDilermando Reis Noite de Lua1daniel nogaraNo ratings yet

- Polaris Parts Templates 75 Scaled NontiledDocument1 pagePolaris Parts Templates 75 Scaled NontiledSavu DanielNo ratings yet

- GA - 24-50 Rev H: General Arrangement RXF 24 - 50 Screw Compressor PackageDocument1 pageGA - 24-50 Rev H: General Arrangement RXF 24 - 50 Screw Compressor Packagekemas biruNo ratings yet

- Azimuthal MapDocument1 pageAzimuthal MapPy4ME Marcos R. SilvaNo ratings yet

- Bomba Electrica 2000gpm (Medidas)Document1 pageBomba Electrica 2000gpm (Medidas)Fire ChileNo ratings yet

- OUTLET G3/8": Confidentiality Class Acc. To 1102 KDocument1 pageOUTLET G3/8": Confidentiality Class Acc. To 1102 Krogerroman24No ratings yet

- FMCH Star Rnav02Document1 pageFMCH Star Rnav02ffgfhyNo ratings yet

- Sheet Roof 4 Sheet Tilt: 11° No of Modules (E)Document1 pageSheet Roof 4 Sheet Tilt: 11° No of Modules (E)DIVAKARNo ratings yet

- Wiac - Info PDF Fatura PRDocument4 pagesWiac - Info PDF Fatura PRFernando PeresNo ratings yet

- Teacher-In-Charge OPCRFDocument1 pageTeacher-In-Charge OPCRFCARMILA DELOS SANTOSNo ratings yet

- Column Long SectionDocument1 pageColumn Long SectionKhandaker Khairul AlamNo ratings yet

- Body - 12X18X282 MMDocument1 pageBody - 12X18X282 MMNeocent DesignsNo ratings yet

- Paredes Lujan-TopoDocument1 pageParedes Lujan-TopoDieleX GAMESNo ratings yet

- BLS.214736.01 D Rig 02 - BDocument1 pageBLS.214736.01 D Rig 02 - BLevi BuratoNo ratings yet

- Mueble para VinosDocument1 pageMueble para Vinosmbueno62No ratings yet

- Motorola Talkabout T82 PDFDocument184 pagesMotorola Talkabout T82 PDFAlex TamayoNo ratings yet

- Xgenus X-Ray PDFDocument61 pagesXgenus X-Ray PDFAli NuriNo ratings yet

- 07 Endodontic RetreatmentDocument64 pages07 Endodontic RetreatmentGayathriNo ratings yet

- 3-Storeyed 31-3-2015-Schedule PDFDocument1 page3-Storeyed 31-3-2015-Schedule PDFSi Thu AungNo ratings yet

- INS2015 Fundamentals of Finance HungCV 1Document3 pagesINS2015 Fundamentals of Finance HungCV 1Phương Anh NguyễnNo ratings yet

- Cable Systems For High and Extra-High Voltage: Development, Manufacture, Testing, Installation and Operation of Cables and Their AccessoriesDocument1 pageCable Systems For High and Extra-High Voltage: Development, Manufacture, Testing, Installation and Operation of Cables and Their AccessorieseddisonfhNo ratings yet

- 02.certificate of Compliance FM UkDocument10 pages02.certificate of Compliance FM Ukmyatthura870No ratings yet

- Century Vemap PDFDocument5 pagesCentury Vemap PDFMaster MirrorNo ratings yet

- World Link YolaDocument3 pagesWorld Link YolaHamilton Obando100% (1)

- Revised Research ZoomDocument51 pagesRevised Research ZoomAubrey Unique EvangelistaNo ratings yet

- Inglês - Degrees of ComparisonDocument4 pagesInglês - Degrees of ComparisonVersehgi IINo ratings yet

- Sheet Metal Cutting Using Geneva MechanismDocument27 pagesSheet Metal Cutting Using Geneva MechanismsingamNo ratings yet

- Pitch Analysis PaperDocument7 pagesPitch Analysis PaperMunib MunirNo ratings yet

- Casio AT 1 Service ManualDocument28 pagesCasio AT 1 Service ManualMario Gabriel MoralliNo ratings yet

- KP For RamDocument23 pagesKP For RamMonu NarwarNo ratings yet

- Statistical MethodsDocument77 pagesStatistical MethodsGuruKPO100% (1)

- Final FirstpartDocument11 pagesFinal FirstpartLance Johnpaul SyNo ratings yet

- Week 8: Spread-Spectrum Modulation - Direct Sequence Spread SpectrumDocument79 pagesWeek 8: Spread-Spectrum Modulation - Direct Sequence Spread SpectrumAmir MustakimNo ratings yet

- Cambridge International AS & A Level: Biology 9700/21Document18 pagesCambridge International AS & A Level: Biology 9700/21Lavanya EaswarNo ratings yet

- Pile Capacity - An Overview - ScienceDirect TopicsDocument15 pagesPile Capacity - An Overview - ScienceDirect TopicssurNo ratings yet

- Cocoon 8002 PDFDocument24 pagesCocoon 8002 PDFaxisNo ratings yet

- Nokia 2690 RM-635 Service ManualDocument18 pagesNokia 2690 RM-635 Service ManualEdgar Jose Aranguibel MorilloNo ratings yet

- Addressing Diversity Through The Years Special and Inclusive EducationDocument6 pagesAddressing Diversity Through The Years Special and Inclusive EducationJiezel SurinNo ratings yet

- ENGLISH TOEFL Structure (3rd Exercise)Document5 pagesENGLISH TOEFL Structure (3rd Exercise)susannnnnnNo ratings yet

- Instruction Manual: Slit Lamp Bon SL-EDocument20 pagesInstruction Manual: Slit Lamp Bon SL-EVladimir LevchenkoNo ratings yet

- THE REFUND - Frigyes Karinthy: AuthorDocument6 pagesTHE REFUND - Frigyes Karinthy: AuthorMilind JamnekarNo ratings yet

- Hemo TecaDocument17 pagesHemo TecaMafer PilcoNo ratings yet

- Research 9: Activity 4: Background of The StudyDocument7 pagesResearch 9: Activity 4: Background of The StudyPhilip AmelingNo ratings yet