Professional Documents

Culture Documents

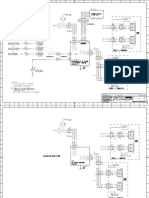

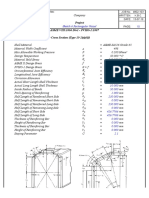

Design data for a hexane drum

Uploaded by

NoppolNorasriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design data for a hexane drum

Uploaded by

NoppolNorasriCopyright:

Available Formats

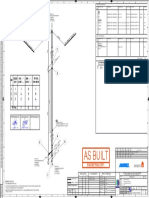

8 7 6 5 4 3 2 1

DESIGN DATA

N N5 ITEM NO. D-755

0° TOP

3/4" DESCRIPTION HEXANE DRUM

SIZE (mm) 1300 ID x 2200 TL-TL

270° 90° 0° 250 Q'TY 1

F 0° 20 F

4-Ø26 HOLES DESIGN CODE ASME SEC.VIII DIV.1

TOP N2 15t 110 15t

180° CAPACITY (m³) LALER

0

2" 315° 45° R3 DESIGN PRESSURE (kg/cm²G) 3.8

400 DESIGN TEMP (C°) 65

OPERATION PRESSURE (kg/cm²G) 0.2

6 Ø6 OPERATION TEMP (C°) 40

Ø26 HOLRS VENT HOLE MAWP (kg/cm²G) LATER

D

4 BC FOR ANCHOR BOLT M24 FLUID CONTAIN HX (HEXANE)

L1b L1a 270° 90° L2b L2a Ø14 2

TOP 5 SPECIFIC GRAVITY OF CONTENT N/A

270°

200

90° 6

280

3/4" 3/4" 2" 2" RADIOGRAPHIC EXAM (CLY/HD) SPOT/FULL

JOINT EFF. (CLY/HD) 0.85/1.00

TOP N3 N1

9 WIND VELOCITY (m/s) 38

9

00

1" 2" SEISMIC FACTOR ZONE 0

R3

25

EMPTY WEIGHT (kg) LATER

20

TEST WEIGHT (kg) LATER

225° 135° OPERATION WEIGHT (kg) LATER

E E

2-EARTH LUG 4 ERECTION WEIGHT (kg) LATER

AT 45°,225° 6t 200 TEST PRESS. WATER (kg/cm²G) LATER

180°

Ø1424 BCD 50 TEST PRESS. AIR (kg/cm²G) NO

SECTION VIEW "B"-"B" PAINTING (INTERNAL)

(PLAN OF SUPPORT CHAIR) DETAIL SUPPORT CHAIR -

180° PAINTING (EXTERNAL) PED-CM-SH-4010

M1 FIRE PROOF YES

CORROSION ALLOWANCE (mm) 3.0

24" 2 HEAT TREATMENT NO

50 INSIDE OUTSIDE INSULATION NO

ORIENTATION VIEW

23

2

("A"-"A") Ø12 HOLE 1ST TIG

PL.6t 2 NOZZLE LIST

60°

BC

2

BC REQ. NOZZLE

MARK SIZE SCH RATING TYPE MAT'L FACE SERVICE

17

N6 N5 N3 N2 L2a NO. MAT'L

112" 3/4" 1" 2" 2" N1 2" 1 A105 80 150lb LWN A105 RF HX FROM E-751

70

10 60° N2 2" 1 A106-B 80 150lb WN A105 RF VG OUT

D DETAIL WELDING "WC" D

300 400 (AT CIR.CUM LINE) N3 1" 1 A105 11.80t 150lb LWN A105 RF SPARE W/B

"A" "A" 1ST TIG

N4 2" 1 A106-B 80 150lb WN A105 RF HX to P-751

3

2-LIFTING LUG DETAIL WELDING "WL" N5 3/4" 1 A105 9.45t 150lb LWN A105 RF PIC-755

ED 2:1 HEAD SEE DETAIL (AT CIR.CUM LINE) N6 11/2" 1 A105 13.45t 150lb LWN A105 RF MIN FLOW P-751

USE THk.6t 2 DETAIL EARTH LUG N7 11/2" 1 A105 13.45t 150lb LWN A105 RF LG-7802

481

L1a-b 3/4" 1 A105 9.45t 150lb LWN A105 RF LI-783

40

SF

L2a-b 2" 2 A106-B 80 150lb WN A105 RF MANHOLE

TL TL M1 24" 1 A516-70 9t 150lb WN A105 RF TG-755

20t

Ø50 HOLE 5

R6

600

9

1 Ø1300 ID 6t

9t

1100

L1a

75

190

3/4"

1450

C N/P BRACKET C

141

SEE DETAIL 6

8

TL

400

40

M1

2200

50

24" 9

210

5

1450

R2

150

N1 N7 9

50

2-EARTH LUG

"B" SEE DETAIL "B" 2" 112"

1200

1100

R3

130

0

150

150

6t

200

750

4-SUPPORT CHAIR DETAIL LIFTING LUG

4 SEE DETAIL

400

400

L1b

B 3/4" A 27-OCT-21 FOR REVIEW NP NP CW B

150

TL TL REV DATE DESCRIPTION PREP CHKD APPD

REVISION HISTORY

40

SF

PROJECT NAME :

481

R1 DONOR CUT TOWER

3 CLIENT :

M24 THAI POLYETHYLENE CO.,LTD.

N4 L2b 11 NAME PLATE SS400 1 PL 4.5t

CONTRACTOR :

2" 2" SQUARE WASHER 10 EARTH LUG SUS304 2 PL 6t

SIZE 70x70x16t 9 LIFTING LUG PAD A516-70 2 PL 6t RAYONG ENGINEERING & PLANT SERVICE CO.,LTD.

8 LIFTING LUG SS400 2 PL 20t

CONTRACTOR :

7 7 ANCHOR BOLT SS400+GALV 4 SET M24 x 300L PILIN PROJECT CO., LTD.

GENERAL NOTE : 6.ALL DIMENSIONS ARE IN MILLIMETER.

300

61/3 Moo 8 Mhonnang, Phanut-nikom, Chonburi, 20140, Thailand

1.ALL BOLT HOLES SHALL STRADDLE THE CENTER LINE UNLESS 7.TELLTALE HOLE SHALL BE LOCATED PERPENDICULAR TO LONGITUDINAL 6 REINFORCE PAD SS400 4 PL 6t Tel : 66(0) 38 475341-2

OTHERWISE SPECIFIED. CENTERLINE OF VESSEL AT THE LOWEST POINT AND SHALL BE FILLED 5 RIB PLATE SS400 8 PL 15t

2.ALL WELDS SHALL BE FINISHED SMOOTHLY, AND THE SURFACE TITLE :

10

WITH HARD GREASE BEFORE TRANSPORTATION. 3

A OF WELD AREA SHALL BE FINISHED FREE FROM SPATTER AND SLAG. 8.NOZZLE FLANGE, GIRTH FLANGE AND COVER FLANGE FACE SHALL BE 4 SUPPORT CHAIR SS400 4 PL 20t HEXANE DRUM ITEM NO. D-755 A

3.ALL FLAME OR PLASMA CUT SURFACE SHALL BE FINISHED SMOOTH FINISH TYPE IN ACCORDANCE WITH ASME B16.5 3 BOTTOM HEAD A516-70 1 PL 6t GENERAL ARRANGEMENT DRAWING (1/1)

SMOOTHLY GRINDING BEFORE INSTALLATION. (Ra 3.2-6.3 µm) 2 TOP HEAD A516-70 1 PL 6t

4.NOZZLE PROJECTIONS SHALL BE FROM OUTSIDE OF SHELL. 9.INSIDE SURFACE OF WELDSEAM SHELL BE FINISHED SMOOTH. DETAIL ANCHOR BOLT DWG. NO. : SHEET NO. : REV. :

TO FLANGE SURFACE, UNLESS OTHERWISE SPECIFIED. 1 SHELL PLATE A516-70 1 PL 6t A

TPE-000-MSE-DGA-D755-00 1 / 5

5.ALL FLANGE BOLT HOLES SHALL STRADDLE NORTH-SOUTH PLANT NO DESCRIPTION MAT'L OTY SPARE REMARK FILE NAME : SCALE : JOB NO :

AXIS OR HORIZONTAL AND VERTICAL AXIS OF VESSEL. BILL OF MATERIAL - 1 : 20 6421-01

8 7 6 5 4 3 2 1

You might also like

- Reference Drawings:: 4mm " 20mm "Document1 pageReference Drawings:: 4mm " 20mm "ArielNo ratings yet

- R1 Donor Cut Tower: Waste Hexane Drum Item No. D-718Document1 pageR1 Donor Cut Tower: Waste Hexane Drum Item No. D-718NoppolNorasriNo ratings yet

- J3BGDF02BR012 01 01Document1 pageJ3BGDF02BR012 01 01saleem naheedNo ratings yet

- Key financial data documentDocument2 pagesKey financial data documentCSEC Uganda Ltd.No ratings yet

- f18p01 m00 000 General ArrangementDocument1 pagef18p01 m00 000 General ArrangementAngga Purnama PutraNo ratings yet

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- F2-FOU-CON-JDN-DT-ST-01210-001-A Secondary Steel, Transition Piece, LV Supports PDFDocument1 pageF2-FOU-CON-JDN-DT-ST-01210-001-A Secondary Steel, Transition Piece, LV Supports PDFAjizul Rohim AkbarNo ratings yet

- F2-FOU-CON-JDN-DT-ST-01210-001-A Secondary Steel, Transition Piece, LV SupportsDocument1 pageF2-FOU-CON-JDN-DT-ST-01210-001-A Secondary Steel, Transition Piece, LV SupportsAjizul Rohim AkbarNo ratings yet

- Ab STR 108 B124Document1 pageAb STR 108 B124arainzada807No ratings yet

- DSF 1104801 1758 3690 43 1 014 - 3Document2 pagesDSF 1104801 1758 3690 43 1 014 - 3Goulet KostNo ratings yet

- Footings SDDocument15 pagesFootings SDdubai eyeNo ratings yet

- F.J. S.J.: Shuqaiq 3 Independent Water ProjectDocument1 pageF.J. S.J.: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- Waterfront Integrated Project Partition Schedule and Opening DetailsDocument1 pageWaterfront Integrated Project Partition Schedule and Opening DetailsHirushan MenukaNo ratings yet

- Fabrication Drawing DetailsDocument1 pageFabrication Drawing DetailsMark Roger Huberit IINo ratings yet

- P&IDDocument1 pageP&ID박성철No ratings yet

- Chasis TMPA8873CSCNG6V11 PDFDocument4 pagesChasis TMPA8873CSCNG6V11 PDFMax Fredi Quispe AguilarNo ratings yet

- Chasis CY8873CDocument4 pagesChasis CY8873Cpolancos05No ratings yet

- Veri. 0: CO T Ic DiDocument4 pagesVeri. 0: CO T Ic Dicfrias_13No ratings yet

- J3BGDF02BR012 01 05Document1 pageJ3BGDF02BR012 01 05Naheed AkhtarNo ratings yet

- Approval by NCRTC QR Code: National Capital Region Transport CorporationDocument1 pageApproval by NCRTC QR Code: National Capital Region Transport CorporationZaid HussainNo ratings yet

- VP 2025JV0P10005 V 111 101 D40 003 V01 (Crude Distillation Column Installation & Fire Proofing Clip)Document1 pageVP 2025JV0P10005 V 111 101 D40 003 V01 (Crude Distillation Column Installation & Fire Proofing Clip)Vasilica BArbarasaNo ratings yet

- ROFI160360 WDocument1 pageROFI160360 WchetanbakkerNo ratings yet

- P790 Electrical Circuit 336-E4169 - 1 - plm-2Document11 pagesP790 Electrical Circuit 336-E4169 - 1 - plm-2shivji007No ratings yet

- As Built: Matchline To Dwg. NoDocument1 pageAs Built: Matchline To Dwg. NoMohamed RamadanNo ratings yet

- P94-1986 Inversor NGPDocument2 pagesP94-1986 Inversor NGPGonzalo GalvezNo ratings yet

- Samsung BN44-00473A - UN40D5003Document6 pagesSamsung BN44-00473A - UN40D5003Jose TeguedorNo ratings yet

- Samsung Bn44-00473a Pslf121a03s Smps Ue40d5003 PDFDocument6 pagesSamsung Bn44-00473a Pslf121a03s Smps Ue40d5003 PDFMagda MolinaNo ratings yet

- Samsung BN44-00473A UE40D5003 LED PSUDocument6 pagesSamsung BN44-00473A UE40D5003 LED PSUFlavien Raymond AndriatsihoaranaNo ratings yet

- 26-D-102c - Basement 1 Floor Plan 3 of 3Document1 page26-D-102c - Basement 1 Floor Plan 3 of 3Jhonson PintoNo ratings yet

- Review of Ramps and Stairs Drawings Shop DrawingDocument1 pageReview of Ramps and Stairs Drawings Shop DrawingPhạm Quốc ViệtNo ratings yet

- Runner Blades - Rev.aDocument2 pagesRunner Blades - Rev.anopppl.fcNo ratings yet

- Siemens: ASK DDocument1 pageSiemens: ASK DMurilo MonteiroNo ratings yet

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- Multi Purpose Hall SF LayoutDocument1 pageMulti Purpose Hall SF LayoutShivraj KmNo ratings yet

- B/F valve assembly drawing and specificationsDocument1 pageB/F valve assembly drawing and specificationssilviNo ratings yet

- 4139M06017 Default 000Document1 page4139M06017 Default 000gopi krishnaNo ratings yet

- DRG-OT-561 - R02 - L-Clamp Assy (Vedang)Document7 pagesDRG-OT-561 - R02 - L-Clamp Assy (Vedang)Puneet SharmaNo ratings yet

- 3x2000kVA DG SYNCRONISING + OUTGOING PANEL - JSPL - GA+Control+Bom - AS BUILT - 02.07.11Document76 pages3x2000kVA DG SYNCRONISING + OUTGOING PANEL - JSPL - GA+Control+Bom - AS BUILT - 02.07.11RITENDRA GHOSHNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- 1233 Pid 03Document11 pages1233 Pid 03Reza AranNo ratings yet

- Conveyor 8F1 Head Chute and Liner DrawingsDocument10 pagesConveyor 8F1 Head Chute and Liner Drawingsjosseph fabianNo ratings yet

- Detail A: Shuqaiq 3 Independent Water ProjectDocument1 pageDetail A: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- Detail "A" Detail "B" Detail "C": Susunan Butterfly Valve Ø300 Bendungan SermoDocument1 pageDetail "A" Detail "B" Detail "C": Susunan Butterfly Valve Ø300 Bendungan SermosilviNo ratings yet

- 1TB01005 005D01 Fos Im LG DWG Ar 71713Document1 page1TB01005 005D01 Fos Im LG DWG Ar 71713Dixit PatelNo ratings yet

- S-03710 M54161-1-Rev. 1-As F 8506-Steam Drum AssemblyDocument1 pageS-03710 M54161-1-Rev. 1-As F 8506-Steam Drum Assemblywylie01No ratings yet

- Renr79520001 1Document4 pagesRenr79520001 1Mouhsine ChakrouneNo ratings yet

- Clarifier Tank Layout - 250 CMH PDFDocument1 pageClarifier Tank Layout - 250 CMH PDFepe civil1No ratings yet

- A - 202 Fsy Pavilion (Elevations and Sections) - 2Document1 pageA - 202 Fsy Pavilion (Elevations and Sections) - 2michael saycoNo ratings yet

- FL3B-474-P-2634 AsbuiltDocument1 pageFL3B-474-P-2634 AsbuiltAlbet MulyonoNo ratings yet

- Scamec 2000 S 100129425 #FB214 Grease SystemDocument23 pagesScamec 2000 S 100129425 #FB214 Grease SystemIvan Andres Seguel BristiloNo ratings yet

- RWH1ADocument1 pageRWH1ANathan BlythNo ratings yet

- 22.5 KL Check PrintDocument1 page22.5 KL Check PrintparveshNo ratings yet

- PH-1518-C960 - Transformer Station Foundation Detail - C2Document1 pagePH-1518-C960 - Transformer Station Foundation Detail - C2Alden BrionesNo ratings yet

- 97 GP Trim Tabs CADDocument2 pages97 GP Trim Tabs CADMike SNo ratings yet

- FL3B-474-P-2603 As BuiltDocument1 pageFL3B-474-P-2603 As BuiltAlbet MulyonoNo ratings yet

- Table of ContentsDocument146 pagesTable of ContentsNoppolNorasriNo ratings yet

- Price Quotation TemplateDocument1 pagePrice Quotation TemplateMukesh DubeyNo ratings yet

- DRG No. - ST 720-92 - SPARTAN - R0Document1 pageDRG No. - ST 720-92 - SPARTAN - R0NoppolNorasriNo ratings yet

- Asme Sec Viii d2 Art D-1Document17 pagesAsme Sec Viii d2 Art D-1DieguitoOmarMoralesNo ratings yet

- Expansion Loop Calculation: IndexDocument73 pagesExpansion Loop Calculation: IndexNoppolNorasriNo ratings yet

- Steel Column DesignDocument15 pagesSteel Column DesignNitesh Singh100% (6)

- Jabra Move Wireless TechnSpecs HighresDocument80 pagesJabra Move Wireless TechnSpecs HighrescehutNo ratings yet

- Buckle Examples 2007Document213 pagesBuckle Examples 2007Rofi MuhammadNo ratings yet

- Attachment-C - Minimum Requirement of PIMDocument1 pageAttachment-C - Minimum Requirement of PIMNoppolNorasriNo ratings yet

- Expansion Loop Calculation: IndexDocument73 pagesExpansion Loop Calculation: IndexNoppolNorasriNo ratings yet

- ASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )Document14 pagesASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )hardik5818100% (2)

- Size Class Material Oprating PRESS (Bar-G) TEMP. (C) 2" B22B A335-P5 1.9 289 3" B22B A335-P5 16.1 289 2" B21A A106-B 13.2 293 3" B21A A53-B 13.2 293Document3 pagesSize Class Material Oprating PRESS (Bar-G) TEMP. (C) 2" B22B A335-P5 1.9 289 3" B22B A335-P5 16.1 289 2" B21A A106-B 13.2 293 3" B21A A53-B 13.2 293NoppolNorasriNo ratings yet

- Gasket Calculator 6.0Document88 pagesGasket Calculator 6.0Latif QaiserNo ratings yet

- Design Data: Estimated WeightsDocument1 pageDesign Data: Estimated WeightsgaurangNo ratings yet

- Appendix 13 Vessels of Noncircular Cross PDFDocument46 pagesAppendix 13 Vessels of Noncircular Cross PDFNoppolNorasriNo ratings yet

- Cp/Cv calculator for mixtures of methane, oxygen, steam, ethane and hydrogenDocument1 pageCp/Cv calculator for mixtures of methane, oxygen, steam, ethane and hydrogenNoppolNorasriNo ratings yet

- G-Series 2012 1 PDFDocument6 pagesG-Series 2012 1 PDFNoppolNorasriNo ratings yet

- Design Selection For Packings PDFDocument8 pagesDesign Selection For Packings PDFDara SatwikNo ratings yet

- Expansion Loop Calculation: IndexDocument73 pagesExpansion Loop Calculation: IndexNoppolNorasriNo ratings yet

- AFESManual by Monkal PDFDocument29 pagesAFESManual by Monkal PDFพศิน จันทะสิมNo ratings yet

- Design Selection For Packings PDFDocument8 pagesDesign Selection For Packings PDFDara SatwikNo ratings yet

- DWG Rev.0Document1 pageDWG Rev.0NoppolNorasriNo ratings yet

- Structure DWGDocument1 pageStructure DWGNoppolNorasriNo ratings yet

- CAD ExDocument19 pagesCAD ExNoppolNorasriNo ratings yet

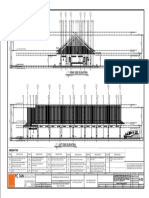

- 2-A-06 Elecation - 1, 2Document1 page2-A-06 Elecation - 1, 2NoppolNorasriNo ratings yet

- Design Selection For Packings PDFDocument8 pagesDesign Selection For Packings PDFDara SatwikNo ratings yet

- SYS Bolt ManualDocument64 pagesSYS Bolt ManualNoppolNorasriNo ratings yet

- 2nd Floor Plan PDFDocument1 page2nd Floor Plan PDFNoppolNorasriNo ratings yet

- DAYCENT Model Overview, Testing and Application To AgroecosystemsDocument28 pagesDAYCENT Model Overview, Testing and Application To AgroecosystemsJunoNo ratings yet

- Which Statement On Physical Development of Infants and Toddlers Is TRUEDocument9 pagesWhich Statement On Physical Development of Infants and Toddlers Is TRUEKristylle Renz100% (1)

- Five Brothers and Their Mother's LoveDocument4 pagesFive Brothers and Their Mother's Lovevelo67% (3)

- Chapter 18Document10 pagesChapter 18nehallakdawalaNo ratings yet

- Solution Manual For Chemistry For Today General Organic and Biochemistry 8th EditionDocument37 pagesSolution Manual For Chemistry For Today General Organic and Biochemistry 8th Editionrepastgraffitie17pv100% (14)

- 4801-Article Text-19217-1-10-20110701Document8 pages4801-Article Text-19217-1-10-20110701David BriggsNo ratings yet

- NURS 366 Exam 1 Study Guide and RubricDocument7 pagesNURS 366 Exam 1 Study Guide and RubriccmpNo ratings yet

- Libyan cuisine: Bazin, asida and moreDocument3 pagesLibyan cuisine: Bazin, asida and moreAndy Atehortua CiroNo ratings yet

- A300-600 Ammfx1 29 24 00 03 0Document5 pagesA300-600 Ammfx1 29 24 00 03 0Fahimeh HayatinasabNo ratings yet

- Bone Tumours and MalignanciesDocument55 pagesBone Tumours and MalignanciesFreeburn SimunchembuNo ratings yet

- Practical 5.17 Protein MaterialsDocument2 pagesPractical 5.17 Protein MaterialsdeeyamullaNo ratings yet

- Chromosomal Basis of Inheritance - Final PDF-1Document3 pagesChromosomal Basis of Inheritance - Final PDF-1Aishwarya ShuklaNo ratings yet

- 8.1 - Production and Diagnostic Use of UltrasoundDocument3 pages8.1 - Production and Diagnostic Use of UltrasoundTakudzwa Antony MasendekeNo ratings yet

- Slide BP Texas City RefineryDocument20 pagesSlide BP Texas City Refineryamaleena_muniraNo ratings yet

- Physical ExaminationDocument7 pagesPhysical ExaminationCha CulveraNo ratings yet

- SGLGB Form 1 Barangay ProfileDocument3 pagesSGLGB Form 1 Barangay ProfileHELEN CASIANONo ratings yet

- X80 Io PDFDocument446 pagesX80 Io PDFHATEM68No ratings yet

- Biosample Urine Sample Collection Protocol Infant v2Document2 pagesBiosample Urine Sample Collection Protocol Infant v2api-531349549No ratings yet

- Cs Varnavrat Land SlideDocument7 pagesCs Varnavrat Land SlideBIJAY KRISHNA DASNo ratings yet

- 1:21-cv-03674 Coomes, Williams, Slater & Tisbert vs. Centerra Group, LLCDocument16 pages1:21-cv-03674 Coomes, Williams, Slater & Tisbert vs. Centerra Group, LLCMichelle EdwardsNo ratings yet

- A Review of Drug-Induced Acute Angle Closure Glaucoma For Non-Ophthalmologists PDFDocument8 pagesA Review of Drug-Induced Acute Angle Closure Glaucoma For Non-Ophthalmologists PDFMeida Putri UtamiNo ratings yet

- Shortened Dental Arch ConceptDocument3 pagesShortened Dental Arch ConceptVivek ShankarNo ratings yet

- Ujian Sains Tingkatan 2Document10 pagesUjian Sains Tingkatan 2SITI ZAIDAH AHMAD50% (6)

- Chapter 6Document2 pagesChapter 6Zhane CruzNo ratings yet

- Lab Report P2 A1 - IDocument19 pagesLab Report P2 A1 - Inzirh 01No ratings yet

- Standardized Recipes - Doc2Document130 pagesStandardized Recipes - Doc2epic failNo ratings yet

- ResiboDocument1 pageResiboAlex RespicioNo ratings yet

- By Pass System in The Dry ProcessDocument34 pagesBy Pass System in The Dry Processfaheemqc100% (1)

- Crop RotationsDocument19 pagesCrop RotationsSarwar M. RasheedNo ratings yet

- Michigan Western District Stay On State Supreme Court Response On Whitmer Emergency Powers 061920Document7 pagesMichigan Western District Stay On State Supreme Court Response On Whitmer Emergency Powers 061920Beverly TranNo ratings yet